Maintenance Guide •SENSOR OPERATED VALVES

C. Wrong OPTIMA Plus model installed; i.e., 3 gpf model installed on 1.0

or 1.5 gpf urinal fixture. Replace with proper OPTIMA Plus model, or refer

to the G2 OPTIMA Plus Conversion Guide (0816453) to convert existing

unit to the proper model.

D. Dirt in Diaphragm Bypass. Clean under running water or replace Flex

Tube Diaphragm.

Note: The EBV-46-A Beam Deflector is no longer required or

available for the G2 OPTIMA Plus.

For information and instructions on field converting G2 OPTIMA Plus

Module settings or to activate the Stadium Flush™ Feature in urinal

models, refer to the Sloan G2 OPTIMA Plus Conversion Guide

(0816453).

This manual and the OPTIMA Plus Repair and Maintenance Guide

are available at www.sloanvalve.com.

RANGE ADJUSTMENT (Adjust only If Necessary)

The G2 OPTIMA Plus has a factory set sensing range:

Water Closet Models — 22" to 42" (559 mm to 1067 mm)

Urinal Models — 15" to 30" (381 mm to 762 mm)

The Factory setting should be satisfactory for most installations.

If the range is too short (i.e., not

picking up users) or too long

(i.e., picking up opposite wall or

stall door) the range can be

adjusted.

Note: Water does not have to be

turned off to adjust range.

Loosen the two Screws on top

of the unit. Remove the Override

Button. Remove the Rubber Plug

from top of Electronic Sensor

Module to uncover the

Potentiometer.

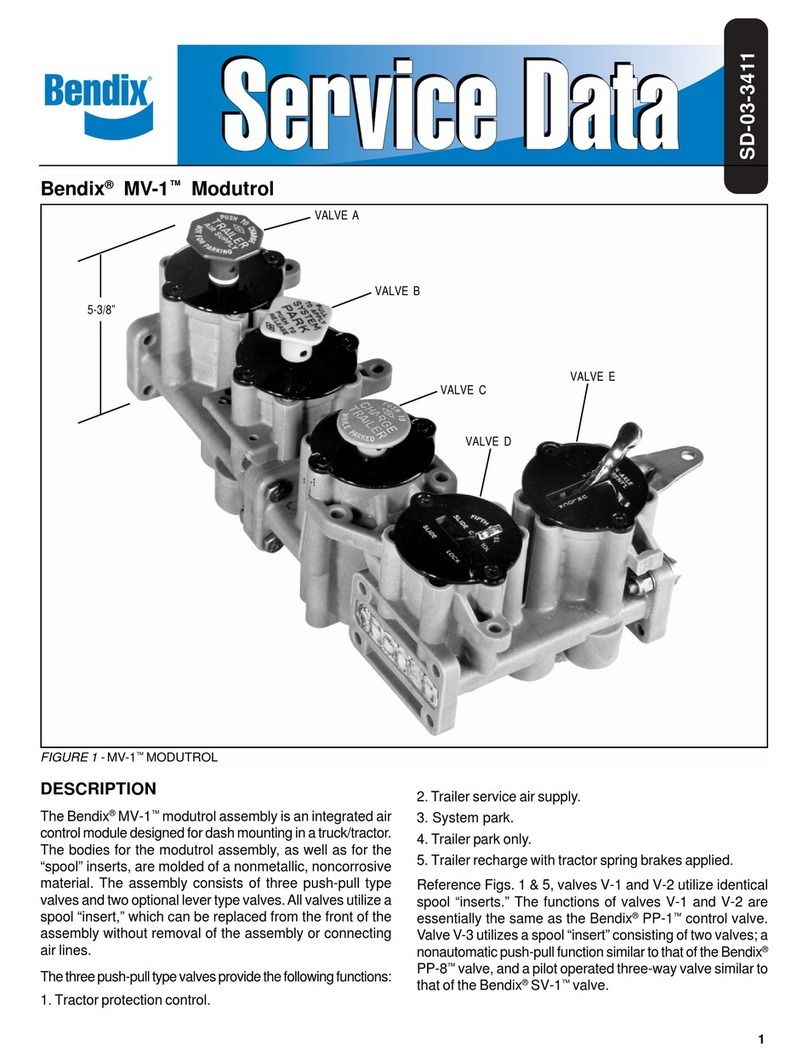

RANGE ADJUSTMENT PROCEDURE

For the first ten (10) minutes of operation, a Visible Red Light flashes in the

Sensing Window of the G2 OPTIMA Plus Flushometer when a user is

detected. This Visible Red Light feature can be reactivated after ten (10)

minutes by opening and closing the Battery Compartment Door.

Check the range by stepping toward the unit until the Red Light flashes,

indicating the Sensor's maximum detection limit. Adjust the Range

Potentiometer Screw located on top of the Sensor Module a few degrees

CLOCKWISE to increase the range or a few degrees COUNTERCLOCKWISE

to decrease the range. Repeat this adjustment until the desired range is

achieved.

Always Determine the Sensing Range with Metal Cover and Lens

Window On Top of the Unit.

Important: Adjust in small increments only! Range Potentiometer

adjustment screw rotates only ¾ of a turn; DO NOT over-rotate.

When range adjustment is satisfactory, replace the Rubber Plug. Reinstall

Override Button and tighten the two Screws on top of the unit.

Troubleshooting and Maintaining the Sloan G2 OPTIMA Plus®Flushometer

I. Sensor Flashes Continuously Only When User Steps Within Range.

A. Unit in Start-Up mode; no problem. This feature is active for the first ten

(10) minutes of operation.

II. Valve Does Not Flush; Sensor Not Picking UpUser.

A. Range too short; increase the range.

III. Valve Does Not Flush; Sensor Picking UpOpposite Wall or Surface, or

Only Flushes When Someone Walks By. Red Light Flashes

Continuously for First 10 Minutes Even with NoOne in Front of the

Sensor.

A. Range too long; shorten range.

IV. Valve Does Not Flush Even After Adjustment.

A. Range Adjustment Potentiometer set at full "max" or full "min" setting.

Readjust Potentiometer away from full "max" or "min" setting.

B. Batteries completely used up; replace Batteries.

C. Problem with Electronic Sensor Module; replace Electronic Sensor

Module.

V.Unit Flashes 4 Quick Times When User Steps Within Range.

A. Batteries low; replace Batteries.

VI. Valve Does Not Shut Off.

A. Bypass Orifice in Diaphragm is clogged with dirt or debris, or Bypass is

clogged by an invisible gelatinous film due to "over-treated" water.

Remove Flex Tube Diaphragm and wash under running water.

Note: Size of Orifice in the Bypass is of utmost importance for the proper

metering of water by the valve. DO NOT ENLARGE OR DAMAGE THIS

ORIFICE. Replace Flex Tube Diaphragm if cleaning does not correct the

problem.

B. Dirt or debris fouling Stem or Flex Tube Diaphragm. Remove Flex Tube

Diaphragm and wash under running water.

C. O-ring on Stem of Flex Tube Diaphragm is damaged or worn. Replace

O-ring if necessary.

D. Problem with Solenoid. If cleaning does not correct problem, replace

with new Isolated Solenoid Operator.

VII. Not Enough Water to Fixture.

A. Wrong Flush Volume Regulator installed in Flex Tube Diaphragm Kit.

Install the correct Regulator (see Step 6 of Installation Instructions

0816452).

B. Wrong OPTIMA Plus model installed; i.e., 1 gpf. urinal installed on 3.5

gal. closet fixture. Replace with proper OPTIMA Plus model, or refer to

the G2 OPTIMA Plus Conversion Guide (0816453) to convert existing

unit to the proper model.

C. Enlarged Bypass in Diaphragm. Replace Flex Tube Diaphragm.

D. Control Stop not adjusted properly. Readjust Control Stop.

E. Inadequate volume or pressure at supply. Increase water pressure or

supply (flow) to Valve. Consult factory for assistance.

VIII.Too Much Water to Fixture.

A. Wrong Flush Volume Regulator installed in Flex Tube Diaphragm Kit.

Install the correct Regulator (see Step 6 of Installation Instructions

0816452).

B. Control Stop not adjusted properly. Readjust Control Stop.

SLOAN VALVE COMPANY • 10500 SEYMOUR AVENUE • FRANKLIN PARK, IL 60131

Phone: 1-800-9-VALVE-9 or 1-847-671-4300 • Fax: 1-800-447-8329 or 1-847-671-4380 • www.sloanvalve.com

Copyright © 2006 Sloan Valve Company Printed in the U.S.A. Made in the U.S.A. G2 OPTIMA Plus M.G. — Rev. 1 (09/06) Code No. 0816456

COUNTER-

CLOCKWISE CLOCKWISE

Decreases

Range

Increases

Range