Sloan Optima ETF-80 User manual

Code No. 0816158

Rev. 4 (11/08)

INSTALLATION INSTRUCTIONS FOR

SENSOR ACTIVATED LAVATORY FAUCETS

LIMITED WARRANTY

Sloan Valve Company warrants its Optima ETF-80 and ETF-880 Faucets to be made of first class materials, free from defects of material or workmanship under normal use and to perform

the service for which they are intended in a thoroughly reliable and efficient manner when properly installed and serviced, for a period of three years (1 year for special finishes) from date

of purchase. During this period, Sloan Valve Company will, at its option, repair or replace any part or parts which prove to be thus defective if returned to Sloan Valve Company, at customer’s

cost, and this shall be the sole remedy available under this warranty. No claims will be allowed for labor, transportation or other incidental costs. This warranty extends only to persons or

organizations who purchase Sloan Valve Company’s products directly from Sloan Valve Company for purpose of resale.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE COMPANY RESPONSIBLE FOR ANY CONSEQUENTIAL DAMAGES

OF ANY MEASURE WHATSOEVER.

PRIOR TO INSTALLATION

Prior to installing the Sloan ETF-80 or ETF-880 Faucet, install the items

listed below. Also, refer to the Rough-In illustrations on Page 2.

•When Using Plug-In Transformer — Install electrical receptacle for

plug-in transformer (120 VAC, 2 amp service for each ETF-233 (24 VAC,

35 VA) plug-in transformer used).

•When Using Box Mount Transformer — Install electrical wiring to

transformer location (120 VAC, 2 amp service for each EL-248-40

(24 VAC, 40 VA) transformer used).

• Lavatory/sink

• Drain line

• Hot and cold water supply lines or tempered water supply line

Multiple Faucets

Multiple faucets can be powered by a single transformer, provided that the

transformer has been properly sized. Allow a minimum of 15 VA of current

rating for each solenoid valve used. Refer to “Step 4 — Install Transformer”

for further information.

Mixing Valve

When installing the faucet with a Sloan mixing valve, these Installation

Instructions AND the Installation Instructions packaged with the mixing

valve MUST be followed.

Important:

• INSTALL ALL ELECTRICAL WIRING IN ACCORDANCE WITH

NATIONAL/LOCAL CODES AND REGULATIONS.

• INSTALL ALL PLUMBING IN ACCORDANCE WITH APPLICABLE CODES

AND REGULATIONS.

• A 24 VAC STEP-DOWN TRANSFORMER MUST BE USED.

• USE APPROPRIATE PRECAUTIONS WHILE CONNECTING TRANSFORMER

TO 120 VAC POWER SOURCE.

• DO NOT PLUG TRANSFORMER INTO POWER SOURCE (RECEPTACLE)

UNTIL ALL WIRING IS COMPLETED. ALLOWING 24 VAC TRANSFORMER

WIRES TO TOUCH OR SHORT WHILE POWER IS BEING SUPPLIED WILL

CAUSE PERMANENT DAMAGE TO THE TRANSFORMER AND CIRCUIT

CONTROL MODULE.

• KEEP THREAD SEALANT OUT OF YOUR WATERWAY TO PREVENT

COMPONENT PART DAMAGE! DO NOT USE ANY SEALANT ON

COMPRESSION FITTINGS. FOR THREADED PIPE FITTINGS, DO NOT

APPLY SEALANT TO THE FIRST TWO “STARTER” THREADS.

• FLUSH ALL WATER LINES UNTIL WATER IS CLEAR BEFORE CONNECTING

SOLENOID TO SUPPLY STOPS.

DO NOT INSTALL THE SPRAY HEAD UNTIL AFTER THE SUPPLY LINES

HAVE BEEN FLUSHED.

BAK-CHEK®TEE USAGE

When connecting the Sloan ETF-80 or ETF-880 Faucet to both hot and cold

water supplies, a Bak-Chek®Tee is provided and required as illustrated in

the Rough-in drawings on Page 2. Water temperature can be controlled by

adjusting the supply stops.

When connecting the faucet to a single line water supply or a pre-tempered

water supply, a Bak-Chek®Tee is not required.

A Bak-Chek®Tee is not required or provided when a Temperature Mixing

Valve is included with the faucet.

TOOLS REQUIRED FOR INSTALLATION

• Open end wrenches for hex sizes: 1”, 5/8”, 9/16” and 1/2”

• Basin wrench

• Slotted screwdriver, 3/16”

• Slotted screwdriver (supplied)

• Phillips head screwdriver, #2

• Pliers

• Wire stripper/crimping tool

Model ETF-80

24 VAC, Sensor Activated Lavatory Faucet

Furnished with a Black Plastic Throat Plate

Model ETF-880

24 VAC, Sensor Activated Lavatory Faucet

Furnished with a Chrome Plated Metal Throat Plate

Compliant to: ASME A112.18.1 and CSA B125.1 Compliant to: ASME A112.18.1 and CSA B125.1

2

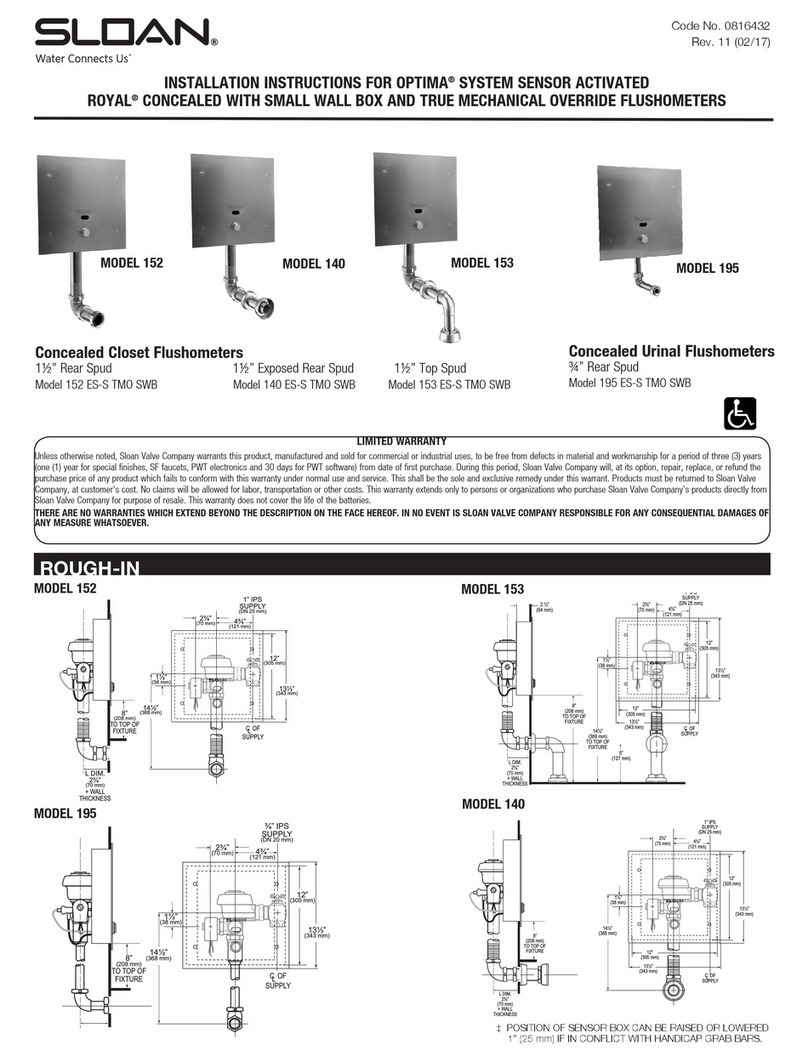

FAUCET ROUGH-IN

ETF-80 Faucet with Bak-Chek®Tee

for Hot and Cold Water Supply

(shown with 4” trim plate)

ETF-80 Faucet with ADM Variation Mixing Valve

for Hot and Cold Water Supply

(shown with 8” trim plate)

ETF-80 Faucet with BDM and BDT Variation

Mixing Valves for Hot and Cold Water Supply

(shown with 4” trim plate)

ETF-880 Faucet with Bak-Chek®Tee

for Hot and Cold Water Supply

(shown with 4” trim plate)

ETF-880 Faucet with ADM Variation Mixing Valve

for Hot and Cold Water Supply

(shown with 8” trim plate)

ETF-880 Faucet with BDM and BDT Variation

Mixing Valves for Hot and Cold Water Supply

(shown with 4” trim plate)

ETF-80 Faucet ETF-880 Faucet

3

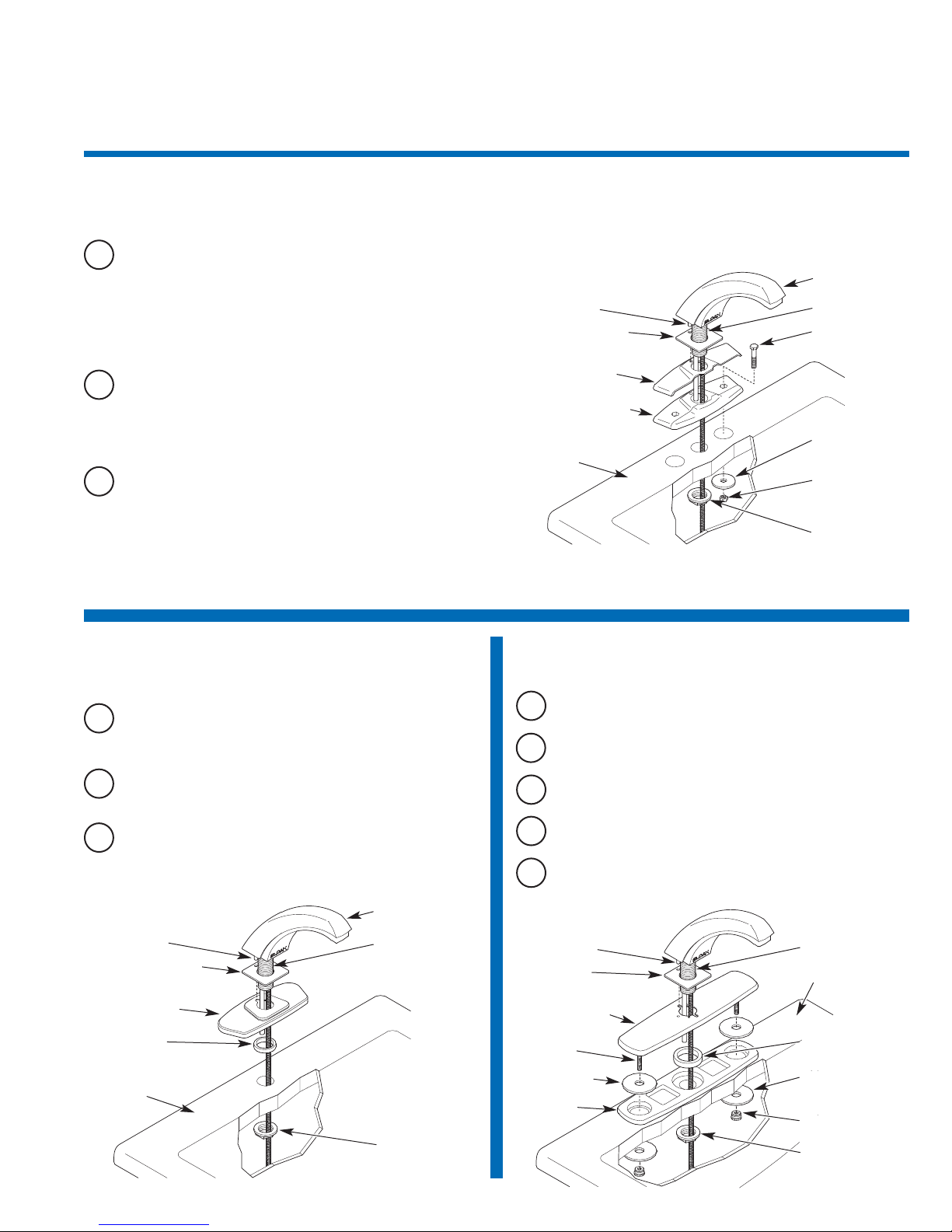

1A ETF-295-A (for ETF-80) Single

Hole 4” Trim Plate

ASlide Rubber Faucet Gasket onto Faucet Shank. Ensure that Roll

Pin on base of Faucet fits into hole in Rubber Faucet Gasket.

Note: When installing with a Sloan Mixing Valve, install Faucet and Trim Plate before installing Mixing Valve. For complete installation guidelines, refer to

the Installation Instructions supplied with the Sloan mixing valve.

BInsert Hex Bolts into Black Plastic Base Plate (if sink has only a

center hole, see note above). Place Chrome Cover Plate over

Black Plastic Base Plate. Slide Trim Plate assembly onto Faucet

Shank. Align Roll Pin with small hole in Trim Plate assembly.

Note: If Trim Plate is used on a sink with a center hole only, Trim Plate

Bolts are not used. Apply plumber’s putty to underside of Trim Plate to

prevent Faucet from rotating.

CInsert Trim Plate Bolts through the 4 inch (102 mm) spread deck

holes and Faucet Shank through the 1 inch (25 mm) minimum

diameter deck hole. Secure Trim Plate to Deck using the large

Plate Washers and Hex Nuts supplied. Secure Faucet from below

Deck using the Flange Nut supplied.

ROLL PIN

RUBBER

FAUCET GASKET

COVER PLATE

BLACK PLASTIC

BASE PLATE

DECK

FAUCET SHANK

TRIM PLATE

HEX BOLTS (2)

PLATE

WASHERS (2)

HEX NUTS (2)

FLANGE NUT

1Install Faucet Spout and Trim Plate — Refer to the appropriate step (1A-1C) for

your application.

1BETF-662-A (for ETF-880) Single

Hole 4” Trim Plate

ASlide Rubber Faucet Gasket onto Faucet Shank. Ensure that Roll

Pin on base of Faucet fits into hole in Rubber Faucet Gasket.

BSlide Trim Plate and Back-up Spacer onto Faucet Shank. Align Roll

Pin with small slot in Trim Plate.

CSecure Faucet from below Deck using the Flange Nut supplied.

ROLL PIN

RUBBER FAUCET

GASKET

TRIM PLATE

BACK-UP

SPACER

DECK

FAUCET SHANK

FLANGE NUT

1CETF-510-A (for ETF-80/880) Single

Hole 8” Trim Plate

ASlide Rubber Faucet Gasket onto Faucet Shank. Ensure that Roll

Pin on base of Faucet fits into hole in Rubber Faucet Gasket.

BSlide Trim Plate and Back-up Spacer onto Faucet Shank. Align Roll

Pin with small slot in Trim Plate.

CSlide Washer Gaskets over Studs. Place Studs and Faucet Shank

through Base Gasket and holes in Deck.

DSecure Trim Plate from below Deck using the two (2) Fender

Washers and two (2) Finger Nuts supplied.

ESecure Faucet from below Deck using the Flange Nut supplied.

ROLL PIN

RUBBER

FAUCET

GASKET

TRIM PLATE

STUD

DECK

FAUCET SHANK

WASHER

GASKET (2)

BASE

GASKET

BACK-UP

SPACER

FENDER

WASHER (2)

FINGER NUT (2)

FLANGE NUT

ETF-880 FAUCET

ETF-80 FAUCET

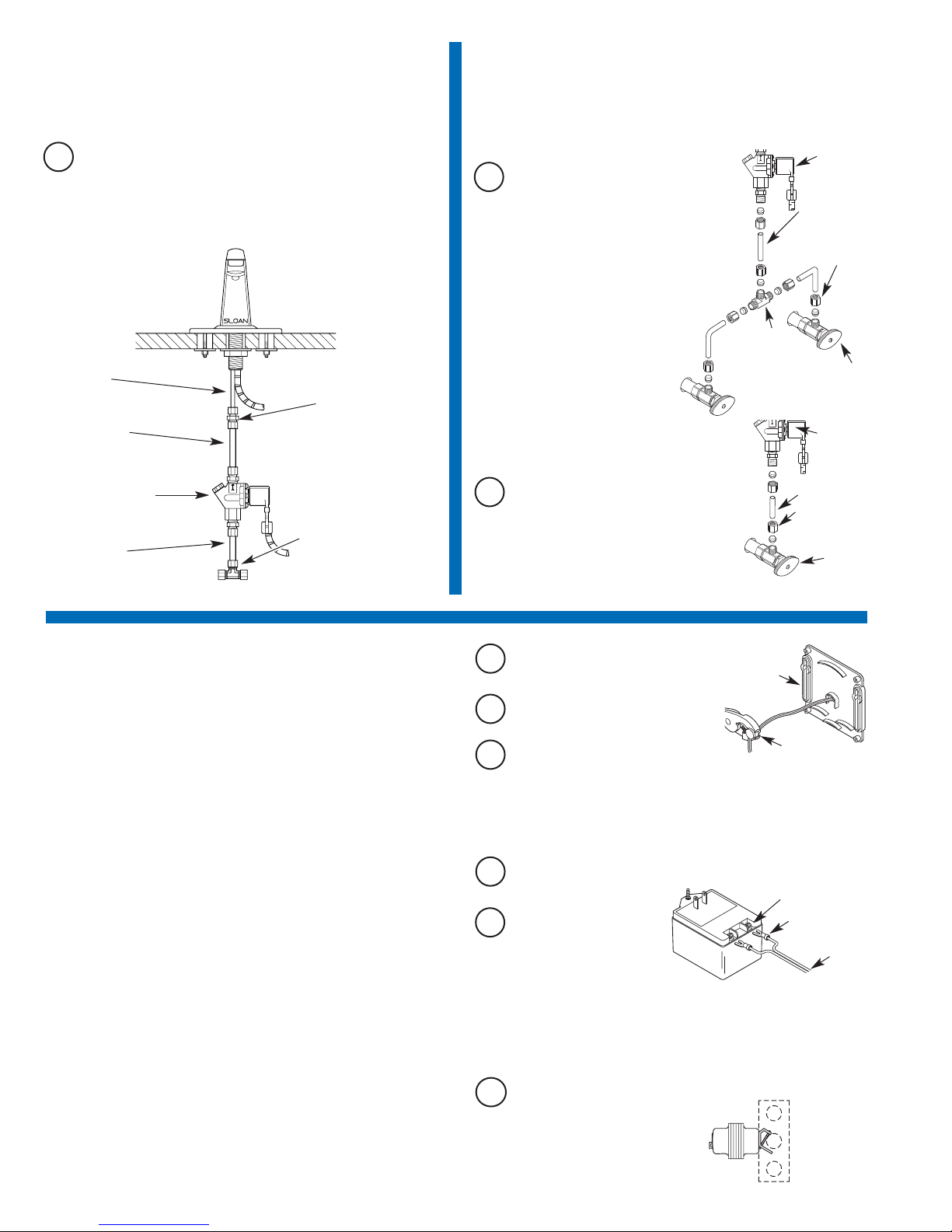

2Install Solenoid Valve

A

Note: Flow direction of Solenoid Valve is indicated by an arrow on the

Valve Body.

Install the 1/4 inch end of the 1/4 to 3/8 inch Compression Fitting

onto the Spout’s copper Supply Tube. Connect 3/8 inch O.D.

Supply Tube between Compression Connection on Solenoid Valve

and Compression Fitting on Spout’s copper Supply Tube.

4Install Transformer

Multiple Faucets

Multiple faucets can be powered by a single transformer that has been

properly sized. Allow a minimum of 15 VA of current rating for each

solenoid valve used. Refer to the following example to determine the

required current rating for 3 OPTIMA faucets.

Example:

Total number of OPTIMA faucets: 3

Total number of solenoid valves: 3

Multiply by current rating: 15 VA

——

Minimum current rating of required transformer: 45 VA

Transformers Available with the ETF-80 and ETF-880 Faucets

Standard Plug-In † ETF-233 120 VAC 35 VA

Standard Box Mount EL-248-40 120 VAC 40 VA

† In Canada, use ETF-416 (120 VAC, 35 VA).

Optional Transformers Available from Sloan

Box Mount EL-154 120 VAC 50 VA

Foot Mount EL-208 120 VAC 100 VA

Box Mount EL-342 240 VAC 50 VA

All Sloan transformers are 50/60 Hz.

Other transformers (not supplied by Sloan) may be used provided they

meet UL requirements for Class 2 transformers.

PLUG-IN TRANSFORMERS

Important: DO NOT plug Transformer into receptacle until all wiring has

been completed. The Transformer is supplied with a 10 foot Cable;

however, this Cable can and should be shortened to meet installation

requirements.

AStrip ends of Transformer Power Cable

approx. 3/16 to 1/4 inch (5 to 6 mm).

EInstall Crimp Connectors and

connect Power Cable ends to

Transformer Terminals.

DConnect Power Cable to Terminal Block on Connector Board. See

Step 6.

CInsert Power Cable and Strain Relief into

hole at back of Control Module. Install right angle Strain Relief so

that Power Cable enters the Control Module from the bottom.

BInstall Strain Relief 3 inches (76 mm)

from one end of Power Cable.

BOX MOUNT TRANSFORMER

Important: DO NOT supply power to primary side of Transformer until

wiring is completed.

Mount Transformer on a metal electrical junction box (supplied by others). (“J”

box should be mounted inside chase wall or above ceiling.) Install Transformer

within 50 feet (15.24 meters) of Faucet. 18 gauge wire is recommended.

ARun wires from secondary side

of Transformer to 3/8 inch (10

mm) hole at back of Control

Module Enclosure. If necessary,

wires can be run through wall and

then inserted through hole in back of

Control Module Enclosure.

CONTROL

MODULE

BASE

POWER CABLE

STRAIN

RELIEF

CRIMP

CONNECTORS

TRANSFORMER TERMINALS

24 VAC

SECONDARY 120 VAC

PRIMARY

BOX MOUNT

TRANSFORMER

(EL-248-40

SHOWN)

3Connect Supply Line(s) from

Supply Stop to Solenoid Valve Inlet

For Dual Line Hot and Cold Water

Supply Applications

Install a 3/8 inch (10 mm) copper supply

tube between Bak-Chek®Compression Tee

and hot and cold supply stops. (Supply

stops and copper supply tube furnished by

installer.) Install a 3/8 inch (10 mm) copper

supply tube between Bak-Chek®

Compression Tee and inlet side of

Solenoid Valve. Tighten

Compression Fittings securely.

Note: Failure to install the Bak-Chek®Tee

can result in a cross flow connection

when the faucet is off and the supply

stops are open. If pressure of the hot

and cold water supply differ, hot water

can migrate into the cold water supply or

vice-versa. Most plumbing codes require that

the Bak-Chek®be used to prevent this.

3/8” (10 mm)

BAK-CHEK®TEE

USED ON DUAL

WATER SUPPLY

APPLICATIONS

ONLY

3/8” (10 mm)

COMPRESSION

FITTING

3/8” (10 mm)

SUPPLY TUBE

SOLENOID

VALVE

SUPPLY

STOP

A

3/8” (10 mm)

COMPRESSION

FITTING

3/8” (10 mm)

SUPPLY TUBE

SOLENOID

VALVE

SUPPLY

STOP

BFor Single Line Water Supply Applications

Install a 3/8 inch (10 mm) copper supply tube

between the supply stop and inlet side of

Solenoid Valve. (Supply stop and copper

supply tube furnished by installer.) Tighten

Compression Fittings securely.

Important: Keep thread sealant out of your waterway and prevent

component part damage! Do not use sealant on compression fittings.

When thread sealant is used, do not apply it to the first two “starter”

threads.

4

COPPER

SUPPLY

TUBE

3/8” SUPPLY

TUBE (NOT

SUPPLIED)

1/4 TO 3/8 INCH

COMPRESSION

FITTING

SOLENOID VALVE

3/8” (10 mm)

BAK-CHEK®

COMPRESSION

TEE

3/8” SUPPLY

TUBE (NOT

SUPPLIED)

Important: Flush dirt, debris, and sediment from the supply line(s).

Important: Twist stranded ends of Power Cable before inserting into

Terminal Block. Fraying of Stranded Power Cable Wire can cause a short

and damage the Control Module and Transformer when powered.

5

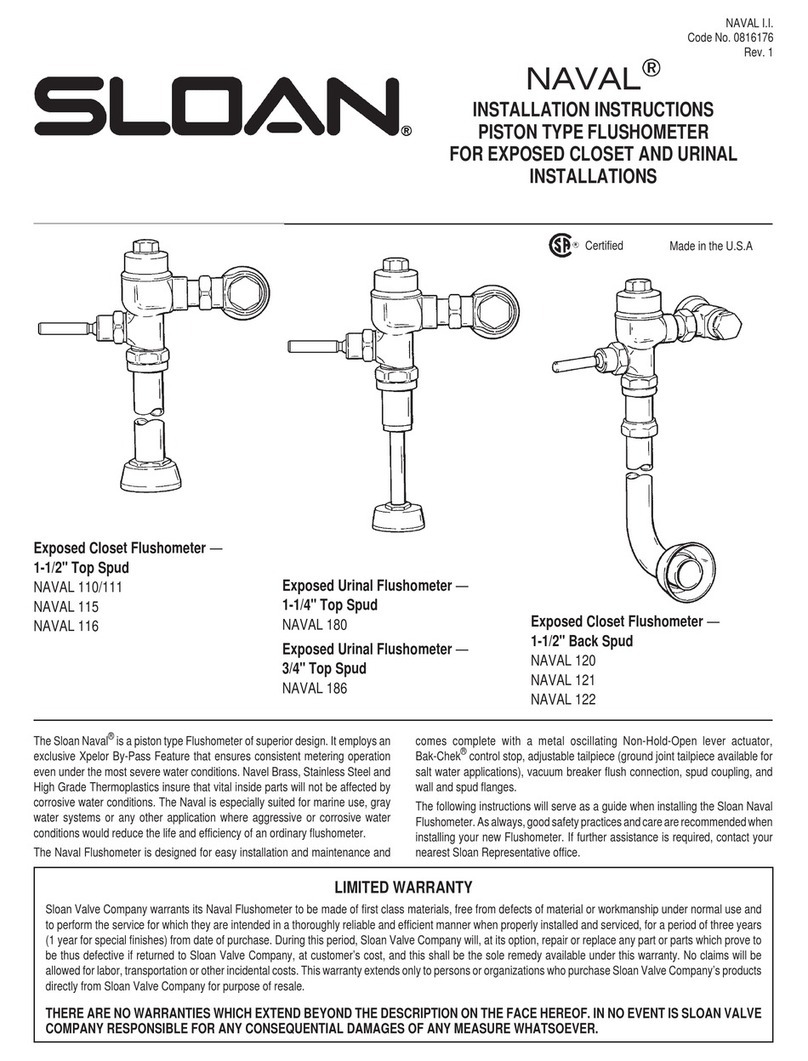

5Mount Control Module to Wall

EXTENSION CABLES

Extension Cables are available as an option from Sloan to allow for

installing the Control Module remote from the Faucet Spout and Solenoid

Valve. Refer to the Parts List for available lengths.

BMount Control Module to wall using Mounting Screws and Plastic

Anchors.

AInstall the Control Module in an appropriate location as shown in

Rough-in. Control Module must be installed so that all cables

enter from the bottom of the unit. When installed, Cables from the

Spout and Solenoid Valve to the Control Module should have

some slack.

4” (102 mm)

6Control Module Connections

BInsert Solenoid Valve Connector into the Modular Receptacle on

Connector Board.

CInsert Locking Connector from Faucet Spout into mating

Receptacle on Connector Board. Allow 3 to 4 inches (76 to 102

mm) of Cable to extend into the Control Module.

DInsert each Conduit Cable into a strain relief slot in the Control

Module.

ARoute Cables from Solenoid Valve and Spout to the Control

Module.

CONTROL

MODULE

ENCLOSURE

FROM SOLENOID

VALVE

FROM

TRANSFORMER

STRAIN

RELIEF

SLOTS

FROM FAUCET

SPOUT

TERMINAL BLOCK -

1. REMOVE

TERMINAL BLOCK

2. INSERT POWER

CABLES

3. SECURE WITH

SCREWS

4. REINSTALL

TERMINAL BLOCK

CONNECTOR

BOARD

POWER CABLE

MODULAR

RECEPTACLE

Plug In Transformer

APlug Transformer into 120 VAC Receptacle.

7

TRANSFORMER

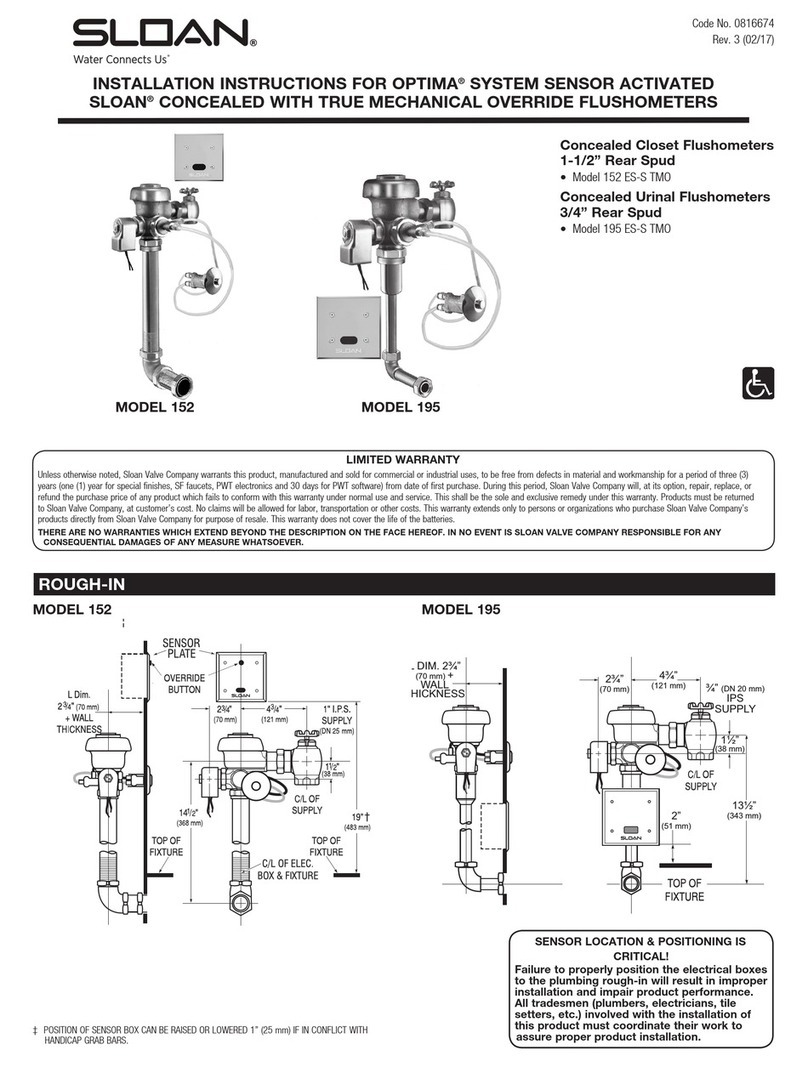

8Start-Up

ASupply power to Transformer.

Note: The Control Module is equipped with two LED lights. When power

is supplied by the Transformer, one LED will illuminate green. When

Sensor is activated, this LED will change to red. A second red LED

illuminates when Solenoid Valve is activated.

BOpen Supply Stop(s). With Aerator removed, activate Faucet for

30 seconds by placing hands in front of Sensor. The Solenoid

Valve should “click” and water should flow from the Spout. If this

does not occur, refer to the Troubleshooting section of this

installation instructions.

CClose Supply Stop(s) and install Spray Head in Spout using the

Key provided. Reopen Supply Stop(s), activate Faucet and check

for leaks.

THREAD THE SPRAY

HEAD INTO OPENING

OF SPOUT

SPRAY HEAD

SPOUT

This manual suits for next models

1

Table of contents

Other Sloan Control Unit manuals

Sloan

Sloan TRUFLUSH TRF 8900-CP User manual

Sloan

Sloan G2 Optima Plus Operating manual

Sloan

Sloan Optima Plus EBV-500-A User manual

Sloan

Sloan NAVAL 110 User manual

Sloan

Sloan 152 ES-S TMO SWB User manual

Sloan

Sloan 152 ES-S TMO SWB User manual

Sloan

Sloan G2 Optima Plus Operating manual

Sloan

Sloan SOLIS 8100 Series User manual