SMC Corporation LEC-BCW Series User manual

- 1 -

Contents

1.Safety Instructions...................................................................................3

2. Outline of Product ...................................................................................5

2.1 What is the data writing software (LEC-BCW)? ...................................5

2.2 What is the blank controller?.................................................................5

2.3 Required devices when using the data writing software....................5

2.4 System structure when using the data writing software....................6

2.5 Operating environment...........................................................................6

3. Preparation ..............................................................................................7

3.1 Procedure before use .............................................................................7

3.2 Installation................................................................................................8

3.3 Uninstallation...........................................................................................8

3.4 Software update.......................................................................................8

4. Function................................................................................................... 9

4.1 List of functions.......................................................................................9

4.2 Software start-up...................................................................................10

4.3 Communication settings ......................................................................11

4.4 Main menu..............................................................................................16

4.4.1 Write by selecting ACT(actuator)..............................................18

(1)Actuator selecting window.......................................................18

(2)Name and function....................................................................19

(3)How to use writing function by selecting ACT (actuator).....20

4.4.2 Writing by specifying files........................................................24

(1)Window........................................................................................24

(2) Name and function....................................................................24

(3)How to use writing function by specifying files .....................25

4.4.3 Backup........................................................................................28

(1)Backup window ..........................................................................28

(2)Names and functions.................................................................28

(3)How to use backup function.....................................................28

4.4.4 Help .............................................................................................30

(1)Help screen.................................................................................30

(2)Names and functions.................................................................30

- 2 -

(3)How to use SV No. check “Read SV Number” buttton...........31

4.5 Software completion............................................................................31

5. Alarm...................................................................................................... 32

7. Wiring of cables/Common precautions................................................ 34

8. Electric actuators/Common precautions............................................. 35

8.1 Design and selection ............................................................................35

8.2 Mounting ................................................................................................36

8.3 Handling .................................................................................................37

8.4 Operating environment.........................................................................38

8.5 Maintenance...........................................................................................39

8.6 Precautions for actuator with lock......................................................39

9.

Precautions:Controller and its peripheral devices Electric actuators/Common

precautions

.................................................................................................. 40

9.1 Design and selection ............................................................................40

9.2 Handling .................................................................................................40

9.3 Installation..............................................................................................41

9.4 Wiring of cables/Common precautions..............................................42

9.5 Power supply.........................................................................................42

9.6 Grounding..............................................................................................42

9.7 Maintenace.............................................................................................43

- 3 -

LEC-BCW/ Data writing software

1.Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential danger with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition to International Standards

(ISO/IEC), Japan Industrial Standards (JIS)*1) and other safety regulations*2).

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems

ISO 4413: Hydraulic fluid power -- General rules relating to systems

IEC 60204-1: Safety of machinery -- Electrical equipment of machines (Part 1: General requirements)

ISO 10218-1992: Manipulating industrial robots -- Safety

JIS B 8370: General rules for pneumatic equipment.

JIS B 8361: General rules for hydraulic equipment.

JIS B 9960-1: Safety of machinery – Electrical equipment for machines. (Part 1: General requirements)

JIS B 8433-1993: Manipulating industrial robots – Safety, etc.

*2) Labor Safety and Sanitation Law, etc.

Caution

Caution

indicates a hazard with a low level of risk which, if not avoided, could result in minor

or moderate injury.

Warning

Warning

indicates a hazard with a medium level of risk which, if not avoided, could result in

death or serious injury.

Danger

Danger

indicates a hazard with a high level of risk which, if not avoided, will result in death or

serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the equipment

or decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with

specific equipment must be deci

ded by the person who designs the equipment or decides its

specifications based on necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the

person who has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest

catalog information, with a view to giving due consideration to any possibility of equipment failure when

configuring the equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is confirmed.

The inspection and maintenance of machinery/equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

When the product is to be removed, confirm that the safety measures as mentioned above are

implemented and the power from any appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

Before machinery/equipment is restarted, take measures to prevent unexpected operation and

malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product is to

be used in any of the following conditions.

1)

Conditions and environments outside of the given specifications, outdoors or in a place exposed to

direct sunlight.

2)Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation,

equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment

or other applications unsuitable for the standard specifications described in the product catalog.

3)

An application which could have negative effects on people, property, or animals requiring special

safety analysis.

4)Use in an interlock circuit, which requires the provision of a double interlock for possible failure caused

by using a mechanical protective function, and periodical checks to confirm proper operation.

- 4 -

LEC-BCW/ Data writing software

Safety Instructions

Caution

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If use of this product in other industries is being condered

, consult SMC beforehand and exchange

specifications or make a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Indemnification

When using the data writing software: LEC-BCW (hereinafter referred to as "this software"),

the "indemnification" below will be applied.

Read and accept them before using the product.

This agreement comes into effect when the user installs this software to a computer.

The user cannot install, use or copy this software unless they agree to this agreement.

License Agreement

Article 1 (Consent)

1. This software is to be used in accordance with this Agreement non-exclusively for the limited purpose of

writing data to the controller for SMC electric actuators.

2. Th

is software can be installed and saved on a PC for the sole purpose specified in the preceding

paragraph.

Article 2 (Restrictions)

1. This software is not to be copied except as specified inArticle 1-2.

2. This software license is not to be transferred o

r lent wholly or in part to a third party, whether for payment

or free of charge.

3. Modification, translation, adaptation or reverse engineering and recompiling of this software is not

permitted.

Article 3 (Precautions)

1. When using any equipment cont

ained in this Software, please read the "Safety Instructions",

"Precautions", "Specific Product Precautions" and "Specifications" described in the manual for the

equipment.

2. This Software or the equipment contained in it are subject to change without prior notice.

Article 4 (Exemption of liability)

1. SMC is not responsible for any damage incurred in the use of this Software.

Article 5 (Termination)

1. If there is any breach of this Agreement, or when SMC decides to terminate this Agreement, it will be

terminated.

2. When thisAgreement is terminated, please destroy this Software and any copies.

Article 6 (Rights of this Software)

The copyright and any other rights of this Software are owned by SMC, and protected by Japanese

copyright laws and international treaty provisions.

- 5 -

2. Outline of Product

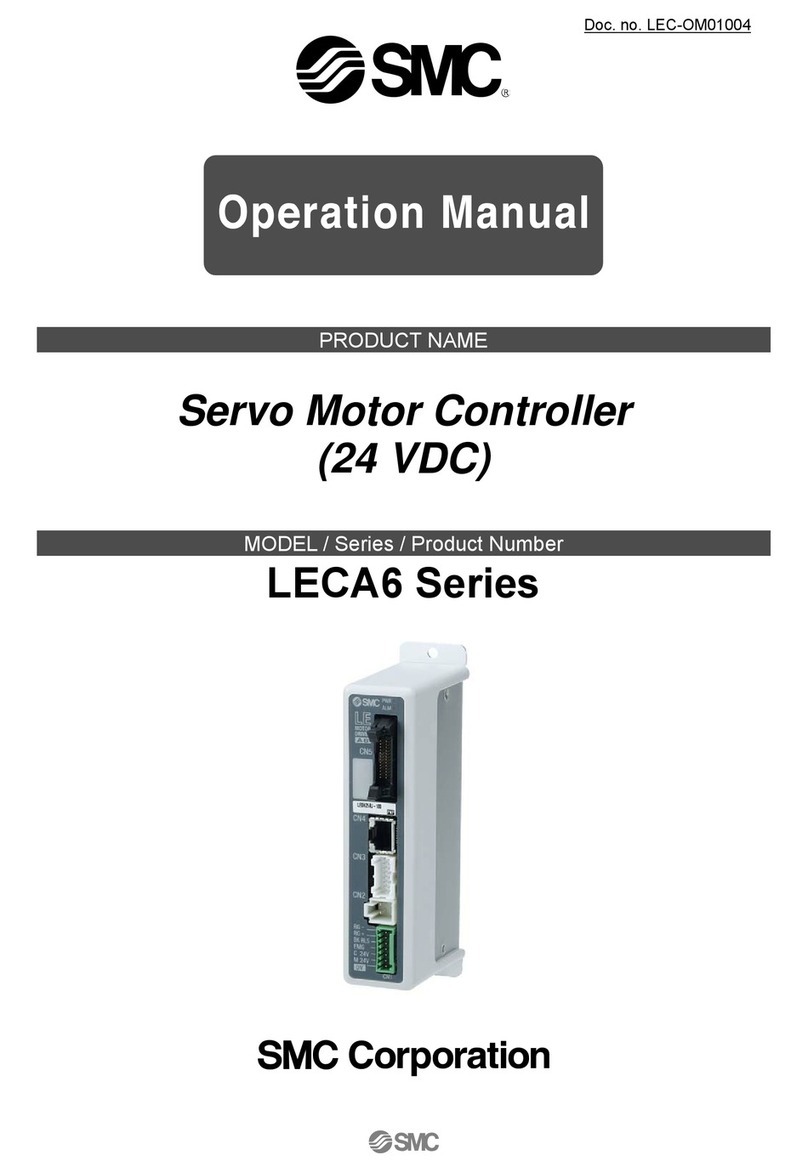

2.1 What is the data writing software (LEC-BCW)?

This software is a tool which writes the parameters and step data of a specified actuator to the blank

controller of the motor controller series (LECP/A series).

It is possible to write default parameters and step data to the controller models below.

Step Motor Controller LECP6*-BC

Servo Motor Controller LECA6*-BC

Pulse Input Type Driver LECPA*-BC

CC-Link Direct Input Type Controller LECPMJ-BC

Please download this software from the SMC website (http://www.smcworld.com/)

Caution

This software is only applicable to the blank controller model (LEC*-BC).

It is not possible to write parameter or step data into any model of controller other than the

blank controller (LEC*-BC).

2.2 What is the blank controller?

Most models of the motor controller series (LECP/A) have the specific combination of actuator data

(parameter and step data) already written into the controllers. This data is specific to the combination of the

controller and actuator model (that has already been specified). For blank controller model (LEC*-BC), no

actuator specific data has been written to the controller.

Therefore, when using the blank controller, the combined actuator specific data needs to be written by

using this software. Once the data has been written, the blank controller can be used in accordance with

the operation manual of the motor controller (LECP/A series).

Caution

・

The blank controller (LEC*-BC) will operate properly only after the writing of the specific

combination of actuator data (parameter and step data) has completed by using this software.

Please verify that the correct actuator part number has been selected prior to writing the data to the

controller using this software.

・

Use this software for writing the actuator specific data (parameter and step data) to the blank

controller (LEC[*-BC).

2.3 Required devices when using the data writing software

(1) Data writing software (LEC-BCW)

(2) Communication cable, and USB cable

Prepare a communication cable LEC-W2-C, and an USB cable LEC-W2-U.

(These cables are included in the controller setting kit LEC-W2.)

(3) PC (Personal Computer)

Refer to 2.5 Operation environment for the required PC specifications.

(4) Blank controller (LEC*-BC)

(5) Power supply (24 VDC)

- 6 -

2.4 System structure when using the data writing software

The system strucure when using the data writing software is described below.

Caution

Refer to the operation manual of the Controller for power supply plug wiring of the

controller.

Refer to 6. Common

Precautions for wiring and cables when handling the wiring and

cables.

Do not connect the PC and controller directly with the general LAN cable.

If the LAN cable is directly connected to the controller (CN4), the controller might be

broken.

2.5 Operating environment

Equipment Description

Corresponding OS Windows® 7 (English 32bit version), Windows® 7 (English 64bit version)

Windows®8.1(English 32bit version),Windows®8.1(English 64bit version)

CPU, Memory More than CPU & Memory specification that OS used recommends

Window specification Windown resolution: 1024 x 768 or more

Number of window colors: full-color (24bit or more)

Hard disk capacity 50MB or more of the hard disk space is requred

Interface USB port (USB1.1 or USB2.0)

(Communication cable LEC-W2 is connected.)

Applicable controller

Step Motor Controller LECP6*-BC

Servo Motor Controller LECA6*-BC

Pulse Input Type Driver LECPA*-BC

CC-Link Direct Input Type Controller LECPMJ*-BC

●Commnication cable

LEC-W2-C

Controller power

supply 24Vdc

Power supply plug

<Applicable cable size>

AWG20 (0.5mm

2

)

These cables are included in the controller

setting kit LEC-W2.

To CN4

Peronal computer

●USB cable

(A-miniB type)

LEC-W2-U

Controller LECP/A*-BC

To USB port

- 7 -

3. Preparation

3.1 Procedure before use

(1) Preparation of devices

Prepare required devices with reference to 2.3 Required devices when using the data writing software.

Note) When the communication cable and USB cable are used with the PC for the first time, a driver

needs to be installed. Please refer to the operation manual of the controller setting kit (LEC-W2) for

installation of the driver.

(2)Installation

Install this software to the PC with reference to 3.2 Installation.

(3)Preparation of devices

Connect the devices with reference to 2.4 System structure when using the data writing software.

(4)Start-up of data writing software

Start-up this software with reference to 4.2 Software start-up.

(5)Communication setting

Perform the communication setting with reference to 4.3 Communication setting.

(6)How to use each function

Use each function with reference to 4.4 Main menu.

(7)Completion of data writing software

Complete this software with reference to 4.5 Software completion.

- 8 -

3.2 Installation

(1)Save the compressed file of the downloaded application from SMC website

(http://www.smcworld.com/) to an arbitrary location and decompress it.

(2)Copy the decompressed application folder to an arbitrary location.

(3)Installation is complete after confirming that the folder and file shown below are included in the copied

application folder.

(It is not necessary to install the software from "Add or Remove Programs".)

The software starts-up when LEC-BCW exe is double-clicked.

3.3 Uninstallation

Delete the application folder which was copied during installation.

* It is not necessary to delete it from "Add or Remove Programs"

3.4 Software update

The latest software is available on the SMC website (http://www.smcworld.com/). Please use the latest

version all the time.

When updating the software to the latest version, uninstall the already installed software first, then

install the latest version.

- 9 -

4. Function

4.1 List of functions

Function Description

Writing function by selecting

ACT (actuator)

Specify the applicable actuator based on the specifications

and product part numbers, and program the actuator data into

the connected controller.

Writing function by specifying

files

Specify the backup file (bkp) previously created with the

backup function, and program the content into the connected

controller.

Backup function Read the data re

gistered in the connected controller and

saves it as a backup file (bkp).

- 10 -

4.2 Software start-up

This software starts up when double clicking the "LEC-BCW.exe" file.

At starts up, a software license agreement window appears, which confirms the use of this

software (see the image below).

After clicking the "Agree" button, the communication setting window is displayed.

Refer to 4.3 Communication setting for how to set communication.

Software License Agreement window

- 11 -

4.3 Communication settings

When communication is established with the controller, the communication setting window appears.

Communication check can be selected from "auto" or "manual" method

(1)Communication settings window

(2) Communication setting window

No.

Description

Function

1 Communication port Select the communication port (COM port number) of the PC

to which the communication cable is connected. The COM

port number can be checked using the Device

Manager. Refer to 4.3 (3) How to perform communication

setting for details.

2 Communication method

Select the communication check method from "Auto" or

"Manual".

- Auto (Automatic): The communication check is performed

without setting the ID and communication speed

which are set in the controller.

Note) If the controller ID and communication speed

are unknown, select the automatic setting.

Note) It may take a few minutes for the

communication confirmation.

- Manual: The communication check is performed with

setting the ID and communication speed which are

set in the controller.

Note) If the controller ID and communication speed are

already known, select the manual setting. It may reduce

the time for communication confirmation.

3 Controller ID For "manual" communication confirmation, the ID which has

been set in the controller can be selected. The range of IDs

are from 1 to 32.

7. Next button

1. Communication port

2. Communication method

3. Controller ID

4. Communication speed

5. Setting initialization button

6. Check Communication button

8. End button

- 12 -

4 Communication speed For "manual" communication confirmation, the communication

speed which has been set in the connected controller can be

selected. The range of communication speeds are 9600,

19200, 38400, 57600, 115200 and 230400[bps].

5 Setting initialization button Manually set ID and communication speed are initialized to the

default values that are stated below. (These values are the

same as the default values of the blank controller.)

・ID:1

・Communication speed:38400[bps]

6 Check Communication

button

The communication check is performed by the already

selected communication check method.

7 End button

“End”: Terminate the software

"Return": The window is returned to the previous page.

8 Next button When the communication to controller is confirmed to be

available, it is possible to move to the main menu by clicking

this button.

(3) How to perform communication setting

a) Click the "communication port selection" list button and select the COM port number of the

communication port to which the "communication cable (LEC-W2-C)" and "USB cable

(LEC-W2-U)" are connected.

Caution

Be sure to set the COM port number of the communication port regardless of

"Automatic" or "Manual" communication check method.

- 13 -

<How to Confirm the Communication Port Number>

Using the start menu, open the "Control panel”, then select "Hardware and sound" and then

select "Device manager". (This start-up method is an example for Window®7. Please

start the device manager in accordance with the operation environment of the PC.)

Confirm the COM port number of the SMC Serial Port from the devices displayed in "Port

(COM & LPT)". In this example, it is shown as COM3.

b) Click the "communication method" selection button and select the communication setting

methods from "Auto" or "Manual".

<Manual setting>

Click the "Controller ID" list button and "communication speed" list button and select the

controller ID and communication speed that has been set in the connected controller.

- 14 -

c) Click the "Check communication" button and confirm whether the set communication method

establishes communication to the controller.

Once the communication is acceptable, the window below is displayed, and controller ID and

communication speed during communication are displayed. Click the "OK" button after

confirmation

.

When communication is established.

The window below is displayed if the communication cannot be established.

In this case, click the "OK" button on the window; confirm the communication setting,

communication cable connection, and the controller power supply. Then check the

communication method again.

“Communication not confirmed” window

- 15 -

If the controller connected is not the blank controller (LEC[]-BC), the window below is

displayed. When the "OK" button is clicked, the window is returned to the communication

setting screen.

Caution

This software is only applicable to the blank controllers (LEC*-BC).

It is not possible to write into the any controllers models other than the blank controllers.

(For the controllers other than the blank controller, "backup" is only displayed on the menu window.)

d)After communication has been established, click the "Next" button. The main menu window

then be displayed. Refer to 4.4 Main menu.

- 16 -

4.4 Main menu

"Func (function)", "Comm (communication) setting" and "Help" can be selected on the main menu.

On "Func"tab, the data writing by selecting ACT or selecting file functions and the "Backup" function can

be selected.

(1)Main menu window

* When connecting to the controller models other than the blank controller, “Backup is the only function

that can be selected.

1.Function

selecting tabs

4.Backup button

2.Writing button by

selecting

ACT(actuator)

3.Writing button by

specifying file

4.Backup button

- 17 -

(2)Name and function

No. Description Function

1 Function selecting

tabs

"Func", "Comm setting" and "Help" windows can be selected.

Refer to 4.3 Communication setting for how to set up

communication to the controller.

Refer to 4.4 Help for "help".

2 Writing button by

selecting ACT

(actuator)

Select the product number of the actuator based on the

specifications and part number of the actuator. Then write the

specific data of the applicable actuator into the controller.

Refer to 4.4.1 Writing after selecting actuators for details.

3 Writing button by

specifying file

Write the data of the specified file into the controller.

Refer to 4.4.2 Writing by specifying files for details.

4 Backup button Reads the data registered in the connected controller and

saves it as a backup file (bkp).

Refer to 4.4.3 Backup for details.

(3)How to use each function

Click the button or tab of the required function.

Refer to the description below for how to use each function

・Communication setting : 4.3 Communication setting

・Help: 4 4.4 Help

・Data writing (writing by selecting ACT actuator: 4 4.1 Writing after selecting actuators

・Data writing (writing by specifying files :4 4.2 Writing by specifying files

・Backup: 4 4.3 Backup

- 18 -

4.4.1 Write by selecting ACT(actuator)

Writing function by selecting ACT (actuator) is to specify the product No. of the actuator by setting the

actuator specifications and controller model and condition, and write the specific data of the applicable

actuator to the controller.

Caution

The actuator specific data written to the blank controller and the actuator model should be

identical. Otherwise, a malfunction or failure could occur. Be sure to write the data which is

compatible with the actuator being used.

(1)Actuator selecting window

1.Search method

5.Seeking product

No.of ACT

4.Search execution button

3.Actuator product No

2.Actuator specification

6.Controller condition

7.Communication setting

button

8.Written data

9.Return button

10.Writing preparation

completion button

- 19 -

(2)Name and function

No. Description Function

1 Search method

Actuators can be selected from "search on condition" or

"search from product No.".

・Search on condition

:Select the "ACT series", "Controller", "Dir. of installing

motor ", "Lead" and "Stroke" of the actuator to which

parameter or step data is written, and search the

product No. of the actuator.

・Search from Product No.

:Input a part of the product part num

ber of the actuator

to which parameter or step data is written, and search

the product No. of the actuator.

2 Actuator specification

Before search on condition, select the "ACT series",

"Controller", "Dir. of installing motor ", "Lead" and "Stroke"

of

the actuator to which parameter or step data is to be

written

3 Actuator product No.

Input a part of the product part number of the actuator to

which parameter or step data is written, and search the

product No. of the actuator.

e.g.1)LE

e.g.2)-400

e.g.3

)

LE*-400

4 Search excution button

Search the product No. which is applicable to the set

actuator from "search on condition" or "search from the

product No.".

5 Seeking product No. of

ACT

Product No. group searched from "search on condition" or

"search from Product No." is displayed. Select the actuator

to which parameter or step data is to be written from this

product No. group.

6 Controller condition Set the "SV No." and "IO type" of the controller.

- SV No.: Controller software version

A

version label is attached to the side of the

controller, showing SV*.**. Refer to

4.4.1 (3)

How to use writing function by selecting ACT

(actuator) for details.

- IO type: Parallel I/O specifications of the controller.

Can be selected from NPN or PNP.

This is described on the label attached to the

front of the controller. Refer to

4.4.1 (3) How to

use writing function by selecting ACT (actuator)

for details.

Check the specifications of the connected controller.

7 Communication setting

button

The communication setting window is displayed. Refer to

4.3 Communication setting for how to set communication.

Table of contents

Other SMC Corporation Controllers manuals

SMC Corporation

SMC Corporation LECA6 Series User manual

SMC Corporation

SMC Corporation LECP1 series User manual

SMC Corporation

SMC Corporation LEF Series User manual

SMC Corporation

SMC Corporation LECP1 series User manual

SMC Corporation

SMC Corporation LECP6 Series User manual

SMC Corporation

SMC Corporation LECSB User manual

SMC Corporation

SMC Corporation LECP1 series User manual

Popular Controllers manuals by other brands

Simex

Simex PUR-44D user manual

Parker

Parker Compax3 Series operating instructions

Sigtronics

Sigtronics SPCC-3 operating instructions

Beamz

Beamz Scene Setter DMX-024PRO instruction manual

Grundfos

Grundfos LLC 1000W Installation and operating instructions

Johnson Controls

Johnson Controls VA-7700 Series manual