BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 8

January 1999

Section 2.1.2 Current Limit

This circuit monitors motor current by utilizing sensors in

series with the armature and field windings. The

information detected by the sensor is fed back to thecard

so that current may be limited to a pre-set value. If heavy

load currents are detected, thiscircuit overrides the

oscillator and limits theaverage current to a value set by

Function 4 and Function 8 of the Handset. TheC/L setting is

based on the maximum thermal rating of the control.

Because of the flyback current through 3REC, the motor

current isusually greater than battery current, except at

100% ON time, or when the lA contactor is closed.

Section 2.1.3 Braking

Section 2.1.3.a Plug Braking

Slow down is accomplished when reversing direction by

providing a small amount of retarding torque for

deceleration. If the vehicle is moving, and the directional

lever ismoved from onedirection to the other, the plug

signal is initiated. Oncethe plug signal has been initiated,

the field is reversed, and the armaturecurrent is regulated

to the plug currentlimitas set by Function 6. Armature

current is regulated by increasing the field current as the

vehicle slows down. Once the field current reaches a

preset value, set by Function 10, and armature plug current

can no longer be maintained, the braking function is

canceled, and the control reverts back to motoring.

All energy produced by themotor during plugging is

dumped as heatin the motor in thisbraking mode.

Section 2.1.3.b Regenerative Braking to Zero Speed

Slow down is accomplished when

reversing direction by providing a

small amount of retarding torque for

deceleration. If the vehicle is

moving, and thedirectional lever is

moved from one direction to the

other, the regen signal isinitiated.

Once the regen signal has been

initiated, thefield current is

increased. Armature current is

regulated to the regen current limit

as set by Function 9. As the vehicleslows down, the field

current continues to increase, and transistor Q2 begins to

chop. The field current will increase until it reaches a

preset value set by Function 10, and transistor Q2 on-time

will increase until it reaches 100% on-time. Once both of

the above conditions have been met, and regen current

limit can no longer be maintained, the braking function is

canceled. The fields will then reverse, and the control

reverts back to motoring.

Part of the energy produced by themotor during regen is

returned to the battery, and part is dumped in the motor as

heat.

Section 2.1.3.c Pedal Position Plug Braking

This feature allows control of the plugging distancebased

on pedal position when therehas been a “directional

switch" change. Pedal position will reducethe plugging

current to the "value set by this function" as the accelerator

is returned to the creep speed position. Maximum plug

current is obtained with the accelerator in the top speed

position. This featureis adjustableby using Function 16 on

the Handset.

Section 2.1.3.d Auto Braking

This featurecan be setup with the Handset using Function

17 to select "Auto Plug/Regen" . This feature is enabled by

initiating a "neutral position" using either the directional

switch or the accelerator switch. Once activated, Auto

Braking operates similar to Pedal Position Plug Braking

and is adjusted by using Function 16 of the Handset.

Section 2.1.3.e Brake Pedal Regenerative Braking

This feature sets or varies the amount of REGEN current

with AUTO-REGEN braking feature. The current is variable

through the use of a pot on the brake pedal to provide a

minimum AUTO-REGEN braking level at pedal up, but

increasing as the pedal is depressed. A set level ofREGEN

CURRENT LIMIT is available with a setresistor on thebrake

pedal. An open inputwith either adjustment modea pot or

resistor will allow coast until either is selected. Minimum

REGEN CURRENT LIMIT requires a 4200 ohm resistor input

(minimum level 50 amp). Maximum REGEN CURRENT LIMIT

requires a 330 ohm resistor input.

Section 2.1.4 Auxiliary Speed Control

Section 2.1.4.a Field Weakening

This function allows the adjustment of the field weakening

level in order to set the top speed of the motor. The function

is enabled when the armature current is less than the value

set by Function 24 and the accelerator inputvoltage is less

than 1 volt. It is important to note that this function is used

to optimize motor and control performance, and this setting

will be determined by GE and OEM engineers at the time of

vehicle development. This setting must not be changed by

field personnel without the permission of the OEM.

Section 2.1.4.b Speed Limits

This feature provides a means to control speed by limiting

motor volts utilizing three "adjustable speed limits", initiated

by individual limitswitches. The NC switches are

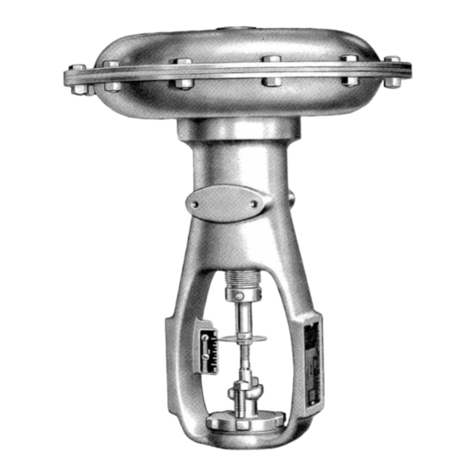

ARM

Q1

Q2