Piping Operating Environment

Series AMP

Air Cleaning Equipment Precautions 2

Be sure to read before handling.

1. Preparation before piping

Before piping is connected, it should be thoroughly blown out

with air (flushing) or washed to remove chips, cutting oil and

other debris from inside the pipe.

2.Wrapping of pipe tape

When screwing together pipes and fittings, etc., be certain

that chips from the pipe threads and sealing material do not

get inside the piping.

Further, when pipe tape is used, leave 1.5 to 2 thread ridges

exposed at the end of the threads.

3. Implement measures to prevent drainage

from collecting inside piping.

For example, drains should be installed in the lower sections

of piping that rises, or piping should be designed with a slight

taper provided along the direction of flow so that drainage

will not accumulate.

Caution

Air Supply

Warning

1. Types of fluid

This product is designed for use with compressed air. Contact

SMC in case a different fluid is to be used.

Contact SMC regarding the types of fluids which can be used in

products designed for use with general purpose fluids.

2. Do not use compressed air which contains

chemicals, organic solvents or corrosive

gases.

Do not use compressed air containing chemicals, organic sol-

vents, salt or corrosive gases, as this can cause damage and

reduced performance, etc.

3. Operating pressure range

The operating pressure range is determined by the equipment

being used. Operation beyond this range can cause damage and

reduced performance, etc.

Warning

5. Locations with impacts or vibration. (Confirm specifications.)

6. Locations with high moisture and dust. (Contact SMC in

advance.)

2. Adhere to the fluid and ambient temperature

ranges.

The fluid and ambient temperatures are determined by the

equipment being used. Operation beyond this range can cause

damage, failure or malfunction, etc.

Maintenance

Warning

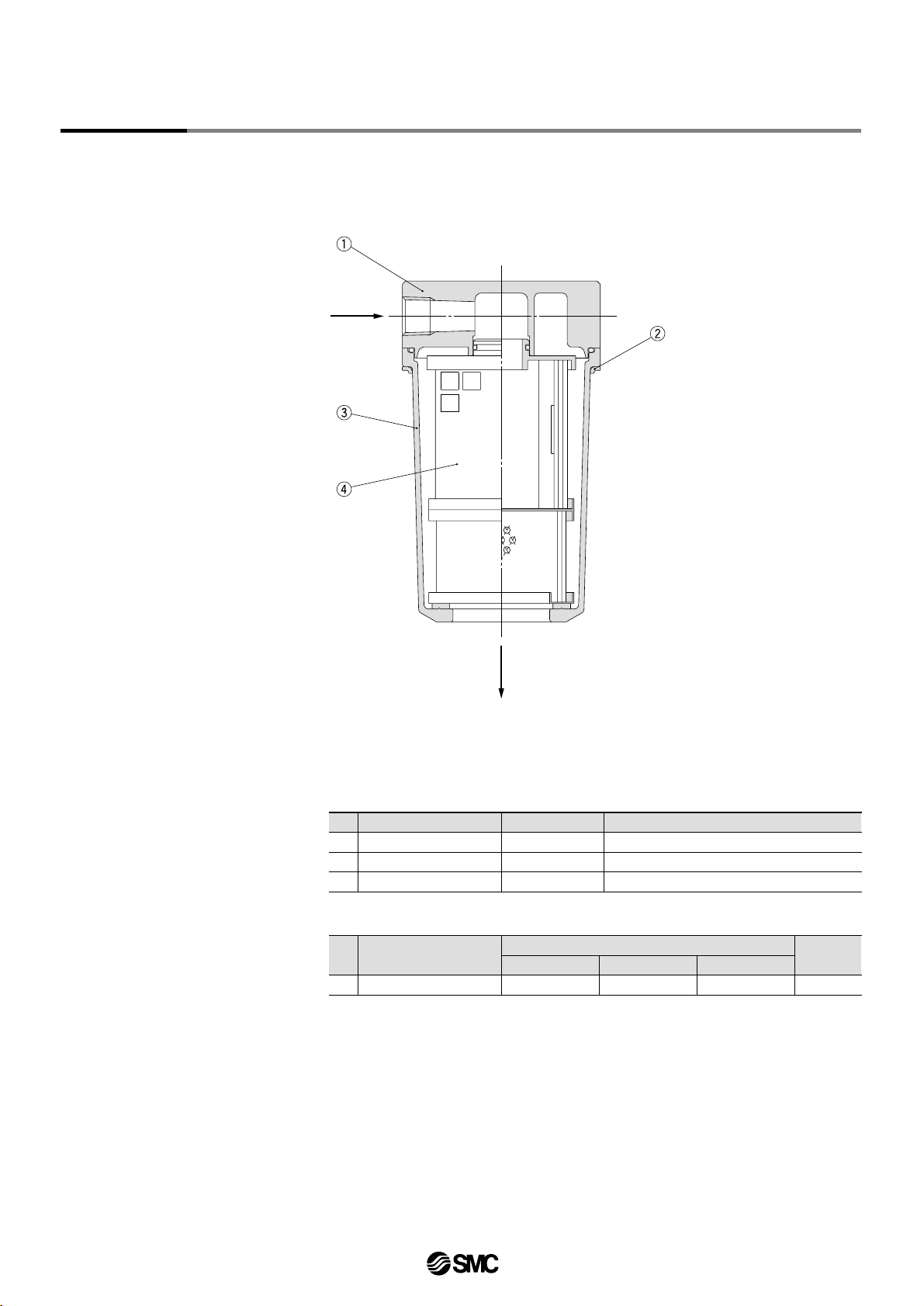

1. Maintenance should be performed in accor-

dance with the procedures in the instruction

manual.

If handled improperly, this can cause damage or malfunction in

equipment and devices, etc.

2. Maintenance operations

Since compressed air can be dangerous if handled improperly,

element replacement and other maintenance, etc., should be per-

formed by personnel having sufficient knowledge and experience

pertaining to pneumatic equipment, while also adhering to the

product specifications.

3. Pre-maintenance checks

When the product is to be demounted, be sure to shut off the sup-

ply pressure, release compressed air in the pipelines and confirm

an atmospheric release condition before proceeding.

4. Post maintenance checks

After mounting, repair or renovation, supply compressed air and

perform suitable function and leak tests. If an audible leak is

detected or equipment does not operate properly, stop operation

and confirm that mounting is correct.

5. When performing inspections, set the com-

pressed air pressure to zero.

When the compressed air side is to be disassembled for inspec-

tions or filter element replacement, etc., first confirm that the pres-

sure is at zero before proceeding.

6. Disassembly and modification is prohibited.

Do not disassemble or modify the main unit.

1. Do not step on or place heavy objects on the

unit.

The equipment may be deformed or damaged, and if balance is

lost, a fall may cause injury.

Operating Environment

Warning

1. Do not use in the following environments,as

this can cause damage and reduced perfor-

mance.

1. Locations with an atmosphere of corrosive gases, organic sol-

vents or chemical solutions, and locations where there may be

contact with the same.

2. Locations where there is contact with sea spray, water or steam.

3. Locations which receive direct sunlight. (Sunlight should be

blocked to prevent deterioration of resin from ultra violet rays and

over heating, etc.)

4. Locations near heat sources with poor ventilation. (Heat sources

should be blocked off, because radiated heat may cause damage

due to softening of materials.)

Caution

7