CONTENTS

GENERAL INFORMATION

1. SAFETY INSTRUCTIONS ---------------------------------------------------------------------------- 1, 2

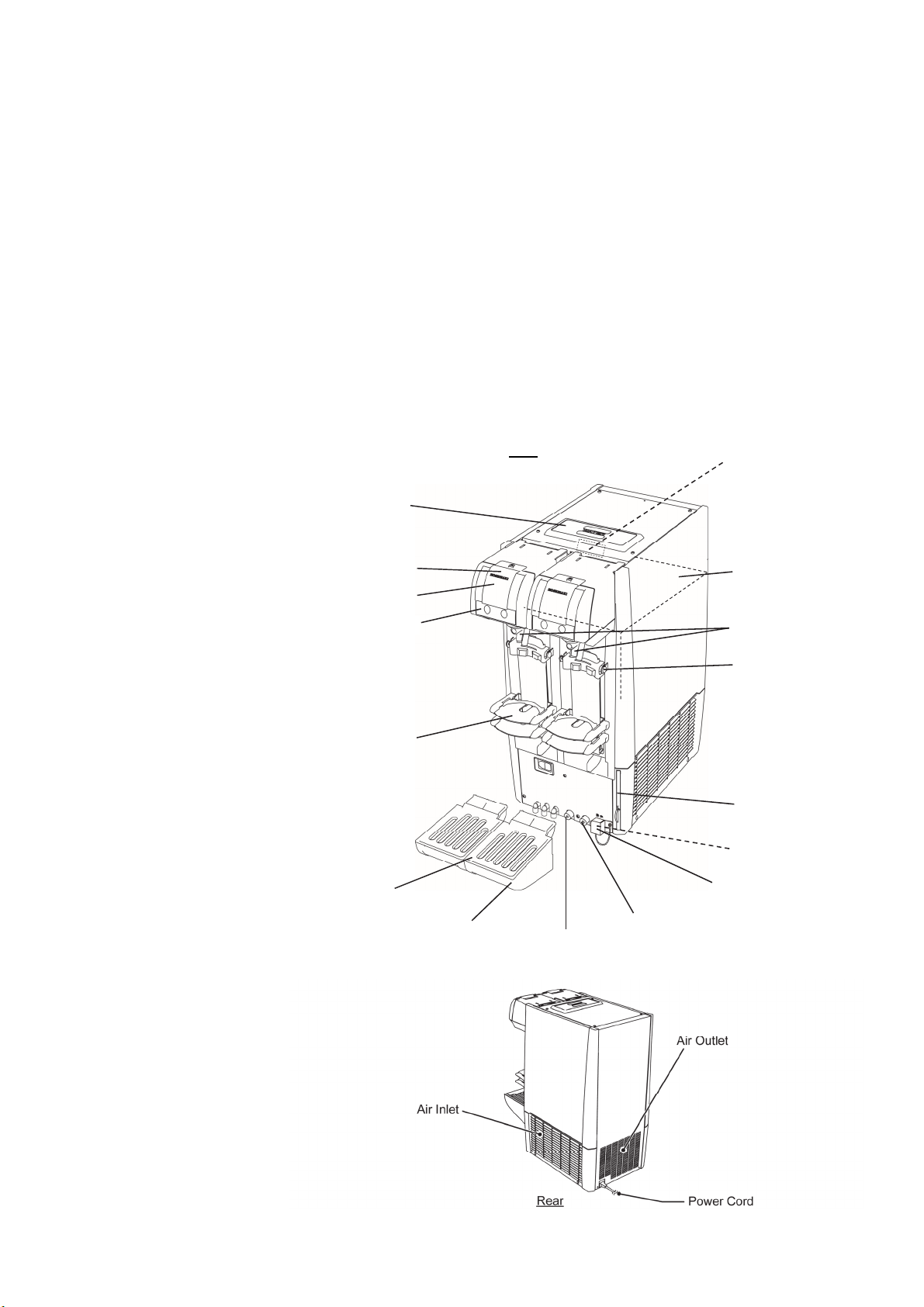

2. CONSTRUCTION --------------------------------------------------------------------------------------------------------- 3

BEER CIRCUIT -------------------------------------------------------------------------------------------------------------- 3

FEATURES ------------------------------------------------------------------------------------------------------------------ 4

3. DIMENSIONS/SPECIFICATIONS --------------------------------------------------------------------------------- 5

(1) DIMENSIONS/SPECIFICATIONS ---------------------------------------------------------------------------------- 5

(2) DISPENSING PERFORMANCE ------------------------------------------------------------------------------------ 6

TECHNICAL INFORMATION

4. UNIT CONTROL ---------------------------------------------------------------------------------------------------------- 7

(1) GENERAL OPERATION ------------------------------------------------------------------------------------------ 7 - 9

5. AUTOMATIC DISPENSING CONTROL ---------------------------------------------------------------------- 10

(1) OPERATION PANEL ------------------------------------------------------------------------------------------------ 10

(2) SETTINGS ------------------------------------------------------------------------------------------------------------- 10

(3) INPUT/OUTPUT ------------------------------------------------------------------------------------------------------ 18

(4) TIMING CHART -------------------------------------------------------------------------------------------------- 19, 20

SERVICE INFORMATION

6. WIRING DIAGRAM --------------------------------------------------------------------------------------- 21

7. CIRCUITS --------------------------------------------------------------------------------------------------- 22

(1) REFRIGERATION CIRCUIT --------------------------------------------------------------------------------------- 22

(2) BEER CIRCUIT ------------------------------------------------------------------------------------------------------- 22

8. ERROR DIAGNOSIS -------------------------------------------------------------------------------------

23

9. SERVICE DIAGNOSIS ----------------------------------------------------------------------------------------- 24 - 44

(1) BEER IS NOT COLD

(2) NO BEER IS DISPENSED

(3) BEER WILL NOT STOP

(4) BEER TAP KEEPS DRIPPING BEER

(5) UNDERFOAMING

(6) OVERFOAMING

(7) LARGE BUBBLES

(8) BEER TASTES STRANGE (WATERY)

(9) CYLINDER RUNS OUT OF GAS EASILY

(10) COOLING WATER MIXED WITH BEER COMES OUT OF OVERFLOW PIPE ON UNIT FRONT

(11) BEER TAP JOINT LEAKS BEER

(12) UNIT LEAKS WATER

(13) ABNORMAL NOISE

(14) BURNING SMELL

(15) AFTER UNIT IS TURNED ON, REFRIGERATION CIRCUIT CLICKS EVERY 3 - 5 MINUTES

CONDENSER FAN MOTOR IS RUNNING, BUT BEER IS NOT COLD

(16) MAIN POWER SUPPLY EARTH LEAKAGE CIRCUIT BREAKER TRIPS

(17) UNIT IS TURNED ON, BUT CONDENSER FAN MOTOR WILL NOT RUN

(18) INSTRUCTIONS FOR HANDLING CONTROLLER BOARD

(19) THERMISTOR SERVICE DIAGNOSIS

(20) BEER WILL NOT STOP