Smith's Heating First PROFILE Series User manual

Other Smith's Heating First Heater manuals

Smith's Heating First

Smith's Heating First SS2E/5 User manual

Smith's Heating First

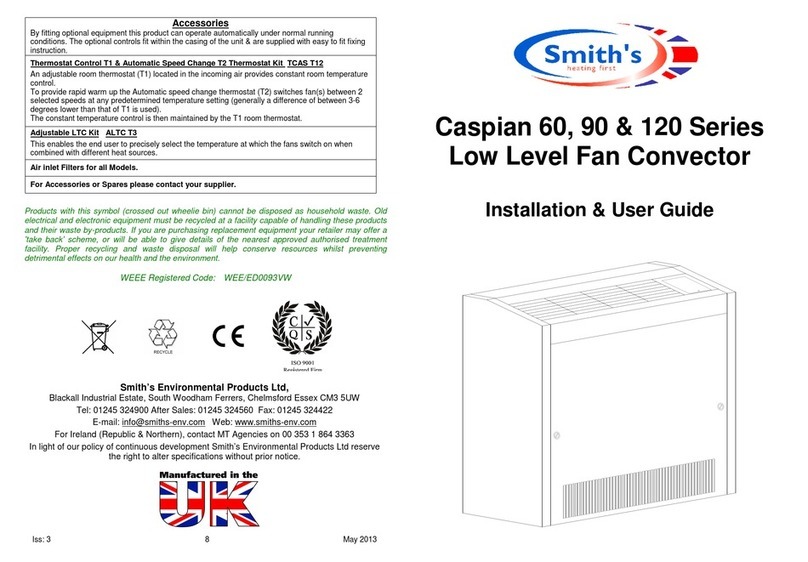

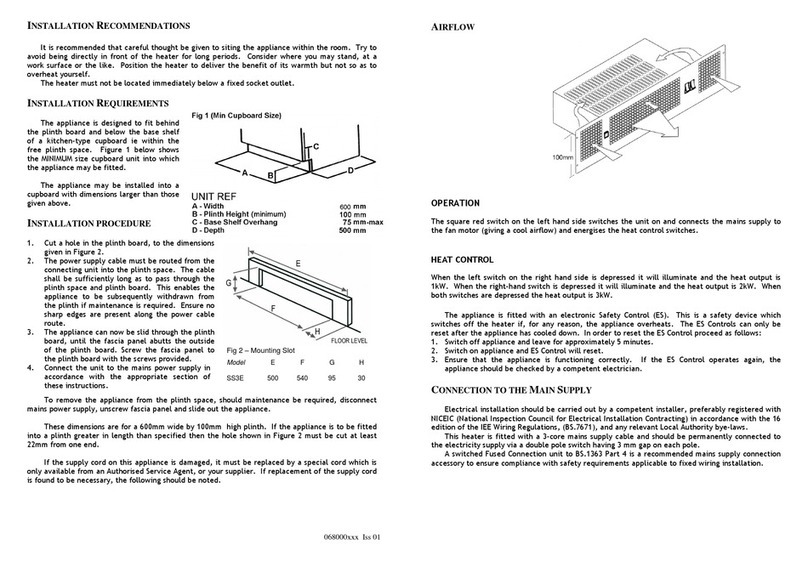

Smith's Heating First Caspian 60 Operation manual

Smith's Heating First

Smith's Heating First SS3E User manual

Smith's Heating First

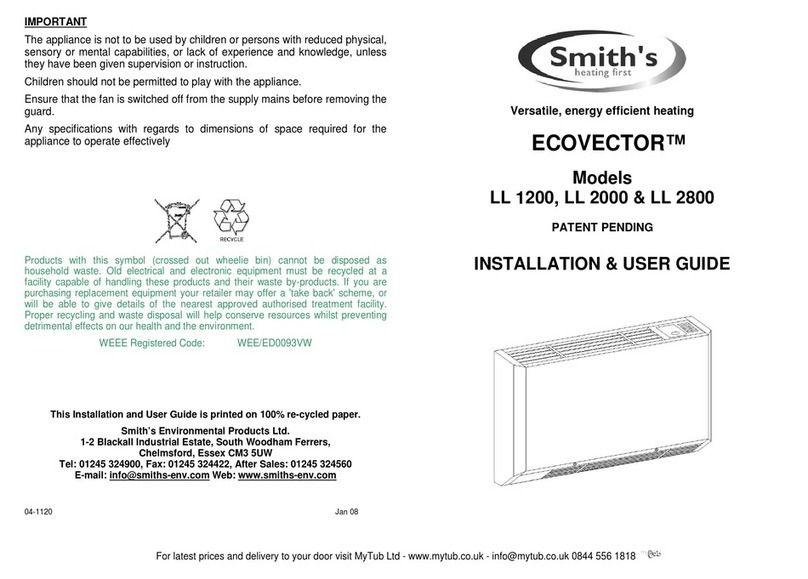

Smith's Heating First ECOVECTOR LL 1200 Operation manual

Smith's Heating First

Smith's Heating First Caspian 60 Operation manual

Smith's Heating First

Smith's Heating First Ostro Guide

Smith's Heating First

Smith's Heating First Eco-Powerad 500 Operation manual

Smith's Heating First

Smith's Heating First Signature Operation manual

Smith's Heating First

Smith's Heating First SS5/Dual User manual

Smith's Heating First

Smith's Heating First PWU 4/6 Operation manual

Smith's Heating First

Smith's Heating First Solano Guide

Smith's Heating First

Smith's Heating First Space saver SS7 User manual

Smith's Heating First

Smith's Heating First SS80E User manual

Smith's Heating First

Smith's Heating First STR7-12V User manual

Smith's Heating First

Smith's Heating First External Control Harness Caspian UVC User manual

Smith's Heating First

Smith's Heating First Caspian EC Series Guide

Smith's Heating First

Smith's Heating First Caspian 60 Operation manual

Smith's Heating First

Smith's Heating First Sterling 3 EL Operation manual

Popular Heater manuals by other brands

Qlima

Qlima R122C operating manual

OCI

OCI OCIE48EH Installation & operation guide

Protemp

Protemp PT-45-KF User's manual & operating instructions

Pinnacle International

Pinnacle International MASTER MH-515-120 User's manual & operating instructions

Bimar

Bimar K80.NE Instruction booklet

Costway

Costway EP25439 Instruction booklet

Gabarron

Gabarron IDP Series Installation instructions and user guide

IRSAP

IRSAP Radiator Company Kura Fitting instructions

EUROM

EUROM HI-Tower 2200 Wi-fi instruction manual

S&P

S&P TL-40 Installation manual and operating instructions

Shini

Shini STM-E Series manual

Clarke

Clarke OFR 9/90 Operation & maintenance instructions