LEC#-TF2Z362EN

Page 1 of 2

Instruction Manual

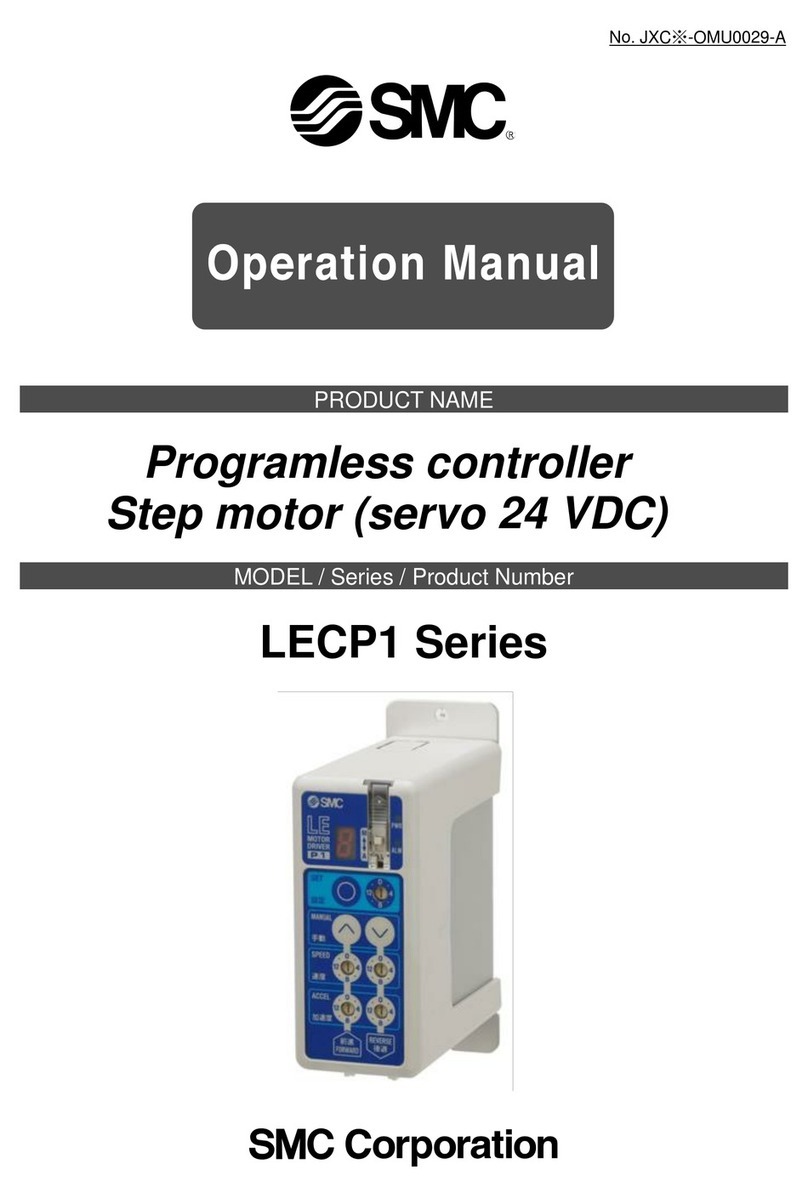

Programless Controller

Step motor (24 VDC)

Series LECP1 / LECP2

The intended use of the programless controller is to control the

movement of an electrical actuator in response to step data / inputs.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)

*1)

, and other safety regulations.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Robots and robotic devices - Safety requirements for

industrial robots - Part 1: Robots.

•Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

•Keep this manual in a safe place for future reference.

Caution

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

•Always ensure compliance with relevant safety laws and

standards.

•All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

2 Specifications

2.1 General specifications

Refer to actuator specifications

Stop

points

LECP2 Stroke ends 2 points (Position 1 and 2).

Compatible encoder Incremental A/B phase

Cable length I/O cable: 5 m maximum

Operating

0

o

C to 40

o

C (no freezing)

o

o

Insulation resistance 50 MΩ(500 VDC)

etween external terminals and case

Weight 130 g (Direct mounting type)

0 g (DIN rail mounting type)

2 Specifications (continued)

Warning

Special products (-X) might have specifications different from those

shown in this section. Contact SMC for specific drawings.

3 Name and function of individual parts

4 Installation

4.1 Installation

Warning

•Do not install the product unless the safety instructions have been read

and understood.

•Design the installation so that the temperature surrounding the

controller is within the specified operating temperature. Leave enough

space between the controllers so that the operating temperature of the

controllers remains within the specification range.

•Mount the controller vertically with 30 mm minimum space at the top

and 60 mm minimum at the bottom of the controller as shown below.

•Allow 60 mm minimum space between the front of the controller and a

door (lid) so that the connectors can be connected and disconnected.

4.2 Mounting

•The controller can be direct mounted using M4 screws (LECP1** /

LECP2**) or mounted on a DIN rail (model LECP1**D / LECP2**D).

•When using DIN rail mounting, hook the controller on the DIN rail and

press the lever in the direction of the arrow to lock it.

Direct mounting DIN rail mounting

Caution

If the mounting surface for the controller is not flat or is uneven, excessive

stress may be applied to the enclosure, which can cause failure. Be sure

to mount on a flat surface.

4 Installation (continued)

4.3 Environment

Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•Do not use in an explosive atmosphere.

•Do not expose to direct sunlight. Use a suitable protective cover.

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

•Do not mount in a location exposed to radiant heat that would result in

temperatures in excess of the product’s specifications.

•Avoid mounting the controller near a vibration source, such as a large

electromagnetic contactor or circuit breaker on the same panel.

•Do not use in an environment with strong magnetic fields present.

5 Wiring

5.1 Wiring

Caution

•Do not perform wiring while the power is on.

•Confirm proper insulation of wiring.

•Do not route wires and cables together with power or high voltage

cables.

•Keep wiring as short as possible to prevent interference from

electromagnetic noise and surge voltage.

•Do not use an inrush current limited type of power supply for the

controller.

•Do not connect multiple wires to one connector terminal.

5.2 Power Supply Connector

The power supply cable with connector (LEC-CK1-1) is supplied with the

controller. Plug the connector into CN1 on the controller.

Pin

Terminal Function Description

1 0V

Common power (-)

Negative common

power for M24V,

2 M24V

Motor power (+)

Positive power for the

actuator motor to be

supplied via the

3 C24V

Control power (+)

Positive control

4 BK RLS

Unlocking (+)

Positive power for lock

5.2.1 Cable / Connector specifications

Connector Manufacturer : J.S.T. Mfg. Co. Ltd.

10 mm minimum (actuator size 25 mm or more)

Controller

60 mm minimum

30 mm minimum

PWR LED (Green) LED is ON: Power ON / Servo ON

2 ALM LED (Red) LED is ON: Power ON / with Alarm

Mode switch protection cover.

4 FG

Functional Ground

(When mounting the controller, tighten

Switch to select auto / manual.

6 7 segment LED

display

Auto mode / Without alarm:

Indicates the position number which is

instructed by ON/OFF of IN0 to IN3 of

the CN4 parallel I/O.

(During command operation: Flashing /

Instruction command completed: ON)

Auto mode / With alarm:

Indicates Alarm Group.

Manual mode: Indicates that content

may vary depending on the operating

7 SET button Determines the settings and gives a

command to operate in manual mode.

9 MANUAL Forward

Performs forward Jog and inching.

10 MANUAL Reverse

Performs reverse Jog and inching.

11 SPEED Forward

16 forward speeds are available.

12 SPEED Reverse

16 reverse speeds are available.

13 ACCEL Forward

16 forward acceleration steps are

14 ACCEL Reverse

16 reverse acceleration steps are

15 CN1 power

Connection for power supply.

16 CN2 Motor drive

Connect motor connector of actuator.

17 CN3 Encode

Connect encoder connector of actuator.

18 CN4 I/O connector

Connection for I/O cable.

Screw

direction

Screw

direction