TROUBLESHOOTING GUIDE

1. Problem: Faucet does not function.

Cause: Adhesive packaging label affixed over sensor eye.

Solution: Remove adhesive label from sensor eye.

Cause: "Permanent Off" activated.

Solution: Press button on faucet throat one time.

2. Problem: Faucet delivers water in an uncontrolled manner.

Cause: Faucet is defective.

Solution: Contact the Sloan Valve Company Installation Engineering

Department (see below).

3. Problem: Faucet does not deliver any water when Sensor is

activated.

Indicator: Solenoid valve produces an audible “CLICK.”

Cause: Water supply stop(s) closed.

Solution: Open water supply stop(s).

Cause: Water supply stop strainer(s) clogged.

Solution: Remove, clean, and reinstall water supply stop

strainer(s).Replace strainer(s) if required.

Indicator: Solenoid valve DOES NOT produce an audible “CLICK.”

Cause: Battery low (battery operated models).

Solution: Replace battery (refer to Battery Replacement on Page 3).

Cause: Power failure (EAF-200 Models).

Solution: Check power supply.

4. Problem: Faucet delivers only a slow flow or dribble when Sensor

is activated.

Cause: Water supply stop(s) are partially closed.

Solution: Completely open water supply stop(s).

Cause: Water supply stop strainer(s) clogged.

Solution: Remove, clean, and reinstall water supply stop

strainer(s).Replace strainer(s) if required.

Cause: Aerator is clogged.

Solution: Remove, clean, and reinstall Aerator. Replace Aerator if

required.

Cause: Faucet is defective.

Solution: Contact the Sloan Valve Company Installation Engineering

Department (see below).

5. Problem: Faucet does not stop delivering water or continues to

drip after user is no longer detected.

Cause: Valve is defective.

Solution: Contact the Sloan Valve Company Installation Engineering

Department (see below).

6. Problem: LED indicator blinks when faucet is in use.

Cause: Battery low (battery operated models).

Solution: Replace battery (refer to Battery Replacement on Page 3).

7. Problem: The water temperature is too hot or too cold on a faucet

connected to hot and cold supply lines.

Cause: Supply Stops are not adjusted properly.

Solution: Adjust Supply Stops.

Cause: For models with integral mixing valve — Mixing valve is set

improperly for the water temperature desired.

Solution: Rotate mixing valve handle clockwise to decrease water

temperature or counterclockwise to increase water temperature.

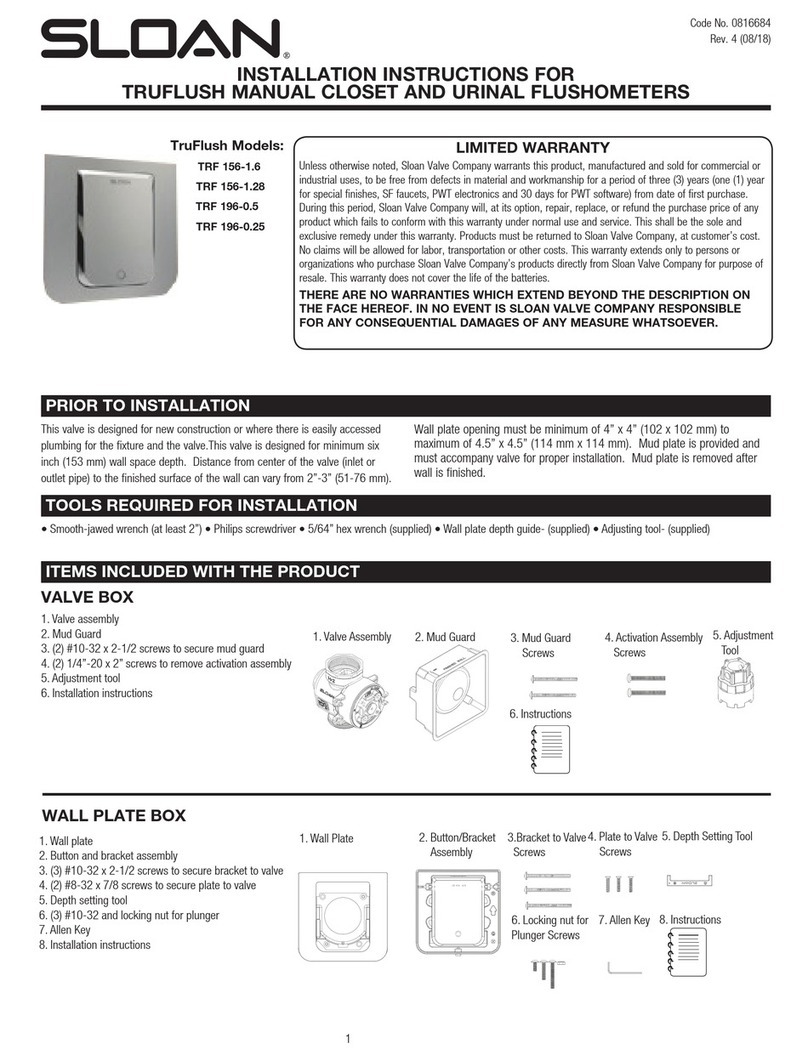

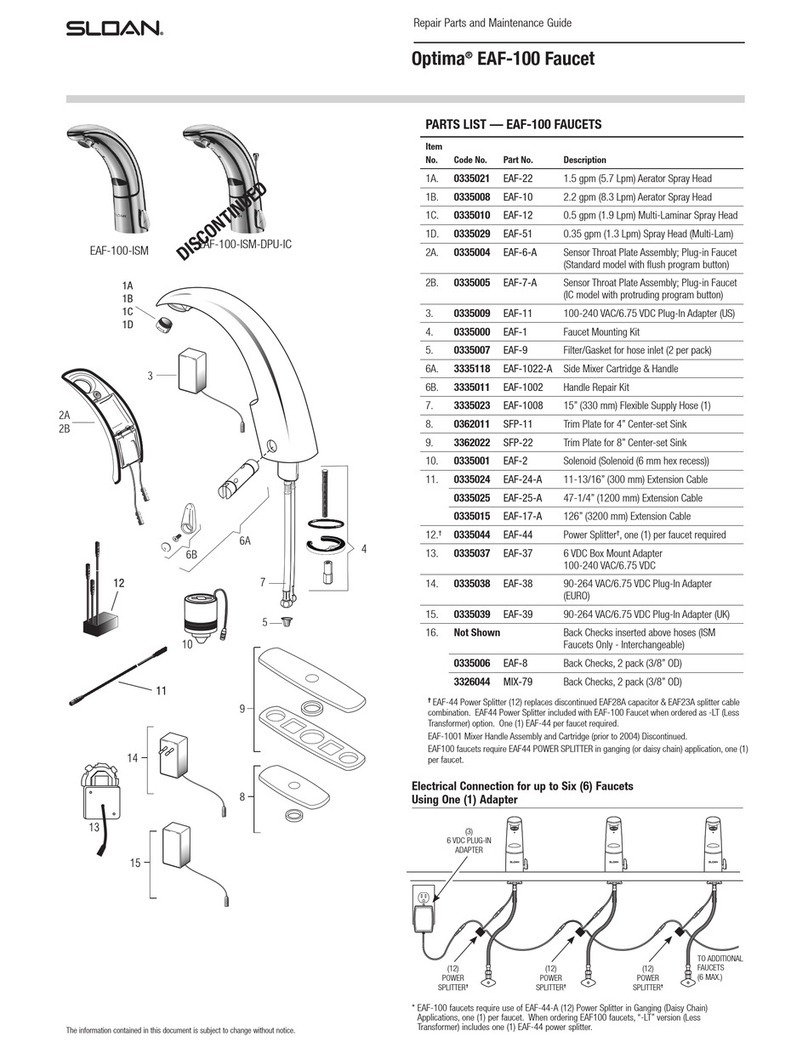

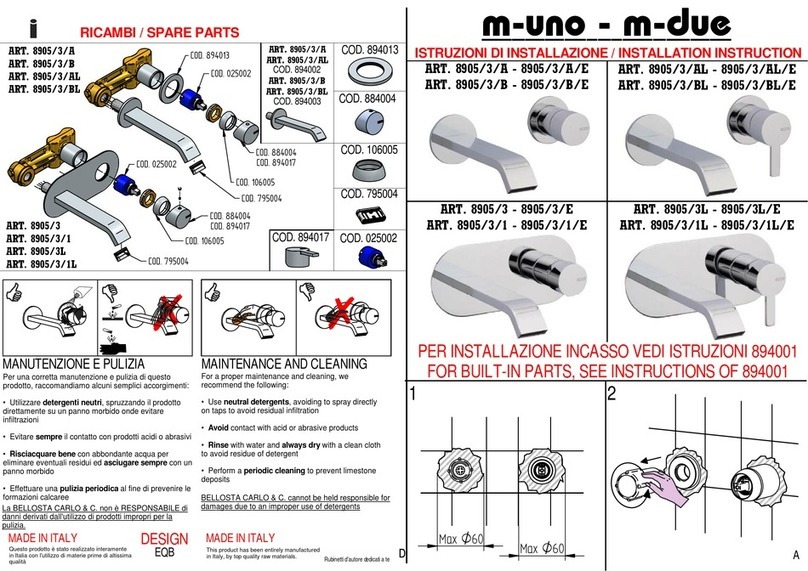

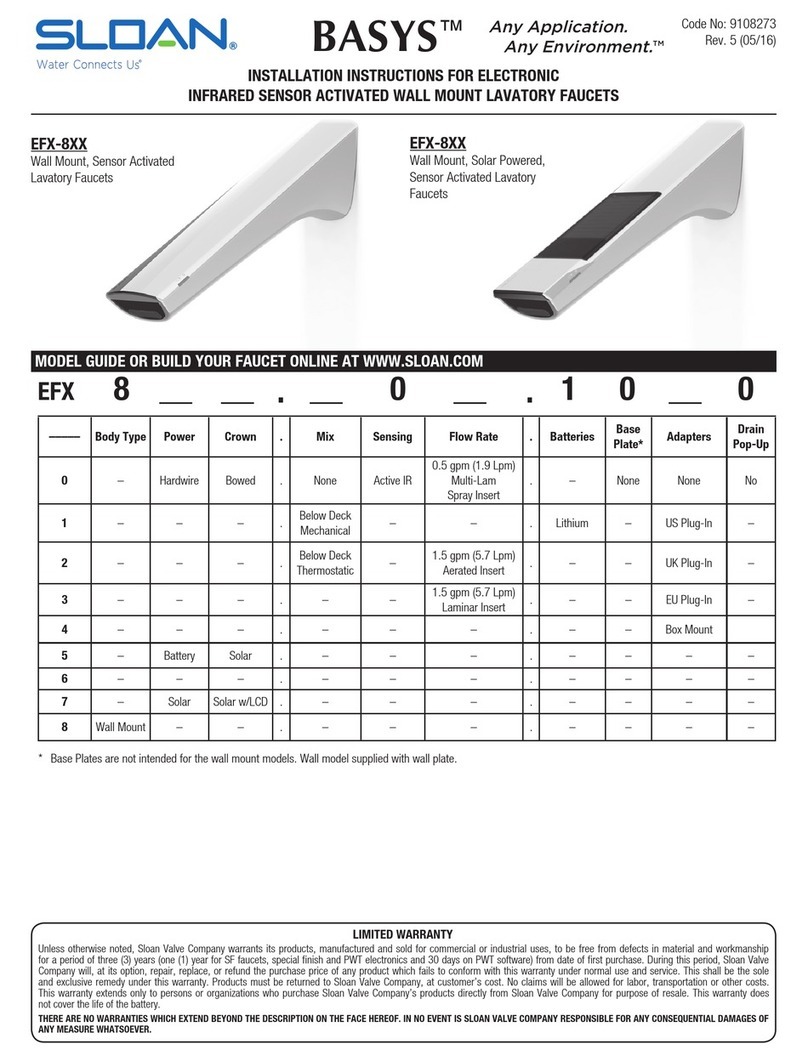

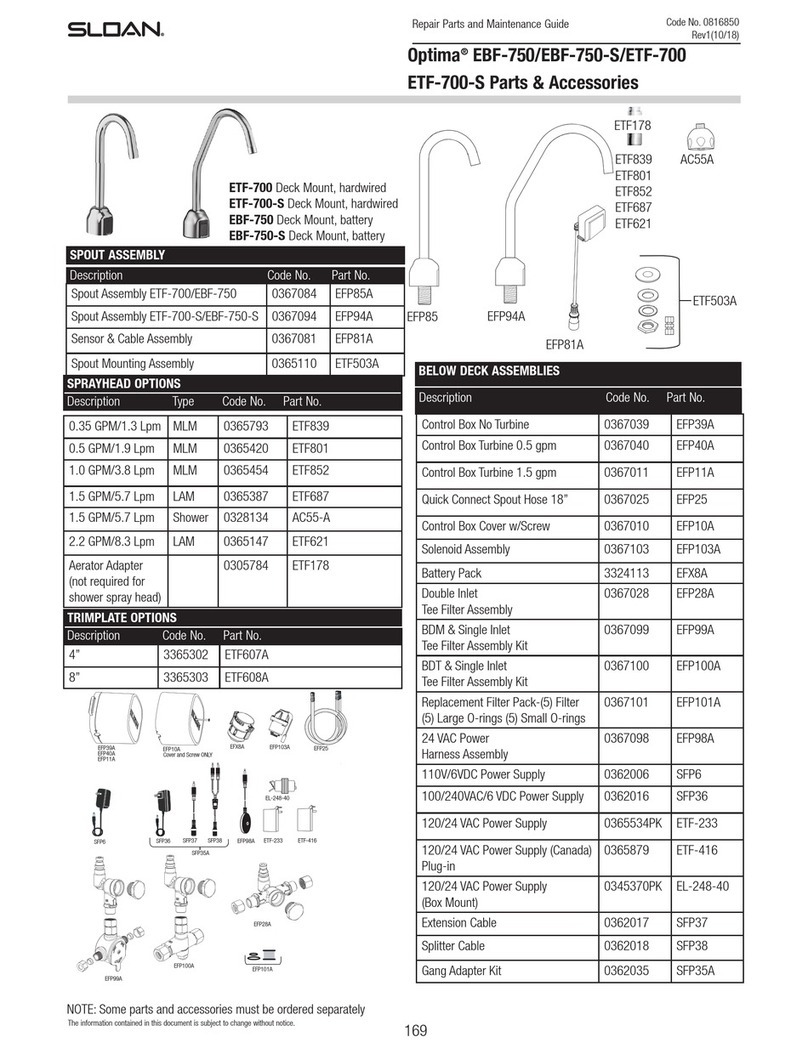

PARTS LIST 2A

2B

Item Part Description

No. No.

1 EAF-14-A Faucet Sensor Assembly

2A EAF-1006 Cap and Solar Cell Assembly (EAF-275 only)

2B EAF-27 Cap (EAF-250 and EAF-200 only)

3A EAF-15 0.5 gpm (1.9 Lpm) VR Aerator Spray Head

3B EAF-10 2.2 gpm (8.3 Lpm) Aerator Spray Head

3C EAF-13 2.2 gpm (8.3 Lpm) Laminar Flow Spray Head

4 EAF-1003 Battery Replacement Kit

5 EAF-1 Faucet Mounting Kit

6 EAF-9 Strainer (Filter)

7A EAF-1004 Mixer Handle Assembly and Cartridge

7B EAF-1005 Handle Repair Kit

8 EAF-1007 Handle Cap

9 EAF-1008 13” (330 mm) Flexible Supply Hose

10 EAF-23-A Splitter Cable

11 EAF-24-A 11-13/16” (300 mm) Extension Cable

EAF-25-A 47-1/4” (1200 mm) Extension Cable

EAF-17-A 126” (3200 mm) Extension Cable

12 ETF-312-A Trim Plate for 4” Centerset Sink

13 ETF-510-A Trim Plate for 8” Centerset Sink

14 EAF-11 Transformer

15 EAF-28 Capacitor Box

3A

3B

3C

When assistance is required, please contact Sloan Valve Company Installation

Engineering Department at:

1-888-SLOAN-14 (1-888-756-2614) OR 1-847-233-2016

7A

7B

4

1

5

13

912

6

8

CARE AND CLEANING OF CHROME AND SPECIAL FINISHES

DO NOT use abrasive or chemical cleaners (including chlorine

bleach) to clean Faucets that may dull the luster and attack the

chrome or special decorative finishes. Use ONLY mild soap

and water, then wipe dry with clean cloth or towel.

While cleaning the bathroom tile, protect the Faucet from any

splattering of cleaner. Acids and cleaning fluids will discolor

or remove chrome plating.

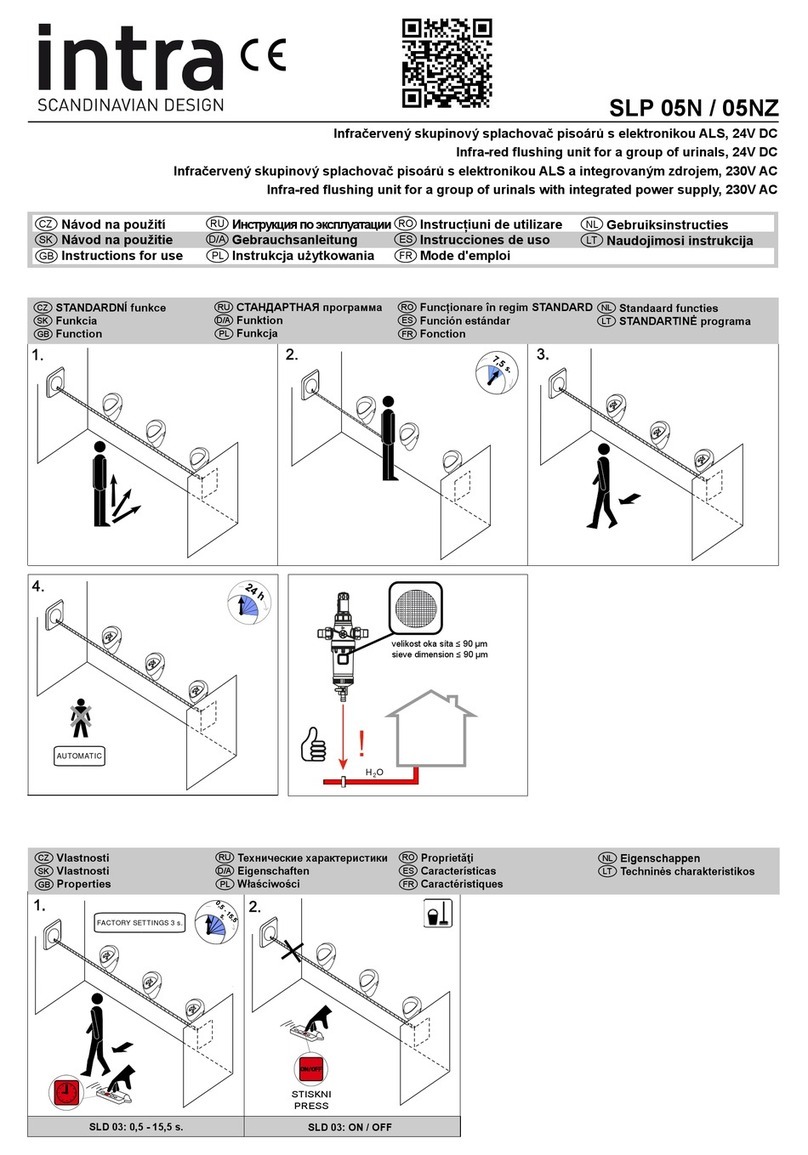

OPERATION

As the user’s hands enter the beam’s effective

range, the beam is reflected back into the sensor

receiver and activates the solenoid valve allowing

water to flow from the faucet. Water will flow until

the hands are removed or until the faucet reaches

its automatic time out limit setting.

14

The information contained in this document is subject to change without notice.

-Click SETTINGS

Function Press Button LED Signal

Continuous Run — 2 minute

default setting (adjustable from

1 - 20 minutes)

1 time for 2 seconds 5 short flashes

reset: 1 time or will reset

automatically after 2 minutes

Temporary Off 2 times (double click) 5 short flashes followed by

periodic flashing

reset: 1 time or will reset

automatically after 2 minutes

Permanent Off Consult Factory Periodic flashing and then

2 long flashes

reset: 1 time

Auto Set Range Adjustment 2 times (double click) and then

1 time for 5 seconds

5 short flashes followed by 4

short flashes

SLOAN VALVE COMPANY • 10500 Seymour Avenue • Franklin Park, IL 60131

Phone: 1-800-9-VALVE-9 or 1-847-671-4300 • Fax: 1-800-447-8329 or 1-847-671-4380

www.sloanvalve.com

Copyright © 2006 SLOAN VALVE COMPANY Printed 11-06

11

10

15