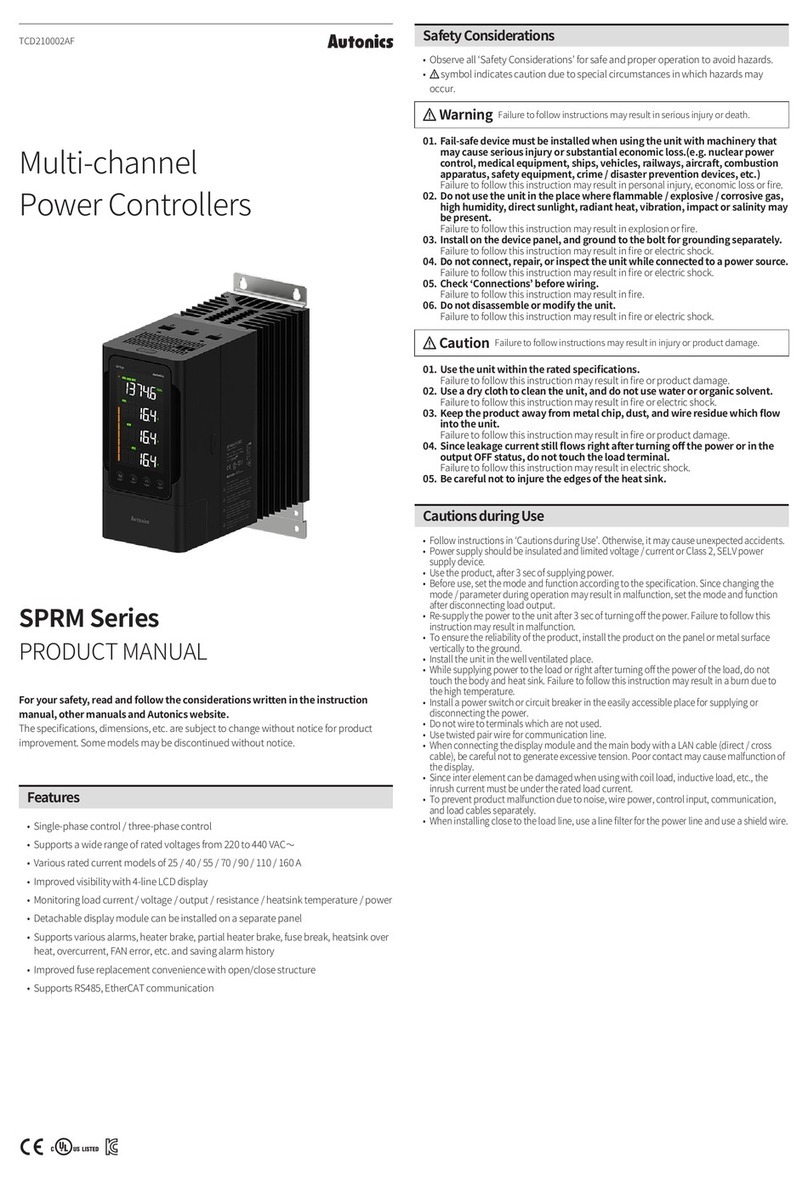

SENSOR CONTROLLER

PA10 SERIES

Thank you for choosing our Autonics product.

Please read the following safety considerations before use.

1. Fail-safe device must be installed when using the unit with machinery that may cause serious injury or

substantial economic loss. (e.g. nuclear power control, medical equipment, ships, vehicles, railways, aircraft,

combustion apparatus, safety equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in re, personal injury, or economic loss.

2. Install on a device panel or DIN rail to use.

Failure to follow this instruction may result in electric shock or re.

3. Do not connect, repair, or inspect the unit while connected to a power source.

Failure to follow this instruction may result in electric shock or re.

4. Check 'Connections' before wiring.

Failure to follow this instruction may result in re.

5. Do not disassemble or modify the unit.

Failure to follow this instruction may result in electric shock or re.

1. When connecting the power/sensor input and relay output, use AWG 24 (0.20mm2) to AWG 15 (1.65mm2)

cable or over and tighten the terminal screw with a tightening torque of 0.98 to1.18N.m.

Use proper cables for the rated load current.

Failure to follow this instruction may result in re or malfunction due to contact failure.

2. Use the unit within the rated specications.

Failure to follow this instruction may result in re or product damage.

3. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in electric shock or re.

4. Do not use the unit in the place where ammable/explosive/corrosive gas, humidity, direct sunlight, radiant

heat, vibration, impact, or salinity may be present.

Failure to follow this instruction may result in re or explosion.

5. Keep metal chip, dust, and wire residue from owing into the unit.

Failure to follow this instruction may result in re or product damage.

Warning

Caution

▣Ordering Information

▣Input Connections

●PA10-V/PA10-W ●PA10-VP/PA10-WP

NPN open

collector type &

NPN universal

output type sensor

PNP open

collector type &

PNP universal

output type sensor

●PA10-U

NPN open

collector

output

type sensor

Sensor

controller

Sensor

controller

Sensor

controller

+12V

5.6㏀

9.4㏀

5.4㏀

1.8㏀

Main circuit

Main circuit

+12V

IN1, IN2 IN1, IN2

(

(

+12V ⑨, ⑬

⑪IN1

⑮IN2

⑩

⑭

IN1, IN2

0V 0V 0V

▣ Specications

Model PA10-U PA10-V PA10-VP PA10-W PA10-WP

Power supply 100-240VACᜠ50/60Hz

Allowable voltage range

90 to 110% of rated voltage

Power consumption

Max. 10VA (condotion:12VDC/200mA resistive load)

Power for external

sensor 12VDCᜡ ±10% approx. 200mA

Input(IN1, IN2)

Selectable NORM/INV.

Selectable OR/AND

operation for IN1, IN2

input. Selection function

for IN2 derivative action.

Selectable NORM/INV.

Operation for IN1, IN2 AND.

Selectable NORM/INV.

Selection function for

IN1, IN2 individual operation.

NPN input type

NPN input type PNP input type NPN input type PNP input type

Input method

●PA10-U

[No-voltage input] Impedance at short-circuit: Max. 680Ω, Residual voltage at short-

circuit: Max. 0.8V, Impedance at open: Min. 100kΩ

●PA10-V/PA10-W

[No-voltage input] Impedance at short-circuit: Max. 300Ω, Residual voltage at short-

circuit: Max. 2V, Impedance at open: Min. 100kΩ

●PA10-VP/PA10-WP

[Voltage input]

Input impedance: 5.6kΩ, "H" level voltage: 5-30VDCᜡ, "L" level voltage: 0-2VDC

Out-

put

Contact output OUT[250VACᜠ 3A(Resistive load)]

OUT1, OUT2 [250VACᜠ 3A(Resistive load)]

Solid-state

output

OᆞC OUT1, OᆞC OUT2

OᆞC OUT

-

NPN open collector output Max. 30VDCᜡ Max. 100mA

Response time Relay output : Max. 10ms, Transistor output : Max. 0.05ms

Time setting

function by

each mode

※Only for

PA10-U

Have

● ON-DELAY MODE

● ONE-SHOT DELAY MODE

● FLICKER ONE-SHOT MODE

● HIGH-SPEED DETECTION MODE

Non ● NORMAL MODE ● FLIP-FLOP MODE ● ENCODER(MODE 9 to 11)

Relay

life

cycle

Mechanical Min.10,000,000 times

Electrical Min.100,000 times(250VAC 3A resistive load)

Dielectric strength 2000VAC 50/60Hz for 1 minute

Insulation resistance Over 100MΩ(at 500VDC megger)

Envi-

ron

ment

Ambient

temperature -10 to 55℃[Storage: -25 to 60℃]

Ambient

humidity 35 to 85%RH [Storage: 35 to 85%RH]

Unit weight Approx. 150g Approx. 160g

▣Dimensions and Installation Interval

※If the load is connected over 200mA at the sensor output, it may cause mechanical trouble.

※Environment resistance is rated at no freezing or condensation.

▣Connections

●PA10-U ●PA10-V/PA10-VP ●PA10-W/PA10-WP

~

INV

MADE IN KOREA

NORM

NORM

OUT

IN 1

IN 2

POWER

INV

+12V

PA10-V

GND

CONTACT OUT:

250VAC 3A

RESISTIVE LOAD

!

SOURCE

100-240VAC

50/60Hz NC

IN2

COM

+12V GND IN1 OᆞC

OUT

NO

8

16

4

7

15

3

6

14

2

1211109

5

13

1

~

SA

INV

INV

AND

SB

SC

SD

T1

T2

O

N

O

N

NORM

OR

M

O

D

E

O

F

F

O

F

F

TIME

A

D

J

MADE IN KOREA

NORM

NORM

OUT2

OUT1

IN 1

IN 2

POWER

+12V

PA10-U

GND

!

SOURCE

100-240VAC

50/60Hz

CONTACT OUT:

250VAC 3A

RESISTIVE LOAD

Brown

Brown Brown Brown

Brown

Brown

Blue

Blue Blue Blue

Blue

Blue

Black

Black Black Black

BlackBlack

NC

IN2

COM

+12V GND IN1 OᆞC

OUT1

OᆞC

OUT2

NO

8

16

4

7

15

3

6

14

2

1211109

5

13

1

~

INV

MADE IN KOREA

NORM

NORM

OUT1

IN 1

IN 2

POWER

INV

OUT2

+12V

PA10-W

GND

CONTACT OUT1,OUT2:

250VAC 3A

RESISTIVE LOAD

OUT1

OUT2

!

SOURCE

100-240VAC

50/60Hz NC1

NC2

+12V GND IN1

IN2

COM1

COM2

NO1

NO2

8

16

4

7

15

3

6

14

2

1211109

5

13

1

▣ Front Panel Indentication

●PA10-U

●PA10-V/PA10-VP ●PA10-W/PA10-WP

Timer volume: Adjust time within the range which is set with

9

.

Terminal block

Power indicator : LED turns on when AC power applied

Output indicator 1 : Indication of output 1 operation status

Output indicator 2 : Indication of output 2 operation status

Sensor input indicator : lndication of sensor input signal

(LED turns on when sensor input is Low)

AND/OR selection switch : Select "AND" or "OR" for IN1, IN2 Input

Selection switch of sensor input signal

: (Input signal reverse turn function)

● NORM : When input signal is low, it is valid signal. ( )

● INV : When input signal is high, it is valid signal. ( )

Derivative action selection of IN2 input signal (AND/OR selection switch: AND)

: (When input signal is high( ), it is effective signal)

● NORM : IN2 input signal is operating as reverse turn function

●

:

Derivative action of IN2 input signal. ※See "▣ Derivation action applications"

Selection switch for operation mode: See "▣ Operation mode" in next page.

Selection switch of time range and max. input frequency: It is the switch

to select time range(1 to 7 mode) or allowable input frequency(9 to 11 mode).

INV

NORM

● Time range: Approx. 0.01 to 0.1sec, Max. input frequency: 100kHz

● Time range: Approx. 0.1 to 1sec, Max. input frequency: 10kHz

● Time range: Approx. 0.1 to 10sec, Max. input frequency: 1kHz

● Time range: Approx. 10 to 100sec, Max. input frequency: 100Hz

T1

T2

O

N

O

F

F

T1

T2

O

N

O

F

F

T2

T1

O

N

O

F

F

T1

T2

O

N

O

F

F

NORM

1

2

3

4

0

!

5

6

7

8

9

PA10-U

IN 1

OUT 1 OUT 2

IN 2

POWER

MADE IN KOREA

9

5

13

1

10

6

14

2

11

7

15

3

12

8

16

4

SA

INV

AND

SB

SC

SD

T1

T2

O

N

O

N

NORM

OR

NORM

M

O

D

E

O

F

F

O

F

F

A

D

J

NORM

INV

+12V

+12V

NC COM NO

GND

GND

IN 1

IN 2

OᆞC

OUT1

OᆞC

OUT2

1

2

3

4

0

!

5

6

7

8

9

▣Derivative Action Applications

◎ Detect label of glass bottle

Brown

Brown

Blue

Blue

Black

Black

~

SA

INV

INV

AND

SB

SC

SD

T1

T2

O

N

O

N

NORM

NORM

NORM

M

O

D

E

O

F

F

OUT2

O

F

F

A

D

J

OUT1

PA10-U

IN 1

IN 2

POWER

MADE IN KOREA

OR

TIME

Output((OUT)

OᆞC

OUT2

OᆞC

OUT1

IN1

(Sensor for detecting

the target)

BEN300-DDT

BEN300-DDT

IN2

(Sensor for

synchroni-

zation)

!

SOURCE

100-240VAC

50/60Hz

12

8

16

4

11

7

15

3

10

6

14

2

9

5

13

1

●Operation

When IN1 is ON and IN2 is ON, OUT will not work.

But when there is no label on bottle, OUT will work when IN2 is ON. OUT will be returned after setting time.

Note)Condition of detecting label on glass bottle is to install with IN1 operating first.

IN1

(Sensor for

detecting

the target)

Derivative action

OUT (3-4)

OUT1

OᆞC OUT2

(14-16)

OᆞC OUT1

(10-12)

OUT2

IN2

(Sensor for

synchronization)

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Label No label

▣Factory Default for S/W

●PA10-U:

MODE1 ON-DELAY

●PA10-V: NORM

●PA10-VP: NORM

●PA10-W: NORM

●PA10-WP: NORM

PA10-

V

INV

INV

NORM

NORM

POWER

PA10-

W

INV

INV

NORM

NORM

POWER

OUT

IN 1

IN 2

MADE IN KOREA

SA

INV

INV

AND

SB

SC

SD

T1

T2

O

N

O

N

NORM

OR

NORM

NORM

M

O

D

E

O

F

F

OUT2

O

F

F

TIME

A

D

J

OUT1

PA10-U

IN 1

IN 2

POWER

MADE IN KOREA

NORM

OUT2OUT1

IN 1

IN 2

MADE IN KOREA

Item

Function

Input No mark NPN input

PPNP input

UHigh function controller

VController

W2 Channel controller

PA10 Multi-function power amplier

PA10 U

● OFF-DELAY MODE

● FLICKER MODE

● LOW-SPEED DETECTION MODE

● ON/OFF-DELAY MODE

1

2

3

4

5

Power indicator

: LED turns on when

AC power applied.

Output indicator

: Indication of output

signal.

Sensor input indicator

: lndication of sensor

input signal.

● PA10-V: LED turns on

when sensor input is Low

● PA10-VP: LED turns on

when sensor input is High

Selection switch of

sensor input signal

● NORM: When sensor

input signal is Low,

it is vaild signal.

● INV: When sensor input

signal is High, it is vaild

signal.

Terminal block

※When IN1, IN2 input signal is AND, OUT will work.

PA10-V

9

5

13

1

10

6

14

2

11

7

15

3

12

8

16

4

+12V

+12V

NC COM NO

GND

GND

IN 1

IN 2

OᆞC

OUT

3

NORM

OUT

IN 1

IN 2

POWER

MADE IN KOREA

NORM

INV

5

2

4

1

INV

※IN1, IN2 operates individually.

PA10-W

4

NORM

OUT1

IN 1

IN 2

POWER

MADE IN KOREA

NORM

INV

6

2

1

INV

OUT2

5

3

9

5

13

1

10

6

14

2

11

7

15

3

12

8

16

4

+12V

+12V

NC1

NC2

COM1

COM2

NO1

NO2

GND

GND

IN 1

IN 2

Power indicator

: LED turns on when AC

power applied

Output 1 indicator

: Indication of output 1

operation status.

Output 2 indicator

: Indication of output 2

operation status.

Sensor input indicator

: lndication of sensor

input signal.

● PA10-W: LED turns on

when sensor input is Low.

● PA10-WP: LED turns on

when sensor input is High.

Selection switch of

sensor input signal

● NORM: When sensor

input signal is Low,

it is vaild signal.

● INV: When sensor input

signal is High, it is vaild

signal.

Terminal block

1

2

3

4

5

6

T

Safety Considerations

※Please observe all safety considerations for safe and proper product operation to avoid hazards.

※Safety considerations are categorized as follows.

Warning Failure to follow these instructions may result in serious injury or death.

Caution Failure to follow these instructions may result in personal injury or product damage.

※The symbols used on the product and instruction manual represent the following

symbol represents caution due to special circumstances in which hazards may occur.

(Unit: mm)

38

SA

INV

INV

AND

SB

SC

SD

T1

T2

O

N

O

N

NORM

OR

NORM

NORM

M

O

D

E

O

F

F

OUT2

O

F

F

TIME

OUT1

PA10-U

IN 1

IN 2

POWER

MADE IN KOREA

A

D

J

94±0.5

Ø5

35.5

82

76

When installing multiple sensor

controllers, please keep space

between units at least 10mm for

heat radiation.

Min. 10mm

◎ Dimensions ◎ Installation interval

DRW171160AA

※The above specications are subject to change and some models may be discontinued without notice.

※Be sure to follow cautions written in the instruction manual and the technical descriptions

(catalog, homepage).

a b

ab

<Forked>

Min.

3.5mm

Max.

7.0mm

※Use teminals of size specied below.

I N S T R U C T I O N M A N U A L