WARNING!

•Read the instructions carefully before installing and/or using the hood.

•Before connecting, make sure that the mains voltage corresponds to the voltage on

the rating plate inside the hood. (see fig. 7)

•Once you remove the appliance from its packaging make sure it is intact. If the

product is damaged, do not use it and contact the Smeg assistance network.

•It is recommended that a qualified technician performs installation and adjustment

operations .

•Before carrying out any kind of maintenance or cleaning, disconnect the hood from

the mains supply.

•Inspect and clean the filters thoroughly and in accordance with the intervals

suggested by the manufacturer.

•Do not cook or fry in a way that could result in flames being sucked into the hood and

causing a fire.

•The hood surface can be cleaned with a damp cloth and a non-bleach liquid

detergent.

•THE MANUFACTURER CANNOT BE HELD RESPONSIBLE IF THE ABOVE

INSTRUCTIONS ARE NOT FOLLOWED

INSTALLATION INSTRUCTIONS:

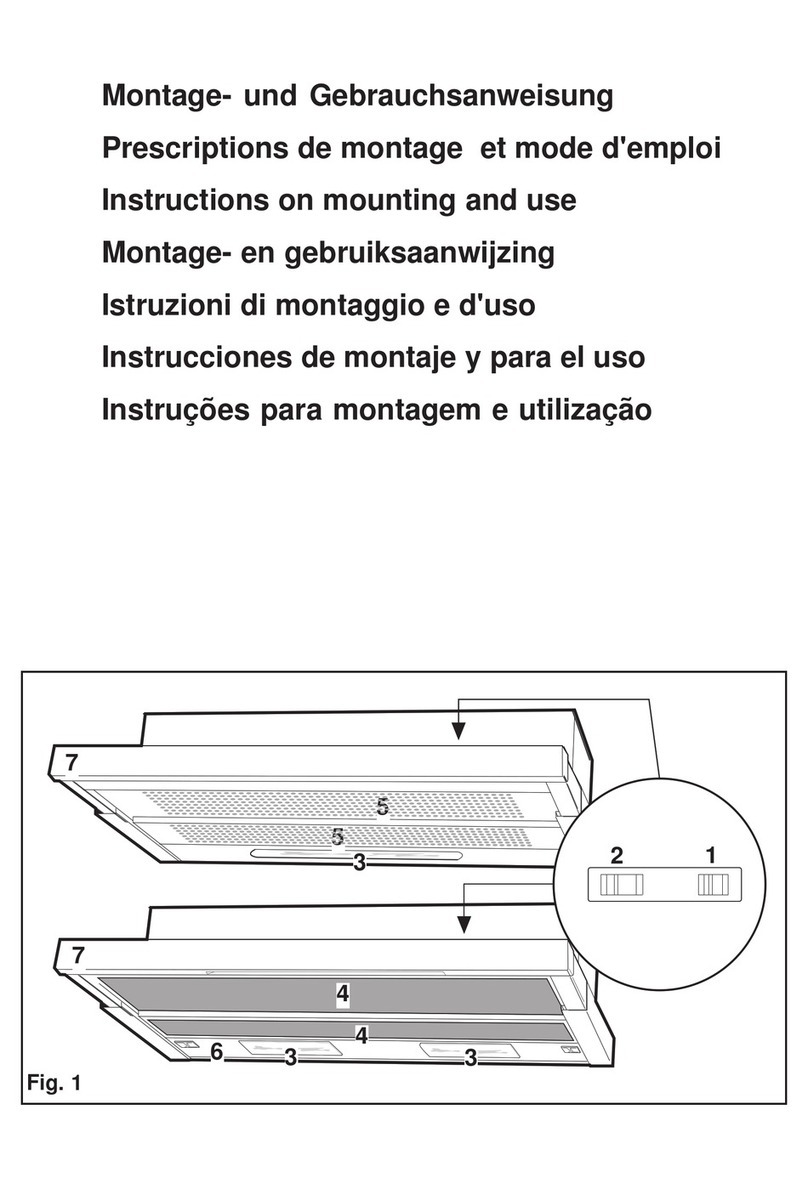

The hood is supplied with all the necessary

accessories for installation.The minimum distance

between the cooker and the lower part of the hood

must be 750 mm for gas cookers and 650 mm for

electric cookers (Fig. 1). The hood is supplied with a

motor intake (Fig 2). If it has not been assembled by

the manufacturer, you can assemble it using the

supplied screws (for type 1) or pushing (for type 2)

If the motor intake is equipped with a non-return

valve, make sure it opens and closes perfectly.

The following instructions will assist installation:

a) The hood should be centred with respect to the

cooker.

The hood is supplied with two supports/hooks (a)

(Fig 3) or bracket (b) that need to be fixed to the

wall by means of wall anchors . The L1 holes for

these supports are on the back of the hood (fig.

4)

Remove the anti-grease filters, put the hood on

the wall and mark the position of the holes for the

supports/hooks.

d) Drill the two previously marked holes after

removing the hood from the wall.

e) Fix the two supports/hooks to the wall.

f) Mark the L2 holes on the wall to fix the hood

safely. (fig. 4) Drill and put the anchors in the

holes.

g) Hang the hood on to the supports/hooks (fig. 5)

and level by means of the adjusting screw

(fig.3).

l) Fix the hood safe by tightening both wall anchors.

Ducted mode or Recirculation mode installation:

Ducted mode:

In the ducted mode, connect the motor outlet to the

fumes outlet duct not less than 120mm diameter.

Warning: if the hood is equipped with an active

carbon filter, it must be removed (see page 7)

02

There shall beadequate ventilation of the room when therange hood is used at thesame time

as appliances burning gas or other fuels. (Not applicable to appliances that only discharge the

air back into the room).

There is a risk of fire if cleaning is not carried out in accordance with the instructions.

Do not flambé under the range hood.

Caution: accessible parts may become hot when used with a cooking appliance.

The appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experienceand knowledge, unless they have been

given supervised or instruction concerning use of the appliance by a responsible person for

their safely.

Young children should be supervised to ensure that they do not play with the appliance.

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person in order to avoida hazard.

The exhaust air must not be discharged into a flue which is used for exhausting fumes from

other appliances burning gas or other fuels. (Not applicable for appliances which only discharge

air back into the room)

The minimum distance between the supporting surface for the cooking vessels on the hob and

the lowest part of the range hood:

When the range hood is located above a gas appliance, this distance shall be 65cm. If the

instructions for the installation for the gas hob specify a greater distance, this must betaken

into account. (the distance of 65 cm can be reduced for non-combustible parts of range hood

and part operating at safety extra lowvoltage provided these parts do not give access tolive

parts. Distance may be reduced to 60cm to alignwith the AGA code.

Regulation concerning the discharge of air have to be fulfilled.

WARNING: Failure to install the screws or fixing device in accordance with the instructions may

result in electrical hazards.

EN 01