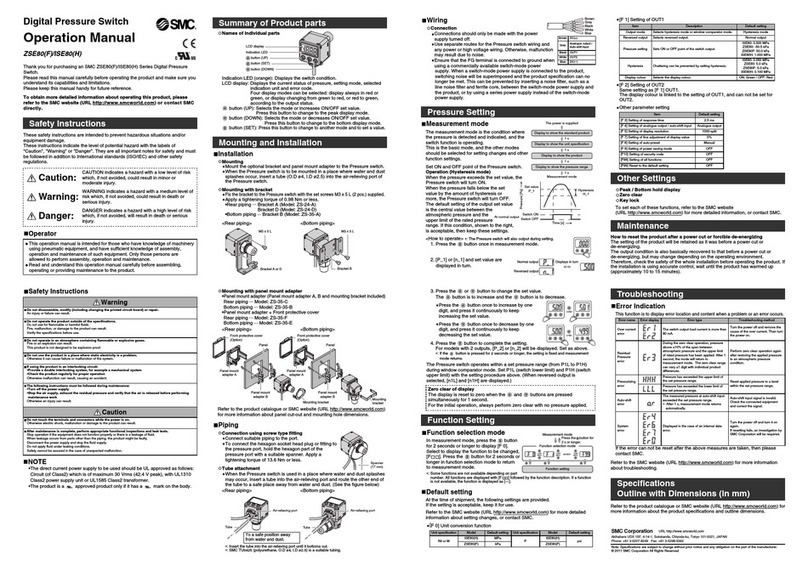

Default setting

The default setting is as follows.

If no problem is caused by this setting,

keep these settings.

Outline of Settings [Measurement mode]

Pressure Setting

●[F 0]

Display units, switch output specifications

and diagnostic information selection function

●Other parameter settings

Other Settings

Peak/ ottom value indication

The max. (min.) pressure when the power is supplied is detected and updated.

The value can be displayed on the sub display by pressing the UP or DOWN button in

measurement mode.

Snap shot function

The current pressure value can be stored to the switch output ON/OFF set point.

When the set value and hysteresis are set, press the UP and DOWN buttons for 1 sec. or

longer simultaneously. Then, the set value of the sub display (right) shows [- - -], and then

values corresponding to the current pressure values are automatically displayed.

Zero-clear function

In measurement mode, when the UP and DOWN buttons are pressed for 1 sec. or longer

simultaneously, the main display shows [- - -], and the reset to zero.

The display returns to measurement mode automatically.

Key-lock function

To set each of these functions, refer to the SMC website (UR http://www.smcworld.com)

for more detailed information, or contact SMC.

Maintenance

How to reset the product after a power cut or forci le de-energizing

The setting of the product will be retained as it was before a power cut or de-energizing.

The output condition is also basically recovered to that before a power cut or deenergizing,

but may change depending on the operating environment. Therefore, check the safety of the

whole installation before operating the product. If the installation is using accurate control,

wait until the product has warmed up (approximately 10 to 15 minutes).

Default settings

When the pressure exceeds the set

value, the switch will be turned on.

When the pressure falls below the

set value by the amount of

hysteresis or more, the switch will

be turned off.

The default setting is to turn on

the pressure switch when the

pressure reaches the center of the atmospheric pressure and upper limit of the rated

pressure range. If this condition, shown to the right, is acceptable, then keep these settings.

DOWN buttonUP button

SET button

LCD display

Operation light (OUT1)

Operation light (OUT2)

IO-Link status indicator light

3 Step Setting Mode

Function Selection Mode

Simple Setting Mode

When tightening, do not hold the upper part

of the product (Display) with a spanner.

Trou leshooting

Error indication function

This function is to display error location and content when a problem or error has occurred.

How to use connector

Align the cable connector key groove with the product connector key to insert and

rotate the knurled part of the connector.

Connect the wires of the lead wire with M12 connector as shown below.

M12 connector (Port Class A)

Power is supplied

The product code is displayed for approximately 3 sec. after power is supplied.

Then, measurement mode will be displayed.

∗: Within approximately 0.2 sec. after power-on, the switch starts.

Press the SET

button once.

Press the SET

button between

1 and 3 sec.

[3 step setting

mode]

Set either of set

value or

hysteresis.

[Simple setting

mode]

Select the set

value, hysteresis

and delay time.

[Function

selection mode]

Change the

function settings.

[Other Settings]

•Zero-clear function

•Key-lock function

∗: The outputs will continue to operate during setting.

∗: If a button operation is not performed for 30 sec. during the setting, the display will flash.

(This is to prevent the setting from remaining incomplete if, for instance, an operator were to leave

during setting.)

∗:

3 step setting mode, simple setting mode and function selection mode settings are reflected each other.

Switch ON

At normal output Switch OFF

Set value

P_1 Hysteresis

H_1

Time

Pressure

[3 step setting mode (hysteresis mode)]

In the 3 step setting mode, the set value (P_1 or n_1) and hysteresis (H_1) can be changed.

Set the items on the sub display (set value or hysteresis) with the UP or DOWN button.

When changing the set value, follow the operation below. The hysteresis setting can be

changed in the same way.

(1) Press the SET button once when the item to be

changed is displayed on the sub display. The set

value on the sub display (right) will star flashing.

(2) Press the UP or DOWN button to change the set

value.

The set value can be increased with the UP button

and can be reduced with the DOWN button. When

the UP and DOWN buttons are pressed and held

simultaneously for 1 sec. or longer, the set value is displayed as [- - -], and the set value

will be the same as the current pressure value automatically (snap shot function).

Afterwards, it is possible to adjust the value by pressing the UP or DOWN button.

(3) Press the SET button to complete the setting.

The pressure switch turns on within a set pressure range (from P1 to P1H) during window

comparator mode. Set P1 , the lower limit of the switch operation, and P1H, the upper limit

of the switch operation and WH1 (hysteresis) following the instructions given above.

(When reversed output is selected, the sub display (left) shows [n1 ] and [n1H].)

∗: Set OUT2 in the same way. (ex. P_2, H_2)

∗: Setting of the normal/reverse output switching and hysteresis/window comparator mode switching are

performed with the function selection mode [F 1] OUT1 setting and [F 2] OUT2 setting.

(1) Press and hold the SET button between 1 and 3 sec. in measurement

mode. [SEt] is displayed on the main display. When the button is released

while in the [SEt] display, the current pressure value is displayed on the

main display, [P_1] or [n_1] is displayed on the sub display (left), and the

set value is displayed on the sub display (right) (Flashing).

(2) Change the set value with the UP or DOWN button, and press the SET

button to set the value. Then, the setting moves to hysteresis setting.

(The snap shot function can be used.)

(3) Change the set value with the UP or DOWN button, and press the SET button to set the

value. Then, the setting moves to the delay time of the switch output.

(The snap shot function can be used.)

(4) Press the UP or DOWN button, the delay time of the switch output can be selected.

Delay time setting can prevent the output from chattering.

The delay time can be set in the range 0.00 to 60.00 sec. in 0.01 sec. increments.

(5) Press the SET button for less than 2 seconds to complete the OUT1 setting.

[P_2] or [n_2] is displayed on the sub screen (left). Continue with setting the OUT2.

Press and hold the SET button for 2 seconds or longer to complete the setting.

The product will return to measurement mode.

In the window comparator mode, set P1 , the lower limit of the switch operation, and P1H,

the upper limit of the switch operation, WH1 (hysteresis) and dt1 (delay time) following the

instructions given above.

(When reversed output is selected, the sub display (left) shows [n1 ] and [n1H].)

∗: Set OUT2 in the same way.

Function selection mode

In measurement mode, press the SET

button between 3 and 5 sec., to display

[F 0]. Select to display the function to

be changed [F□□]. Press and hold the

SET button for 2 sec. or longer in

function selection mode to return to

measurement mode.

∗:

Some products do not have all the functions.

If no function is available or selected due

to configuration of other functions, [- - -] is

displayed on the sub display (right).

If the product is to be used with changed settings, refer to the SMC website

(UR http://www.smcworld.com) for more detailed information, or contact SMC.

•The upper part (display) of the product can be

rotated by 336°.

Rotating the display with excessive force will damage

the end stopper.

Item Default setting

Unit specification ["Nil" or M]:

MPa

PNP

A

Display unit

Switch output

specifications

Item Default setting

[F 3] Digital filter setting 0.00 ms

[F 4] Auto-preset function OFF

0.0%[F 6]

Fine adjustment of display value

std (Standard)[F10] Sub display setting

1000-split[F11]

Display resolution setting

0.0[F14] Zero cut-off setting

Item Default setting

[F80] Power saving mode OFF

[F81] Security code OFF

[F90] Setting of all functions OFF

-[F96]

Number of pressurizing errors

N/A (normal output)

[F98] Output check

OFF[F99]

Reset to default settings

Press the SET button

between 3 and 5 seconds.

Measurement mode

Function selection mode

F0 Function

setting F1 Function

setting F99 Function

setting

Item

Output mode

Reversed output

Pressure setting

Default setting

Hysteresis

Hysteresis mode

ISE70(G): 0.500 MPa/ISE71: 0.800 MPa/

ISE75G: 1.000 MPa/ISE76G: 2.50 MPa/

ISE77G: 5.00 MPa

Normal output

ISE70(G): 0.050 MPa/ISE71: 0.080 MPa/

ISE75G: 0.100 MPa/ISE76G: 0.25 MPa/

ISE77G: 0.50 MPa

Delay time 0.00 sec.

●[F 1] Setting of OUT1

Display colour

Output ON: Green Output OFF: Red

( inked to OUT1)

●[F 2] Setting of OUT2

Same setting as [F 1] OUT1.

The switch output load current is

80 mA or more.

Turn the power off and remove

the cause of the over current.

Then supply the power again.

Over

current

error

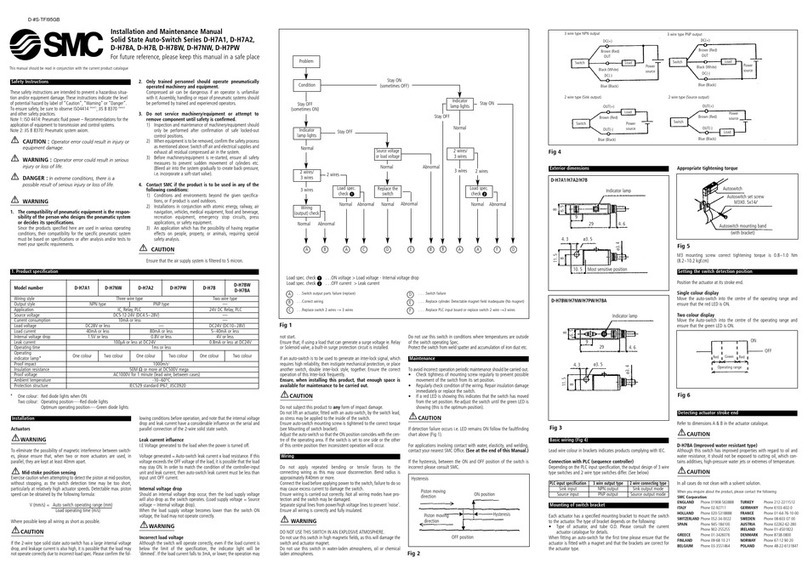

Error Error displayed Description Measures

Residual

pressure

error

Pressurizing

error

Version

does not

match

During zero clear operation, pressure

greater than ±7%F.S. is present. Note that

the mode is returned to measurement

mode automatically 1 sec. later. The zero

clear range varies by ±1%F.S. due to

variation between individual products.

Release the applied pressure

to atmospheric pressure, and

retry the zero clear operation.

Pressure exceeding the upper limit of

the set pressure range is applied.

Displayed if an internal data error has

occurred.

Reset applied pressure to a

level within the set pressure

range.

Turn the power off and on

again.

If the failure cannot be solved,

contact SMC.

Pressure exceeding the lower limit of

the set pressure range is applied.

,

,

,

System

error

IO- ink Master and product version

are not matched.

Mismatch because master version is 1.0.

Align the master IO- ink

version to the device.

,

No. Name

1 +

2 DO

-3

C/Q4

Function

18 to 30 VDC

Switch output 2

0 V

Communication data (IO- ink)/

Switch output 1 (SIO)

ead wire colour

Brown

White

Blue

Black

[Measurement mode]

Detects the pressure after power is supplied, and indicates the display and switch

operating status. This is the basic mode; other modes should be selected for set-point

changes and other function settings.

Current pressure value (Main display)

Set value or peak/bottom value

(Sub display (right))

Item (Sub display (left))

Sub display

In measurement mode, the sub display can be temporarily changed by pressing the UP

or DOWN buttons.

OUT1

set value

OUT2

set value

OUT2

hysteresis

OUT1

hysteresis

Peak

value

Bottom

value

∗: Arbitrary

display

Mode

display

∗: One arbitrary display mode can be added to the sub display by setting the [F10] sub display.

If the sub display is switched during the arbitrary display setting, the display will be returned to

the arbitrary display 30 sec. later. (The default setting does not include arbitrary display.)

Measurement mode screen

Press the SET

button between

3 and 5 sec.

Diagnostic

information

Before Use

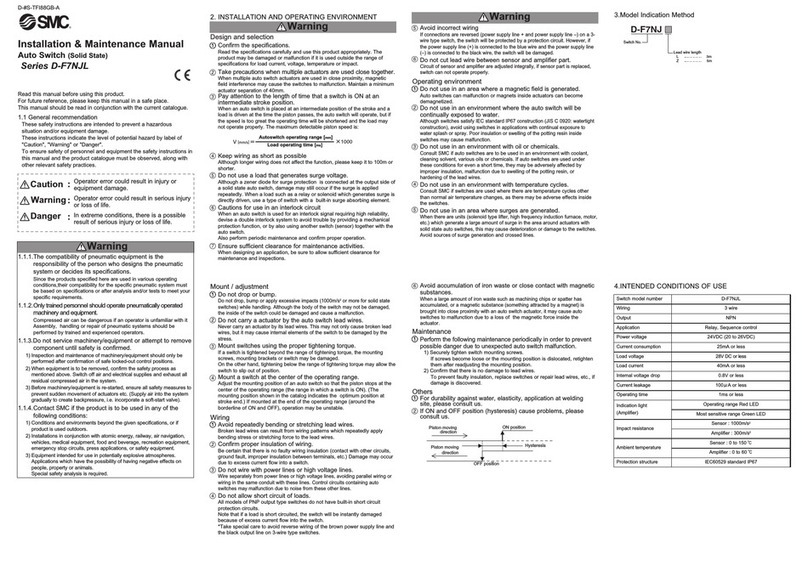

High-precision Digital Pressure Switch

ISE70/ISE71/

ISE70G/ISE75G/ISE76G/ISE77G

Thank you for purchasing an SMC ISE70/ISE71/ISE70G/ISE75G/ISE76G/ISE77G

Series High-precision Digital Pressure Switch.

Please read this manual carefully before operating the product and make sure you

understand its capabilities and limitations. Please keep this manual handy for

future reference.

To obtain the operation manual about this product and

control unit, please refer to the SMC website

(UR http://www.smcworld.com) or contact SMC directly.

Safety Instructions

CAUTION indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Caution:

Warning:

Danger:

WARNING indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

DANGER indicates a hazard with a high level of risk which,

if not avoided, will result in death or serious injury.

These safety instructions are intended to prevent hazardous situations and/or

equipment damage.

These instructions indicate the level of potential hazard with the labels of

"Caution", "Warning" or "Danger". They are all important notes for safety and must

be followed in addition to International standards (ISO/IEC) and other safety

regulations.

Operator

The operation manual is intended for those who have knowledge of machinery

using pneumatic equipment, and have sufficient knowledge of assembly,

operation and maintenance of such equipment. Only those persons are

allowed to perform assembly, operation and maintenance.

Read and understand the operation manual carefully before assembling,

operating or providing maintenance to the product.

Safety Instructions

Do not disassem le, modify (including changing the printed circuit oard) or repair.

An injury or failure can result.

Do not operate in an atmosphere containing flamma le or explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

Do not use the product in a place where static electricity is a pro lem.

Otherwise it can cause failure or malfunction of the system.

If using the product in an interlocking circuit:

•Provide a dou le interlocking system, for example a mechanical system

•Check the product regularly for proper operation

Otherwise malfunction can result, causing an accident.

The following instructions must e followed during maintenance:

•Turn off the power supply

•Stop the air supply, exhaust the residual pressure and verify that the air is released efore performing

maintenance work

Otherwise an injury can result.

After maintenance is complete, perform appropriate functional inspections and leak tests.

Stop operation if the equipment does not function properly or there is a leakage of fluid.

When leakage occurs from parts other than the piping, the product might be faulty.

Disconnect the power supply and stop the fluid supply.

Do not apply fluid under leaking conditions.

Safety cannot be assured in the case of unexpected malfunction.

Do not touch the terminals and connectors while the power is on.

Otherwise electric shock, malfunction or damage to the product can result.

Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

Warning

Caution

Summary of Product parts

Names of individual parts

Mounting and Installation

Piping

Piping specification: -02 and -N02

After hand tightening, tighten the fitting using

a spanner on the flat surfaces of the fitting.

The tightening torque must be 8 to 12 Nm.

Piping specification: -F02

After hand tightening, tighten the fitting using

a spanner on the flat surfaces of the fitting.

The tightening torque must be 4 to 5 Nm.

336° rotation

Wiring

Connections should be made with the power supply turned off.

Use a separate route for the product wiring and any power or high voltage wiring.

Otherwise, malfunction may result due to noise.

If a commercially available switching power supply is used, be sure to ground the frame

ground (FG) terminal. If the switching power supply is connected, switching noise will

be superimposed and it will not be able to meet the product specifications.

In that case, insert a noise filter such as a line noise filter/ferrite between the switching

power supplies or change the switching power supply to the series power supply.

Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

© 2017 SMC Corporation All Rights Reserved

Akihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN

Phone: +81 3-5207-8249 Fax: +81 3-5298-5362

URL http://www.smcworld.com

PS※※-OMV0002-B

Specifications/Outline with Dimensions (in

mm)

Refer to the product catalog or SMC website (UR http://www.smcworld.com) for more

information about the product specifications and outline dimensions.

If the error cannot be reset after the above measures are taken, or errors other than above

are displayed, please contact SMC.

Refer to the SMC website (UR http://www.smcworld.com) for more information about

troubleshooting.

NOTE

•The direct current power supply to be used should be U approved as follows:

Circuit (of Class 2) which is of maximum 30 Vrms (42.4 V peak), with U 1310

Class 2 power supply unit or U 1585 Class 2 transformer.

•The product is a U approved product only if it has a mark on the body.

Installation

Mounting with racket

Mount the bracket to the body with mounting screws (Cross recessed round head

screw: Nominal size M4 x 6 (2 pcs)), then set the body to the specified position.

∗: Tighten the bracket mounting screws to a torque of 0.76±0.1 Nm.

Cross recessed

round head screw:

Nominal size M4 x 6L

Bracket A

Cross recessed

round head screw:

Nominal size M4 x 6L

Bracket B

•Bracket A (Part No.: ZS-50-A) •Bracket B (Part No.: ZS-50-B)

Mounting with orifice

∗: Tighten the orifice to a torque of 1.5±0.1 Nm.

∗: ISE70G/ISE75G/ISE76G/ISE77G can be mounted.

•Orifice (Part No.: ZS-48-A)

Spanner

Upper part

of the product

(Display)

Fitting

(width across flats: 24 mm)