SmarAct PICOSCALE User manual

PICOSCALE

USER MANUAL

www.smaract.com

Copyright © 2018 SmarAct GmbH

Specifications are subject to change without notice. All rights reserved. Reproduction of images,

tables or diagrams prohibited.

The information given in this document was carefully checked by our team and is constantly up-

dated. Nevertheless, it is not possible to fully exclude the presence of errors. In order to always

get the latest information, please contact our technical sales team.

SmarAct GmbH, Schuette-Lanz-Strasse 9, D-26135 Oldenburg

Phone: +49 (0) 441 - 800879-0, Telefax: +49 (0) 441 - 800879-21

Internet: www.smaract.com, E-Mail: info smaract.com

Document Version: 2.1.4

2

PicoScale User Manual

TABLE OF CONTENTS

1 Introduction ................................................................................................................................. 6

1.1 Preface ................................................................................................................................. 6

1.2 Technical support ................................................................................................................ 6

1.3 Signal words and symbols in this manual.......................................................................... 7

1.3.1 Signal words ............................................................................................................. 7

1.3.2 Symbols .................................................................................................................... 8

2 Product safety ............................................................................................................................. 9

2.1 Optical safety ....................................................................................................................... 9

2.2 Electrical safety .................................................................................................................... 10

2.3 Safety precautions............................................................................................................... 11

2.4 Compliance .......................................................................................................................... 12

2.4.1 CDRH/EN60825-1 ..................................................................................................... 12

2.4.2 Low voltage directive ............................................................................................... 12

2.4.3 EMC directive............................................................................................................ 12

2.4.4 RoHS directive .......................................................................................................... 13

2.4.5 Declaration of Conformity ....................................................................................... 14

2.5 Intended use........................................................................................................................ 15

2.6 Unpacking ............................................................................................................................ 15

2.7 Disposal of old equipment.................................................................................................. 15

3PICOSCALE fundamentals ......................................................................................................... 16

3.1 General setup and basic components................................................................................ 16

3.2 Measurement principle....................................................................................................... 17

3.2.1 Michelson interferometer........................................................................................ 17

3.2.2 Sinusoidal phase modulation.................................................................................. 18

3.2.3 Working range.......................................................................................................... 19

3.3 Traceability........................................................................................................................... 19

3.4 Environmental compensation............................................................................................. 19

3.4.1 Dead path................................................................................................................. 20

4 Basic Concepts ........................................................................................................................... 21

4.1 Modular architecture........................................................................................................... 21

4.1.1 Advanced trigger...................................................................................................... 21

4.1.2 Stream generator..................................................................................................... 21

4.1.3 Digital and analog GPIO, AquadB............................................................................ 23

4.1.4 Clock Generator ....................................................................................................... 23

4.1.5 Signal Generator ...................................................................................................... 23

4.1.6 Calculation System................................................................................................... 23

4.1.7 Counters ................................................................................................................... 23

4.1.8 Environmental Module ............................................................................................ 24

3

PicoScale User Manual

TABLE OF CONTENTS

4.2 Data sources ........................................................................................................................ 24

4.3 Signal flow............................................................................................................................ 25

4.4 Adjustment auto function ................................................................................................... 26

4.5 Events................................................................................................................................... 26

4.6 System filters ....................................................................................................................... 26

4.7 Streaming aggregation ........................................................................................................ 27

4.8 Network discovery protocol ................................................................................................ 27

5 PicoScale hardware .................................................................................................................... 29

5.1 PICOSCALE controller ........................................................................................................ 29

5.2 Interfaces ............................................................................................................................. 31

5.2.1 Environmental Module interface ............................................................................ 31

5.2.2 Optical outputs......................................................................................................... 32

5.2.3 Power connection .................................................................................................... 32

5.2.4 USB slave interface .................................................................................................. 33

5.2.5 Ethernet interface .................................................................................................... 33

5.2.6 USB master interface............................................................................................... 33

5.2.7 SmarAct Sensor Interface (SI).................................................................................. 33

5.2.8 SmarAct High Speed Sensor Interface (HSI)........................................................... 33

5.2.9 GPIO and Digital Differential Interface ................................................................... 33

5.3 Breakout-Box ....................................................................................................................... 35

5.3.1 Differential Digital Interface DDI............................................................................. 36

5.3.2 BOB digital GPIOs..................................................................................................... 38

5.3.3 BOB analog GPIOs ................................................................................................... 39

5.4 Sensor heads ....................................................................................................................... 40

5.5 Environmental Module........................................................................................................ 41

6 Setup and installation................................................................................................................. 42

6.1 System checklist .................................................................................................................. 42

6.2 Unpack the system .............................................................................................................. 43

6.3 Cabling ................................................................................................................................. 43

6.4 System power up................................................................................................................. 45

6.5 PICOSCALE software and APIinstallation......................................................................... 46

6.6 Firmware updates................................................................................................................ 46

6.6.1 Performing a PICOSCALE firmware update .......................................................... 47

6.6.2 System diagnostics data .......................................................................................... 47

7 PicoScale Control GUI ................................................................................................................ 49

7.1 Configuration of the PicoScale............................................................................................ 50

7.1.1 Connecting to the controller ................................................................................... 50

7.1.2 General settings ....................................................................................................... 50

7.1.3 Status........................................................................................................................ 51

7.2 Adjustment .......................................................................................................................... 53

7.3 Advanced Trigger................................................................................................................. 55

7.3.1 Trigger Source configuration ................................................................................... 56

7.3.2 Trigger configuration ............................................................................................... 60

7.4 Interfaces ............................................................................................................................. 63

7.4.1 Digital IO interface configuration ............................................................................ 63

7.4.2 Digital Differential Interface (DDI) configuration.................................................... 64

4

PicoScale User Manual

TABLE OF CONTENTS

7.4.3 DAC interface configuration .................................................................................... 66

7.5 Modules ............................................................................................................................... 67

7.5.1 Clock Generator ....................................................................................................... 67

7.5.2 Arbitrary Signal Generator....................................................................................... 68

7.5.3 Calculation System................................................................................................... 69

7.5.4 Counter..................................................................................................................... 70

7.6 Streaming Monitor .............................................................................................................. 71

7.6.1 Configure data receiver layout ................................................................................ 71

7.6.2 Setting up a data receiver........................................................................................ 72

7.6.3 Manipulate the data................................................................................................. 73

7.6.4 Configure the data stream ...................................................................................... 73

7.6.5 PicoScale Data Reader ............................................................................................. 74

7.7 Environmental Monitor ....................................................................................................... 76

7.8 Configuration Manager ....................................................................................................... 77

7.9 Property Dialog.................................................................................................................... 78

8 Concluding Remarks .................................................................................................................. 79

5

PicoScale User Manual

1INTRODUCTION

Congratulations on your purchase of the SmarAct PICOSCALE interferometer! You have acquired

a powerful tool for displacement measurements with picometer resolution. We are convinced

that the innovative features will make working with the PICOSCALE a pleasant and remarkable

experience.

1.1 Preface

This manual contains user information for the SmarAct PICOSCALE system, which includes a

control box, various sensor heads, a Breakout-Box and an Environmental Module.

NOTICE

Read this manual carefully before operating the PICOSCALE for the first time.

Special attention should be given to the material in chapter 2 "Product Safety",

which describes the secure handling of the PICOSCALE system.

1.2 Technical support

Should you experience any difficulties with your PICOSCALE system or need any technical in-

formation, please visit our web site: www.picoscale.com. Additional support can be obtained by

contacting our technical support at PicoScaleSupport smaract.com or by phone at +49 441 800 879

0. When communicating with our Technical Support, the Support Engineer responding to your

request will require the model and the serial number.

6

PicoScale User Manual

1 INTRODUCTION

1.3 Signal words and symbols in this manual

This manual may contain sections in which particular hazards are defined or special attention is

drawn to particular conditions. These sections are indicated with signal words according to ANSI

Z-535.6 and safety symbols (pictorial hazard alerts) in accordance with ANSIZ-535.3 and ISO 7010.

1.3.1 Signal words

Four signal words are used in this documentation: DANGER,WARNING,CAUTION and NOTICE.

The signal words DANGER,WARNING and CAUTION designate the degree or level of hazard when

there is a risk of injury:

DANGER

Indicates a hazardous situation that, if not avoided, will result in death or serious injury.

Do not proceed beyond a DANGER notice until the indicated conditions are fully understood

and met. This signal word is to be limited to the most extreme situations.

WARNING

Indicates a hazardous situation that, if not avoided, could result in death or serious in-

jury. Do not proceed beyond a WARNING notice until the indicated conditions are fully

understood and met.

CAUTION

Indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury. Do not proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

The signal word NOTICE is used when there is a risk of property damage:

NOTICE

Indicates information considered important, but not hazard-related.

Messages relating to hazards that could result in both personal injury and property damage are

considered safety messages and not property damage messages.

7

PicoScale User Manual

1 INTRODUCTION

1.3.2 Symbols

The signal words DANGER,WARNING and CAUTION are always emphasized with a safety symbol

that indicated a special hazard, regardless of the hazard level:

This symbol is intended to alert the operator to the presence of important oper-

ating and maintenance instructions.

This symbol is intended to alert the operator to the danger of exposure to haz-

ardous visible and invisible laser radiation.

This symbol is intended to alert the operator to the presence of dangerous volt-

ages within the product enclosure that may be of sufficient magnitude to consti-

tute a risk of electrical shock.

8

PicoScale User Manual

2PRODUCT SAFETY

2.1 Optical safety

Because of its special properties, laser light poses safety hazards not associated with light from

conventional sources. The safe use of the lasers require that all laser users, and everyone near

the laser system, are aware of the danger involved. The safe use of the laser depends upon

the user being familiar with the instrument and the properties of coherent, intense beams of

light.

CAUTION

The PICOSCALE Controller contains an infrared diode laser with an output of

less than 0.2 mW at 1520 nm - 1580 nm (less than 0.3 mW for V1.4 and less than

0.6 mW for V1.4-HP) and red diode laser with an output power of less than 0.6

mW at 650 nm (no red laser for V1.4-HP).

Although the PicoScale is a Class Iproduct due to the low output power, it is

a good practice not to stare directly into the laser beam. Never use optical

instruments to observe the beam, this can cause serious eye damage.

Always use the PicoScale as intended by this manual!

9

PicoScale User Manual

2 PRODUCT SAFETY

2.2 Electrical safety

The SmarAct PICOSCALE controller contains hazardous voltages. Do not disassemble the en-

closure. There are no user-serviceable components inside. All units are designed to operate as

assembled. Warranty will be voided if the enclosure is disassembled.

WARNING

High voltage inside. To avoid electrical shock before powering the unit, make

sure that the protective conductor of the 3-conductor power cord is correctly

connected to the protective earth contact of the socket outlet. Improper ground-

ing can cause electric shock resulting in severe injury or even death.

WARNING

Shock warning. Do not operate without cover installed. Do not stick any mate-

rial through the ventilation holes. Do not operate under wet/damp conditions.

WARNING

Observe all terminal ratings. To avoid damage, fire or shock hazard, observe

all ratings marked on the PicoScale Controller or documented in the manual.

NOTICE

High electrostatic charges readily accumulate in the human body and equipment

and can easily discharge without detection. Although the electronics features

have impressive input protection, permanent damage may occur on devices

subjected to high-energy electrostatic discharges. Therefore, proper ESD pre-

cautions are recommended to avoid performance degradation.

The most common ESD damage occurs while handling the device during instal-

lation or use. Take the necessary measures to protect the system from ESD, e.g.

by wearing a wrist strap.

Dry air and carpet can create an even higher potential for ESD. Precautions or

shielding need to be taken for demonstrations or trade show exhibitions.

10

PicoScale User Manual

2 PRODUCT SAFETY

2.3 Safety precautions

NOTICE

End of life handling. The equipment contains substances that could be harm-

ful to the environment or human health. In order to avoid release of such sub-

stances into the environment, we encourage you to recycle this product in an

appropriate system that will ensure that most of the materials are reused or

recycled appropriately. Please contact your local authorities for disposal or recy-

cling information.

NOTICE

Provide proper ventilation. In order to prevent overheat events, system fail-

ure and damage the ventilation holes of the PicoScale Controller must not be

covered. Do not stack several PICOSCALE Controllers.

NOTICE

Always clean fiber prior connection! Prior to connecting an interferometer

head, make sure to clean both the fiber connector and the fiber receptacle with

suitable fiber cleaners. This is necessary to achieve the optimal signal quality

and avoid permanent damage to the fiber end surfaces.

For further information, please refer to the information presented in section 6.3.

NOTICE

Handle with care! The sensor heads and the optical fibers are small high-

precision parts and subject to damage under rough handling. Please make sure

to treat the fibers carefully and do not bend them too tightly; the minimum bend-

ing radius of 30 mm should always be respected. Be sure that the interferome-

ter heads are not torn or sheared offthe fibers. The PICOSCALE control system

contains sensitive optics and electronics. Make sure to use the original PicoScale

case for transport.

11

PicoScale User Manual

2 PRODUCT SAFETY

2.4 Compliance

The PICOSCALE laser interferometer and its accessory products have been certified in coopera-

tion with an independent testing lab to be in compliance with the environmental and safety direc-

tives listed in the following chapters.

2.4.1 CDRH/EN60825-1

The PICOSCALE laser interferometer system complies with all of the requirements of EN60825-1.

It further complies with 21 CFR 1040.10 except for deviations pursuant to Laser Notice No. 50,

dated June 24, 2007.

The following table lists PICOSCALE part or model numbers, and their corresponding CDRH ac-

cession numbers.

Table 2.1: PICOSCALE CDRH Accession Numbers

Part/Model number Accession Number Part/Model number Accession Number

PS-CTRL-V1.1-TAB (*) 1711061-000 PS-CTRL-V1.3-RACK (*) 1711061-000

PS-CTRL-V1.2-TAB (*) 1711061-000 PS-CTRL-V1.4-RACK 1711252-000

PS-CTRL-V1.3-TAB (*) 1711061-000 PS-CTRL-V1.4-TAB-HP 1810594-000

PS-CTRL-V1.4-TAB 1711252-000 PS-CTRL-V1.4-RACK-HP 1810594-000

(*) Discontinued

2.4.2 Low voltage directive

The PICOSCALE laser interferometer complies with the basic requirements of the Low Voltage

Directive 2014/35/EU.

Compliance with this directive has been verified by application of the following harmonized stan-

dards:

•EN 61010-1:2010:

Safety Requirements - Part 1: General requirements

•EN 60825-1:2014:

Safety of laser products - Part 1: Equipment classification and requirements (compare 2.4.1)

2.4.3 EMC directive

The PICOSCALE laser interferometer complies with the basic requirements of the EMC Directive

2014/30/EU.

Compliance with this directive has been verified by application of the following harmonized stan-

dards:

12

PicoScale User Manual

2 PRODUCT SAFETY

•EN 61326-1:2013:

EMC requirements - Part 1: General requirements

•EN 55011:2011:

Radio-frequency disturbance characteristics - Limits and methods of measurement

According to EN 61326-1:2013 the following test specifications have been used:

•EN 61000-4-2:2009 - Electrostatic discharge immunity test

•EN 61000-4-3:2010 -Radiated, radio-frequency, electromagnetic field immunity test

•EN 61000-4-4:2010 - Electrical fast transient/burst immunity test

•EN 61000-4-5:2006 - Surge immunity test

•EN 61000-4-11:2004 - Voltage dips, short interruptions and voltage variations immunity tests

2.4.4 RoHS directive

The PICOSCALE laser interferometer complies with the basic requirements of the RoHS Directive

2011/65/EU.

Compliance with this directive has been verified by application of the following harmonized stan-

dards:

•EN 50581:2012:

Technical documentation with respect to the restriction of hazardous substances

13

PicoScale User Manual

2 PRODUCT SAFETY

2.4.5 Declaration of Conformity

Declaration of

Conformity

according to DIN EN ISO/IEC 17050-1:2010

Manufacturer: SmarAct GmbH

Manufacturer’s Address: Schütte-Lanz-Strasse 9

26135 Oldenburg, Germany

The manufacturer hereby declares that the product and its related accessory

Product Name: PicoScale

Model Numbers: PS-CTRL-V1.1-TAB, PS-CTRL-V1.2-TAB, PS-CTRL-V1.3-TAB,

PS-CTRL-V1.4-TAB, PS-CTRL-V1.3-RACK, PS-CTRL-V1.4-RACK

Product Options: all

complies with the following European directives:

2014/35/EU: Low Voltage Directive

2014/30/EU: EMC Directive

2011/65/EU: RoHS Directive

The applied standards certifying the conformity are listed below:

Electromagnetic Emission: DIN EN 61326-1:2013

DIN EN 55011:2011, Groupe 1, Class B 1

Electromagnetic Immunity: DIN EN 61000-4-2:2009/DIN EN 61326-1:2013 (DIN EN 61000-6-2)

DIN EN 61000-4-3:2010/DIN EN 61326-1:2013 (DIN EN 61000-6-1)

DIN EN 61000-4-4:2010/DIN EN 61326-1:2013 (DIN EN 61000-6-2)

DIN EN 61000-4-5:2006/DIN EN 61326-1:2013 (DIN EN 61000-6-2)

DIN EN 61000-4-11:2004/DIN EN 61326-1:2013 (DIN EN 61000-6-2)

Safety (Low Voltage Directive): EN 61010-1:2001

Environmental Affairs: EN 50581:2012

Articles manufactured on or after the Date of Issue of the Declaration of Confirmity do not contain

any of the restricted substances in concentrations/applications not permitted by the RoHS

Directive.

July 25, 2016

Oldenburg, Germany

Axel Kortschack

Managing Director

1with active PS-BOB-V1.0-TAB the emission Class is A

14

PicoScale User Manual

2 PRODUCT SAFETY

2.5 Intended use

The PICOSCALE Controller is intended to be used in indoor locations with constant temperatures

inside the specified range (see table 2.2). Temperature fluctuations can have influence on laser

stability and measurement results and should be kept small (e.g., avoid exposure to direct sun-

light).

Table 2.2: Operation conditions for PICOSCALE Controller

General Conditions

Power supply 90-246 VAC 47-63 Hz

Input current 0.5 ARMS 230 VAC

Environment Pollution degree 2; Indoor location

Environmental temperature 15 °C - 30 °C

Environmental humidity 5% to 80% RH, non-condensing

Storage temperature 0 °C - 50 °C

2.6 Unpacking

Before unpacking the PICOSCALE Controller please refer to chapter 6 of this manual.

2.7 Disposal of old equipment

According to the EU directive 2012/19/EU, as of August, 13, 2012, electrical and electronic equip-

ment may not be disposed in the member states of the European Union with other waste.

SmarAct GmbH respects the manufacturer’s prod-

uct responsibility and will take care of environmen-

tally correct disposal of old SmarAct products free of

charge. To dispose old SmarAct equipment, you can

return it to SmarAct to the following address postage-

free:

SmarAct GmbH

Schütte-Lanz-Strasse 9

26135 Oldenburg, Germany

15

PicoScale User Manual

3 PICOSCALE FUNDAMENTALS

The PICOSCALE is a powerful system for optical and non-invasive displacement and vibration

measurements. The three channel system is based on a miniaturized Michelson interferometer.

The system features powerful interfaces and flexible software modules. Due to useful accessories

the system can be adapted to specific needs. The PICOSCALE GUI allows to operate the system

out of the box. In summary, these versatile characteristics make the PICOSCALE a very powerful

tool for every lab!

3.1 General setup and basic components

Each PICOSCALE measurement setup requires a few basic components. The PICOSCALE con-

troller is the core component. In the controller, coherent light is generated by a laser diode. A

fiber network distributes the laser light into three output channels.

Sensor headReferencemirrorTarget mirrorWorking distanceOptical fiberPICOSCALE

Figure 3.1: Basic setup of a PICOSCALE displacement measurement. Miniaturized sensor heads

are connected to the PICOSCALE controller via optical fibers. The system measures

the displacements of a target mirror relative to the sensor head.

Up to three sensor heads can be connected to the controller via optical FC/APC-terminated fibers.

Within the sensor head, the laser light is divided into a reference and a measurement beam by

a beam splitter, being the central component of a Michelson interferometer. In standard sensor

heads one side of the miniaturized beam splitter cube is coated with a reflective coating, which acts

as reference mirror. The measurement beam exits the head and is reflected by the measurement

target, which can be a mirror, a piece of glass or almost any other technological relevant surface.

Both, the reflected reference and measurement beam interfere in the center of the beam splitter

cube and the combined light is guided back to the controller. Due to advanced signal processing

methods, based on lock-in detection and fast FPGA based evaluation algorithms, the PICOSCALE

is able to measure target mirror displacements with single picometer resolution and sample rates

of up to 10 MHz.

16

PicoScale User Manual

3PICOSCALE FUNDAMENTALS

3.2 Measurement principle

3.2.1 Michelson interferometer

The PICOSCALE displacement sensor is based on a Michelson interferometer with an extremely

compact and stable reference arm. .

λ/4λ/2InterferometersignalDisplacement0vanishingsensitivityhighsensitivitySensor headTarget mirror

Figure 3.2: Measurement principle of a Michelson interferometer. Constructive and destructive

interference occur due to a displacement of the target mirror. To circumvent these

blind spots the PICOSCALE utilizes sinusoidal phase modulation, see section 3.2.2.

The interferometer is driven by a laser, which is a coherent light source, that is required if a

Michelson interferometer is operated with (very) unequal arm lengths as it is the case for the

PICOSCALE. At a beam splitter, the light is divided into two parts. One part is reflected at a fixed

reference mirror and guided back to the beam splitter. The other part of the light hits the target

mirror. This light is also reflected while picking up a relative phase with respect to the reference

beam. Inside the beam splitter, both reflected beams interfere and the coherent superposition is

recorded by a photo detector.

In the PICOSCALE system, the beam splitter is located in the sensor head, whereas the light

source, a stabilized, distributed-feedback (DFB) laser diode and the photo detector are located in

the controller housing. The wavelength of the laser is around 1550 nm. Inside the controller, a

fiber network distributes the laser light to three independent measurement channels. The output

power of each channel is around 150 µW.

17

PicoScale User Manual

3PICOSCALE FUNDAMENTALS

The integration of the miniaturized beam splitter into the sensor head ensures that changes in the

fiber length, possibly caused by temperature gradients, do not affect the measurement.

In a Michelson interferometer, two light beams interfere with each other. Due to path length

differences in the measurement and the reference arm of the interferometer, constructive and

destructive interference occur. In case of constructive interference, the recorded interferometer

signal is high, while at destructive interference the recorded signal is low. A displacement of the

target mirror causes a change in the relative optical path lengths and thus in the phase difference

of target and reference beam, compare figure 3.2. As a result, the intensity measured by the photo

diode is changed. This intensity change in turn is used to infer positions and displacements with

high accuracy.

In standard interferometry, the interference signal is sinusoidally dependent on the phase differ-

ence between the reference and probe beam. This phase difference depends on the target mirror

position. Thus, during constant movement, the resulting intensity signal is a sinusoid, similar to

the signal shown in figure 3.2. Due to the symmetry of the sinusoid, it is not possible to determine

the movement direction at every working point. Furthermore, the sensitivity (change in signal in-

tensity due to change in target position) is not constant during movement. Thus, for long range

and high-resolution position measurements, the standard Michelson interferometry is not ideally

suited.

The PICOSCALE uses sinusoidal phase modulation of the laser beam to overcome these disadvan-

tages and provides high accuracy and resolution of position measurements as well as information

on the direction of the moving object mirror!

3.2.2 Sinusoidal phase modulation

Figure 3.3: Quadrature signal detection: points of low sensitivity in one signal are compensated by

high sensitivity in the quadrature signal.

Thus, sinusoidally modulating the wavelength of the laser light can overcome the aforementioned

disadvantages. This wavelength modulation is initiated by modulating the injection current of

the used distributed feedback (DFB) laser diode. The modulation of the wavelength produces

a sinusoidally phase modulated (SPM) interference signal. Due to appropriate demodulation, it

18

PicoScale User Manual

3PICOSCALE FUNDAMENTALS

becomes possible to extract the quadrature signal, which is a two dimensional signal, dependent

on the target mirror position, depicted in figure 3.3. The two extracted sinusoidal signals are

phase-shifted by 90 degrees and thus are in quadrature. The X and Y components are shown in

figure 3.3, left. Constant movement of the target mirror produces a circle in a two dimensional

representation. The right part of the figure shows both signal components simultaneously and

it can be seen that any blind spot in one signal is compensated by a high sensitivity point in the

other. Thus, the sensitivity is maintained high during movement.

Furthermore, the phase relationship between the two components allows to unambiguously in-

fer the movement direction. While an increasing relative position of the target mirror leads to

a counter-clockwise rotation of the X-Y vector, a decreasing position leads to a clockwise rota-

tion. Thus, sinusoidal phase modulation interferometry is perfectly suited for high-resolution,

long-range position measurements.

3.2.3 Working range

During the initial adjustment phase it is required to define a so-called working range. This is the

region where the target mirror is expected to be during the measurement. The setting of the

working range is mapped to internally stored configuration values and an appropriate setting sub-

sequently leads to highest accuracy and performance of the PICOSCALE position measurements.

3.3 Traceability

Although the DFB laser has a very high spectral purity, spectral width below 10 pm, the emitted

wavelength is not constant due to unavoidable thermal drifts. Since the measured target position

is directly dependent on the emitted wavelength, a feedback system stabilizing the wavelength of

the DFB laser is mandatory. In order to stabilize the temperature of the laser diode, it is equipped

with a thermo-electric cooler (TEC). Besides stabilizing the temperature, the TEC element can be

used to actively control and tune the temperature and thus the emitted wavelength. The wave-

length is locked to an absorption line of a gas absorption cell, according to the standards NIST

SRM 2517a or SRM 2519a. This reference cell is filled either with acetylene or hydrogen cyanide

and allows to determine the wavelength of the laser within a range of lower than ±1 pm. The gas

absorption cells are extremely insensitive to environmental parameters like temperature, humid-

ity, pressure and also on electro-magnetic fields. Thus, these cells offer a persistent and reliable

wavelength standard to stabilize the wavelength of the DFB laser diode.

The gas absorption cell is integrated in the PICOSCALE controller housing. One part of the mod-

ulated laser light is guided through the reference cell and the transmitted signal is recorded and

evaluated. A feedback loop controls the laser chip temperature such that the wavelength is con-

tinuously kept at an absorption line.

3.4 Environmental compensation

When the interferometer is used in a vacuum environment, no environmental compensation is

necessary. When the interferometer system is operated in ambient conditions, variations in the

19

PicoScale User Manual

3PICOSCALE FUNDAMENTALS

refractive index of the air can significantly influence interferometric position measurements. The

refractive index of air may change due to fluctuations in temperature, pressure and humidity

(TPH). If the refractive index increases, the optical path length of the laser light increases propor-

tionally. This effect would pretend a movement of the object mirror even if the geometrical path

did not change. To compensate a variation of the refractive index, it is necessary to measure the

atmospheric conditions such as air temperature, pressure and humidity. Based on these values,

the National Institute of Standards and Technology (NIST) suggests a formalism based on a set

of modified Edlén equations to calculate the refractive index of air1. The PICOSCALE follows the

suggested formalism to calculate the refractive index and thus to correct the position data.

3.4.1 Dead path

The dead path is the distance between the absolute and relative zero position of the PICOSCALE

system. As figure 3.4 highlights, the absolute zero position is at the surface of the beam splitter

cube. The relative zero position can be defined freely. The system measures any position change

Sensor head

Reference

mirror

Target mirror

Optical fiber

absolute Position

relative Position

0

-D

D

0

D+X

X

Figure 3.4: The dead path is the distance between the absolute zero position, at the front face of

the beam splitter cube and the freely defined relative zero position.

relative to this internal zero position. When the measurement is done in ambient environment,

the changes in the refractive index cause a measurable change in the PICOSCALE position signal.

Based on the recorded environmental parameters the system calculates a correction factor to

compensate this virtual drift. The PICOSCALE measures the absolute distance between sensor

head and target mirror during the initial adjustment phase. When the absolute measurement

is done, the controller automatically zeros the internal position value, such that the measured

absolute distance is equal to the dead path. The measured dead path is stored automatically in

the system and can be accessed with appropriate properties. Furthermore, each time the internal

position value is set, the dead path is updated automatically, if the environmental compensation

is active.

1http://emtoolbox.nist.gov/Wavelength/Documentation.asp#EdlenorCiddor

20

PicoScale User Manual

Table of contents

Other SmarAct Control System manuals

Popular Control System manuals by other brands

JWM

JWM GUARD TOUR WM-5000F3 user manual

Safety Xpress

Safety Xpress REMBOLSMU PRODUCT INFORMATION & INSTALLATION GUIDE

uAttend

uAttend CB1000 quick start guide

Hyundai Heavy Industries

Hyundai Heavy Industries ACONIS 1000 user manual

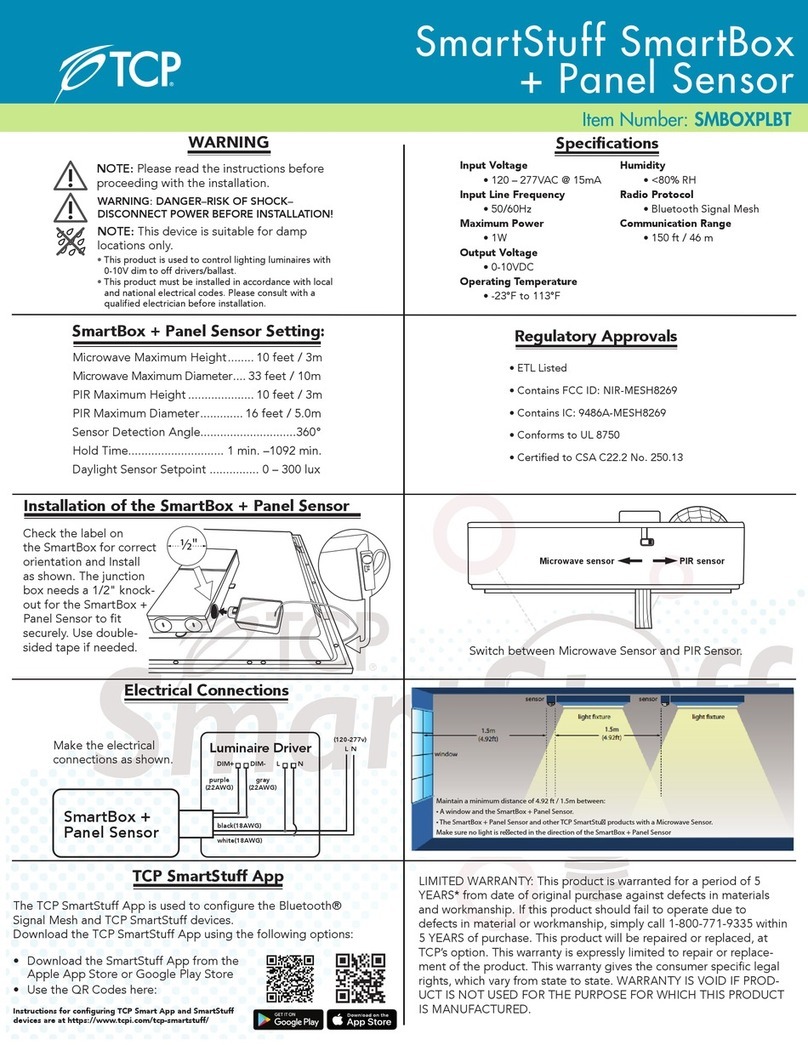

TCP

TCP SmartStuff SmartBox quick start guide

Fagor

Fagor CNC 8070 Original instructions