HGM7100N GENSETCONTROLLER USER MANUAL

HGM7100N Genset Controller 2017-08-26 Version1.0 Page 3 of 48

CONTENTS

1 OVERVIEW.............................................................................................................................................. 5

2 PERFORMANCE AND CHARACTERISTICS......................................................................................... 5

3 SPECIFICATION OPERATION ............................................................................................................... 7

4 OPERATION............................................................................................................................................ 8

4.1 KEY FUNCTION............................................................................................................................ 8

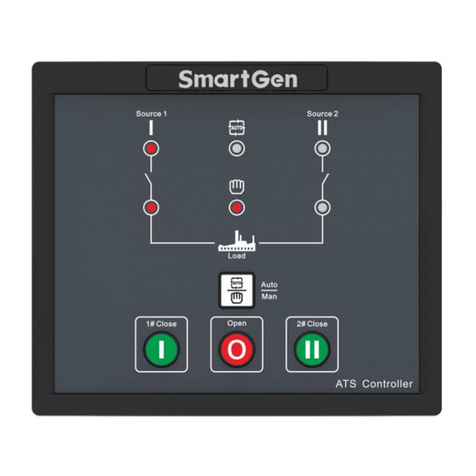

4.2 CONTROLLER PANEL.................................................................................................................. 9

4.3 AUTO START/STOP OPERATION.............................................................................................. 10

4.3.1. ILLUSTRATION.................................................................................................................. 10

4.3.2. AUTO START SEQUENCE................................................................................................ 10

4.3.3. AUTO STOP SEQUENCE.................................................................................................. 10

4.4 MANUAL START/STOP OPERATION..........................................................................................11

4.5 EMERGENCY START UP............................................................................................................11

5 BREAKER CONTROL PROCESS OF GENSET CONTROLLER ........................................................ 12

5.1 HGM7120N BREAKER CONTROL PROCESS.......................................................................... 12

5.1.1. MANUAL SWITCHING PROCESS.................................................................................... 12

5.1.2. AUTO SWITCHING PROCESS......................................................................................... 12

5.2 HGM7110N BREAKER CONTROL PROCESS .......................................................................... 13

5.2.1. MANUAL SWITCHING PROCESS.................................................................................... 13

5.2.2. AUTO SWITCHING PROCESS......................................................................................... 13

6 PROTECTION ....................................................................................................................................... 14

6.1 WARNINGS ................................................................................................................................. 14

6.2 SHUTDOWN ALARM .................................................................................................................. 16

6.3 TRIP AND STOPALARM ............................................................................................................ 18

6.4 TRIPALARM................................................................................................................................ 18

7 WIRINGS CONNECTION...................................................................................................................... 19

8 SCOPES AND DEFINITIONS OF PROGRAMMABLE PARAMETERS ............................................... 22

8.1 CONTENTS AND SCOPES OF PARAMETERS......................................................................... 22

8.2 DEFINITION CONTENT OF PROGRAMMABLE OUTPUT PORTS 1~6................................... 22

8.2.1. CUSTOM PERIOD OUTPUT............................................................................................. 35

8.2.2. CUSTOM COMBINED OUTPUT........................................................................................ 35

8.3 DEFINED CONTENTS OF CONFIGURABLE INPUT PORTS 1~7............................................ 36

8.4 SELECTION OF SENSORS........................................................................................................ 38

8.5 CONDITIONS OF CRANK DISCONNECT SELECTION............................................................ 39

9 PARAMETERS SETTING...................................................................................................................... 40

9.1 MENU ITEMS .............................................................................................................................. 40

9.2 CONTROLLER PARAMETER SETTINGS.................................................................................. 40

9.3 LANGUAGE SELECTION ........................................................................................................... 40

9.4 EVENT LOG ................................................................................................................................ 40

9.5 CONTROLLER INFORMATION.................................................................................................. 40

9.6 TIME SETTING............................................................................................................................ 41

9.7 CYCLE START SETTING............................................................................................................ 41

9.8 BATTERY UNDER VOLTAGE START SETTING........................................................................ 41

10 GENSETS CYCLE START.................................................................................................................... 41