SMART-SCAN 5K8 Series Assembly instructions

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 1

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

5K8 Series Safety Light Curtain

Installation Sheet (CD339/060711)

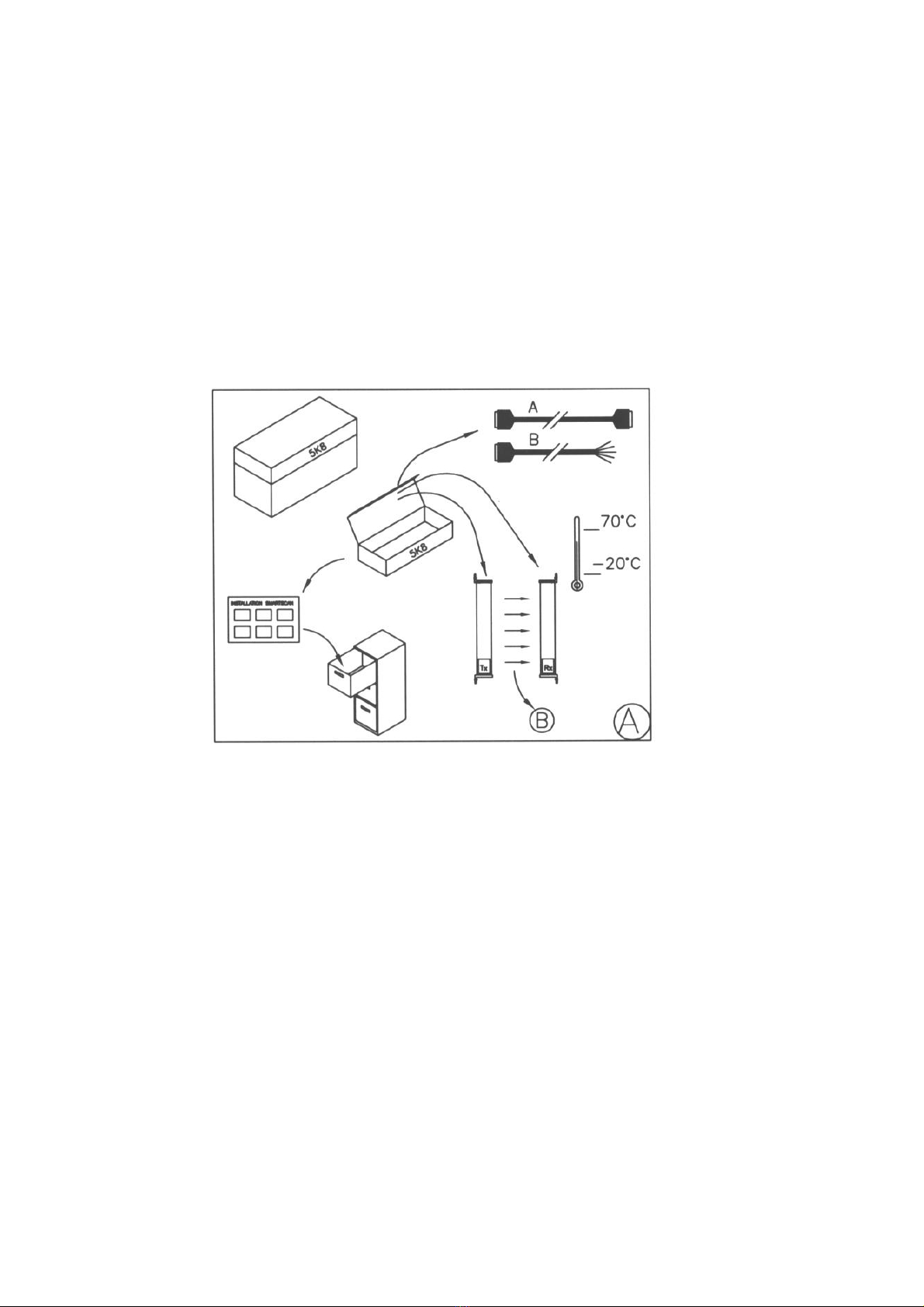

Figure A Unpacking

Remove all packaging material and retain it

Locate and keep the delivery note

Inspect all items for transit damage

Match goods supplied to those specified on the delivery note

Keep the Installation Sheet in a safe place

Each 5K8 system supplied would normally include:

Light curtain

Cables (A) and (B)

Installation sheet

Service questionnaire form

Storage requirements

Humidity -<95%

Temperature range between -20C and +70C

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 2

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

Figure B Operating Requirements

Humidity <95%

Temperature range between 0 and 50 degrees C

Vibration frequency <55Hz max. Displacement <0.35mm

Equipment should not be used in potentially explosive atmospheres. The

units are not ‘EX’ rated. Do not use the equipment in explosive

atmospheres. For further information on explosive-proof enclosures contact

Smartscan Ltd.

Noise generated by the equipment will never exceed 70 dB

K -Detection zone width

R -Scanning range of the light curtain

Detection zone width (K) –Must be of a suitable height for each application

to prevent personnel access to the danger area either over, under or around

the light curtains detection zone.

Range (R) –Ensure the particular light curtain specification is capable of

satisfying the range requirement for the application.

Fig. B also shows the connection points for the three different cable options

used with the 5K8 series.

The A (Interconnect) cable has two 25 pin D connector sockets and is

connected between the transmitter (TX) and the receiver (RX) head of the 5K8

series.

The B (User) cable has one 25 pin D connector plug at one end with the other

end consisting of the colour coded wires for the end user to interface into the

machine control system. The B (User) cable is either connected directly onto

the receiver head or to the reset station if used.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 3

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

The X Cable is required if the user has opted to use a Smartscan reset station.

The X cable has two 25 pin D connectors with one end having a socket and

the other end with a plug. The cable is interfaced with the socket end

connected to the Reset station and the plug end connected to the receiver

head of the 5k8 series.

Since the X cable is a 25 pin D type connector with a Plug and Socket, the X

cable can also be used as an extension cable for either A (Interface) cable or

the B (User) cable.

To ensure correct operation of the system cable lengths as stated should not

be exceeded: A cable = 50 metres. B cable = 50 metres. X cable = 10 metres

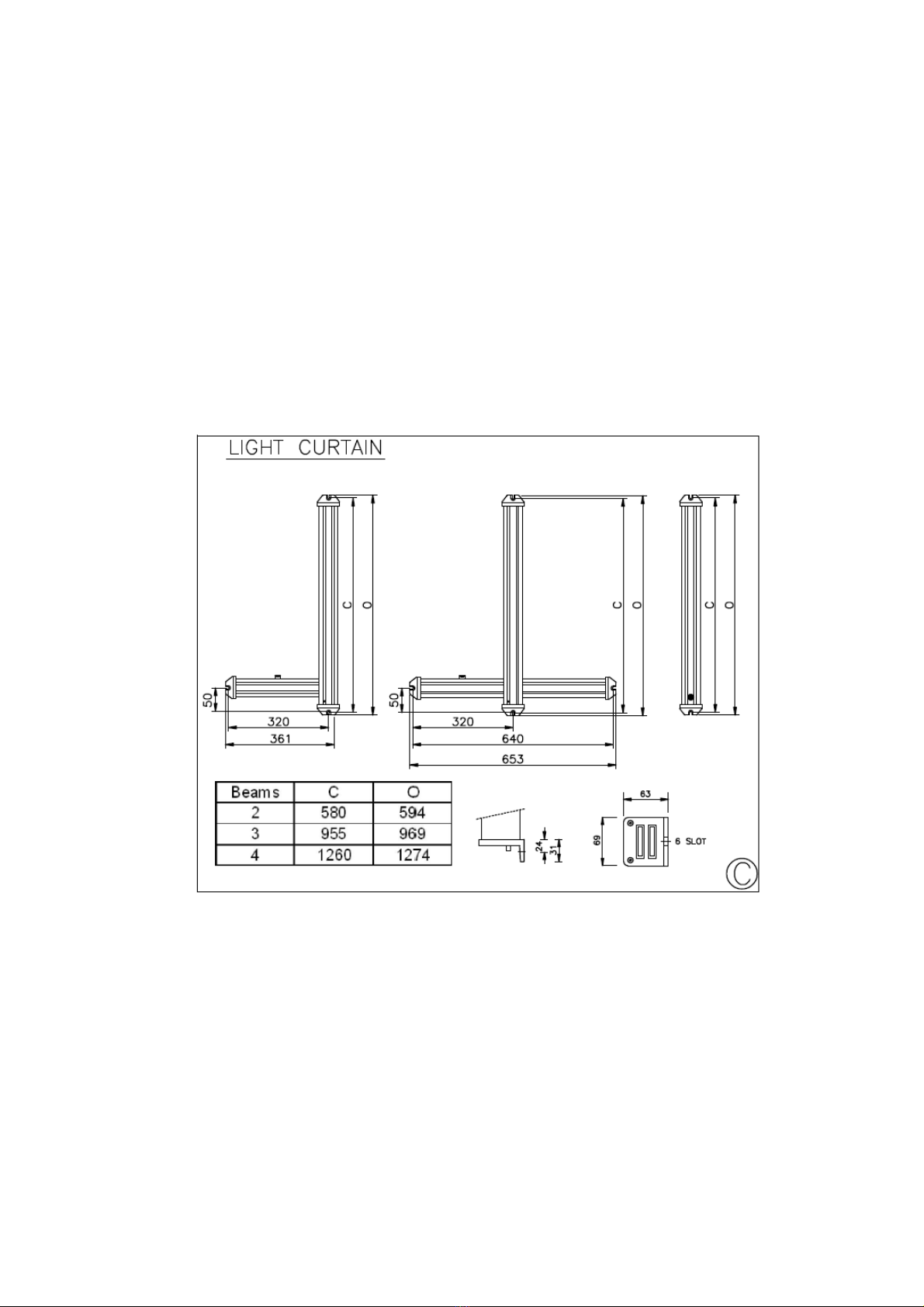

Figure C Mounting and Dimensional Information

The 5K8 series safety light curtain is supplied with mounting brackets fitted as

standard. The mounting brackets are located at the ends of the light curtain as

shown above and 6mm bolts should be used to mount the light curtain in

position.

The table above provides useful mounting measurements for the L, inverted ‘T’

and the straight light curtain.

C = Mounting centres

O = Overall Length

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 4

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

Figure D shows 5K8 Series light curtain end-bracket dimensions. Use M6

bolts for the mounting brackets.

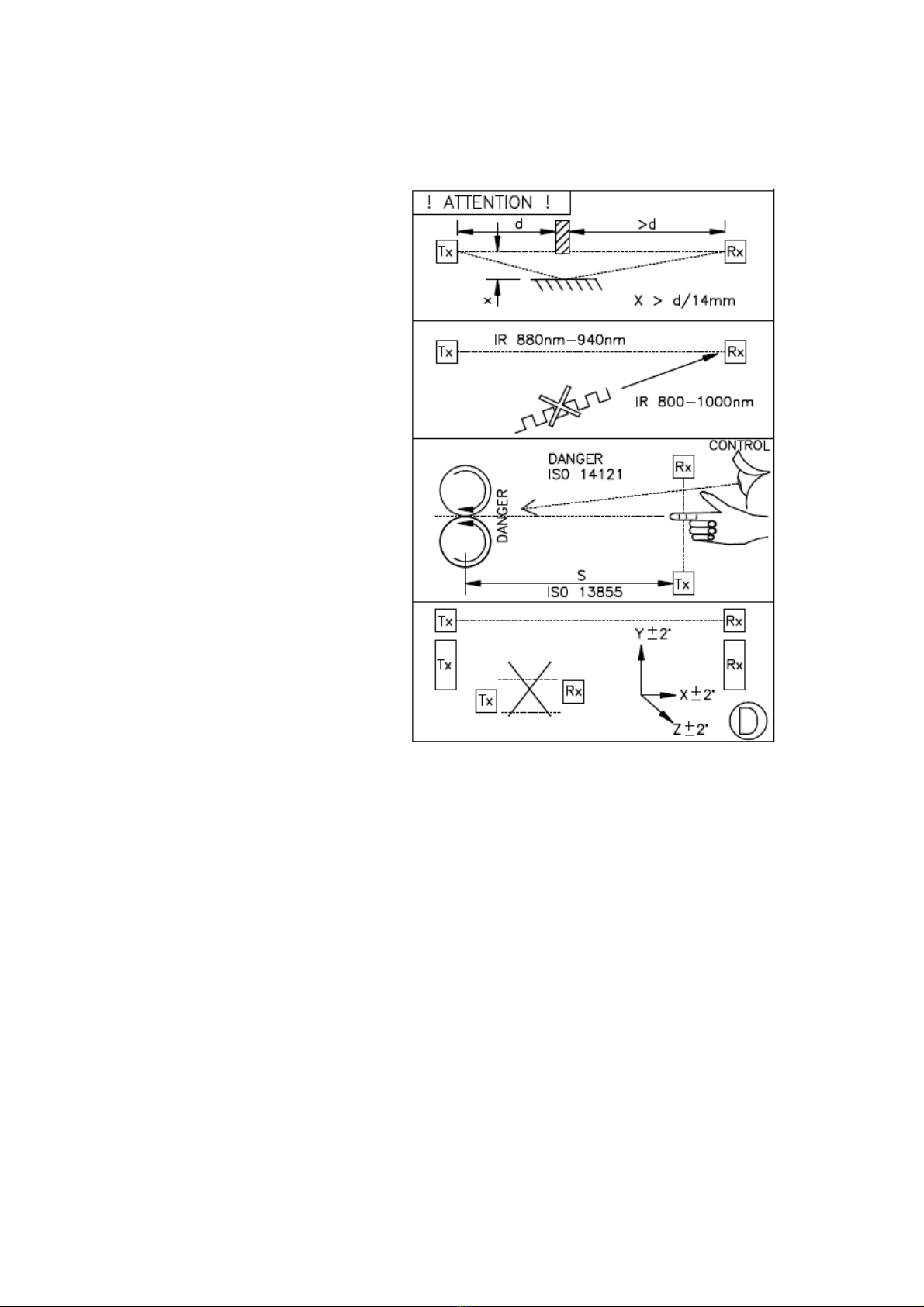

1. Consider reflective

surfaces that may give rise

to an optical ‘short circuit’

from the direct path of the

light curtain’s infrared

beams as shown in the first

illustration of Fig. D. To

ensure the light curtain is

mounted far enough away

from reflective surfaces use

the formula provided to

calculate the minimum

distance (X) between the

light curtain and reflective

surface.

2. To prevent intermittent

tripping of the light curtain

ensure that extraneous

infrared energy between

800 and 1000 nanometres

is not directed towards the

Perspex window of the

receiver unit (RX).

Extraneous sources would

include infrared sensors,

infrared remote controls or

scanning systems.

3. Ensure the mounting position of the light curtain in respect to the nearest

danger point meets the requirements of European Standard ISO 13855.

See Appendix 1.

4. Ensure the light curtain transmitter (TX) and receiver (RX) units are

mounted accurately in-line with each other and are both perpendicular and

parallel to each other within the parameters shown for each axis.

5. If utilising mirrors to deflect the light curtain ensure the mirror length is

50mm longer at either end of the light curtain detection zone width and

mounted centrally to the zone. To ensure reliable operation the light

curtain deflection angle (A) from the mirror must not be less than 40

degrees or greater than 100 degrees.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 5

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

Figure E shows examples of the identification labels that are affixed to the

transmitter (Tx) and receiver (Rx) columns.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 6

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

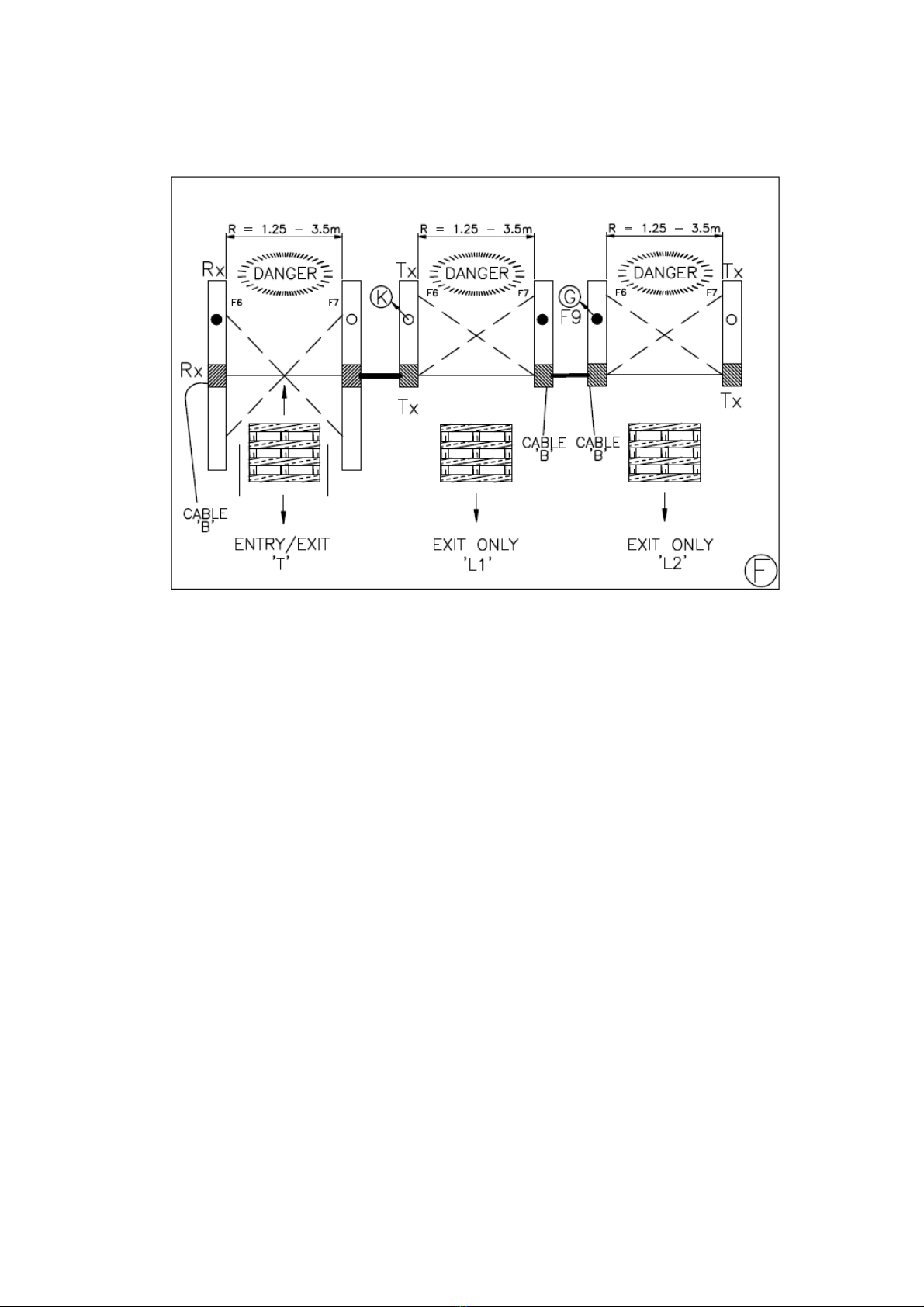

When installing a Smartscan 5K8 Series light curtain your attention is drawn to

the following: (Figure F)

The inverted T 5K8 series light curtain is also known as an entry/exit system.

This system is normally used between two zones (machines) allowing transfer

of the pallets from one zone to the other. The horizontal mute module

provides 2 muting beams at either end of the mute module transmitting infra

red mute beams diagonally across to the receiver side forming a cross beam

muting arrangement.

The system works by the square pallet load moving into the two mute beams

and interrupting them. The two mute beams are monitored with a disparity

timer of two seconds to provide a mute initiation of the light curtain.

The L shaped 5K8 series light curtain is also known as the exit only system.

There are two types of ‘L’ available, right hand (L1) and left hand (L2). The Left

or right hand indicates where the User B cable is connected as shown above.

You will note that the mute cross beams are arranged on one side of the light

curtain. They function in the same format as the T shape explained above.

The cross beams must always be on the Danger side and therefore the pallet

can only travel in one direction moving away from the danger to the safe side

of the machine.

It is a control requirement for the 5K8 series that an additional 3rd mute input is

provided via the conveyor run signal. This signal acts as a permissive signal

to the cross beam mutes and/or external mute input signals.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 7

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

Figure G shows the functions table for the 5K8 series

Safety Outputs (F1) –5K8 series safety light curtains have cross-monitored

output switching relays mounted inside the receiver column. The output relays

provide two safety ‘volt free’ forcibly guided switching contacts which are

internally connected to the wires in the multi-core user cable ‘B’ as follows:

OSSD1 (Output 1): orange (OR) and pink (PK). OSSD2 (Output 2): turquoise

(TU) and grey (GY). Maximum contact switching power 24V DC, 2A or

maximum 110V AC, 2A.

Status Output (F2) -Relay provides one non-safety ‘volt free’ switching

contact which is internally connected to the wires in the multi-core user cable

‘B’, wires red (RD) / black (BK) and red (RD) / brown (BN). The switching relay

contacts are ‘normally open’ outputs from this relay and should only be used

for non-safety applications. Maximum switching power 110V, 1A. The status

relay activates when the safe output relays (F1) turn ON and de-activates

when the safe outputs (F1) turn OFF.

EDM (F4 & F5) (SMM OUT & SMM IN) -An External Device Monitoring

contact signal is provided for the user to monitor external switching devices.

This is to ensure those devices respond in unison with the safety outputs (F1)

each and every time the light curtain is interrupted.

The green (GN) (cable B) wire should be connected to a N/C contact of the

device being monitored. The other side of the EDM switch contact should be

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 8

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

connected to the green (GN) / red (RD) wire. If the EDM function is not

required for a particular application it is necessary to link the green (GN) wire

to the green (GN) / red (RD) wire. If the link is not fitted the safety system will

trip and it will not be possible to reset the light curtain.

Mute inputs M1 (F6) and M2 (F7) -Mute inputs M1 (mute 1) yellow (YE) wire

and M2 (mute 2) white (WH) wire are for connecting external muting signals to

the 5K8 safety light curtain. The input signals should come from separate

sources, so that a single fault cannot cause a failure of the protective function.

When using the two external mutes the two mute signals are monitored via the

two second mute disparity timer.

Mute output (F8) –The customer may need an additional mute lamp

indication on the machine as a visual warning for the operator. Connection of

a mute indicator lamp can be made by the wires in the B user cable. Connect

the yellow (YE) / blue (BU) wire to one side of the mute lamp and the other

side of the mute lamp is connected to +24V DC. Maximum switching current

rating is 500mA.

Mute lamp output (F9) –This lamp is integrated within the horizontal muting

arm of the light curtain. The lamp acts as a visual warning indicator and will be

illuminated during a mute condition, i.e. pallet transfer.

Mute enable input (F10) –It is a control requirement for the 5K8 series that an

additional 3rd mute input is provided via the conveyor run signal so as to maintain a

high level of safety integrity. This signal acts as a permissive signal to the cross

beam mutes and/or external mute input signals.

Connection of the 3rd mute input is via the red (RD) / blue (BU) wire to a normally –

open (N/O) ‘volt free’ contact to 0V DC. Contact closed when conveyor running.

Guard Override (F11) –providing the light curtain is in a tripped condition and

the curtain is blocked by a loaded pallet then turning and holding the activate

switch (spring return) to ON will automatically turn-on the safety outputs (F1),

for a maximum period of 3 minutes. As soon as the loaded pallet clears the

light curtain the safety system will automatically reactivate to a ‘fully guarded’

condition and the spring return switch can now be released.

The Activate and Guard Override inputs are available from the user (B) cable.

The yellow (YE) / red (RD) is connected to a normally open switch contact and

the other side of the switch is connected to 0V DC.

Note:

These are for external mute inputs, e.g. inductive loops. When using

a self-muting 5K8 system e.g. inverted ‘T’ shape they are not available.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 9

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

Activate (F13) -A push button or key switch is required, having a N/O switch

contact. Connect the blue (BU) wire from the user cable (B) to one side of the

switch and the other side of the switch to L- (0v dc).

Manual Restart -Turning the ‘activate’ switch to ON and then releasing the

switch will automatically turn on the safety outputs (F1), providing the light

curtain is clear of obstruction.

(RX) Light curtain ‘clear’ indicator (F14) -A green LED indicator mounted on

the receiver unit illuminates when the light curtain is clear of obstruction.

Mute ‘clear’ indicators M1 (F15) and M2 (F16) -Amber LED indicators

mounted on the receiver unit extinguish independently, when mute sensors M1

and M2 are blocked.

(RX) Light curtain ‘block’ indicator (F17) -A red LED indicator mounted on

the receiver unit illuminates when the light curtain is obstructed.

Safe output ‘on’ (F18) -A green LED indicator mounted on the receiver unit

illuminates when the signal output switching relays are ON.

Safe output ‘off’ (F19) -A red LED indicator mounted on the receiver unit

illuminates when the signal output switching relays are OFF.

Status output indicator –(F20) –An amber LED indicator mounted on the

receiver unit is illuminated when the status relay is de-energised, but

extinguishes when the status relay is on.

Mute condition ‘On’ indicator (F21) -Amber LED indicator mounted on the

receiver unit illuminates when the light curtain output relays are in a muted

condition.

(TX) transmitter diode on indicators –(F22). A red LED corresponding to

each transmitter diode is illuminated when each transmitter is operational.

Activate ‘On’ indicator –(F23). A red LED mounted on the receiver unit to

indicate reset switch activation.

EDM ‘On’ indicator –(F24). A red LED mounted on the receiver unit

illuminates when an EDM signal is present.

Mute Enable (ME) ‘On’ indicator –(F25). A red LED mounted on the receiver

unit illuminates when a mute enable (conveyor run) signal is present.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 10

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

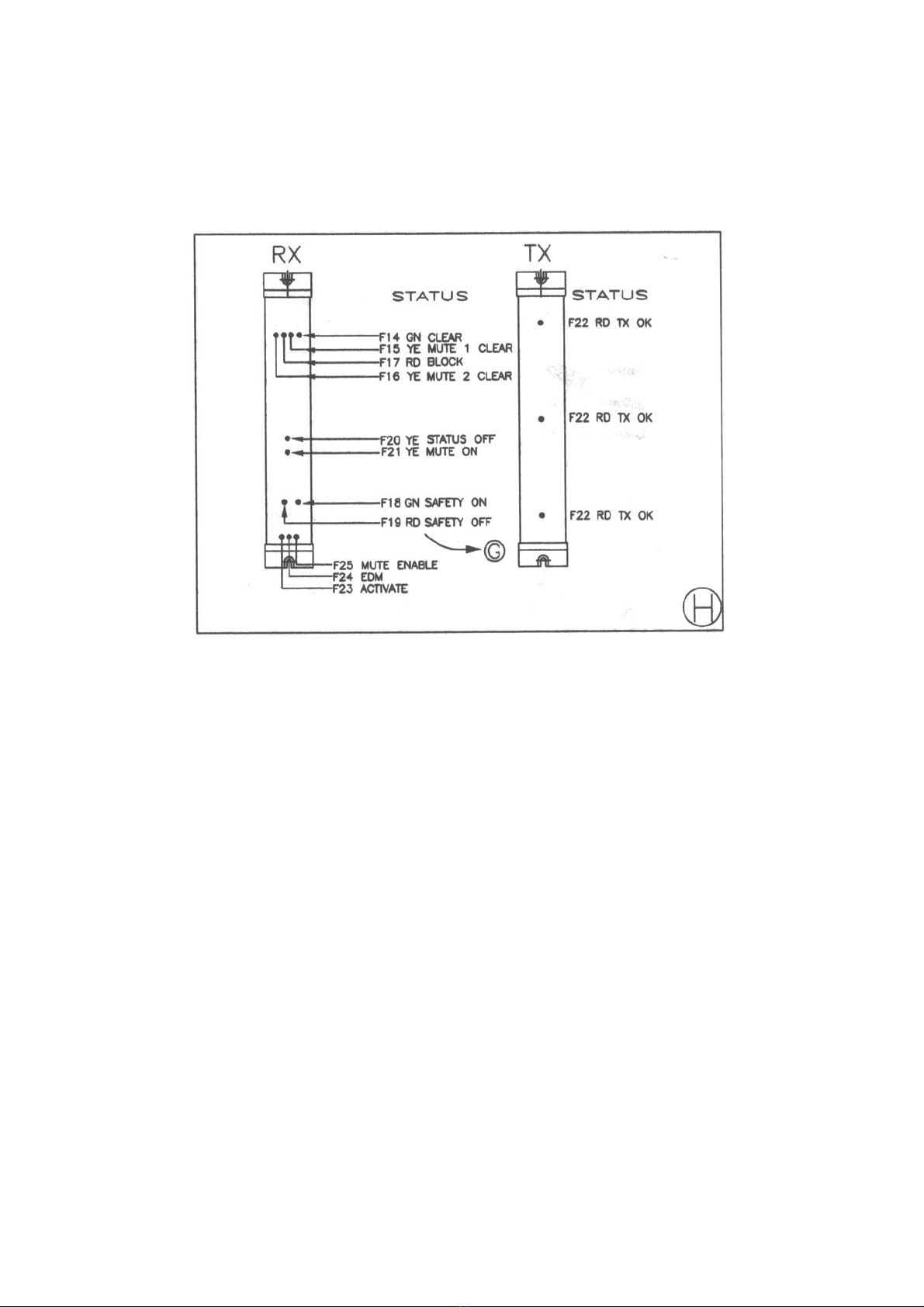

Figure H shows a diagrammatic arrangement of all the function LEDs and

location on the 5K8 series safety light guard. See Fig. G above for a detailed

explanation.

LED Status Indicators on the R/X

F14 Green Guard Clear

F15 Yellow Mute 1 Clear

F17 Red Guard Blocked

F16 Yellow Mute 2 Clear

F20 Yellow Status relay off (Auxiliary / Non-safety Output)

F21 Yellow Mute on

F18 Green Safety outputs on

F19 Red Safety outputs off

F25 Red Mute enable on

F24 Red EDM on

F23 Red Activate on

LED Status Indicators on the T/X

F22 Red Beam(s) transmitting

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 11

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

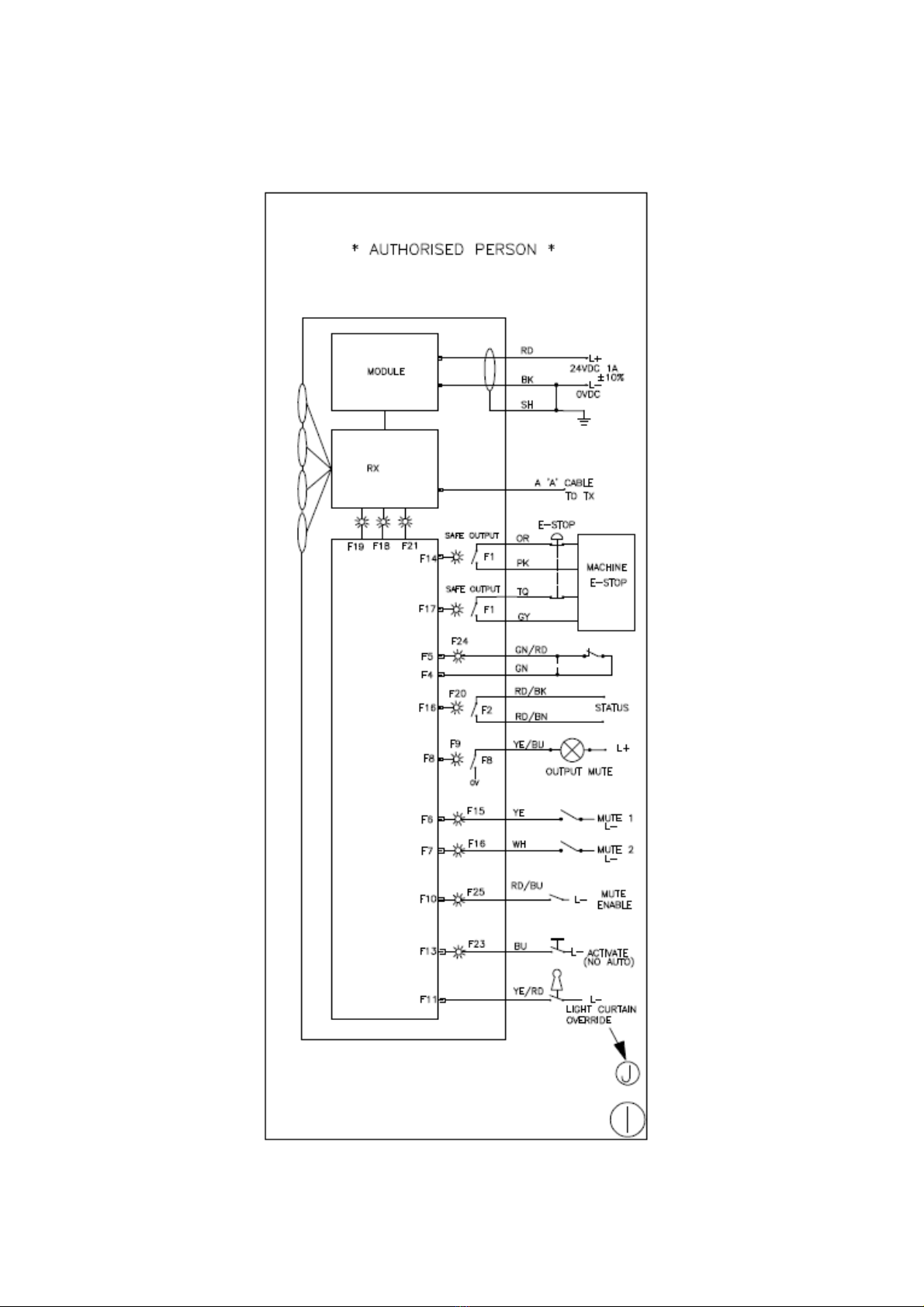

Figure I shows all the input and output connections to and from the 5K8 series.

The drawing also shows the wire colour coding. Please see Appendix 2 for

examples of typical 5K8 series wiring configurations.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 12

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

Power supply -Use a regulated supply +24V DC, 2A ƒ10%. Protect the +24V

input with a 1.5A fuse. Connect the power supply to cable B as follows: The

red (RD) wire to +24V DC and the black (BK) wire to L- V DC. Connect the

screen to ground.

All input and output connections from the Smartscan 5K8 Series are via a plug

connected into the Receiver (RX) head –Cable B (User).

Note:

Prior to initial power up of the light curtain check the following:

Red (RD) / blue (BU) wire ‘mute enable’, is connected to 0V DC

via a 3rd mute signal, e.g. conveyor run.

EDM. Is connected across the N/C contact of the FSD. If not used

link the green (GN) wire to the green (GN) / red (RD) wire.

Note:

Prior to initial power up of the light curtain check the following:

If the Smartscan system is connected directly to a 24V DC source

supplied by the user, it must be emphasised that the supply should be

regulated and suppressed to prevent transient voltages and other forms of

electrical interference from affecting correct operation of the Smartscan

equipment.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 13

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

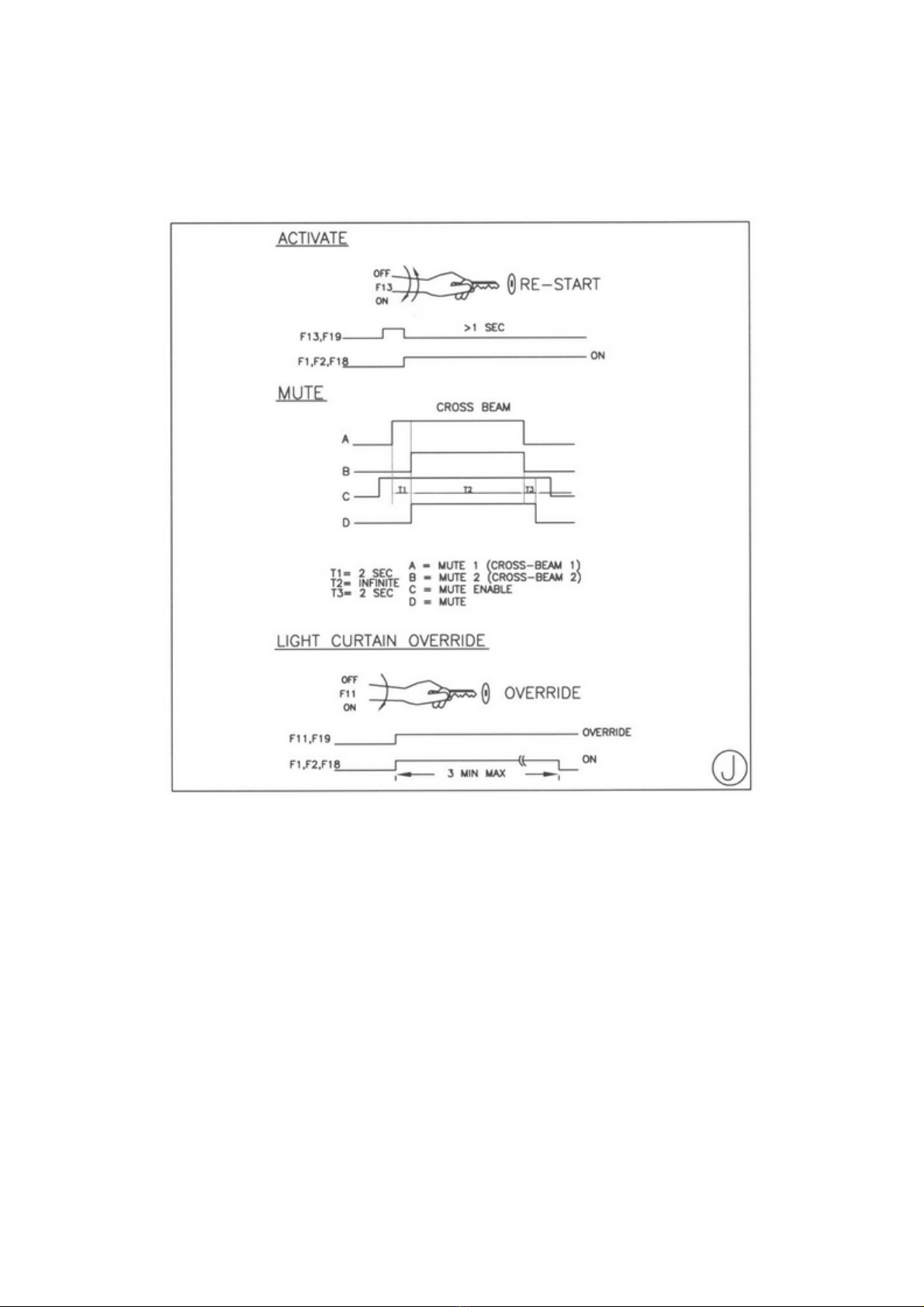

Fig J shows the standard timer functions used in the 5K8 Series for muting

and guard override applications. The timers used in cross-beam muting are

also shown below.

T1 (Mute Disparity Time) –The maximum time allowed between activation of

signals mute 1 (M1) and mute 2 (M2). This is set at 2 seconds.

T2 (Mute Time Out Period) -No overall mute timeout,(infinite).

T3 (Mute Off Delay Time) -A predetermined time that the light curtain will

remain in a muted condition following de-activation of one or both of the mute

signals. This is set at 2 seconds.

It is assumed that the Mute enable signal is energised during the entire

pallet transfer process.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 14

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

Fig. Kshows the on-board dip switches for user to set the light curtain in either

automatic or manual start-up. It is supplied factory set to manual restart mode.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 15

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

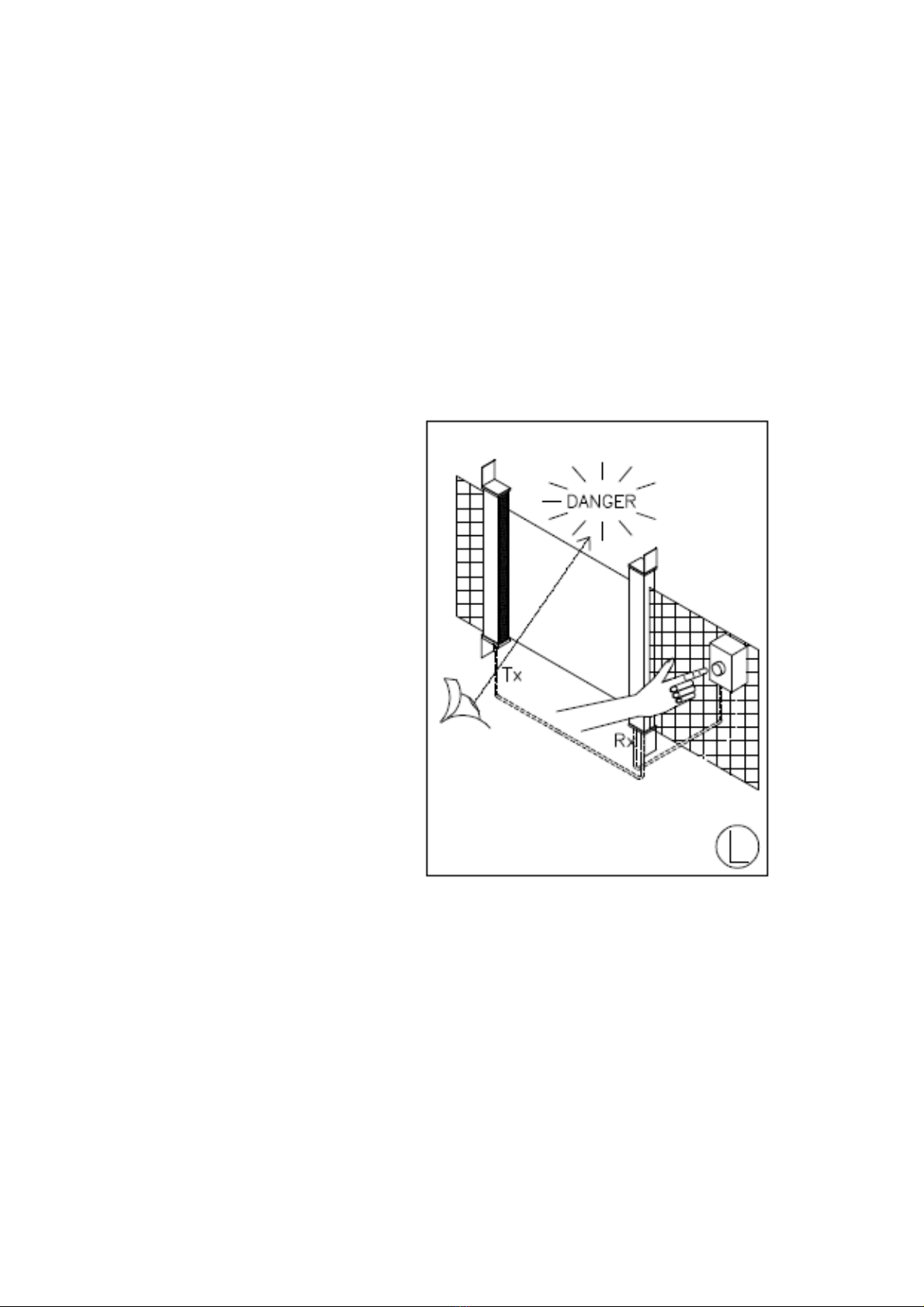

Figure L Activate and Guard Override Functions

Manual Restart -At power-up or, following a tripped condition, the activate

switch is used to restart (reset) the output relays to an ON state. The switch

must be activated and released to enable a restart condition.

The reset switch must be located so that the operator cannot reset the light

curtain from inside the dangerous area. In addition the reset switch must be

positioned so that the operator can see that the dangerous area is safe / free

of personnel before resetting the machine.

Guard Override -This function should only be used when using the light

curtain to transfer pallet loads from one zone to another.

If the safety system trips when a

pallet load is interrupting the

sensing field of the light curtain

the safety system cannot be

restarted. In order to remove

the blockage from the light

curtain the 5K8 series provides

a guard override facility. This is

achieved by activating and

holding the guard override

switch until the blockage has

cleared the sensing field of the

light curtain. The maximum time

permitted for this is 3 minutes.

However if the time is

inadequate the process can be

repeated by simply releasing the

active switch and re-activating

and holding the switch again.

The guard override switch can

be a push button, preferably a

key switch of the type ‘spring

return’.

Please note that the light curtain’s safety outputs (OSSDs) can only be reset

once the light curtain sensing field is free of the obstruction. Therefore the

override function is only available whilst a pallet load is blocking the sensing

field of the light curtain.

The Restart controls must be located such that the danger area can be

seen to be clear of persons before the system is activated.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 16

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

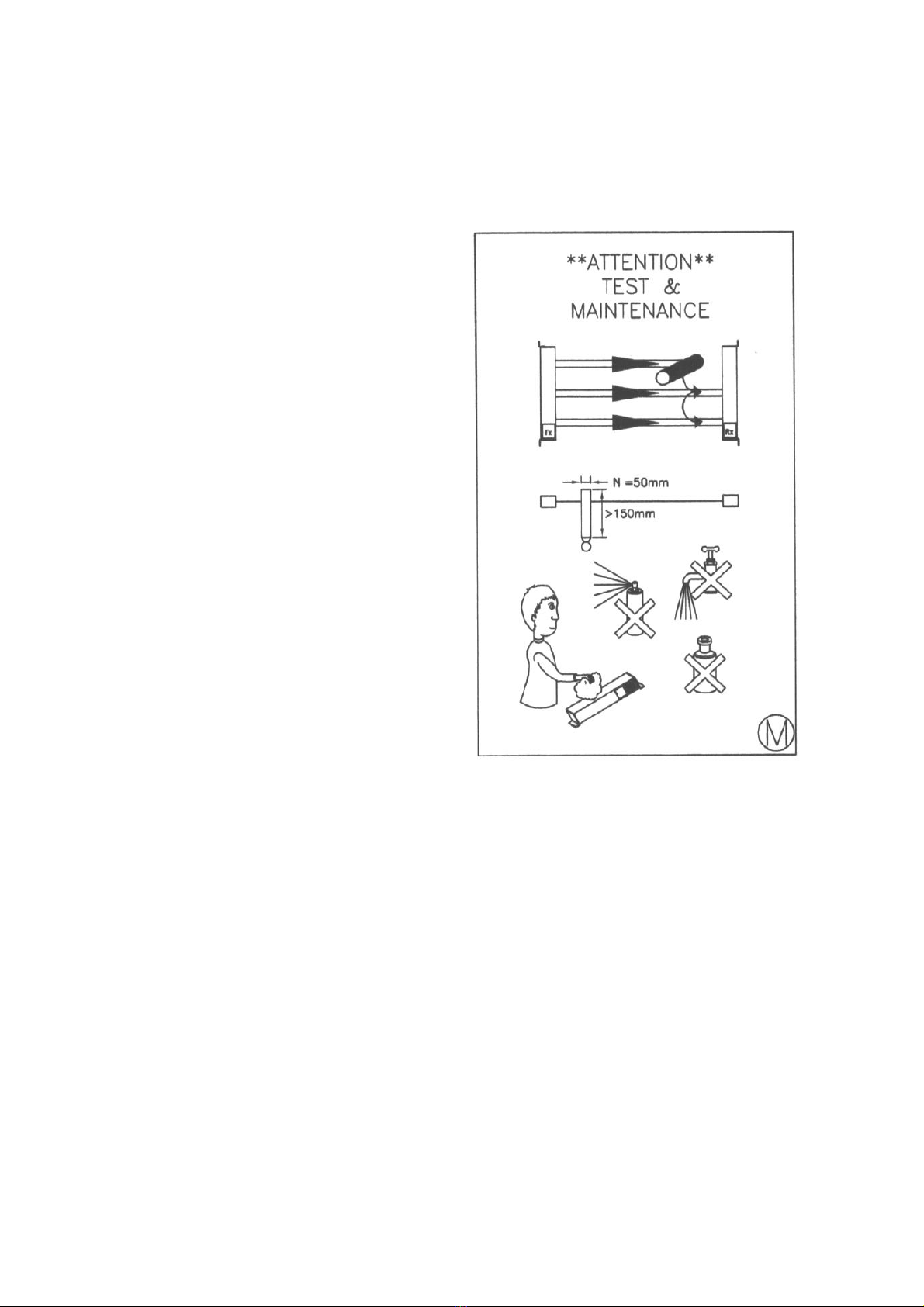

Figure MTest and Maintenance

Power-up the light curtain and activate the output switching circuits to an ON

condition.

Insert a test piece of appropriate size

into the top light beam, 150mm from

the transmitter unit. At this point the

output switches will turn OFF as the

test piece totally obscures the beam.

Repeat this process through each of

the beams in the light curtain.

Ensure that while the test piece is

obscuring each beam the output

switches are OFF.

The test procedure should be carried

out frequently as indicated by the risk

assessment for the particular

installation. Smartscan Ltd

recommends the test should be

carried out daily.

The Transmitter (Tx) and Receiver (Rx) windows should be cleaned regularly

as indicated on the Installation Sheet.

Dirt build up on the windows may lead to intermittent tripping or a totally

blocked condition of the light curtain. Clear adhesive tape may be applied to

the windows of curtains in dirty or abrasive conditions. Renew the clear

adhesive tape periodically.

Clean the windows with a clean damp cloth using a mild detergent. Never use

abrasive, corrosive cleaners or spray detergents.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 17

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

Figure N shows an operations chart for the 5K8 series.

Before installation read and

understand the Installation

Sheet provided paying

particular attention to the

information provided in Figure

D.

Refer to Figure M for test and

maintenance procedures.

Every 24 hours carry out tests

as indicated in Figure M.

Every 6 months check the

entire installation paying

particular attention to Figure D.

If the equipment fails to

operate as intended check the

electrical connections as

shown in Figure I.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 18

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

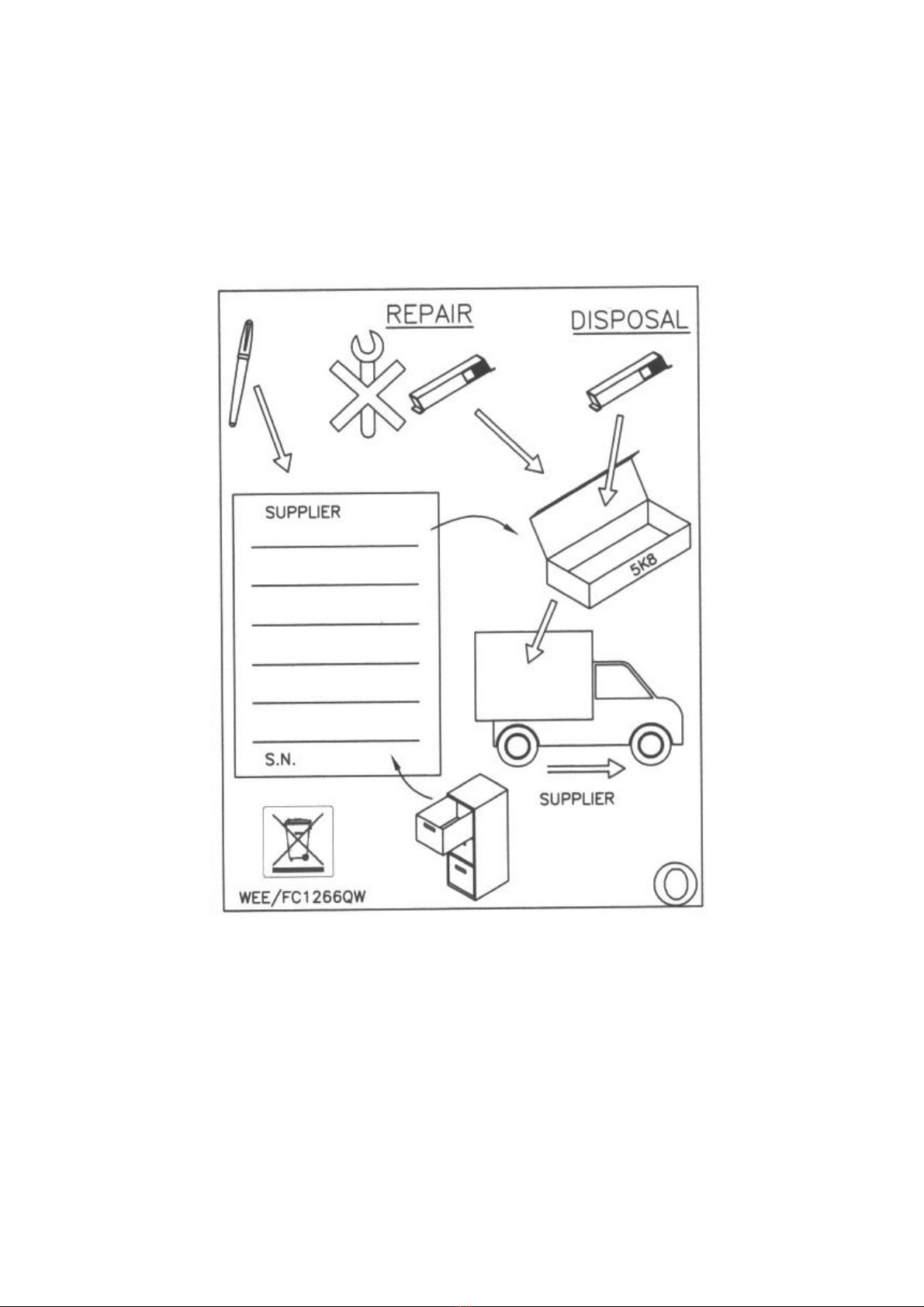

Figure Ooutlines the procedure for returning a Smartscan product.

If a fault occurs that cannot be resolved or the equipment is damaged return the

system to the nearest Smartscan distributor or Smartscan Ltd. Indicate the

nature of the fault and the symptoms displayed on the form provided.

Returned guards must be matching serial number pairs. This is to

ensure that the Service department can carry out a full and proper

inspection of the returned light curtain system.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 19

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

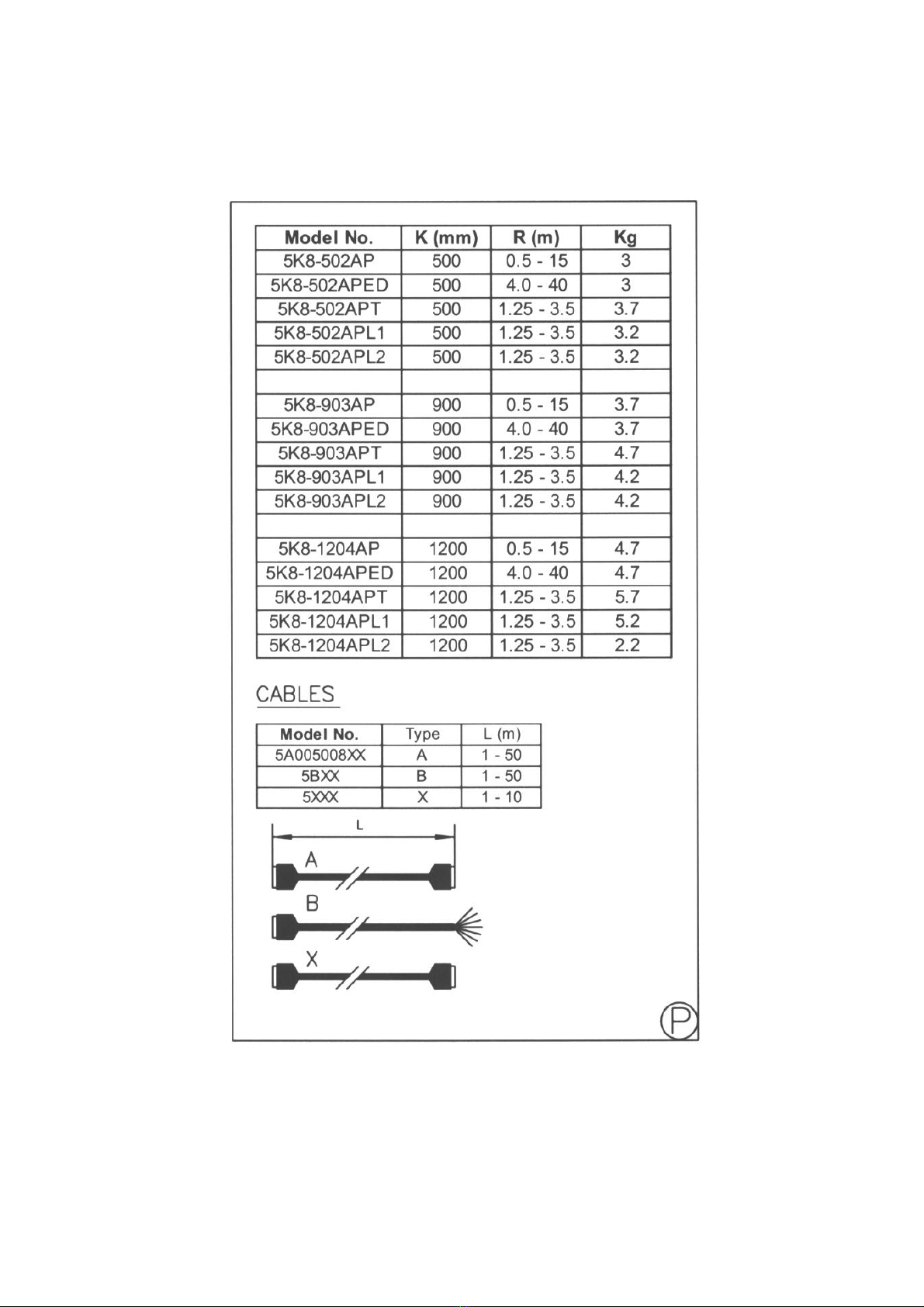

Figure Pshows a list of the model numbers and cable types. It describes the

detection zone width (K), the maximum scanning range and weights for the

5K8 series.

SMARTSCAN 5K8 SERIES LIGHT CURTAIN 20

CD401/130711 INSTALLATION SHEET EXPLAINED

Please note that the Installation Sheet Explained documents are periodically updated. The product Installation Sheets

supplied with the product should be referenced first for current installation information.

Figure Qshows a copy of the 5K8 series declaration of conformity.

This manual suits for next models

2