Smartoptics mini User manual

EN

Copyright © 2023 smart optics Sensortechnik GmbH. All rights reserved.

– Translation of the Original Operating Manual –

Operating Manual

A product from smart optics Sensortechnik GmbH

EN

Copyright © 2023 smart optics Sensortechnik GmbH. All rights reserved.

– Translation of the Original Operating Manual –

Legal notice

FIRST-LEVEL SUPPORT FOR SMART OPTICS PRODUCTS

Find a smart optics reseller in your region:

Reseller locator www.smartoptics.de/en/dental/reseller-locator/

or via the contact form www.smartoptics.de/en/contact/

Support and first-level support:

smart optics Help Center support.smartoptics.de

CHANGES

We reserve the right to make changes to the product and to this documentation.

Current software version, catalog, flyer, instructions in the Download Center www.smartoptics.de

BRANDS AND TRADEMARKS

Adesso Split

Artist/arTO

K. Baumann, DE-75210 Keltern

Artex

Amann Girrbach AG, AT-6842 Koblach

exocad

exocad GmbH, DE-64293 Darmstadt

FlyCapture

Point Grey Research, Inc.

OnyxCeph3™

Image Instruments GmbH, DE-09125 Chemnitz

SILADENT

SilaPart

SILADENT Dr. Böhme & Schöps GmbH, DE-38644 Goslar

Triple Tray

Premier Dental, Plymouth Meeting, PA 19462, US

Windows

.NET Framework

Visual C++

Microsoft Corporation

Operating Manual smart optics mini

Edition: 08-2023 Table of Contents 3

Table of Contents

1Explanation of Symbols ................................................4

2Technical Data ...............................................................5

3Scope of Delivery...........................................................6

4General Safety Information .........................................6

4.1 Intended Use .................................................................6

4.2 Scannable Materials......................................................6

4.3 User Qualification..........................................................7

4.4 Protection against Injuries...........................................7

4.5 Protection against Damage to Property.....................8

5Components ..................................................................9

5.1 Scanner...........................................................................9

5.2 Accessories...................................................................10

5.2.1 Universal Plate.............................................................10

5.2.2 3D Calibration Model ..................................................11

6Commissioning............................................................11

6.1 Workplace ....................................................................11

6.2 Unpacking ....................................................................12

6.3 Connecting...................................................................12

6.3.1 Checklist Connections.................................................12

6.3.2 Procedure.....................................................................13

6.3.3 Attaching the Rotary Swivel Unit ...............................14

6.4 Installing.......................................................................14

6.4.1 Requirements ..............................................................14

6.4.2 Installation ...................................................................15

6.4.3 Upgrades......................................................................15

6.5 Calibration....................................................................15

6.5.1 Positioning the 3D Calibration Model.......................15

6.5.2 Calibration Procedure.................................................16

7Scanning ...................................................................... 17

7.1 General Information................................................... 17

7.2 Scanning a Jaw Model................................................. 18

7.2.1 Jaw Model on Mounting Plate ................................... 18

7.2.2 Jaw Model on Universal Plate .................................... 18

7.3 Jaw Models in Simple Occlusion................................ 19

7.4 Scanning Articulator ................................................... 19

7.4.1 Articulator Workflow .................................................. 19

7.4.2 Rotary Swivel Unit ....................................................... 20

7.4.3 Positioning the Articulator......................................... 20

8Maintenance and Cleaning........................................ 21

8.1 Maintenance................................................................ 21

8.2 Cleaning ....................................................................... 22

9Fault and Repair.......................................................... 22

9.1 First Level Support...................................................... 22

9.2 First Help...................................................................... 24

9.2.1 Base Check................................................................... 24

9.2.2 Failed Calibration ........................................................ 24

9.2.3 Hardware Problems.................................................... 25

9.2.4 Connectivity Problems ............................................... 25

9.2.5 Scan Problems............................................................. 26

10 Paid Extensions ........................................................... 27

10.1 Unlocking..................................................................... 27

10.2 Impression Holder...................................................... 28

10.3 multiDie........................................................................ 29

10.4 smart optics Comfort Mode....................................... 30

10.5 Availability of Software Functions............................. 31

11 Disposal........................................................................ 32

11.1 Disposing of Packaging.............................................. 32

11.2 Disposing of the Device.............................................. 32

12 CE Conformity ............................................................. 33

Operating Manual smart optics mini

Edition: 08-2023 Explanation of Symbols 4

1Explanation of Symbols

Symbols on the Device

Warning

against electrical voltage

Conformity of the scanner with EU directives

USB connect

or

Hollow plug connector

Symbols in these Instructions

Characters

Signal Word

Meaning

Notice

Danger

Warning

Caution

Warning against possible:

–

Damage to property

–

Injuries (severe – moderate)

–

Injuries (minor)

–

Danger to life

Action

—

Simple list

1.

Numbered list

Cross

-reference (link)

smart

optics Help Center (external link)

Paid

extension (module/accessory)

Software function released

Software function locked

Important note

Operating Manual smart optics mini

Edition: 08-2023 Technical Data 5

2Technical Data

Housing

Dimensions W × H × D

337 × 347 × 322 mm

Weight

9.5 kg

Rotary swivel unit

removable

Material

PUR, Acrylic, Aluminum Sheet

Color

black and white (matt)

Power switch

LED pressure switch

E-Technology

Power supply

24 V DC

Power consumption

max. 60 W

Connections

1 × USB | 1 × Power

USB cable

USB 3.0 | 1.8 m | Plug A/B

External power supply

2.5m | AC 110/230V

Room Climate

Operating temperature

18°C – 30°C

Storage temperature

5°C – 50°C

Relative humidity

40 % – 60 %, max. 80 %

Measuring

Resolution

1.6 Mpx

3D measurement technology

Stripe light triangulation, Blue Light LED

Measuring field XYZ

≙

max. object size

80 × 60 × 85 mm

Measurement accuracy acc. to ISO 12836

6 µm

System Requirements PC

PC (minimum)

CPU: i3 with 4 × 3.6 GHz | RAM: 16 GB | Port: USB 3.0

HDD: approx. 40 – 100 GB free | Graphics card RAM: 1 GB

PC (recommended)

CPU: i7 with 6 × 4.7 GHz| RAM: 32 GB | Port: USB 3.0

SSD: approx. 100 – 250 GB free | Graphics card RAM: 6 MB

Operating system

Windows 10 64-bit

Windows 11 64-bit (recommended)

Interfaces

CAD software exocad®DentalCAD

Orthodontics Software OnyxCeph3™

Operating Manual smart optics mini

Edition: 08-2023 General Safety Information 6

3Scope of Delivery

smart optics mini, in addition:

Universal plate with adhesive pads

3D calibration model

External power supply

USB cable (USB 3.0)

Data carrier with:

Scan software dental scan

Calibration data (scanner-specific)

Manual

PC and screen are not in the scope of delivery.

4General Safety Information

smart optics mini was developed according to applicable safety standards

and produced with protective measures. Nevertheless, some residual risks

cannot be ruled out.

4.1

Intended Use

Use in Dental Technology

The scanner is to be used for:

the three-dimensional optical measurement of human

jaw models/jaw impressions,

Reconstructions and archiving in prosthetics and orthodontics,

Scans in occlusal relation with reference to the position of the skull,

Scans of dental bite registers, dental modelling (wax-up) and screwable

reference bodies (scan bodies).

4.2

Scannable Materials

The materials must be firm, dimensionally stable, dry, light and opaque.

Moving parts must be fixed. Reflective and dark surfaces must be matted

with 3D scan spray.

Operating Manual smart optics mini

Edition: 08-2023 General Safety Information 7

4.3

User Qualification

To commission, install and operate the scanner, you need specialist know-

ledge of dental technology, in particular CAD/CAM technology, as well as

knowledge of the scanner from operating instructions, instruction or

training.

4.4

Protection against Injuries

WARNING

Electric shock, burns

Electric shock and burns can be caused by:

defective electrical devices or cables (e.g. lack of insulation),

wetness on electricity-carrying parts,

electrical connections without earthing,

overloaded wall sockets and lines.

Use electrical equipment properly and have it checked regularly.

Replace defective cables and power supplies.

Disconnect the power supply from electricity when the scanner is not

in operation.

Do not use a defective scanner.

WARNING

Magnetic disturbance of electronic implants

Magnets are included in scanners (system plate) and accessories

(adhesive discs).

Persons with implants, e.g. heart pacemakers, may only operate

scanners and accessories with medical permission.

WARNING

Stripe light as a triggering stimulus

In appropriately predisposed persons, stripe light can trigger migraines

or epileptic seizures.

Cover the opening during operation, e.g. with opaque foil.

Operating Manual smart optics mini

Edition: 08-2023 General Safety Information 8

CAUTION

Pulling in of garments, jewelry, hair

Loose garments, jewelry or hair can be pulled in by automatically

moving components.

At the scanner workstation, avoid scarves, ties, long chains, open

long hair, etc.

If something is pulled in, turn off the scanner immediately and

disconnect the power supply from electricity.

4.5

Protection against Damage to Property

NOTICE

Inaccurate measurements or device defect due to mechanical

damage, soiling or incorrect cleaning of electronic components

All electronic components, in particular the 3D sensor (LED projector,

camera) and the contact surfaces of the rotary swivel unit, are sensitive

to contact, dirt, moisture, cleaning agents and sharp-edged tools.

Keep the scanner clean. Avoid, e.g., milling, grinding and sawing

work nearby.

Use 3D scan spray outside the scanner.

If electronic components become dirty, do not clean them yourself.

Contact the First Level Support.

NOTICE

Data loss due to magnetic fields

Data carriers, chip cards or technical devices can be disturbed by

magnetic fields. Magnets are included in scanners (system plate) and

accessories (adhesive discs).

Keep a distance between interference-prone devices and magnets.

Operating Manual smart optics mini

Edition: 08-2023 Components 9

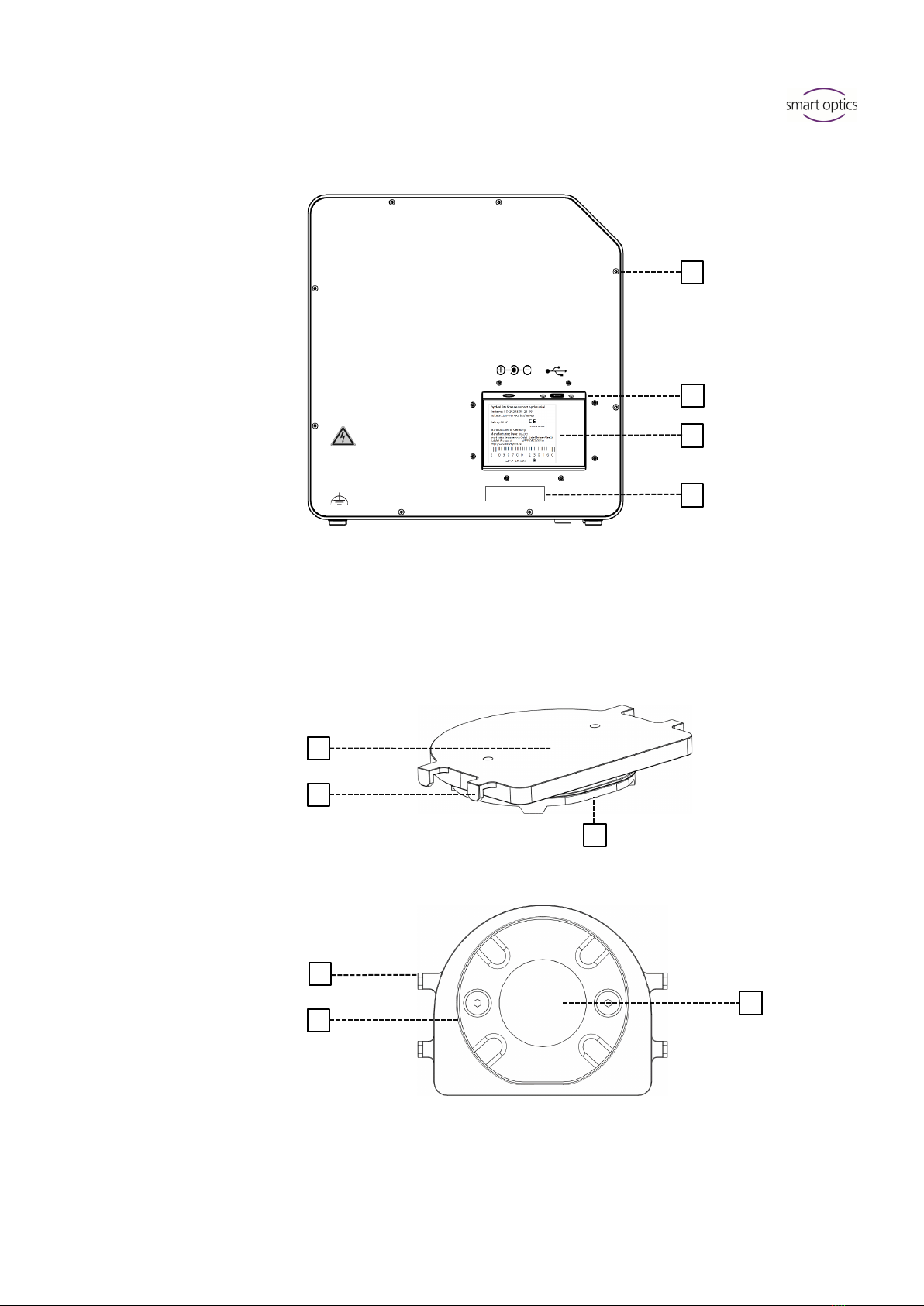

5Components

5.1

Scanner

Front

Right Side

Key

1 3D sensor

(LED projector, camera)

2 Rotary swivel unit

(removable)

3 LED pressure switch (ON/OFF)

Key

1 3D sensor

(LED projector, camera)

2 Rotary swivel unit

2a Retaining pins (2 at the top,

2 at the bottom)

2b Attachment plate for the

rotary swivel unit

2c Base plate suitable for

Splitex/Adesso Split®

1

2

3

1

2b

2

2a

2c

Operating Manual smart optics mini

Edition: 08-2023 Components 10

Rear

5.2

Accessories

5.2.1

Universal Plate

View from Above

View from Underneath

Key

1 Rear panel screw connection

2 Ports (power, USB)

3 Type plate

4 Sensor number

Key

1 Place for jaw models

2 Fixing hooks for rubber bands

(simple occlusion)

3 Plate type

Splitex/Adesso Split®

3a Magnetic adhesive disc

3

4

2

1

Serialno 3D-Sensor

SO-20293.00-23-001

1

2

3

2

3

3a

Operating Manual smart optics mini

Edition: 08-2023 Commissioning 11

5.2.2

3D Calibration Model

6Commissioning

6.1

Workplace

The scanner must be next to the PC, preferably on a laboratory table or

professional work table.

Check List

Laboratory, factory, manufacturing

Table

opaque, stable, low vibration

Place

337 × 347 × 322 mm (W × H × D)

Stability

2 × 9.5 kg

Indirect light

Temperature

18°C – 30°C

Wet room areas

NOTICE

Inaccurate measurements or device defect due to non-compliance

with workplace requirements

Avoid reflections on the measurement object. Protect the scan area

in intense ambient light (artificial light, sunlight), e.g. with opaque

foil.

Keep the scanner clean. Avoid, e.g., milling, grinding and sawing

work nearby.

Key

1 Hemispheres (for distance

measurement)

2 Cylinders (for height

measurement)

3 Label with model number

and reference values

1

2

3

1

Operating Manual smart optics mini

Edition: 08-2023 Commissioning 12

6.2

Unpacking

The original packaging is the best transport protection for scanners and

accessories. Keep them for later transporting.

1. Check the delivery for visible damage and discoloration on the shock

indicators (indicator label). Log and complain damages in accordance

to the shipping terms.

2. Transport the box to the workplace.

3. Open the box from above and remove the padding material.

4. Remove the accessory boxes (stored on the side).

5. Grab under the scanner and lift it out of the box.

6. Place the scanner on the work table next to the PC (distance max.

2 meters).

6.3

Connecting

6.3.1

Checklist Connections

Distance scanner – PC

max. 2 m

Sockets

min. 3

Power cable without power supply

Extension cable

Multi-plug

Socket adapters

USB Hub

USB extension

Carrying points

= allowed

= prohibited

5.

Operating Manual smart optics mini

Edition: 08-2023 Commissioning 13

NOTICE

Incorrect data transmission or device damage due to inappropriate

cabling

USB Hubs, USB extensions and USB cables longer than 2 meters

deteriorate the data transfer.

The scanner requires an external power supply for the power

connection.

USB cables or power supplies with the same specification as the

included ones are suitable as a replacement.

6.3.2

Procedure

1. Plug the USB and power connectors into the ports on the rear of the

scanner.

2. Connect the USB cable to a USB 3.0 port (blue) on the back of the PC.

3. Connect the plug-in power supply to the socket. If necessary, insert a

socket adapter in between (not included).

Once connected, the scanner can stand close to the wall.

USB 3.0

Hollow plug connector

Operating Manual smart optics mini

Edition: 08-2023 Commissioning 14

6.3.3

Attaching the Rotary Swivel Unit

The rotary swivel unit is delivered separately in a box.

NOTICE

Malfunction due to damage to contact surfaces

The contact surfaces on the rotary swivel unit and on the attachment

plate in the scanner are sensitive electronic components for the

transmission of data and electricity.

Do not touch the contact surfaces.

Avoid soiling or mechanical damage.

1. For fixing in the scanner, hang the rotary swivel unit from above on the

holding pins of the attachment plate.

2. Press against the rotary swivel unit to snap it into place on the lower

retaining pins.

6.4

Installing

6.4.1

Requirements

Does the PC meet the system requirements?

If you are using a notebook: connection to the electricity supply system

is required.

Are all updates for Windows and drivers installed?

Does the virus protection allow the scan software to run?

Does the Windows user have the right to run setups and apps?

5

1. 2.

Click!

Operating Manual smart optics mini

Edition: 08-2023 Commissioning 15

6.4.2

Installation

1. Insert the scanner-specific data carrier into a suitable PC port and open

the drive in Windows Explorer.

2. Execute the dental Scan.exe setup file by double-click.

3. Follow the instructions of the Installation Wizard.

4. Apply the default values. This simplifies the support and the setup of

interfaces.

The program files are installed, an entry in the start menu and a

desktop icon are available.

6.4.3

Upgrades

New versions of the scan software are available free of charge.

smart optics recommends using the current version.

www.smartoptics.de | Download Center (Software + Release-Notes)

Install an upgrade to the same destination folder as the previous

version to replace it.

6.5

Calibration

Calibration is a prerequisite for correct measurements and the last step of

commissioning. For calibration you will need:

the 3D calibration model,

the universal plate with adhesive pads,

the data carrier with scanner-specific calibration data.

6.5.1

Positioning the 3D Calibration Model

1. Cover the surface of the universal plate completely with adhesive pads,

at least three strips (product from the scope of delivery or comparable

specification, no other adhesive material).

2. Firmly press the 3D calibration model onto the universal plate (round to

round, straight to straight).

3. Place the universal plate with the 3D calibration model on the base

plate of the scanner (rounding inwards).

Desktop icon dental scan

Operating Manual smart optics mini

Edition: 08-2023 Commissioning 16

The adhesive pads can remain on the universal plate.

6.5.2

Calibration Procedure

Calibration is mandatory for commissioning. How to proceed:

1. Turn on the scanner (front LED pressure switch).

2. Insert the scanner-specific data carrier into the PC port.

3. Start the scan software. You will be asked to identify the folder

containing the calibration data.

4. Select the SO-20293... folder on the data carrier. After confirmation, the

calibration data is automatically copied to the correct destination

folder.

5. The scan software requires a calibration.

6. For #1 and #2, enter the values from the label of the 3D calibration

model (exact values with commas and decimal places).

7. Now position the 3D calibration model.

Desktop icon dental scan

Label with sample values

No.

1234

#1

52,6789

#2

9,9876

15

3.

Operating Manual smart optics mini

Edition: 08-2023 Scanning 17

8. Start the calibration. Wait until the final message.

After successful calibration, you can start scanning.

Data backup

Calibration data is not transferable to other scanners.

After initial installation, the calibration data are permanently available for

operation and calibration.

File path:

C:\ProgramData\3D-Scanner\DeviceCharacteristics\Sensors

Store the data carrier for possible reinstallation of the scanner.

7Scanning

7.1

General Information

The information in this manual is focused on handling. Detailed

instructions for scanning can be found integrated in the scan software or

in the user manual.

Tips on specific projects can be found in an instruction or training.

Scanning with Attached Small Parts

Prosthetic small parts or modeling can be scanned on the jaw model:

Mush bite as a representative of the antagonist jaw in scan mode

single jaw,

Gingiva and wax-up for segments with corresponding marking,

Scan bodies for segments with the indication implant.

Attach the small parts to the jaw model (with removable glue on a few

points).

Mattifying the Scan Object with 3D Scan Spray

Reflective or dark scan objects must be matted with 3D scan spray

(specified for dental technology, very finely grained).

Without matting, the scan result becomes worse. Use 3D scan spray

outside the scanner.

Spray the scan object thinly and evenly, do not touch the spray layer.

23

Operating Manual smart optics mini

Edition: 08-2023 Scanning 18

Service Position of the Rotary Swivel Unit

When positioning scan objects, the rotary swivel unit can be moved

unintentionally. As a result, the position of the rotary swivel unit stored in

the scan software no longer corresponds to the actual position.

Correct the position of the rotary swivel unit with the Service Position

function (after positioning, before scanning).

7.2

Scanning a Jaw Model

7.2.1

Jaw Model on Mounting Plate

Jaw models on a mounting plate of type Splitex/Adesso Split®with

magnetic adhesive disc can be scanned without further mounting.

Place the Splitex/Adesso Split®mounting plate directly on the base

plate of the scanner.

7.2.2

Jaw Model on Universal Plate

Jaw models without mounting plate and articulated jaw models on non-

Splitex/Adesso Split®mounting plates are scanned on the universal plate.

The universal plate must be covered with at least three strips of adhesive

pads.

1. Press the jaw model or mounting plate firmly onto the adhesive pads

(bottom towards centre, dental arch towards rounding). Test the fixture

by gently turning and tilting.

2. Place the universal plate on the base plate of the scanner (rounding

inwards).

2.

Operating Manual smart optics mini

Edition: 08-2023 Scanning 19

7.3

Jaw Models in Simple Occlusion

Jaw models in simple occlusion are scanned on the universal plate. The

simple occlusion is closed with rubber bands (texture: new, stable, about

0.4 cm thick). Ring rubbers and cruciate rubbers are possible. The material

does not interfere with the vestibular scan.

Rubber Band Attachment

1. Loosely place the UJ model in occlusion on the LJ model.

2. Select one of the following methods:

Form a long rubber ring into an eight and place it buccally over the

UJ model.

Place two short rubber rings x-shaped over the UJ model.

Place a cross rubber band around both jaw models so that the

crosses are on top and underneath and the bands are tensioned in

an x-shape.

3. Firmly press the connected jaw models onto the universal plate (with

adhesive pads). Test the fixture by gently turning and tilting.

4. Wrap the rubbers around the hooks on the universal plate, if

necessary, several times until the rubber is taut.

7.4

Scanning Articulator

Mean-value vestibular scans can be created with all common articulators.

With AMANN GIRRBACH Artex® and Baumann Dental Artist/arTO®,

condyle-related vestibular scans are possible.

7.4.1

Articulator Workflow

The scan software guides you through the following steps:

Removing the rotary swivel unit.

Putting the articulator in front of the camera.

Starting the scan (with timer).

Removing the articulator.

Reattaching the rotary swivel unit.

min. 8.5 cm

max. 8 cm

Hooks

View from the rear

View frow the side

Operating Manual smart optics mini

Edition: 08-2023 Scanning 20

You can change the steps positioning the articulator and starting the scan.

With a little practice, you will save time. You can change the timer, i.e. the

waiting time until the scan, in the software settings (5 seconds by default).

7.4.2

Rotary Swivel Unit

Wait until the scan software requires the rotary swivel unit to be removed.

1. Pull the rotary swivel unit off the attachment plate in the scanner

(slightly forward, then lift off the holding pins).

2. Place the rotary swivel unit in a protected place.

The contact surfaces must not be soiled or touched.

After the scan, wait until the scan software requires the rotary swivel unit

to be attached.

7.4.3

Positioning the Articulator

1. If necessary, remove the upper support pin.

2. Place the articulator before the attachment plate of the scanner.

3. Tilt the articulator so that the dental arch is facing the 3D sensor. Check

the alignment in the scan software (live image).

4. Wait for the timer in the scan software. The articulator must remain

motionless until measurement. The scan software reports when the

articulator can be removed.

14

1.

2.

Table of contents

Other Smartoptics Medical Equipment manuals

Popular Medical Equipment manuals by other brands

LeMaitre

LeMaitre TRIVEX System Operation & service manual

Bionet

Bionet BM1 user manual

B. Braun

B. Braun INFUSOMAT Secura operating instructions

Contec Medical Systems Co.

Contec Medical Systems Co. PM10 user manual

Hillrom

Hillrom TruSystem 7500 U14 Instructions for use

MicroPace

MicroPace StimLab User instruction manual

Hillrom

Hillrom Primo P02033 user manual

HEALTH RIDER

HEALTH RIDER Sotfstrider S600 Installation

Hadeco

Hadeco Bidop ES-100V3 operating manual

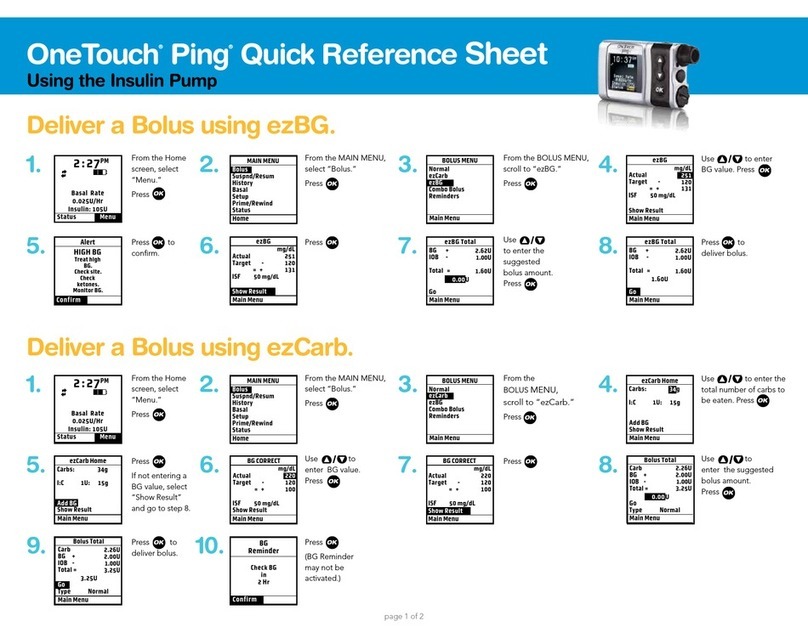

OneTouch

OneTouch Ping Quick reference sheet

B. Braun

B. Braun Aesculap MINOP Instructions for use/Technical description

Mind Media

Mind Media NeXus-10 MKII quick start