SGM595GasSensor

t: 01905 797989

FEATURES

■Natural Gas or Propane detection sensor

■Catalytic Sensor Technology

■4-20mA signal sensor output

■Automatic Calibration

■Sintered Head

■IP55 Protective Rating

■CE Certied and approved to EN50194

■2 Year Guarantee - 3 Year by Registering at duomo.co.uk

APPLICATION

Duomo is recognised within the gas industry for providing a

comprehensive range of low cost, high reliability gas detection for

many applications. We have installed and commissioned natural gas

and carbon monoxide sensors in applications such as boiler rooms,

kitchens, car parks, factories and shopping centres. The SGM595

is the gas sensor used with the complete range of Duomo detector

panels. All Duomo products are manufactured to meet relevant

European Normatives and proposals for explosive and toxic gases.

OPERATION

When the SGM595 senses the presence of gas it sends a 4 - 20mA

signal to the detector proportional to the level of gas. The detector

then operates a prealarm relay - used for remote sirens or visual

indicators if the level of gas continues to rise then the main alarm

relay is activated to break the electrical supply to a safety shut o

valve, and is xed at 20% LEL of Natural Gas or LPG.

The SGM595 microprocessor conducts both self diagnostics and

automatically calibrates the sensor when ambient conditions vary,

thus avoiding false alarms.

SGM595 Natural Gas / Propane Sensor

4-20mA

IP55 Propane

Natural

Gas SPECIFICATION

Power

Power Supply 12-24V DC ± 10% from controller

Power Consumption 80mA at 13.8V

Relay contact range

Technical Specication

Gas(es) Detected L.P.G or Natural Gas

Sensor Technology Catalytic

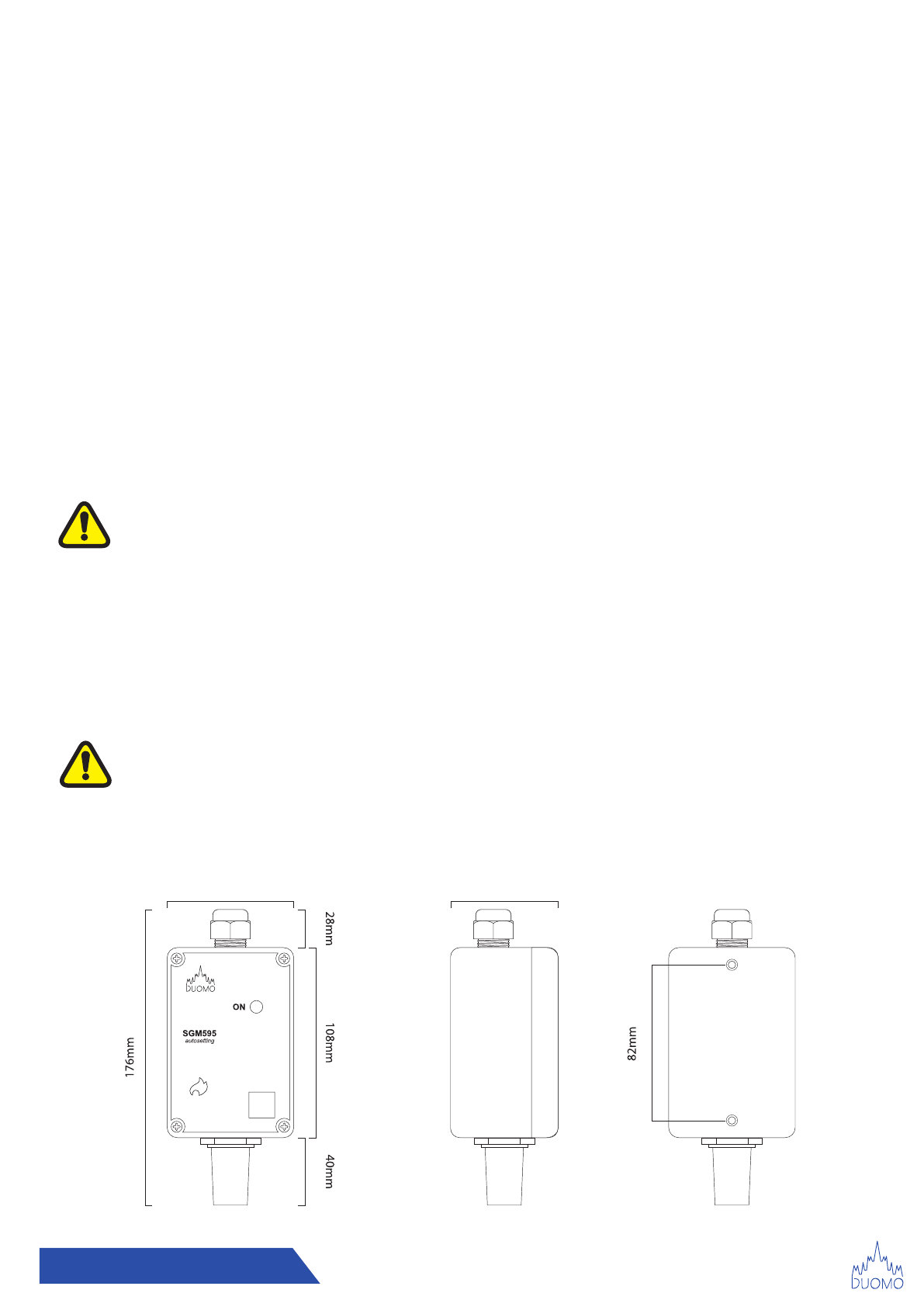

Dimensions Width 76mm |Height 176mm |Depth 57mm

LED indicator Green: Power ON

Mounting Wall Mounted

Output Signal 4-20mA

Device Precision 1% FS

Clean Air Shift < ± 3% LEL

Reaction Time <10 seconds

Autosetting Yes

Working Temperature -10°C to 40°C

Functioning Humidity

Protective Rating IP55

Perhipheral Specication

Maximum Sensor Distance 100m

Cable Diameter for Sensors 1mm2CSA

(Screened and earthed at the controller end)

Compatibility

Controller Compatibility All Conventional Duomo Controllers

(Not Addressable BXI32)

Calibration Gas Compatibility Duomo test Gases

Approvals, Certications and Guarantee

Approvals CE Certication: No.96125

Guarantee 2 Year as Standard

3 Year by Registering at www.duomo.co.uk

Expected Lifespan 5 years