Code No. 08160044

Rev. 1(11/21)

INSTALLATION INSTRUCTIONS FOR

TRUFLUSH ELECTRONIC DUAL FLUSH WALL PLATE

LIMITED WARRANTY

Unless otherwise noted, Sloan India Pvt. Ltd warrants this product,

manufactured and sold for commercial or industrial uses, to be free

from defects in material and workmanship for a period of five (5)

years and 1 Year- All Electronic & battery not covered in warranty

from date of first purchase. During this period, Sloan India Pvt. Ltd

will, at its option, repair, replace, or refund the purchase price of any

product which fails to conform with this warranty under normal use

and service. This shall be the sole and exclusive remedy under this

warranty. Products must be returned to Sloan India Pvt. Ltd, at

customer’s cost. No claims will be allowed for labor, transportation or

other costs. This warranty extends only

to persons or organizations who purchase Sloan India Pvt. Ltd

products directly from Sloan India Pvt. Ltd for purpose of resale. This

warranty does not cover the life of the batteries.

THERE ARE NO WARRANTIES WHICH EXTEND

BEYOND THE DESCRIPTION ON THE FACE

HEREOF. IN NO EVENT IS SLOAN INDIA PVT. LTD

RESPONSIBLE FOR ANY CONSEQUENTIAL

DAMAGES OF ANY MEASURE WHATSOEVER.

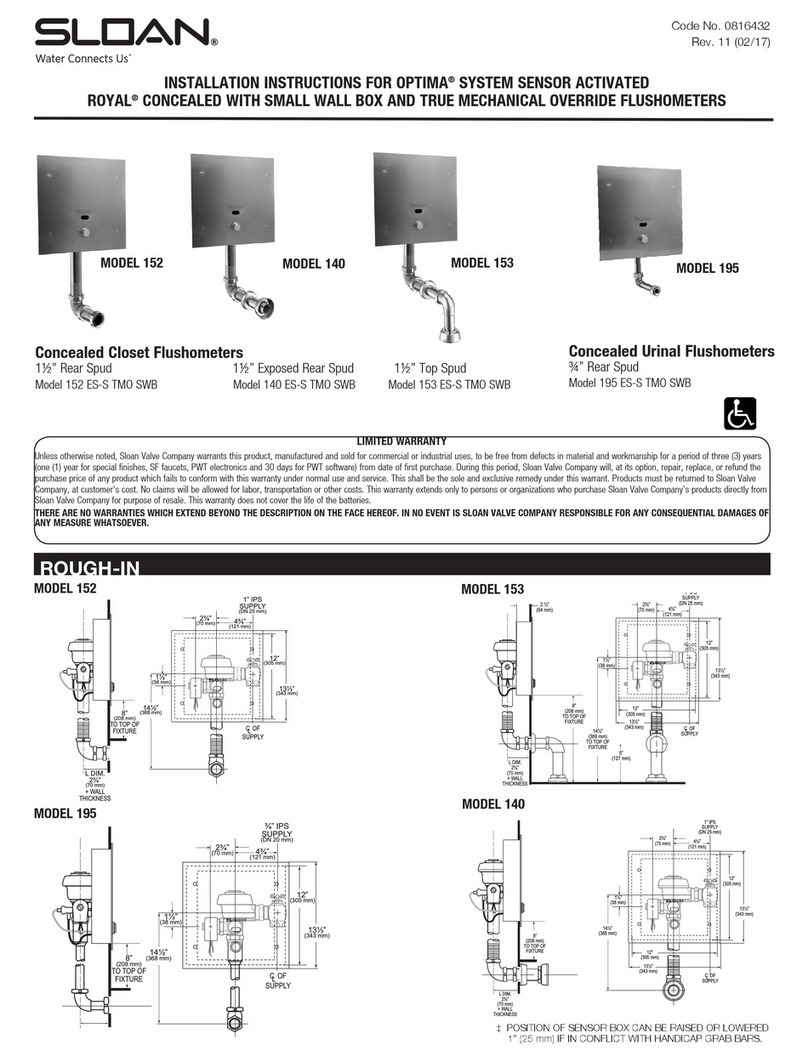

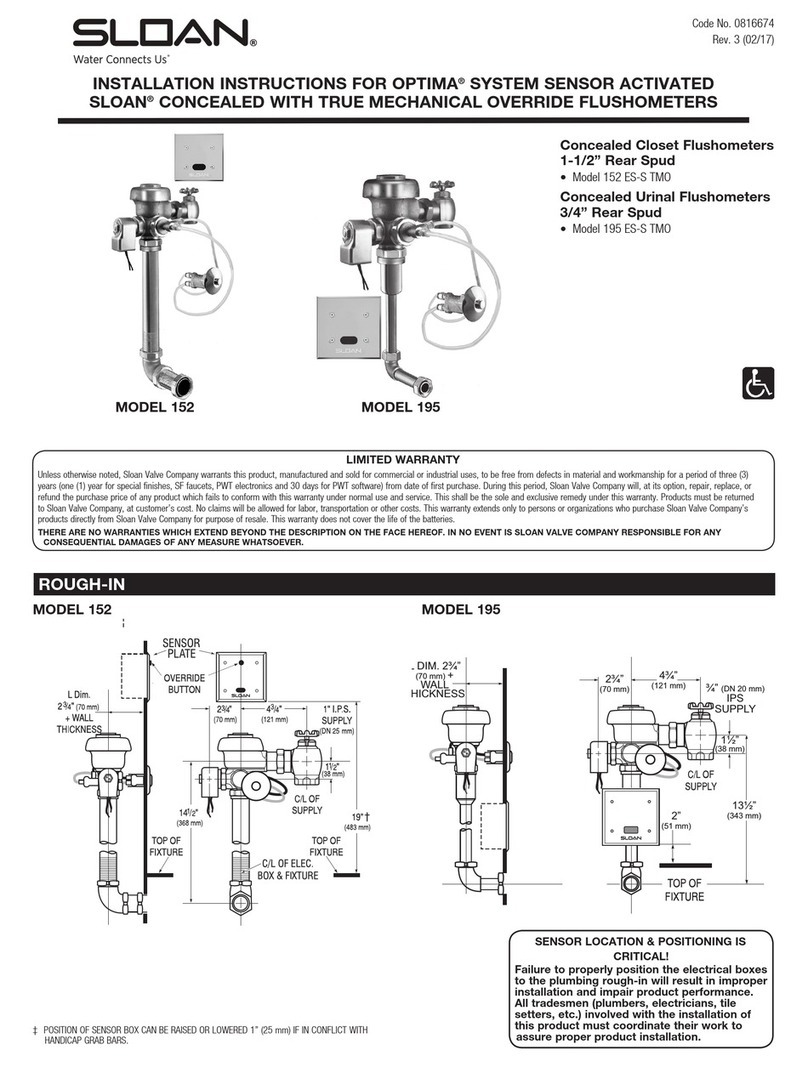

TruFlush Model:

TRF 8900-CP

PRIOR TO INSTALLATION

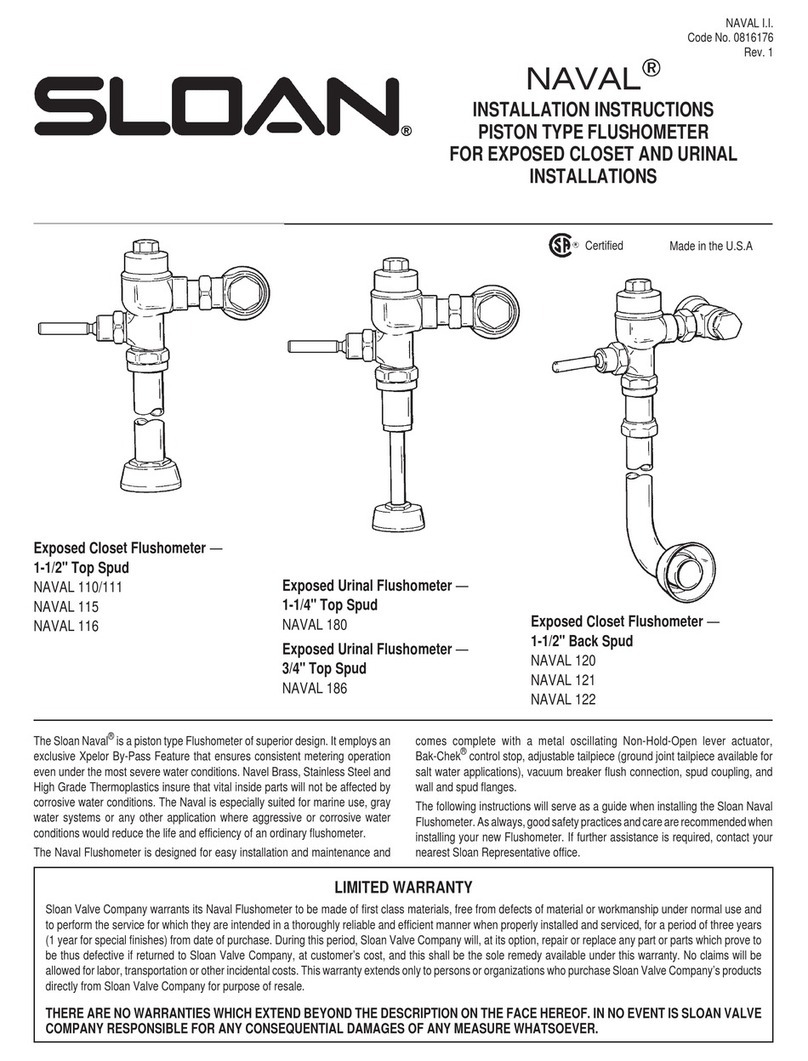

TOOLS REQUIRED FOR INSTALLATION

• Phillips screwdriver

This valve is designed for new construction or where there is easily

accessed plumbing for the xture and the valve.

This valve is designed for minimum six inch (152 mm) wall space

depth. Distance from center of the valve (inlet or outlet pipe) to the

nished surface of the wall can vary from 2”-3” (51-76 mm).

Wall plate opening must be of 5.6” x 5.6” (142 x 142 mm). Mud plate

is provided and must accompany valve for proper installation. Mud

plate is removed after wall is nished.

ITEMS INCLUDED WITH THE PRODUCT

ITEM #1: WALL BOX AND

ELECTRONIC VALVE

ASSEMBLY

ITEM #2: MUD GUARD

ITEM #3: ACTIVATION

ASSEMBLY TOOL

ITEM #4: #8-32 X 2" TRUSS

HEAD SCREWS

ITEM #5: 1/4-20 X 2"

SCREWS

SENSOR VALVE BOX

ITEM #1: WALL BOX

ITEM #2: WALL PLATE

ITEM #3: SENSOR ASSEMBLY

ITEM #4: ACTIVATION BUTTON

ITEM #5: BATTERY PACK

ITEM #6: 4X BATTERIES

ITEM #7: 4X #8-32 X 2"

TRUSS HEAD SCREWS

ITEM #7: 5/64" HEX KEY

WALL PLATE BOX

ITEM #1: WALL BOX AND

ELECTRONIC VALVE

ASSEMBLY

ITEM #2: MUD GUARD

ITEM #3: ACTIVATION

ASSEMBLY TOOL

ITEM #4: #8-32 X 2" TRUSS

HEAD SCREWS

ITEM #5: 1/4-20 X 2"

SCREWS

SENSOR VALVE BOX

ITEM #1: WALL BOX

ITEM #2: WALL PLATE

ITEM #3: SENSOR ASSEMBLY

ITEM #4: ACTIVATION BUTTON

ITEM #5: BATTERY PACK

ITEM #6: 4X BATTERIES

ITEM #7: 4X #8-32 X 2"

TRUSS HEAD SCREWS

ITEM #7: 5/64" HEX KEY

WALL PLATE BOX

• Adjusting tool (supplied)

1. Wall Bracket

2. Wall Plate

3. Sensor Assembly

4. Battery Pack

5. (4) Batteries

6.(4) #8-32 x 2 Screws

7.Allen Key

8.Installation instructions

WALL PLATE BOX

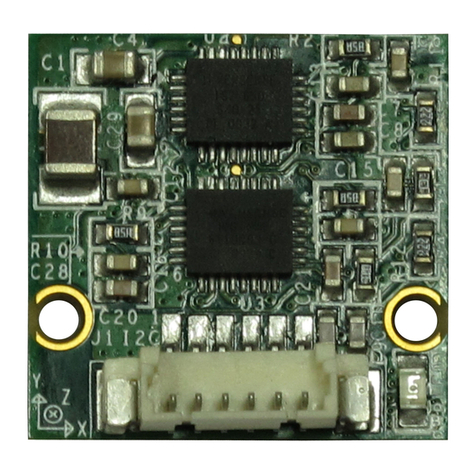

1. Wall Bracket 2. Wall Plate 3.PCB Assembly

4. Battery Pack 5. (4) Batteries 6. (4) #8-32 x 2 Screws 7. Allen

Key

8. Instructions

• Flathead screwdriver .118”

(3 mm or below)

• Wire stripper tool