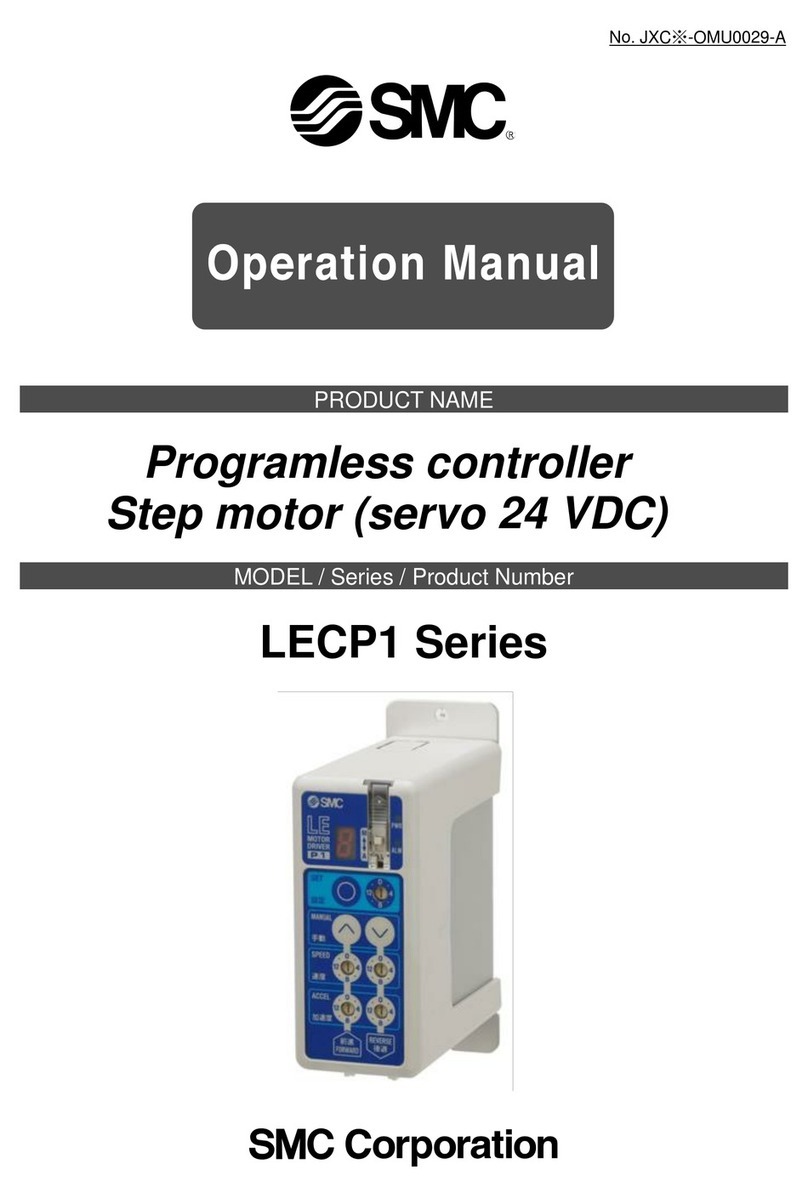

SMC Corporation LECP1 series User manual

PRODUCT NAME

Programless controller

Step motor (servo 24 VDC)

MODEL/ Series

LECP1 Series

No. LEC-OM03907

(No.JXC※-OMU0029)

- 1 -

Contents

1.Safety Instructions..........................................................................................4

2. Outlines of Product........................................................................................6

2.1 Features.....................................................................................................................................6

2.2 How to Order..............................................................................................................................7

2.3 Structure of the product ..............................................................................................................8

2.4 Procedure(How to start the actuator)........................................................................................9

(1) Checking the contents of the package.....................................................................................9

(2) Mounting the Controller ...........................................................................................................9

(3) Controller Wiring / Connection.................................................................................................9

(4) Power supply ON, and theAlarm check.................................................................................10

(5) Data (Operation pattern) setting.............................................................................................10

(6) Test run..................................................................................................................................10

3. Specifications............................................................................................... 11

3.1 Basic specifications..................................................................................................................11

3.2 Details of the controller.............................................................................................................12

3.3 Outer dimensions .....................................................................................................................13

(2) DIN rail mounting...................................................................................................................13

(LECP1□□D-□) ................................................................................................................13

(1) Mounting screw.....................................................................................................................13

(LECP1□□-□) ...................................................................................................................13

3.4 Mounting ..................................................................................................................................14

(1) Mounting................................................................................................................................14

(2) Connection to ground ............................................................................................................14

(3) Location for mounting............................................................................................................15

4. External connection.....................................................................................16

4. 1 CN1: Power supply connector .................................................................................................16

4. 2 CN2: Motor power connector, CN3: Encoder connector ..........................................................16

4. 3 CN4: Parallel I/O connector.....................................................................................................16

5. CN1: Power supply cable.............................................................................17

5. 1 Power supply cable specification.............................................................................................17

5. 2 Wiring of power supply cable...................................................................................................17

(1) Wiring of power supply ..........................................................................................................17

(2) Wiring of forced unlocking switch...........................................................................................18

(3) Stop the power supply for the motor ......................................................................................18

6. CN4: Parallel I/O cable ................................................................................20

6.1 Paralles input / output...............................................................................................................20

6.2 Parallel input / output circuit (NPN, PNP)..................................................................................20

- 2 -

(1) Parallel I/O input circuit (NPN, PNP common) .......................................................................20

(2) Parallel I/O output circuit........................................................................................................20

6.3 Parallel input / output signal......................................................................................................21

6.4 Parallel I/O connector wiring (Example)....................................................................................23

7. Setting method ............................................................................................24

7.1 Setting procedure.....................................................................................................................25

7.2 Setting parameters...................................................................................................................32

7.3 Controller modes......................................................................................................................35

(A) Before return to origin............................................................................................................36

(B) Auto mode after return to origin.............................................................................................37

(C) Manual mode after retun to origin..........................................................................................38

7.4 Test function.............................................................................................................................39

8. Operations...................................................................................................40

8.1 Return to origin.........................................................................................................................40

8.2 Positioning................................................................................................................................41

8.3 Pushing operation.....................................................................................................................41

(1) Successful pushing operation................................................................................................41

(2) Unsuccessful pushing operation (Idling) ................................................................................42

(3) Movement of workpiece after the completion of the pushing process ....................................42

8.4 Jog / inching operation .............................................................................................................43

8.5 Servo ON .................................................................................................................................44

8.6 Response time for the controller input signal............................................................................44

8.7 LED display in auto mode.........................................................................................................45

9.Operation (Example).....................................................................................46

9.1 Positioning / Return to origin.....................................................................................................46

9.2 Pushing operation.....................................................................................................................47

9.3 Stoppage during operation........................................................................................................48

9.4 Alarm generation and reset.......................................................................................................49

10. Initial setting value per actuator .................................................................50

10.1 Initial setting value of LEF series............................................................................................50

10.2 Initial setting value of LEH series............................................................................................53

10.3 Initial setting value of LES series...........................................................................................56

10.4 Initial setting value of LEY and LEYG series...........................................................................57

10.5 Initial setting value of LER series............................................................................................59

10.6 Initial setting value of LEP series............................................................................................60

10.7Initial setting value of LEL series............................................................................................61

10.8 Initial setting value of LEM series...........................................................................................62

- 3 -

11. Options ......................................................................................................63

11.1 Actuator cable [5 m or less].....................................................................................................63

11.2 Actuator cable [8 to 20m] .......................................................................................................63

11.3 Actuator cable (for sensor / lock) [5 m or less]........................................................................64

11.4 Actuator cable (for sensor / lock) [8 to 20 m]...........................................................................64

12. Alarm detection..........................................................................................65

12.1 Alarm group output.................................................................................................................65

12.2 Alarms and countermeasures.................................................................................................66

13. Wiring of cables/Common precautions.......................................................69

14. Electric actuators/ Common precautions....................................................70

14.1 Design and selection..............................................................................................................70

14.2 Mounting ................................................................................................................................71

14.3 Handling.................................................................................................................................71

14.4 Operating environment...........................................................................................................73

14.5 Maintenance...........................................................................................................................74

14.6 Precautions for actuator with lock...........................................................................................74

15. Controller and its peripheral devices / Specific product precautions...........75

15.1 Design and selection..............................................................................................................75

15.2 Handling.................................................................................................................................75

15.3 Installation..............................................................................................................................76

15.4 Wiring of cables/Common precautions ...................................................................................77

15.5 Power supply..........................................................................................................................77

15.6 Grounding...............................................................................................................................77

15.7 Maintenace.............................................................................................................................78

16. Troubleshooting.........................................................................................79

16.1 Operation troubles.................................................................................................................79

16.2 Position / Speed troubles.......................................................................................................81

- 4 -

LECP1 Series / Controller

1.Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or

“Danger.”

They are all important notes for safety and must be followed in addition to International Standards

(ISO/IEC)*1) , and other safety regulations.

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems.

ISO 4413: Hydraulic fluid power -- General rules relating to systems.

IEC 60204-1: Safety of machinery -- Electrical equipment of machines .(Part 1: General requirements)

ISO 10218: Manipulating industrial robots -Safety.

etc.

Caution

Caution indicates a hazard with a low level of risk which, if not avoided, could result

in minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk which, if not avoided, could

result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if not avoided, will result

in death or serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the

equipment or decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications based on

necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the person who

has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest catalog

information, with a view to giving due consideration to any possibility of equipment failure when configuring the

equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is

confirmed.

1.The inspection and maintenance of machinery/equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

2.When the product is to be removed, confirm that the safety measures as mentioned above are implemented

and the power from any appropriate source is cut, and read and understand the specific product precautions

of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product is

to be used in any of the following conditions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to

direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or

other applications unsuitable for the standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or animals requiring special safety

analysis.

4.Use in an interlock circuit, which requires the provision of double interlock for possible failure by using a

mechanical protective function, and periodical checks to confirm proper operation.

- 5 -

LECP1 Series / Controller

Safety Instructions

Caution

1. The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange

specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited warranty and Disclaimer” and “Compliance

Requirements”.

Read and accept them before using the product.

Limited warranty and Disclaimer

1.The warranty period of the product is 1 year in service or 1.5 years after the product is

delivered,whichever is first.2)

Also, the product may have specified durability, running distance or replacement parts.

Please

consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our

responsibility,

a replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other damage

incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and

disclaimers

noted in the specified catalog for the particular products.

2) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the vacuum

pad or failure due to the deterioration of rubber material are not covered by the limited

warranty.

Compliance Requirements

1. The use of SMC products with production equipment for the manufacture of weapons of

mass destruction(WMD) or any other weapon is strictly prohibited.

2. The exports of SMC products or technology from one country to another are governed by

the relevant security laws and regulation of the countries involved in the transaction. Prior

to the shipment of a SMC product to another country, assure that all local rules governing

that export are known and followed.

- 6 -

2. Outlines of Product

2.1 Features

Features of the controller.

Actuator control

Servo control enables the positioning and the operation with a specified thrust of

the actuator.

Operation and settings are available with the controller.

Settings can be altered and operation can be run from the controller. Adjustments of the

position, speed, acceleration and test runs are available without the teaching box, PC, and

PLC.

Operation with specified thrust

The holding force and pushing force of the actuator can be controlled in three steps.

Separated power supply input

Power supply input is separated into the motor power supply and control power supply.

Even if the power supply for the motor is turned off, the information of the encoder position is

not lost while the control power supply is on, and parallel I/O control is available.

Automatic sequence function of the returning to origin position

Returning to origin position is available through I/O signal combination.

Alarm detection

Abnormal conditions are self-detected. Alarms are displayed by LED on the controller and

abnormal conditions are output to the outside by the parallel I/O terminal.

14 points positioning / pushing is available

Through the combination of parallel I/O inputs, 14 points (position number 1 to 14(E)) of

positioning / pushing are available. The speed and acceleration of the positioning can be set

by the switch for each operating direction.

Data input method

Parameter settings, test runs, and alarm resets can be performed by the controller.

Caution

When the device is set up or failure occurs, please refer to the operation manual of the actuator as

well as this operation manual.

Keep this operation manual accessible so it can be referred to when necessary.

S

- 7 -

2.2 How to Order

How to order is shown below.

Controller

Actuator +Controller

Caution

Single controllers are also shipped after setting the actuator specification parameters.

Confirm the combination of the controller and the actuator is correct.

L E H Z 1 0 L K 2 -4 A F -R 1 1 N 1 □

L E C P 1 N □□- □

Parallel I/O type

I/O cable length

Applicable motor

(Enter from the actuator model "LE"

to ”stroke”)

e.g.: LEHZ10LK2-4AF-R11N1

Enter "LEHZ10LK2-4"

Controller

Actuator Model

Step data

P

Step motor

(servo 24 VDC)

1

14 points (Programless)

N

NPN type

P

PNP type

Nil

No cable

1

1.5 m

3

3 m

5

5 m

1.5 m power cable is included

* Power cable length is 1.5m

only

Controller

I/O cable length*

Actuator type

Applicable actuators

Electric gripper LEH Series

Electric slide table LES Series

Electric actuator / Rod type LEY Series

Electric actuator / Slider type LEF Series

Electric actuator / Rotary type LER Series

Electric actuator / Guide rod Slider LEL Series

Electric actuator / Miniature type LEP Series

Electric actuator / Low profile slider type

LEM Series

Nil

No controller*

1N

With programless controller (NPN)

1P

With programless controller (PNP)

Nil

No cable

1

1.5 m

3

3 m

5

5 m

If the actuator is ordered without the controller, the I/O cable type is not available.

LECP6 series I/O cables cannot be used due to different specification.

Fill in How to Order referring to How to Order of the catalog

of Actuators.

Please refer to the table below for the applicable actuators.

e.g.: LEHZ10LK2-4AF-R11N1

Nil

Not mountable

D

Mountable

DIN rail

Nil

Not mountable

D

Mountable

DIN rail

- 8 -

PLC

Input/output signal

power supply

24 VDC

Controller input

power supply

24 VDC

2.3 Structure of the product

Structure of the controller.

* These items are included when ordered using the part number for an actuator set.

Warning

Refer to 4. External connection for wiring.

Refer to 13. Wiring of cables/Common precautions when handling the wiring and cables.

*

●Electric actuator

To CN4

To

CN1

To CN2

To CN3

●I/O cable

Part no.: LEC-CK4-□

*

●Controller

*

●Actuator cable

[Robot cable]

Part no.: LE-CP-□-□

[Standard cable]

Part no.: LE-CP-□-□-S

●Power supply cable

Part no.: LEC-CK1-1

*When conformity to UL is required, the electric actuator and controller should be used with a UL1310 Class

2 power supply.

- 9 -

2.4 Procedure(How to start the actuator)

Install, wire, set and operate the controller referring to the procedure below when the product is used

for the first time.

(1) Checking the contents of the package

After unpacking everything, check the description on the label to identify the controller and the

number of accessories.

* These items are included when ordered using the part number for an actuator set.

If parts are missing or damaged, please contact our distributor.

(2) Mounting the Controller

Refer to 3.4 Mounting to mount the controller.

(3) Controller Wiring / Connection

Connect cables to the controller connectors (CN1 to CN4). Refer to 4. External connection for the

wiring of the cables.

Part’s name

Quantity

Controller (LECP1□□-□)

1 pcs.

Power supply cable (LEC-CK1-1)

1 pcs.

I/O cable *(LEC-CK4-□)

1 pcs.

Actuator *

1 pcs.

Actuator cable *

Robot cable: LE-CP-□-□

or

Standard cable: LE-CP-□-□-S

1 pcs.

Controller

Power supply cable

Connectors

I/O cable

Actuator cable

- 10 -

(4) Power supply ON, and the Alarm check

Supply power 24VDC.

Description

LED turns on

Condition

PWR

Green LED is on

Servo is turned on

Green LED is flashing

Servo is turned off

ALARM

Red

Alarm is generated

If the conditions are normal, the LED[PWR] on the front of the controller changes from a flashing to a

solid light. The servo is turned on if the conditions are normal. If an alarm is generated, the LED

[ALM] on the front of the controller lights up red.

Caution

When an alarm is generated

Confirm the content of the alarm with 7-segment LED of the controller or I/O output.

Eliminate the cause referring to 12. Alarm detection .

(5) Data (Operation pattern) setting

Set the stop position, speed and acceleration per operating direction with the buttons and switches

on the controller. Operations other than position setting, jog/inching can be performed after

returning to origin position. Refer to 7. Setting method for the details of settings.

(6) Test run

Test run is performed with the buttons and switches of the controller or I/O signal. Refer to 7.1

Setting procedure and 6.3 Parallel input / output signal for details.

Controller

- 11 -

3. Specifications

3.1 Basic specifications

Basic specifications of the product.

Item

Specifications

Controlled motor

Unipolar winding method 2-Phase HB step motor

Power supply

specification (*1)

Power supply voltage: 24 VDC±10% (2)

When conformity to UL is required, use UL1310 compliant Class 2

power supply unit for direct current.

Parallel input

Input 6 points (Photo coupler insulation)

Parallel output

Output 6 points (Photo coupler insulation)

Stop points

14 points (Location number 1 to 14(E))

Encoder

A/B phase, line receiver input specifications

Pulse number: 800 pulse/rev

Memory

EEPROM

LED display

LED (Green/Red) 1 for each

7-segment LED display

(*3)

1 digit, 7-segment display (red)

Figures are expressed in hexadecimal (10 to 15 in decimal number are

expressed as A to F)

Locked

With forced lock-release terminal

Cable length

I/O cable: 5 m or less

Actuator cable: 20 m or less

Cooling method

Air-cooling type

Operating temperature

range

0 to 40°C (No freezing)

Operating humidity range

90%RH or less (No condensation)

Storage temperature

range

-10 to 60°C (No freezing)

Storage humidity range

90%RH or less (No condensation)

Insulation resistance

Between external terminals and case: 50MΩ (500 VDC)

Weight

130g (Mounting screw type), 150g(DIN rail mounting type)

*1) Do not use inrush current suppressor type as the power supply for the controller input.

*2) Power consumption depends on actuator. Please refer to the operation manual of actuators

for details.

*3)"10" to "15" in decimal number are displayed as follows in the 7-segment LED

10

A

11

b

12

c

13

d

14

E

15

F

Decimal display

Hexadecimal display

- 12 -

3.2 Details of the controller

No.

Display

Description

Details

(a)

PWR

Power supply

LED

Power supply ON/No alarm: Green turns

on

Power supply ON/Servo OFF: Green

flashes

(b)

ALM

Alarm LED

Power supply ON/With alarm: Red flashes

Power supply ON/Parameter setting:

Red flashes

(c)

―

Cover

Protection for the change in the mode using

the mode switch (Close the cover after

changing the SW position).

(d)

―

FG

Frame ground (Tighten the bolt with the nut

when mounting the controller. Connect the

grounding cable.)

(e)

―

Mode switch

Changes the mode (Manual mode <-> Auto

mode)

(f)

―

7-segment

LED

Displays the stop position, value set using

the position switch (h), and alarm

information.

(g)

SET

Set button

Determines the settings and gives a

command to operate in manual mode.

(h)

―

Position

switch

Assigns the position to drive (1 to 14) and

the origin (15)

(i)

MANU

AL

Forward

button

Performs forward jog and inching.

(j)

Reverse

button

Performs reverse jog and inching.

(k)

SPEED

Forward

speed

switch

16 forward speeds are available. *1)

(l)

Reverse

speed

switch

16 reverse speeds are available *1)

(m)

ACCEL

Forward

acceleration

switch

16 forward acceleration steps are available.

*1)

(n)

Reverse

acceleration

switch

16 reverse acceleration steps are available.

*1)

(o)

CN1

Power supply

connector

Power supply cable is connected.

(p)

CN2

Motor driving

connector

Motor connector of the actuator cable is

connected.

(q)

CN3

Encoder

connector

Encoder connector of the actuator cable is

connected.

(r)

CN4

I/O connector

I/O cable is connected.

1) The Set value of speed and acceleration are set for back and forth directions.

The set value will be reflected in the operation of all position numbers.

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(i)

(j)

(m)

(h)

(k)

(l)

(n)

(r)

(q)

(p)

(o)

- 13 -

Caution

Use a flat blade watchmaker's screwdriver of the size shown below when changing position

switch (h) and the set value of the speed/acceleration switches (k) to(n).

<Size>

End width L:2.0 to 2.4 [mm]

End thickness W:0.5 to 0.6 [mm]

Magnified view of the end of the flat blade screwdriver

3.3 Outer dimensions

The appearance of the product is shown below.

L

W

For body mounting

For body

mounting

When DIN rail is locked

Detached from DIN rail

(2) DIN rail mounting

(LECP1□□D-□)

(1) Mounting screw

(LECP1□□-□)

- 14 -

3.4 Mounting

(1) Mounting

Controller mounting methods are shown below.

(2) Connection to ground

Tighten the bolt with the nut when mounting the ground cable as shown below.

Caution

● M4 screws, cable with crimping terminal and serrated washer are prepared by customer.

● Ground the controller to reduce noise.

● Controller attaching hole (Installation position of grounding cable) and SG (Signal ground) are

connected in the controller. Please do not ground the controller when using it in the plus earth

environment.

(1) Screw mounting (LECP1□□-□)

(Mounting with two M4 screws)

Mounting

direction

Mounting

direction

Grounding cable

Controller

M4 screw

Cable with crimping terminal

Serrated washer

DIN rail

Hook the controller on the DIN rail

and press the lever of section A in

the arrow direction to lock it.

A

(2) DIN rail mounting (LECP1□□D-□)

Grounding cable

Grounding cable

- 15 -

Caution

(1) A dedicated Ground connection must be used. Use a D-class ground connection

(ground with a resistance of less than 100Ω).

(2) The cross sectional area of the grounding cable shall be 2mm2or more.

Grounding location shall be in the vicinity of the controller. Keep the grounding cable short.

(3) The controller case mounting part is connected to 0V of the power supply.

(3) Location for mounting

Select the size and the installation style so that the surrounding temperature of the controller is 40oC or less.

Mount the controller vertically on the wall as shown. Leave a minimum of 30 mm of clearance at the top of the

controller or 60 mm below the controller so that the cables can be connected and disconnected.

Keep 60mm or more between the front of the controller and the cover (lid) so that buttons and switches can be

operated.

Keep enough space around the controller so that the operating temperature of the controller stays within the

specification range.

Avoid mounting the controller near a vibration source, such as a large electromagnetic contactor or circuit fuse

breaker on the same panel.

Caution

When there are dents, bumps or warping on the mounting surface of the controller, excessive

force can be applied to the case, which can cause failure. Mount on a flat surface.

0 mm or more: Body size 16 or less Only the LEH series apply to all size

10 mm or more: Body size 25 or more

30 mm or more

60 mm or more

60 mm or more

Controller

Shared grounding --- Not acceptable

Controller

Other

equipment

Dedicated grounding --- Good

Controller

Other

equipment

Ground with

the resistance

less than 100

ohm

Door (Lid)

Controller

- 16 -

4. External connection

4. 1 CN1: Power supply connector

Examples of standard wiring are shown for each connector (CN1 to CN4) of the controller.

Refer to 5. CN1: Power supply cable for wiring.

Caution

Do not use inrush current suppressor type as the power supply for the controller input.

4. 2 CN2: Motor power connector, CN3: Encoder connector

Connect the controller and the actuator with the actuator cable (LE-CP-□-□or LE-CP-□-□-S).

4. 3 CN4: Parallel I/O connector

* Refer to 6.4 Parallel I/O connector wiring (Example) for wiring.

* Refer to 6.3 Parallel input / output signal for the details of parallel input / output signals.

Controller

Actuator cable

CN2

CN3

Actuator

Motor

Controller

CN1

Controller input

power supply 24VDC

(Controller input power supply of 24VDC is prepared by

customer.)

Power supply cable

Controller

CN4

PLC etc.

(PLC is prepared by customer)

I/O cable

- 17 -

Controller

input power

supply

Controller

5. CN1: Power supply cable

5. 1 Power supply cable specification

Included power supply cable specification is shown below.

Item

Specifications

Connector

Manufacturer: J.S.T. Mfg. Co.,Ltd.

Product number :VHR-4N

Cross sectional

area of the cable

AWG20

Length (L)

LEC-CK1-1:1.5m only

5. 2 Wiring of power supply cable

Referring to (1) to (4), connect the power supply cable included in accessories to the controller input

power supply 24VDC and insert it to the controller CN1 power supply connector.

(1) Wiring of power supply

Connect the positive side (+) of the controller input power supply 24VDC to the C24V and M24V

terminals of the power supply cable, and connect the negative side (-) to the 0V terminal.

Caution

Do not use the power supply of "inrush current prevention type" for the controller power supply

(24VDC).

Terminal

Color of

covered wire

Function

Functional explanation

0V

Blue

Common power supply (-)

Negative common power for M24V, C24V, and BK

RLS.

M24V

White

Power supply of motor (+)

Positive power for the motor to be supplied via the

controller.

C24V

Brown

Control power (+)

Positive control power to be supplied to the

controller.

BK RLS

Black

Unlocking (+)

Positive power for lock release. Connected to the

M24V in the controller internal circuit.)

Power supply cable (LEC-CK1-1)

6.0)

(L)

(60)

(35)

(13.3)

(10.5)

(15.8)

24V

0V

0V

M24V

C24V

BK RLS

- 18 -

Controller

input power

supply

(2) Wiring of forced unlocking switch

When manual unlock is required for adjustment or reset of the actuator with lock, please install a switch. *

The switch (24V DC, contact capacity: 0.5A or more) needs to be prepared by the user.

One side of the switch should be connected to the positive side of the controller input power supply 24V DC,

and the other side should be connected to the BK RLS terminal of the power supply plug. When the switch

is closed, the controller/motor is forcibly unlocked.

Caution

For the actuator without lock, please do not connect the BK RLS terminal.

The only case where 24V DC can be applied to the BK RLS terminal is as described below, 24V DC

should not be applied in other cases.

- STOP command(CN4 14pin STOP)is turned ON and Servo is turned OFF.

- When the control power supply(C24V)is shut off.

(3) Stop the power supply for the motor

If it is necessary to shut off the power supply for the motor from outside, connect the relay between the

input power supply for the controller 24VDC and the power supply plug for the controller M24V.

(Refer to the wiring diagram in the next page.)

The motor power supply should be shut off after the STOP command(CN4 14pin STOP)is turned ON.

Refer to 6.3 Parallel input signals for the STOP command.

Warning

-Do not perform return to origin when the the motor drive power (M24V) is disconnected. The

controller cannot recognize the correct origin point if a return to origin instruction is made with the

motor drive power (M24V) disconnected.

- If the M24V is shut off during actuator operation, there will be an additional delay experienced

before it stops (the stop distance will be extended) due to inertia of work pieces or regenerated

energy. When the M24V is tutned off, and the the STOP command is turned ON(CN4 14pin

STOP)simultaneously the the time to stop can be shortened.

- If the motor drive power is shut off during vertical stop, the table may drop due to brake response.

- BK RLS is internally connected to the M24V in the controller, so please do not apply 24V DC to the

BK RLS terminal when the M24V is shut off.

Switch for forced

unlocking

Controller

0V

M24V

C24V

BK

RLS

24V

0V

- 19 -

Controller

input power

supply

Controller

input power

supply

Controller

input power

supply

1st product

【Example of the circuit】*The figure below shows the stopped state.

24VDC

Ry

0V

STOP

switch

Surge suppressor

Reset switch for stop

Ry

Ry

Controller

0V

M24V

C24V

BK RLS

24V

0V

Ry

Controller

24V

0V

Ry

Controller

24V

0V

3rd product

0V

M24V

C24V

BK RLS

2nd product

0V

M24V

C24V

BK RLS

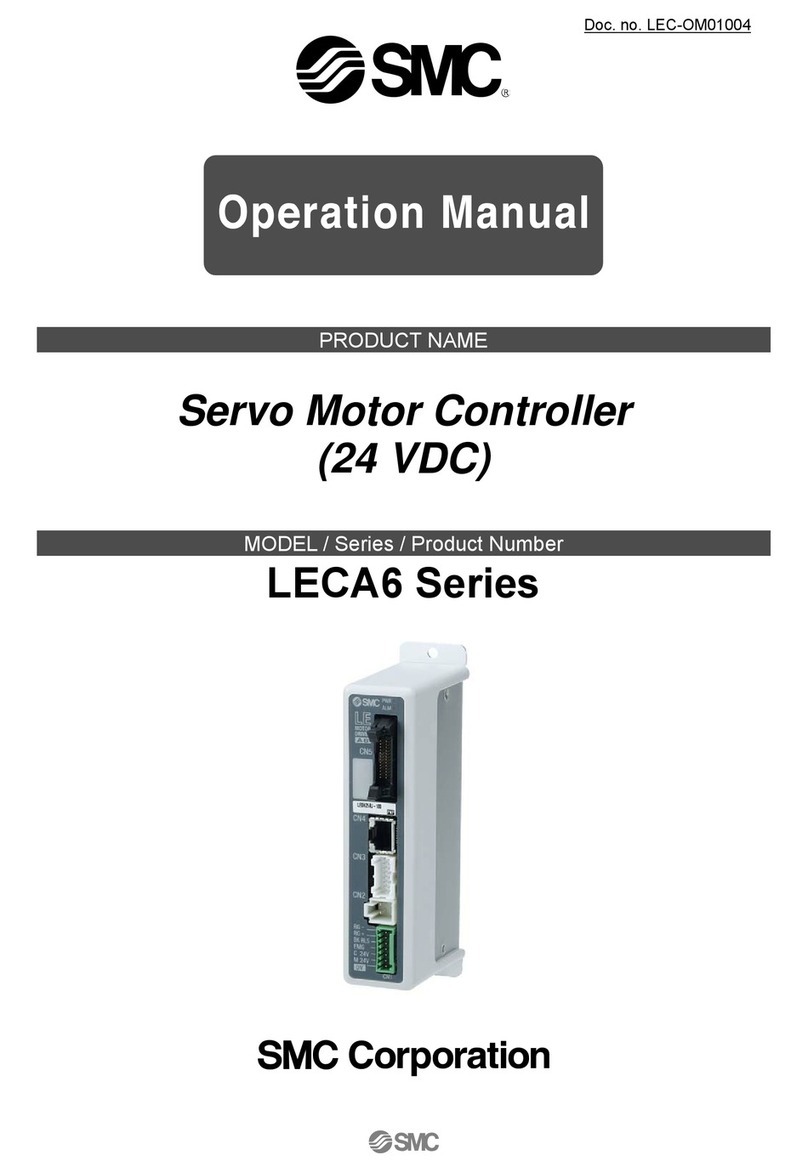

Other manuals for LECP1 series

2

Table of contents

Other SMC Corporation Controllers manuals

SMC Corporation

SMC Corporation LECP1 series User manual

SMC Corporation

SMC Corporation LECP6 Series User manual

SMC Corporation

SMC Corporation LECP1 series User manual

SMC Corporation

SMC Corporation LECA6 Series User manual

SMC Corporation

SMC Corporation LECSB User manual

SMC Corporation

SMC Corporation LEF Series User manual

SMC Corporation

SMC Corporation LEC-BCW Series User manual