Sloan Soap/Sanitizer Dipensers User manual

Installation & Operating

Instruction Manual

Thoroughly read this instruction booklet

before operating Sloan dispensers.

Keep this Installation & Operating

Instruction Manual with other product

information for future reference.

Manual Dispensers

SJS-1000 Soap Dispenser

SJS-1100 Foam Soap Dispenser

SJS-1400 Sanitizer Dispenser

Electronic Dispensers

SJS-1050 Touchless, Sensor-Operated

Soap Dispenser

Table of Contents Page

Dimensions 2-3

Installation and Set-up 4-7

Operation 8-9

Maintenance 9-10

Troubleshooting 11

Emergency Measures 11

Consumables Chart 11

Soap/Sanitizer

Dispensers

Electronic

Dispensers

Manual

Dispensers

2

Sight glass

Identifies

amount of

soap/sanitizer

remaining.

Key

Insert the key into the

keyhole, and the cover

will open toward you.

Lever

Push the lever,

and the liquid is

dispensed.

Keyhole

Mounting

holes

Mounting

plate

5.28"

(134 mm)

2.17"

(55 mm)

Mounting hole

1.41"

(36 mm)

10.04"

(255 mm)

5.31"

(135 mm)

4.41"

(112 mm)

Dimensions – Manual Models (Fig. 1)

Parts – Manual Models (Fig. 2)

Foaming Soap Pouch

Sanitizer and Skin Care Pouch

Soap/Sanitizer

Pouches –

Manual Models

(Fig. 3)

Note the difference

in the pouch nozzles.

3

Key

Insert the Key into the

Keyhole, and the cover

will open toward you.

Sight glass

Soap levels

can be checked.

Sensor

When the sensor

senses the palm,

the unit operates.

Nozzle

Liquid is dispensed.

Keyhole Mounting

holes

DC jack

Pilot lamp

Mounting

plate

2.17"

(55 mm)

Mounting hole

1.41"

(36 mm)

6.07"

(154 mm)

10.83"

(154 mm)

3.51"

(89 mm)

5.75"

(146 mm)

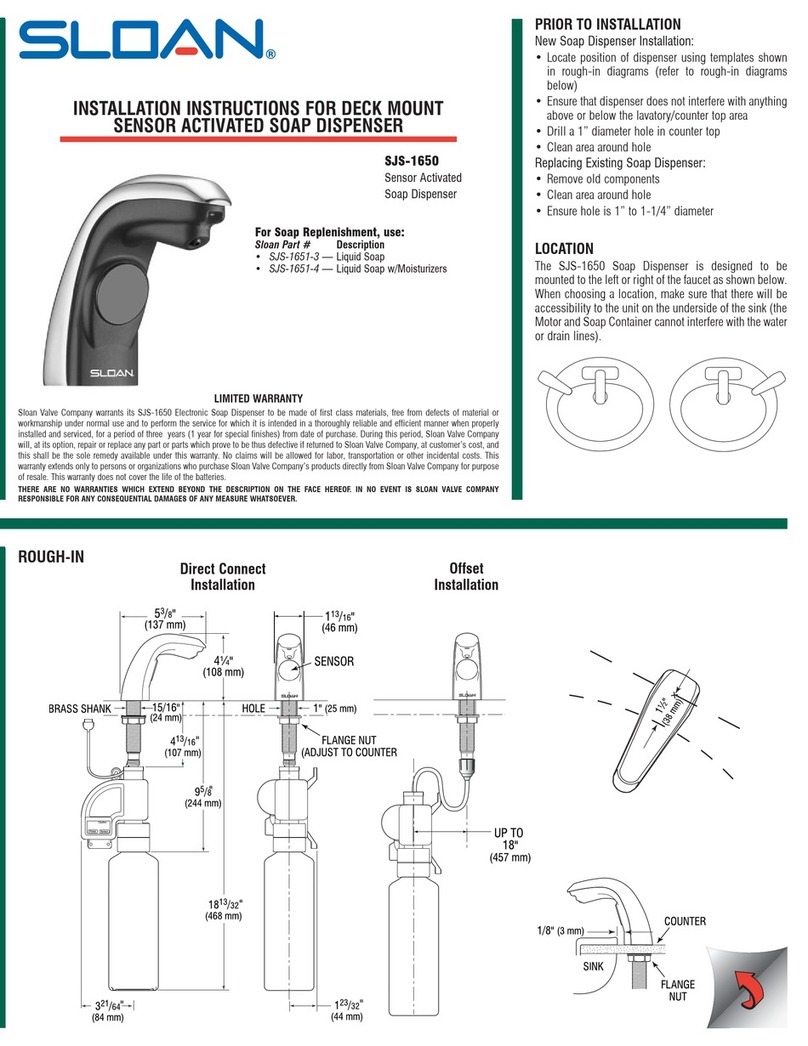

Dimensions – Sensor Models (Fig. 4)

Parts – Sensor Models (Fig. 5)

Soap Pouch

Soap Pouch – Sensor

Models (Fig. 6)

4

Parts

Dispenser (1)

Key (1)

Alcohol Wipe (1)

Screws (5)

Wall Anchors (5)

Double Face Tape (1)

C-Cell Batteries (4) – sensor models only

STEP 1.

Select an area on the wall with

sufficient support

The installation wall must be at least

.25” (6 mm) thick or the area should be

reinforced or risk failure due to the

dispenser falling.

Install in an area that does not

experience extreme temperatures

Avoid exposure to direct sunlight and

keep away from heat sources such as

cooking areas and heating devices.This

may result in fire.The dispenser should be

installed in an area that maintains an

ambient temperature between 32°F

and 95°F.

Excessive moisture or water spray may

result in rusting or malfunction.

Direct sunlight may result in malfunction.

Tools for Installation

1/4” drill bit

1/8” drill bit

Power drill

Phillips screwdriver

Measure/Ruler

Hammer

Installation Procedure

Check the installation wall. The wall

anchors and screws are required for

installation on a concrete wall. If the wall is

weak paneling or plasterboard less than

.25” (6 mm), the area should be reinforced.

Optional AC Adapter for Sensor Models

1. If an outlet is not available in the

installation area contact an electrician.

2. The power supply is AC100V-120V

(50/60Hz). Wiring must conform to

power supply requirements.

3. Keep moisture or water away from the

outlet.

4. The length of the AC adapter cord is

5’-9” (1.8 m). The outlet must be within

this range.

STEP 2.

Positioning the dispenser (Fig. 7)

To properly use key and to open door

fully, allow clearance above and below

dispenser as shown in Figure 7.

INSTALLATION AND SET-UP

Obstruction

Obstruction

Manual

Model

Sensor

Model

Obstruction

Obstruction

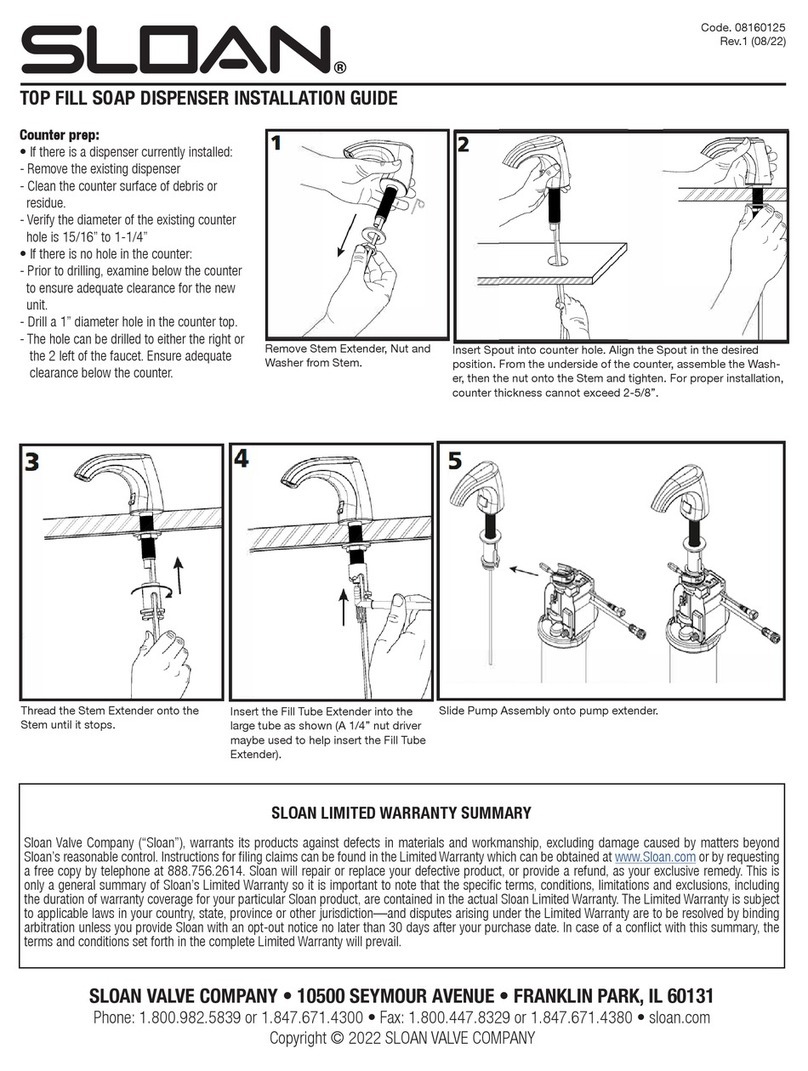

STEP 3.

Install the mounting plate (Fig. 8)

Use the mounting plate holes as a guide

for drilling.

Screws

Mounting

plate

Wall

anchor

Fig. 8

Fig. 7

5

Once tape is secured to the mounting

plate, peel the protective paper from the

double face tape and press the plate

firmly to the wall and hold for 10 seconds.

Leave the mounting plate attached to the

wall and allow to dry for 24 hours before

installing the dispenser.

NOTE: Double face tape may not be used to

mount the unit onto a wall with a coated

surface or wallpaper. Double face tape

cannot adhere to a wall with uneven or

rough surface.

STEP 4.

Installing the main body (Fig. 10)

Position the main body over the mounting

plate and snap into place.

Mounting

plate

Double face tape

Main body

Mounting plate

STEP 5.

Removing the dispenser from the

main body (Fig. 12)

Insert the key or a flathead screwdriver

into the keyhole and slide the main body

upward.

Fig. 9

Fig. 10

When installing onto a concrete wall or

drywall, drill 1” to 1.5” deep holes using a

1/4” drill bit. Mount plate with three wall

anchors and screws.

For wood walls, drill guide holes using a

1/8” bit and attach plate with three screws.

Before drilling the holes, make sure there

are no pipes or wires located behind the

wall.

Using double face tape to install the

mounting plate (Fig. 9)

When the installation area does not allow

drilling, use double face tape to mount the

dispenser by placing the tape on the back

of the mounting plate after is has been

cleaned of dust, dirt, oils and grease with

the alcohol wipe.The wall area must also

be cleaned in this manner. Let both the

wall and mounting plate dry for at least 10

minutes.

Keyhole

Inside of the main body (Front view)

Key or

flathead

screwdriver

Fig. 12

6

STEP 7.

Installing/replacing batteries for sensor

models (Fig. 14)

1. Open the cover. Remove the pouch

holder.

2. Place the key into the battery box hole

to remove the battery box cover.

3. Install four new C-cell batteries in

proper +/- orientation.

NOTE: Supplied batteries are intended for

checking operational status only. Install new

batteries before operating. If the unit will be

dormant for some time, remove batteries

and store properly. Immediately remove

batteries and replace when the red LED

flashes.

Cover

Keyhole

Cover

Key

STEP 8.

Installing/replacing Soap/Sanitizer

pouches for manual units (Fig. 15)

1. Open the cover and remove the pouch

from the dispenser.

2. Place the new pouch in the holder.

3. Remove the cap from the pump.

4. Close the cover.

Installing/replacing Soap Pouches for

Sensor Units (Fig. 16)

1. Open the cover and remove the pouch

from the dispenser.

2. Place the new pouch in the holder.

3. Set the pouch pump in the battery box.

4. Remove the cap from the pouch pump.

5. Close the cover.

Fig. 13

Fig. 14

STEP 6.

Opening/closing the cover (Fig. 13)

Place the key into the keyhole on the top

of the dispenser. Holding the cover, open

it toward you.

Return the cover to its original position

and press it until it snaps into place.

7

How to set the liquid and spray pump

Insert the nozzle into the holder hole.

How to set the foam pump

Place pouch into holder, align nozzle with

pins and snap into position as shown.

Sanitizer/Soap Type

Cap

Cap

Holder Holder

Pouch

Pouch

Foaming Soap Type

Knob

Cap

Battery box

How to set the pump

Hold the knob and remove the cap. While holding the

pump knob, press it to the set position until it clicks.

Fig. 15

Fig. 16

8

Place your hands under the dispenser to

activate the sensor. For multiple soap

applications, remove hands and place

again under the unit to re-activate.

Sensor Model features:

Sensor: Recognizes hands so there is

no need to touch the unit.

Safety switch: Open the cover, set the

power to OFF and the unit will no

longer dispense.

Pilot lamp: When the sensor

recognizes a user’s hands, the red LED

will light. When the batteries lose

power, the red LED light flashes.

Key: Use the special key to open/close

the dispenser cover.

Precautions

• Before using the dispenser,

thoroughly read the “Precautions”

attached to the liquid products.

• Immediately clean any spill on the

floor to help avoid falling, injuries or

other hazards.

STEP 1.

Operating instructions for manual

models (Fig. 17)

Press the lever to dispense the soap or

sanitizer onto hands.

NOTE: After the pouch is installed, liquid may

not dispense immediately. To prime the unit,

pump the lever until it dispenses.Do not

pump violently.

OPERATION

Dispensing Long Short Medium

Mode

Position of Left Middle Right

Mode Switch

Indicator Blink 1X Blink 2X Blink 3X

Lamp

STEP 2.

Mode setting for Sensor Models

(Fig. 18)

Dispensing times can be adjusted to any

of three modes.

1. Open the cover.

2. Pull out mode switch cover.

3. Using a screwdriver or the tip of a pen,

switch the mode switch to the desired

setting.The indicator lamp will blink

according to the mode selected.

Fig. 17

9

STEP 1.

Cleaning the unit body

To ensure longevity, carry out periodic

maintenance.

For standard cleaning, wipe off dirt with

soft, dry cloth.

For dispensers that are very dirty, wipe

with a wet, soapy cloth.

DO NOT USE: Thinner, benzene, alcohol,

petroleum, powder soap, polishing powder,

detergent other than neutral detergent,

boiling water, acids, alkaline materials, scrub

brushes, etc.

STEP 2.

Cleaning the nozzle of Sensor Models

(Fig. 19)

A clogged nozzle may result in poor

dispensing or malfunction.

To clean the nozzle:

1. Open the cover and clear the

dispensing hole at the end of the

nozzle with a thin wire pin (less than

0.5 mm) – paper clips work well.

2. Close the cover.

3. Check if the unit dispenses properly. If

the unit does not dispense properly,

replace the pouch.

Mode switch cover

Mode switch

Indicator lamp

Nozzle

Thin wire pin/

paperclip

MAINTENANCE

Fig. 18

Fig. 19

10

MAINTENANCE

STEP 3.

Cleaning the nozzle of Manual

Models (Fig. 20)

A clogged nozzle may result in poor

dispensing or malfunction.

To clean the nozzle:

Soap

1. Open the cover and clear the

dispensing hole at the end of the

nozzle with a thin wire pin (less than

0.5 mm) – paper clips work well.

2. Close the cover.

3. Check if the unit dispenses properly. If

the unit does not dispense properly,

replace the pouch.

Sanitizer

1. Open the cover and soak only the

nozzle in hot water for approximately

two minutes.

2. If the clog is still visible, clear the

dispensing hole at the end of the

nozzle with a thin wire pin (less than

0.5 mm) – paperclips work well.

3. Close the cover and test again.

4. If the unit does not dispense properly,

replace the pouch.

Thin wire pin/

paperclip

Nozzle

Nozzle

Hot water

Fig. 20

11

TROUBLESHOOTING

Before calling for repair of

Sensor Models

Problem: The unit does not operate

1. Check if the unit is securely closed

2. Check if pump is securely set

3. Check if the batteries need

replacement (flashing red LED)

Problem: Liquid is not dispensed

1. Check if the liquid has run out

2. Check if nozzle is clogged

Before calling for repair of

Manual Models

Problem: The unit does not operate

1. Check if the liquid has run out

2. Check if nozzle is clogged

If trouble continues, call 877-752-6726.

CONSUMABLES REFERENCE CHART

Product No. Description For use with Order No.

SJS-1001 Manual Wall-Mount Liquid Soap SJS-1000 5700200

SJS-1001-1 Manual Wall-Mount Liquid Soap with Moisturizers SJS-1000 5700201

SJS-1051 Sensor Wall-Mount Liquid Soap SJS-1050 5700400

SJS-1051-1 Sensor Wall-Mount Liquid Soap with Moisturizers SJS-1050 5700401

SJS-1101 Manual Wall-Mount Foam Soap SJS-1100 5700500

SJS-1101-1 Manual Wall-Mount Foam Soap with Moisturizers SJS-1100 5700501

SJS-1401 Manual Alcohol Hand Sanitizer SJS-1400 5700600

Take emergency measures listed on pouch

label according to chemical being used.

Eye contact: Flush eyes with water for a

minimum of 15 minutes and consult a

physician immediately.

Ingestion: Drink water to induce vomiting

and consult a physician immediately.

Inhalation: Get fresh air immediately.

If condition does not improve, consult a

physician immediately.

EMERGENCY MEASURES

The information contained in this document is

subject to change without notice.

Air Delights, Inc.

9974 SW Arctic Drive

Beaverton, Or. 97005

Phone: 800-440-5556

Fax: 503-643-8224

www.sloanvalve.com

©2009 Sloan Valve Company

Printed in the U.S.A. JSD6031.1 01/09

This manual suits for next models

1

Table of contents

Other Sloan Dispenser manuals