Smartswitch TC-8000 User manual

SMARTSWITCH

TC-8000

Tank Monitor/Controller

Installation Manual

Introduction 1

System Overview 2

Wiring Block Diagram 3

System Layout 4

Wiring Diagram (HT-100 & HB-200) 5

Wiring Diagram (HT-100/P & HB-200/P) 6

Product Photos 7

Installation Steps 8

Mounting Instructions 9

Sensor Installation 10

Sensor Programming Instructions 11

Sensor Programming Instructions (cont.) 12

Setting Rotary Switch (network address) 13

Seacock Interlock Switch Installation 14

Pump Current Sensing 15

Programming Instructions 16

Programming Instructions (cont.) 17

Programming Instructions (cont.) 18

Programming Instructions (cont.) 19

Programming Instructions (cont.) 20

Operating Instructions 21

Operating Instructions (cont.) 22

Operating Instructions (cont.) 23

Electrical Specifications 26

Table of Contents

1

Thank you for purchasing the TC-8000 Holding Tank Controller.

Smartswitch is very proud to be able to provide this product to you.

The Smartswitch Research and Development Team has spent considerable time and

effort in developing, designing and producing this system specifically for the marine

environment. We see this as a first in the marine environment and consider

Smartswitch to be leading the world in the design and development of distributable

intelligence controller systems.

The Holding Tank Controller has been developed with intelligent intervention for

monitoring fluid levels and controlling pumps on up to 8 tanks.

The Smartswitch Holding Tank Controller is a versatile, compact, modern, stylish, user-

friendly intelligent network system.

The TC-8000 allows builders and retrofitters to offer a system with maximum

functionality thereby providing boat owners with easy and accurate management.

Installation

Smartswitch recommends a Qualified Marine or Auto-Electrician installs this product.

Introduction

2

System Overview

TC-8000 Master Display Unit (MDU)

Provides the following functions:

•full control from one central location on your boat

•visual indication of tank level (bar graph or lts / gals & percentage)

•visual indication of seacock position & pump status

•ability to turn holding tank macerator pump on & off manually or automatically

•ability to turn holding tank macerator pump on manually & off automatically

•all tanks are name programmable e.g. (Aft-Grey) (Port Fuel) (Aft-Fuel)

•audible alarm

•backlight

HT-100 or HB-200 or HT-100/P or HB-200/P Input/Output

Unit:

Is a controller which provides an input for the fluid level sensor. Each tank on the network

requires an IOU. The HT-100 or HB-200 allow for monitoring only while the

HT-100/P or HB-200/P provide monitoring and management of pumps connected to them.

The HT-100 or HT-100/P is to be used if using the pressure sensor.

The HB-200 is used with the ultra-sonic sensor for monitoring only.

The HB-200/P is duel purpose and used for the ultra-sonic sensor or the pressure sensor for

both monitoring and pump control.

Features include:

•teach-in level sensor with 5 point interpolation for irregular shaped tanks

•controls the pump and provides the input for the level sensor

•reversed output for tanks programmed as either fuel, enabling for fuel transfer pumps

to turn on when the tank is empty and off when full

•tank high level output which can be connected to the Aus/Sea toilet controller and will

disable the toilet when the holding tank is full

•an internal pump on/off override switch for tank servicing and cleaning

•supplied in two different models:

HT-100 or HB-200 features level sensor and tank high output

HT-100/P or HB-200/P features level sensor, tank high output, pump & electric

seacock control

RD-800 Remote Display Unit (RDU)

The RD-800 Repeater Display is an optional extra.

Any number of these may be connected throughout the vessel for convenient tank

monitoring. Note: The RDU is for monitoring only and will not allow control.

3

WARNING: As the HT-100/P & HB-200/P supply power for the pump, the supply

cables & fuse need be rated as per the pump manufacturer’s specifications.

Black

Battery

negative

Red

Battery

positive

Display Unit

TC-8000

Display Unit

RD-800

Batt +

Batt -

White=Net -

Blue=Net +

High Relay

Sensor

Pump

White=Net -

Blue=Net +

White = Net –

Blue = Net +

Wiring Block Diagram

Sensor

- +

Battery

To next device

HT-100/P or

HB-200/P (IOU)

HT-100 or

HB-200 (IOU)

4

Tank full

Disable output

Pump

Tank full

Disable output

Tank full

Disable output

Model RD-800

Eight Channel Holding Tank Controller System Layout for Model TC-8000

Any Device can sit Anywhere on this Two Core Bus cable.

Any combination of HT-100/P, HB-200/P and or HT-100, HB-200 (up to eight) can be connected, plus any number of repeater display units - Model RD-800.

NOTE: The HT-100/P & HB-200/P have the pump and valve option, while the HT-100 & HB-200 do not.

HT-100/P or HB-200/P

Tank

Sensor

Input/Output

Controller

Pump

Tank

Sensor

Input/Output

Controller

Pump

HT-100/P or HB-200/P

Tank full

Disable output

Tank

Sensor

Input/Output

Controller

HT-100/P or HB-200/P

Tank

Sensor

Input Controller

HT-100 or HB-200

Tank full

Disable output

Tank

Sensor

Input Controller

HT-100 or HB-200

Tank full

Disable output

Tank

Sensor

Input/Output

Controller

Pump

HT-100/P or HB-200/P

Fuel transfer

pump

Input/Output

Controller

Model TC- 8000

Model RD-800

Water Pump

Tank

Sensor

Input/Output

Controller

HT-100/P or HB-200/P

HT-100/P or HB-200/P

Tank Sensor in

the Day Tank.

See page 18

2 core Network cable

5

Wiring For Pressure Sender SEN-B300

Gnd = Black on Pressure Sensor

Sensor In = Green on Pressure Sensor

+ 5 vdc = Red on Pressure Sensor

Wiring For Ultra-Sonic Sender

Gnd = Black on Ultra-Sonic Sensor

Sensor In = Green on Ultra-Sonic Sensor

Battery + = Red on Ultra-Sonic Sensor

Wiring Diagram for Model HT-100

LED

Program Button

Rotary Switch

Network Cable

Net -

Net +

Com

N/C

N/O

Relay

Tank

sensor

Wiring Diagram for Model HB-200

LED

Program Button

Rotary Switch

Sensor In

Gnd

+ 5 vdc

Network

Net -

Net +

Com

N/C

N/O

Relay

Battery -

Battery +

6

If no Seacock Interlock Switch is used then place a jumper between Link and V/In1 (see page 14)

Pump positive

Pump negative

Battry negative

Battery positive

Tank

sensor

LED

Program Button

Rotary Switch

GND

V/ln2

V/ln1

V/Out

Link

Com

N/C

N/O

Relay Two

Wiring Diagram for Model HT-100/P

Network Cable

Net -

Net +

Com

N/C

N/O

Relay One

Pump positive

Pump negative

Battery negative

Battery positive

Tank

sensor

LED

Program Button

Rotary Switch

V / INPUT

+ 12 VDC

GND

Sensor Input

+ 5 VDC

Com

N/C

N/O

Relay Two

Pressure sender

Com

N/C

N/O

Relay One

Network Cable

Net -

Net +

Wiring Diagram for Model HB-200/P

Pressure

Sensor Wires

Black

Green

Red

7

HB-200 Input/Output Unit

Rotary Switch

Program Button

LED

HT-

SEN-100/250 Plug Connection

Rotary Switch

Program Button

Notch for Sensor wire in case

LED

HT-100/P or HB-200/P Input/Output Unit

8

Step 1:

Install and connect the Master Display Unit.

Step 2:

Install, connect and calibrate the tank sensors.

Step 3:

Install and connect the I/O units (HT-100, HB-200 or HT-100/P, HB-200/P).

Step 4:

Set-up Rotary Switches.

Step 5:

Seacock Interlock Switch or Jumper.

Step 6:

Set-up Pump Sensing.

Step 7:

Program the Master Display Unit.

Step 8:

Test system.

Installation Steps

9

Position the mounting template tool provided and mark all three pilot holes. Drill a 3mm hole on the two outside

holes and fit the mounting screws provided. Place the template tool back over the screws and tighten the screws

until the template tool can just slip on and off the screws (ensure the tool in not too loose).

Drill the bottom hole to 12 mm (cable hole).

Place the Display Unit keyholes over the two screws and gently pull down. If the screws have been tightened to the

correct depth the Display will clip down and self tighten.

If the Smartswitch pressure sensor is being fitted see pages 10, 11 and 12.

PLEASE NOTE: If a charcoal filter is fitted to the Black tank see Special Pump (page 19)

If the Ultra-Sonic sensor is being fitted see page 12.

Mounting the TC-8000 Master Display Unit

Sensor Installation

Pilot Holes

Pilot Hole

Sensor Installation

10

PLEASE NOTE: If a charcoal filter is fitted to the Black tank see Special Pump (page 19)

PLEASE NOTE: For sensor Model SEN-100 The Maximum Tank Height is 1 Meter

PLEASE NOTE: For sensor Model SEN-250 The Maximum Tank Height is 2.5 Meter

The maximum surge and safe pressure is 28psi.

For more information see “Calibration Tips & Tricks” on our web site

www.smartswitch.co.nz

Mounting Adaptors Available:

A range of mounting adaptors are available which include flat sidewall, top mount, 1.5” pipe, 2” pipe, 3” pipe and drain

valve. Ask your dealer for details.

Interface Adaptors:

Should a 4 to 20 milliamp loop sensor supplied by another manufacturer be used, then the adaptor (part number SM-

420) will need to be installed.

Should a 0 to 180 or 33 to 230 ohm sensor supplied by another manufacturer be used, then the adaptor (part number

SM-180) will need to be installed.

Sensor Installation:

The sensor should be mounted as low in the sidewall as possible using a ¾” spin-in or the flat sensor adaptor. If the

sensor adaptor is used it will require drilling a 5/8” hole in the sidewall. Apply silicon glue liberally to the bottom of the

adaptor. Using #10 x ½” stainless steel self-tapping screws attach the adaptor to the sidewall. Once the adaptor is

attached make sure that the hole in the adaptor is clear of any excess glue. Allow drying as per the instructions for the

glue. Wrap the threads of the sensor using Teflon plumbers tape and install the sensor. Tighten by hand. It is not

recommended to install the sensor in the bottom of the tank. Although the sensor will operate correctly it will provide an

area for debris to collect which would be difficult to flush out.

! WARNING !

Tank

Top mount adaptor

(Tube not supplied)

Tank

Sidewall adaptor

Tank

The top-mounting adaptor requires 3/4" ABS or

PVC pipe cut to the proper length so that the

pipe is about 1/2" from the bottom of the tank.

This pipe glues into the adaptor and the sensor

screws into the top of the adaptor. It is held on

with 2 self-tapping screws. Care must be taken

that the sensor threads are sealed with teflon

tape and screwed in tight to ensure no air

leaks, as the tube must remain pressurized.

The sensor will be damaged if subject to over

pressure during installation, caused by

compressing the small air gap between the

sensor and the ball valve.

DO NOT PRESSURE TEST TANK WITH SENSOR FITTED

Pipe adaptor

Valve

11

Two different methods of tank programming are available if using the pressure sensor:

2 Point Calibration: sets tank low and tank high points which can only be used if the tank is a regular size and

shape.

5 Point Calibration: sets tank low, tank quarter, tank half, tank three quarters and tank full points, offering more

accuracy if the tank is an irregular size and shape.

2 Point Calibration:

Turn Rotary Switch on the I/O Box to position 0

When calibration mode is entered (holding down the program button for 3 seconds) the LED will flash very fast,

while the I/O Box is calculating the Empty point. Once this has finished you will see Three slow flashes and the

LED will stay on indicating it has programmed the Empty point. It is now ready to set the Full point.

When the button is pressed again, to set the Full point, the LED will flash very fast, while the I/O Box is calculating

the Full point. Once this has finished you will see Three slow flashes indicating it has programmed the Full point.

The LED will then turn off.

NOTE: While the fast flashing continues it is indicating the tank contents have not settled enough for the unit to

take a good reading (wait for the contents to settle).

NOTE: If you see 12 slow flashes this indicates the unit could not see any difference between the Empty point

setting and the Full point setting. The Empty and Full points need to be different.

Turn Rotary Switch to correct position (see Setting Rotary Switch page 13)

Note: The Bottom Only, Top Only and Setting The Calibration From One IOU To Another, only applies to HT-100 or HT-

100P units with manufacture dates after March 2007.

After calibrating the bottom and top settings of a tank you may wish to go back and change either of these

settings individually:

The Bottom Only setting can be changed by turning the Rotary Switch to position A

Fill the tank to the required TANK LOW LEVEL, minimum suggested is liquid just covering the sensor. Wait approx. 30

seconds for the fluid to settle. Press and hold down the Program Button (on the IOU) until the LED starts to fast flash

(approx. 3 seconds) release the button, the LED will fast flash until the contents are stable, then the LED will give 3 slow

flashes and turn off. The tank low point has now been saved and the unit will automatically leave program mode. The

device is now ready for use.

Turn Rotary Switch to correct position (see Setting Rotary Switch page 13)

The Top Only setting can be changed by turning the Rotary Switch to position B

Fill the tank to the required TANK FULL LEVEL and wait approx. 30 seconds for the fluid to settle. Press and hold down

the Program Button (on the IOU) until the LED starts to fast flash (approx. 3 seconds) release the button, the LED will

fast flash until the contents are stable, then the LED will give 3 slow flashes and turn off. The tank high point has now

been saved and the unit will automatically leave program mode.

The device is now ready for use.

Turn Rotary Switch to correct position (see Setting Rotary Switch page 13)

Tank

High Point

Low Point

Sensor Programming Instructions

12

5 Point Calibration:

Turn Rotary Switch (IOU) to position F

When calibration mode is entered (holding down the program button for 3 seconds) the LED will flash very fast,

while the I/O Box is calculating the Empty point. Once this has finished you will see Six slow flashes and the LED

will stay on indicating it has programmed the Empty point. It is now ready to set the 1/4 point.

When the button is pressed again, to set the 1/4 point, the LED will flash very fast, while the I/O Box is calculating

the 1/4 point. Once this has finished you will see Two slow flashes indicating it has programmed the 1/4 point. The

LED will stay on indicating it has programmed the 1/4 point. It is now ready to set the 1/2 point.

When the button is pressed again, to set the 1/2 point, the LED will flash very fast, while the I/O Box is calculating

the 1/2 point. Once this has finished you will see Three slow flashes indicating it has programmed the 1/2 point.

The LED will stay on indicating it has programmed the 1/2 point. It is now ready to set the 3/4 point.

When the button is pressed again, to set the 3/4 point, the LED will flash very fast, while the I/O Box is calculating

the 3/4 point. Once this has finished you will see Four slow flashes indicating it has programmed the 3/4 point. The

LED will stay on indicating it has programmed the 3/4 point. It is now ready to set the Full point.

When the button is pressed again, to set the Full point, the LED will flash very fast, while the I/O Box is calculating

the Full point. Once this has finished you will see Five flashes indicating it has programmed the Full point. The LED

will then turn off.

NOTE: While the fast flashing continues it is indicating the tank contents have not settled enough for the unit to

take a good reading (wait for the contents to settle).

Turn Rotary Switch to correct position (see Setting Rotary Switch page 13)

Setting The Calibration From One Input/Output Unit To Another:

Once the IO/Box has been calibrated you can transmit the calibration settings from that unit to as many more as

required (tanks would need to be the same shape, size and content).

The I/O Box can transmit to, or receive from, any I/O Box and vice versa.

Note: This must be done independently from the complete system setup (only the 2 IOU’s connected).

Step 1: Connect the power and network cable to both units.

Step 2: Turn the Rotary Switch to position C for the master transmitter (the unit that is calibrated).

Step 3: Turn the Rotary Switch to position D for the slave receiver (the unit that needs calibrating).

You will see both LED’S flashing, please wait (approx 20 seconds) for the LED’S to stop flashing, the slave receiver

now has the same calibration setting as the master transmitter.

For more information see “Calibration Tips & Tricks” on our web site www.smartswitch.co.nz

Ultra-Sonic Sensor :

If using the Ultra-Sonic sensor turn the Rotary Switch to position 1

Press and hold down the Program Button for 3 seconds, the LED will flash 4 times and turn off.

Turn Rotary Switch to correct position (See Setting Rotary Switch page 13

Tank

High Point

Low Point

3/4 Point

Half Point

1/4 Point

13

Setting Rotary Switch (Network Address)

Each Input/Output Unit (HT-100, HB-200 or HT-100/P, HB-200/P) on the network must

have the Rotary Switch set to a unique number (from 2 to 9). NO two devices may share the same

Rotary Switch number.

The Rotary Switch is situated inside the Box of the HT-100/P and HB/200P Input/Output Unit and on the outside of the

case on the HT-100 and HB-200 (see diagrams below and page 7 for position).

For ease of reference fill in Table 1 below prior to programming as this will enable quick reference when programming the

Display Unit. See example below.

Swit Switch #

Tank Position

Tank Type

Tank Vol

2

AFTPORT

GREY

400L

Table 1

Example

HT-100/P & HB-200/P (Inside Case)

HT-100 & HB-200 (Side of Case)

Tank

sensor

LED

Program Button

Rotary Switch

LED

Program Button

Rotary Switch

14

Seacock Interlock Switch Installation

Important: The HT-100/P and the HB-200/P provide for an interlock with a seacock valve to prevent the pump

from starting in the event the seacock valve is closed. In the event there is no interlock contact on the

seacock, the following procedure MUST be followed to allow the pump to operate in either manual or

automatic mode.

If an Interlock Switch is fitted then wire as follows. When the Seacock Valve is closed and the pump is activated, the

pump will not turn on and the system will alarm you (see Alarms page 22).

HB-200/P

HT-100/P

Note: For the HT-100/P ONLY, in the event there is no interlock contact on the seacock, the following

procedure MUST be followed to allow the pump to operate in either manual or automatic mode: Place a link

wire between the Link & V/In 1 terminals (see page 6 for diagram)

Tank

sensor

LED

Program Button

Rotary Switch

Switch Input

+ vdc

Seacock Switch

Tank

sensor

LED

Program Switch

Rotary Switch

GND

V/In 2

V/In 1

V/Out

Link

Seacock switch

If NO Interlock

switch is fitted

then no action

is required

If NO If If NO Interlock Switch is fitted:

Place a Place a link wire between the Link &

V/In 1 terminals (see page 6 for

diagram)

15

The HT-100/P & HB-200/P are equipped with special current sensing circuitry to detect if after a pump is turned

on, it is in fact running.

If a pump is turned on, either Manually or Automatically, and the pump fails to start due to short or open circuit, the

pump icon for that tank will flash and the alarm will sound indicating a fault. Pressing the Mute key will mute the alarm.

If the attached load/pump is below the current sensing range, or the output is connected to a relay, then this feature will

need to be disabled.

This option can be enabled or disabled by the position of the Current Sensing Control Jumper.

To Enable this feature Remove the Jumpers.

To Disable this feature Insert the Jumpers.

Pump Current Sensing

Pump positive

Pump negative

Battery negative

Battery positive

Tank

sensor

LED

Program Button

Current Sensing

Control Jumper

.

.

16

Programming Instructions

Step 1: Placing the unit in Program Mode

Press and hold down the Mute & Select Up keys together for 3 seconds. This will bring you to the Set-Up Menu and

place the unit in program mode.

Scroll to PROGRAM TANK and press the Mute key.

Note: After a tank has been programmed any of the settings may be changed by scrolling to the option

requiring changing and pressing the Mute key.

Step 2: Programming a Tank

Once in program mode each tank can be individually programmed and the screen will display: “Select Switch # ”. Use

the Select Up or Down key to change the Switch number which corresponds to the I/O unit you wish to program (refer to

Table 1 on page 13) for Switch number.

Once the Switch number has been selected press the Mute key.

Step 3: Selecting Tank Name

The display will now show:

NOTE: There is a list of pre-programmed names for you to choose from, if you want to change a name see step 3a

below. Once a name has been used DO NOT use the same name again when programming another tank choose

another name from the list to either use or change.

Use the Select Up or Down key to scroll through the pre-programmed tank names. Press the Mute key once the

required name has been found. Otherwise if you would like to change the name, press the Pump key and see next

step 3a.

Step 3a: Changing Tank Name Text

The tank name text may be changed. After selecting the Tank (name), as above, use the Dim Up or Down key to

move the cursor to each individual letter and the Select Up or Down key to scroll through the alphabet. Press the

Mute key to enter, once you have finished.

SET-UP MENU

PROGRAM TANK

SUB MENU

DAY TANK MENU

ERASE TANK

EXIT MENU

Push Mute To ENTER

GREY TANK

Select TankText #

Push PUMP To Change

Push MUTE To Enter

17

Step 4: Selecting Tank Type

The display will now show:

Use the Select Up or Down key to scroll through the tank various types (note this is not the tank name, it is the tank

type). Press the Mute key once the appropriate tank type has been found.

Step 5: Setting the Alarm Point

The display will now show:

Use the Select Up or Down key to scroll through the tank levels 0 to 16 bars. (0 = Empty 16 = Full). Once you have

selected the required level, of the alarm trigger point, press the Mute key.

Step 6: Audible Alarm

The screen will now display: “DO YOU WANT AN AUDIBLE ALARM”.

Press the Select Up key to select “Yes” or the Select Down key to select “No”.

If Yes is selected the audible alarm will sound based on the Alarm Point as set above.

If No is selected there will be no audible alarm associated with that tank, only a visual bell.

Step 7: Tank Volume (see Note 1 page 24)

The screen will now display: “DO YOU WANT TO SET TANK VOLUME”.

This allows for displaying the tank volume in either Liters or Gallons. If this feature is required press the Select Up key to

select “Yes”. Next select “Ltrs” for Liters or “Gal” for Gallons.

The screen will now display: “Set Vol 00000”. Use the Select Up and Down key to change the value of each digit and

the Mute key to enter and move to the next digit. . When the last digit is reached and the Mute key is pressed, the system

will save all associated data programmed for that particular tank and return to the Set-Up Menu.

Otherwise press the Select Down key to select “No”. The system will save all associated data programmed for that

particular tank and return to the Set-Up Menu.

You have now completed the programming of a particular tank. This must be repeated for all additional tanks.

Grey=1 Black=2

Fuel=4 Water=3

Select TankType #

Use Select Keys

Push MUTE To Enter

Set Alarm On Point

Use Select Keys

Push MUTE To Enter

E ############# F

18

Erasing Tanks:

A tanks data may be completely erased. From the Set-Up Menu scroll to ERASE TANK and press the Mute key.

The display will now show:

Use the Select Up or Down key to scroll through the Switch numbers to the tank that requires erasing. Once the tank is

displayed press the Mute key. Or to exit this screen and return to the Set-Up Menu press the Pump key.

The display will now show:

Use the Select Up key for YES or the Select Down key for NO. If Yes is selected the Tank Position and Type will be

erased for that Switch position and the unit will return back to the Set-Up Menu. If No is selected the unit will return

back to the Set-Up Menu.

Day Tank Menu:

This menu allows you to set where the fuel is coming from and where it is going to. This allows for automatic cut off if the

supply tank is empty.

The display will now show:

Use the Select Up or Down key to scroll through to the tank fuel is TRANSFERING TO. Once the tank is displayed press

the Mute key.

GREY TANK

Select Switch #

Push MUTE To Enter

Push PUMP To EXIT

GREY TANK

Are You Sure

Yes No

PORT DAY FUEL

SELECT THE TANK

FUEL IS GOING TO

Use Select Keys

Push MUTE To Enter

NOTE: The transfer pump needs to be connected to the Tank Controller (HT-100/P or HB-200/P)

that is monitoring the Day Tank .

This is the DAY TANK

Table of contents

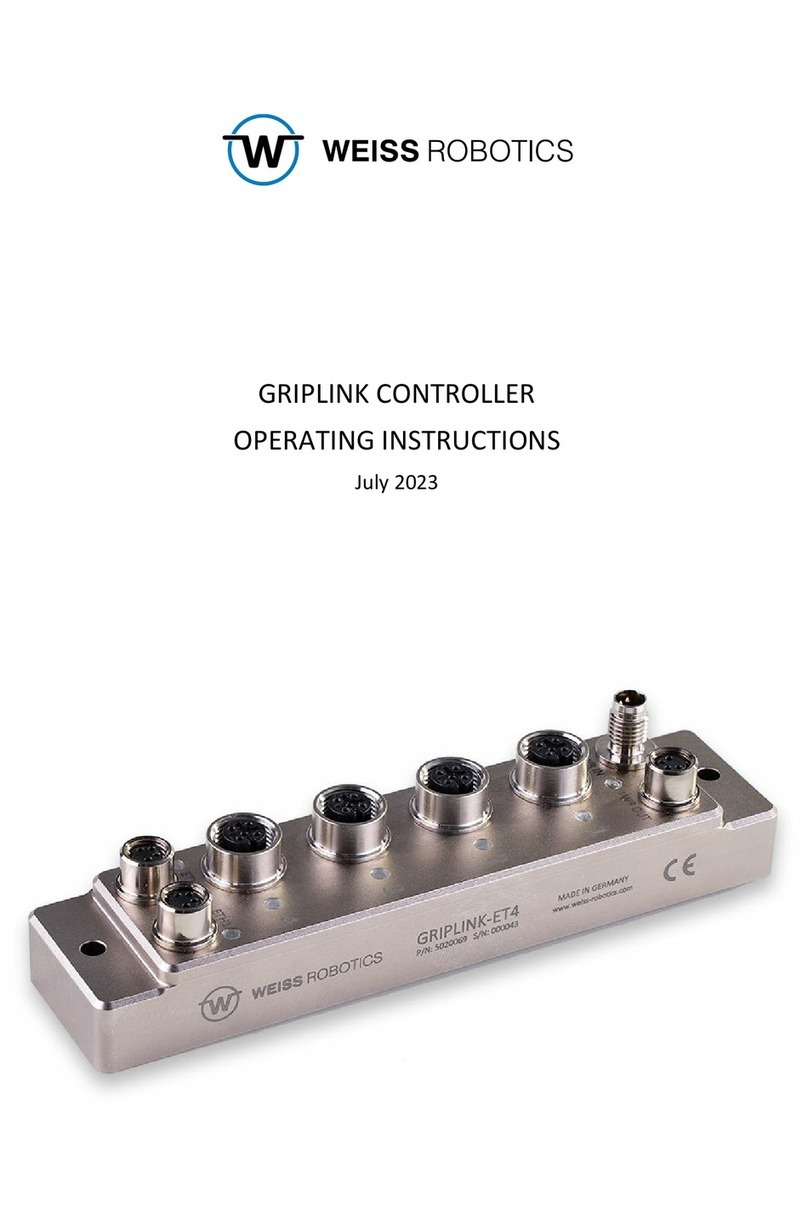

Other Smartswitch Controllers manuals

Popular Controllers manuals by other brands

Siemens

Siemens Simatic S7-1500 manual

Honeywell

Honeywell 10260S series Replacement instructions

Avonic

Avonic CM-CON100 user manual

Ametek

Ametek 88740.01210 Translation of the original function and connection guide

Chamberlain

Chamberlain Garos CS 300 operating instructions

Befaco

Befaco VCMC Assembly guide