detector). A terminal resistor (5,6KΩ) should be

installed on the end of the line(see figure 2).

On the EXT BUZ terminal we can connect an

external buzzer BS-542.

An external sensor (BS-692, BS-693) can be

connected to the terminals+VS, GND, S. The

external sensor uses a specific protocol to

communicate with the unit.You can connect only

one external sensor with cable at least diameter

3*0.75mm and length no more than 50m.

WARNING!! If an external sensor is installed then

the positions 1-2 on JMP2 must be linked. Failing

to link these two point will result in non-

communication between the two devices. The

link should be done when the unit is not operating.

Sensitivity

The BS-690 detectors are activated when the

content of gas (propane or butane), in the

monitored area, exceeds 5 - 15% of the lower

explosive level (L.E.L).

The BS-691 detectors are activated when the

content of gas (methane), in the monitored area,

exceeds 5 - 15% ofthe lower explosive level

(L.E.L). The same detectors can also be used as

an alcohol vapor detector.

The are connected and operate with the mains

power supply voltage of 230VAC.

When the detector is activated, an internal

sounder(buzzer) is sounded and the internal

relay is activated. The relay can be used to control

an electro-valve. The buzzer stop sounding when

the gas content drops below 5-15% of the L.E.L.

The electro-valve is reset manually.

Indications LEDS and operation

The green LED shows the presence of the mains

power supply. When first installed, the green LED

blinks for 20 seconds until the sensor

compensates to its surroundings.

When the red LED is lit then the unit is in alarm

mode. Alarm mode can be triggered from:

a) The sensor of the unit

b) The external sensor (BS-692, BS-693)

c) From a fire detection zone.

When the yellow LED is lit the unit has an fault

which can because by:

a) The sensor of the unit(e.g. Dis-connected

sensor).

b)The external sensor (e.g. Communication

problem)

c) The fire detection zone (e.g. Open or short

circuit condition).

A blinking red LED means that there was an

alarm condition but it has now passed. The same

applies for a blinking yellow LED and the fault

condition.

When the test button is pressed, the system is

tested and restarted. During the test the internal

circuits are checked, the relay is activated and the

internal buzzer sounds. Also, during the test all

alarm and fault indications are reset. Finally the

fire detection zone is reset.

After the test and if an electro-valve was

connected to the unit, a manual reset of the

electro-valve must be done.

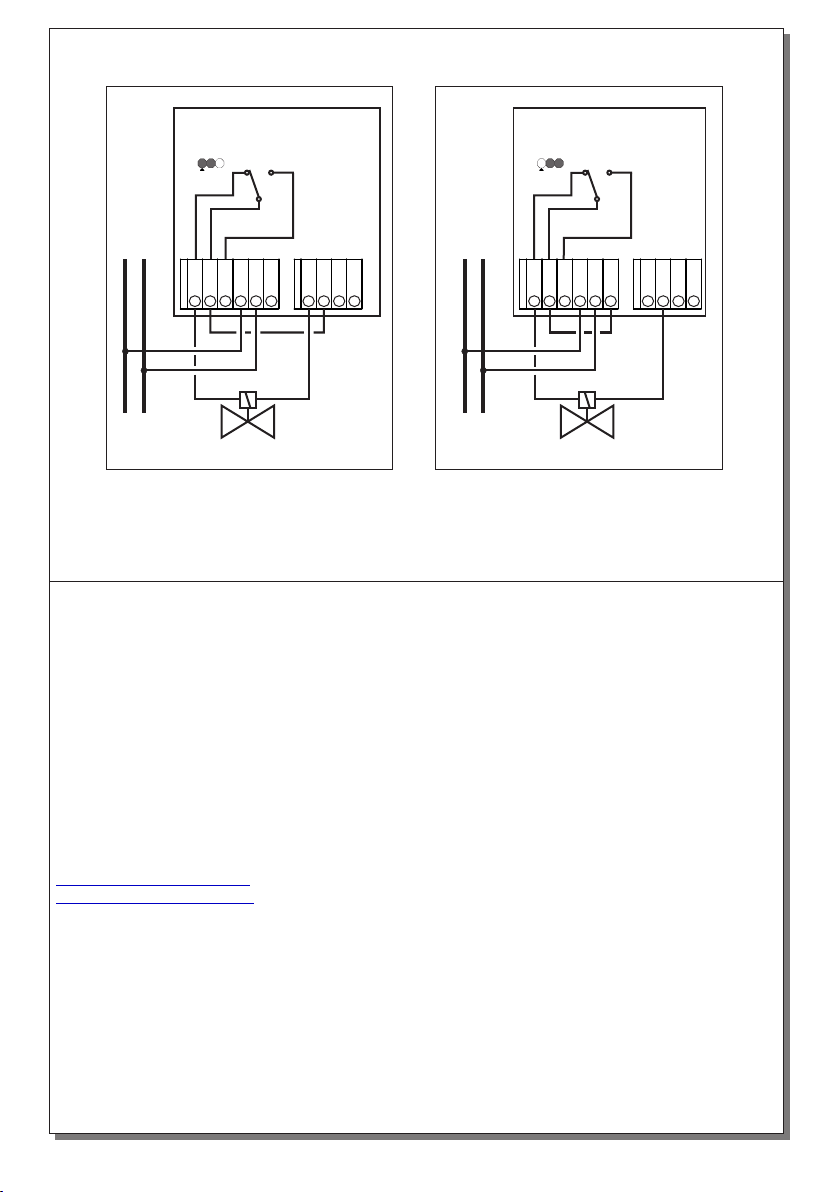

Installation of an electrovalve

The gas supply is automatically turn OFF in the

event of an alarm or fault condition. The electro-

valve can only be reset manually by the user, by

pressing on point “Α” as show in figure 1.

Depending on the type of electro-valve used, the

corresponding connection diagram is shown in

figure 4. Care must be taken to position the link of

JMP1 in the correct position. It is suggested that

this unit is used in cooperation with Οlympia

Electronics Electro-valves type BS-684 (12V

N.O.) Or BS-682 ( 230VAC N.O.). The

connection cable, when you use BS-684, must

be at least 2x2.5mm diameter and no more than

4m length.

There is a screw behind the plastic cover

Figure 1. Remove the plastic cover

Remove the plastic cover using a flat screwdriver

921691000_09_016

Page 2 from 5