Smith's Heating First PWU 4/6 Operation manual

Other Smith's Heating First Heater manuals

Smith's Heating First

Smith's Heating First SS80E User manual

Smith's Heating First

Smith's Heating First Caspian 60 Operation manual

Smith's Heating First

Smith's Heating First External Control Harness Caspian UVC User manual

Smith's Heating First

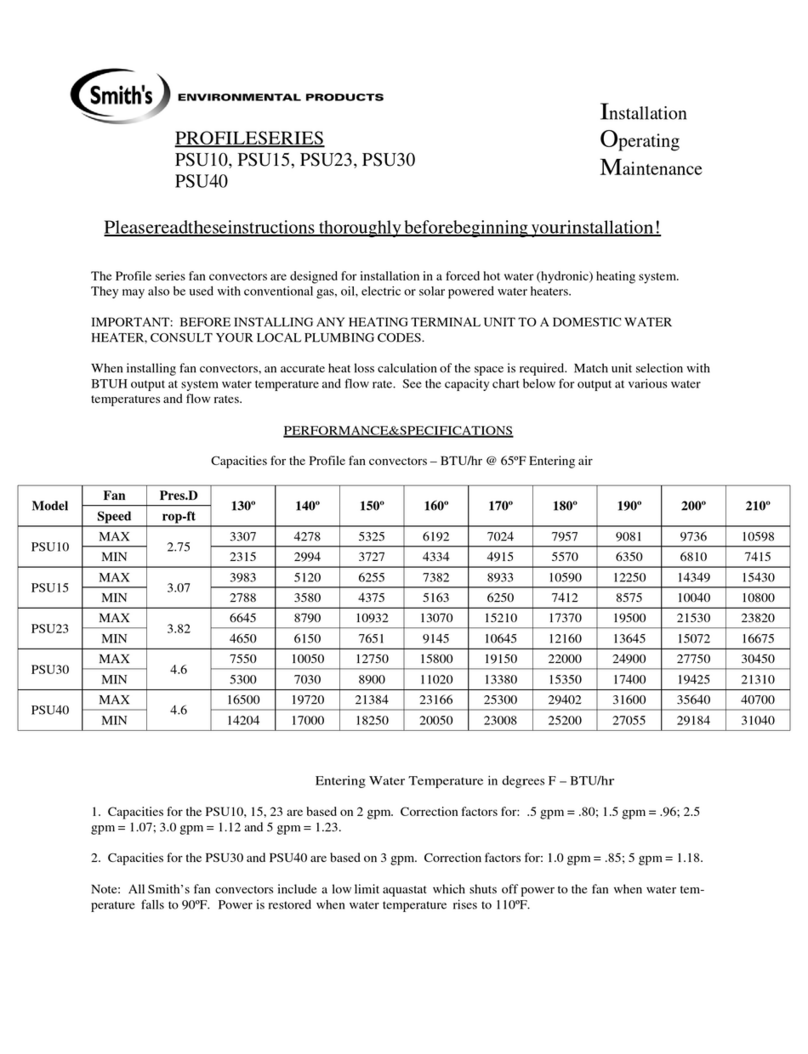

Smith's Heating First PROFILE Series User manual

Smith's Heating First

Smith's Heating First Caspian 60 Operation manual

Smith's Heating First

Smith's Heating First Eco-Powerad 500 Operation manual

Smith's Heating First

Smith's Heating First Caspian EC Series Guide

Smith's Heating First

Smith's Heating First SS2E/5 User manual

Smith's Heating First

Smith's Heating First Sterling 3 EL Operation manual

Smith's Heating First

Smith's Heating First Caspian 60 Operation manual

Smith's Heating First

Smith's Heating First Ostro Guide

Smith's Heating First

Smith's Heating First ECOVECTOR LL 1200 Operation manual

Smith's Heating First

Smith's Heating First Space saver SS7 User manual

Smith's Heating First

Smith's Heating First SS3E User manual

Smith's Heating First

Smith's Heating First Signature Operation manual

Smith's Heating First

Smith's Heating First Solano Guide

Smith's Heating First

Smith's Heating First SS5/Dual User manual

Smith's Heating First

Smith's Heating First STR7-12V User manual

Popular Heater manuals by other brands

Webasto

Webasto HL 90 Operating and servicing manual

Challenge

Challenge DL06-1 TIMER instruction manual

Consort

Consort PHSL2 Series Installation & Control Guide

GÜDE

GÜDE GSH 500 K mini Translation of the original operating instructions

Orbegozo

Orbegozo CV 4000 A instruction manual

Castle Heaters

Castle Heaters KMH-30 instruction manual

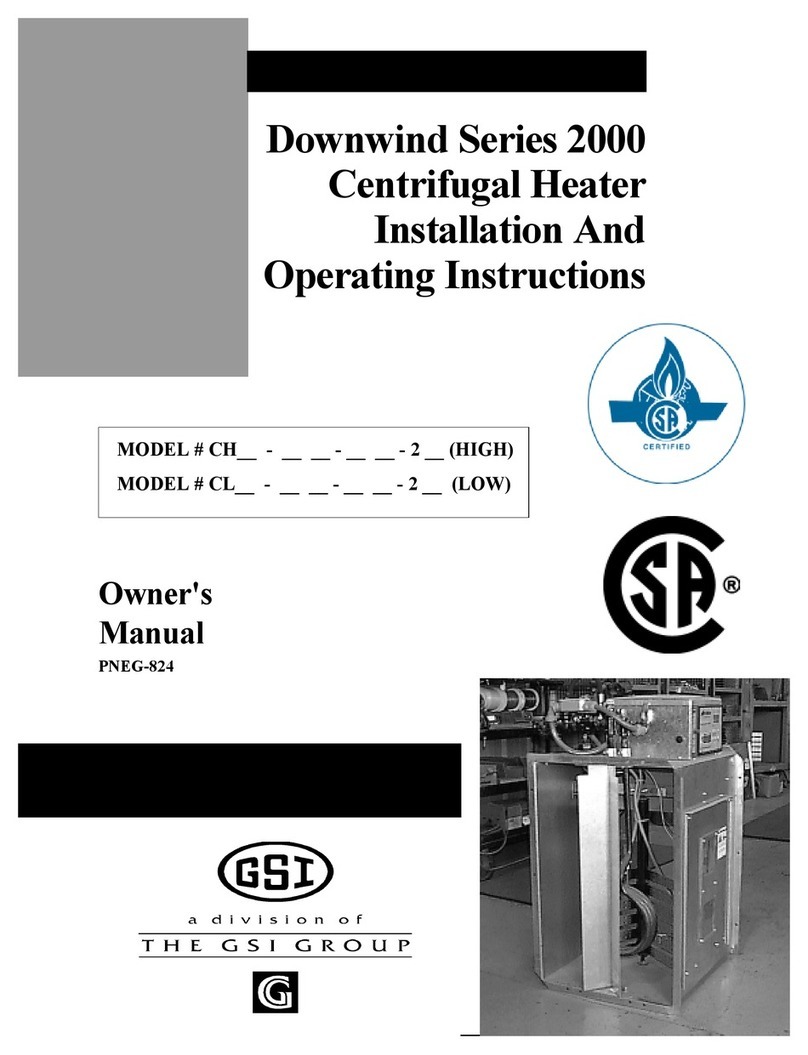

GSI Group

GSI Group 2000 Series Installation and operating instructions

Zephyr

Zephyr Z-1970-Y instruction manual

hylite

hylite SLIMLINE ECO HEATER Assembly & fitting instructions

Phillips & Temro industries

Phillips & Temro industries FLOWSTART FS user guide

CLIMAMEISTER

CLIMAMEISTER IR 20 T instruction manual

MILL

MILL CO1200WIFI3 Assembly and instruction manual