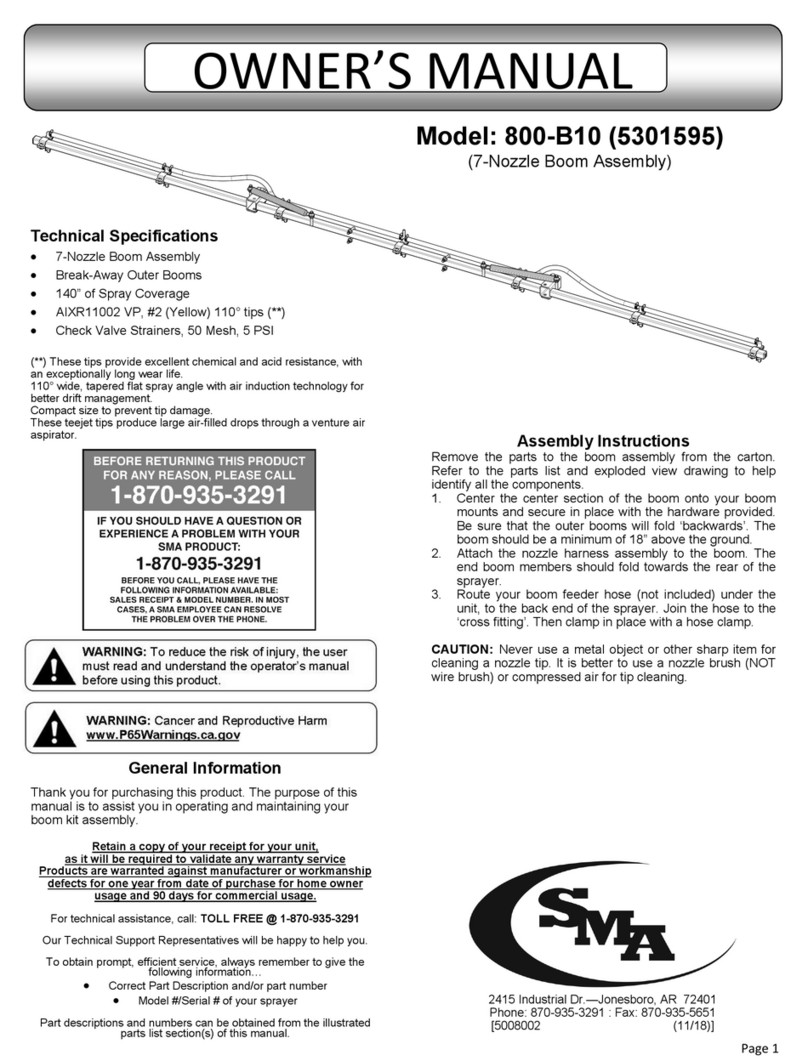

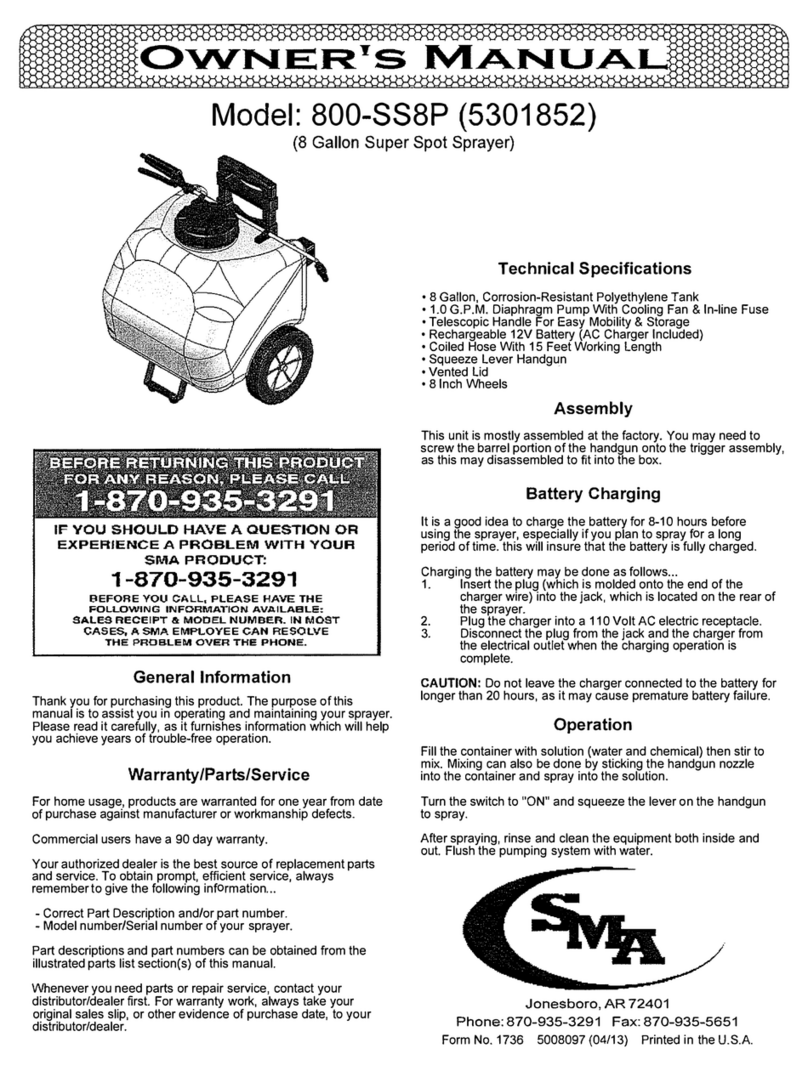

Time Required in seconds to travel a distance of:

17 344.0

5.0

6.0

7.0

9.0

8.0

10.0

7.6

6.8

9.7

8.5

14

11

15

14

19

17

23

27

100 Ft.

68 sec.

2.0

3.0

1.0

(Miles per Hour)

Speed in M.P.H.

Speed Chart

136 sec.

34

23 45

68

200 Ft.

51

23

20

26

29

41

34

205 sec.

300 Ft.

102

68

Page 2

Operation

Your sprayer is equipped with (1) ON/OFF switch. It is on the

wire assembly that you hook up to your battery. The "-" is the

"ON" position and the "o" is the "OFF" position for the switch.

Make sure the switch is depressed in the "-" position for

operation.

The pump is equipped with an electronic pressure switch that is

factory pre-set for it to shut off at 60 p.s.i.. This switch assembly

is the 'square box' on the head portion of the pump.

Always fill the tank with a desired amount of water first, and then

add the chemical slowly, mixing as you pour the chemical into

the tank. You may use the handgun to spray into the solution in

order to mix the chemical and water.

The pumping system draws solution from the tank, through the

strainer/filter, and to the pump. The pump forces the solution

under pressure to the handgun and/or boom nozzles.

Open the handgun by squeezing the handle lever.

•

Rotating the adjustable nozzle tip on the handgun will change

•

the tip pattern from a straight stream to a cone pattern (finer

mist).

This sprayer is designed to be towed behind a garden tractor.

The nozzles on the boom will spray an 100 inch wide swath.

Check the nozzle pattern by spraying water on a concrete

surface. Raise the boom to a higher mounting position to get

more spray pattern overlap, if desired.

Calibration

Chemical labels may show application rates in gallons per

acre, gallons per 1000 square feet, or gallons per 100 square

feet. You will note that the tip chart shows all 3 of these rating

systems.

Once you know how much you are going to spray, then

determine (from the tip chart) the spraying pressure (PSI), and

the spraying speed (MPH).

Determining the proper speed of the pulling vehicle can be

done by marking off 100, 200, & 300 feet. The speed chart

indicates the number of seconds it takes to travel the

distances. Set the throttle and with a running start, travel the

distances. Adjust the throttle until you travel the distances in

the number of seconds indicated by the speed chart. Once

you have reached the throttle setting needed, mark the throttle

location so you can stop and go again, returning to the same

speed.

Add water and proper amount of chemical to the tank and

drive to the starting place for spraying.

Testing the Sprayer

NOTE:

It is VERY important for you to test your sprayer with

plain water before actual spraying is attempted. This will

enable you to check the sprayer for leaks, without the

possibility of losing any expensive chemicals.

Add water to the tank & drive to the starting place for

spraying. When you are ready to spray, turn the boom valve

to the "on" position. This will start solution spraying from the

tips of the boom. The pressure will decrease slightly when the

boom is spraying. Adjust the pressure by turning the

"ON/OFF" valve lever on the bypass line valve.

Read the operating instructions and Initially begin spraying by

closing the 'bypass' valve and opening the boom line valve.

This will enable the air in the line to be eliminated (purged)

through all the tips, while building pressure. When everything

tests all right (no leaks, & good pressure), add the desired

chemicals to the mixture and water combination and start

your spraying operation. Adjust the pressure and spray as

you did in the testing procedure.

Conditions of weather and terrain must be considered when

setting the sprayer. Do not spray on windy days. Protective

clothing must be worn in some cases.

Be sure to read the chemical label(s) correctly!

WARNING:

Some chemicals will damage the pump valves if

allowed to soak untreated for a length of time. ALWAYS

thoroughly flush the pump with water after use. DO NOT

allow chemicals to sit in the pump for extended times of

idleness. Follow the chemical manufacturer's instructions on

disposal of all waste water from the sprayer.

Winter Storage

Drain all water out of your sprayer, paying special attention to

the pump, handgun, and valve(s). These items are especially

prone to damage from chemicals and freezing weather.

The sprayer should be winterized before storage by pumping a

solution of RV antifreeze through the entire plumbing system.

This antifreeze solution should remain in the plumbing system

during the winter months. When spring time comes and you

are preparing your sprayer for the spray season, rinse the

entire plumbing system out, clearing the lines of the antifreeze

solution. Proper care and maintenance will prolong the life of

your sprayer.

After Spraying

After use, fill the sprayer tank part way with water. Start the

sprayer, and allow the clear water to be pumped through the

plumbing system and out through the spray nozzles.

Refill the tank about half full with plain water and use FIMCO

Tank Neutralizer and Cleaner, and repeat cleaning instructions

above.

Flush the entire sprayer with the neutralizing/cleaning agent,

then flush out one more time with plain water. Follow the

chemical manufacturer's disposal instructions of all wash or

rinsing water.

For the boom, (if applicable) remove the tips and screens from

the nozzle assemblies. Wash these items out thoroughly. Blow

the orifice clean and dry. If the orifice remains clogged, clean it

with a fine bristle (NOT WIRE) brush, or with a toothpick. Do not

damage the orifice. Water rinse and dry the tips before storing.

WARNING: Some chemicals will damage the pump valves if

allowed to soak untreated for a length of time! ALWAYS

flush the pump as instructed after each use.