11

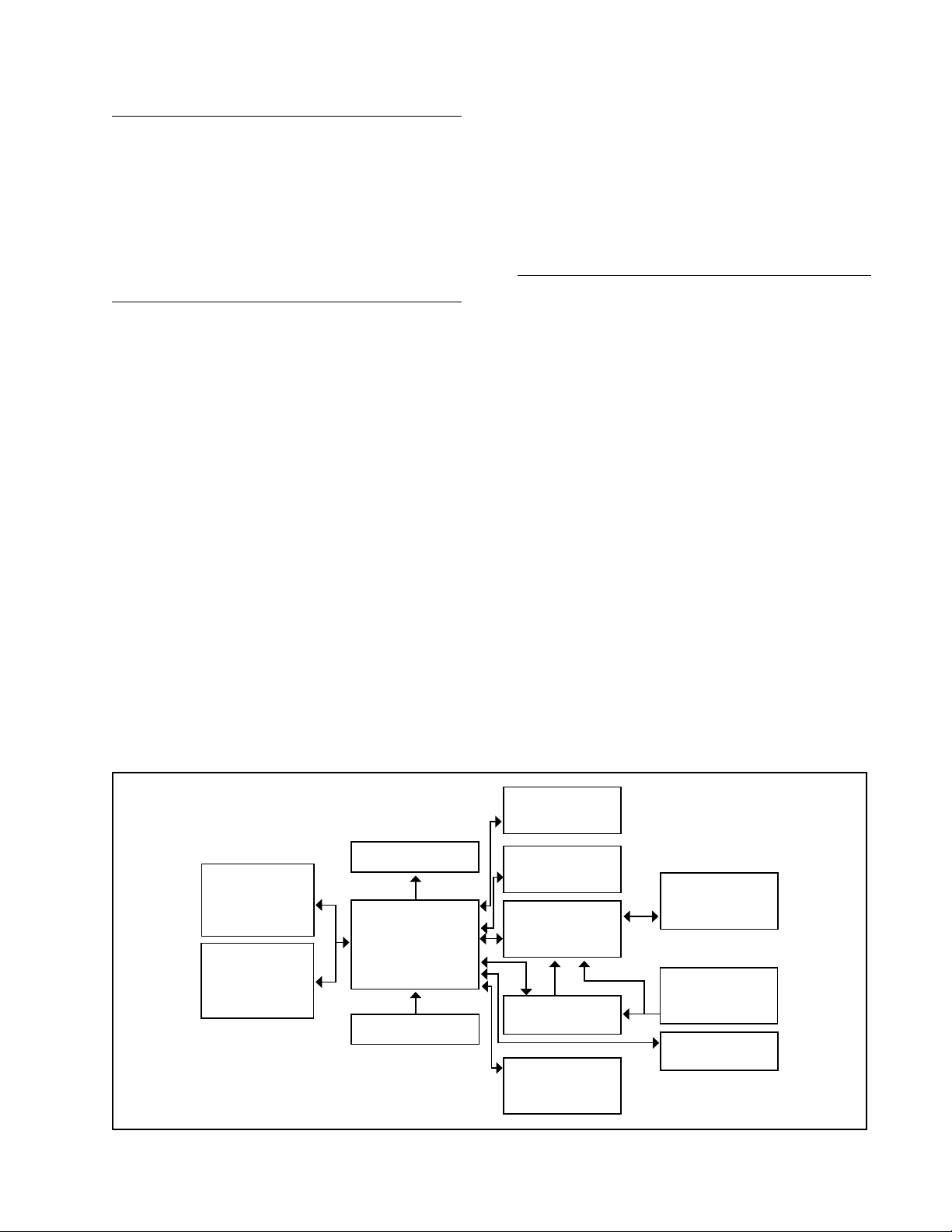

Flash PROM Technology

Program memory for the pump is stored in

Flash Programmable Read Only Memory

(Flash PROM). This type of memory allows

modification of the contents without physically

removing the device from the circuit board.

Under certain circumstances, the program

can also be downloaded through the I/O

port on the side of the pump. Several layers

of redundancy in the programming system

prevent accidental erasing or modification of

the PROM.

Gate Array Circuitry

The Gate Array contains circuitry which

controls memory address decoding,

keyboard debounce, Light Emitting Diode

(LED) indicator status, LCD command

buffering, Battery Backed RAM interface, and

miscellaneous signal line buffering functions.

Audible Alarm Circuitry

Audible alarm circuitry consists of a piezo

electric disk and independent oscillator. The

disk flexes or bends in resonance with the

output of the oscillator. The piezo disk is

mounted to the pump housing to enhance

sound level. The oscillator which drives the

piezo disk is capable of providing two driving

frequencies. The low frequency is in the range

of 700 to 1500 Hz and the high frequency

is in the range of 1600 to 2500 Hz. The

microprocessor controls the audible alarm via

control lines from the Gate Array. When the

microprocessor selects both the low and high

frequency control lines, the audible alarm

enters a warble mode where it oscillates

between the low and high frequency sound

at a rate of 0.8 and 2 Hz. Low battery voltage

detection and watchdog timer circuitry also

have the ability to enable the audible alarm

via the Gate Array.

Watchdog Timer Circuit

Watchdog timer circuitry is provided to

monitor the status of the microprocessor

and disable the motor and enable the audible

alarm if the microprocessor fails to function

properly. The microprocessor must strobe

the watchdog circuit at least once every

second in order to prevent the watchdog from

performing its reset function. The reset output

from the watchdog circuit is a pulse output.

This acts to “jump start” the microprocessor.

This unique feature allows the microprocessor

to test the watchdog circuit on every power‑

up. By setting a flag in memory and not

strobing the watchdog, the microprocessor

can force a watchdog time‑out. After being

reset, the microprocessor checks the status

flag to see if this was a time‑out test. If so,

the microprocessor continues normal power‑

up activities. If the reset occurred when the

microprocessor was not expecting it, the

microprocessor traps the event, sounds the

audible alarm and displays an error message

on the LCD.

Motor Driver/Motor Watchdog Circuit

Motor drive circuitry is composed of a

series of power FET transistors, passive

components, and two voltage comparators.

Built into the motor drive circuitry is an RC

timer which times how long the motor runs

each time it is turned on. If the motor runs

for more than an average of 4 seconds, the

circuit will time out and disable the motor. A

unique feature of this circuit is that control

lines to and from the microprocessor circuit

allow the microprocessor to perform a

complete functional test of the motor drive

circuit without running the motor. The

microprocessor performs this test function

every several minutes to assure its continued

functionality. An input from the watchdog

circuit prevents motor operation if the

watchdog timer expires.

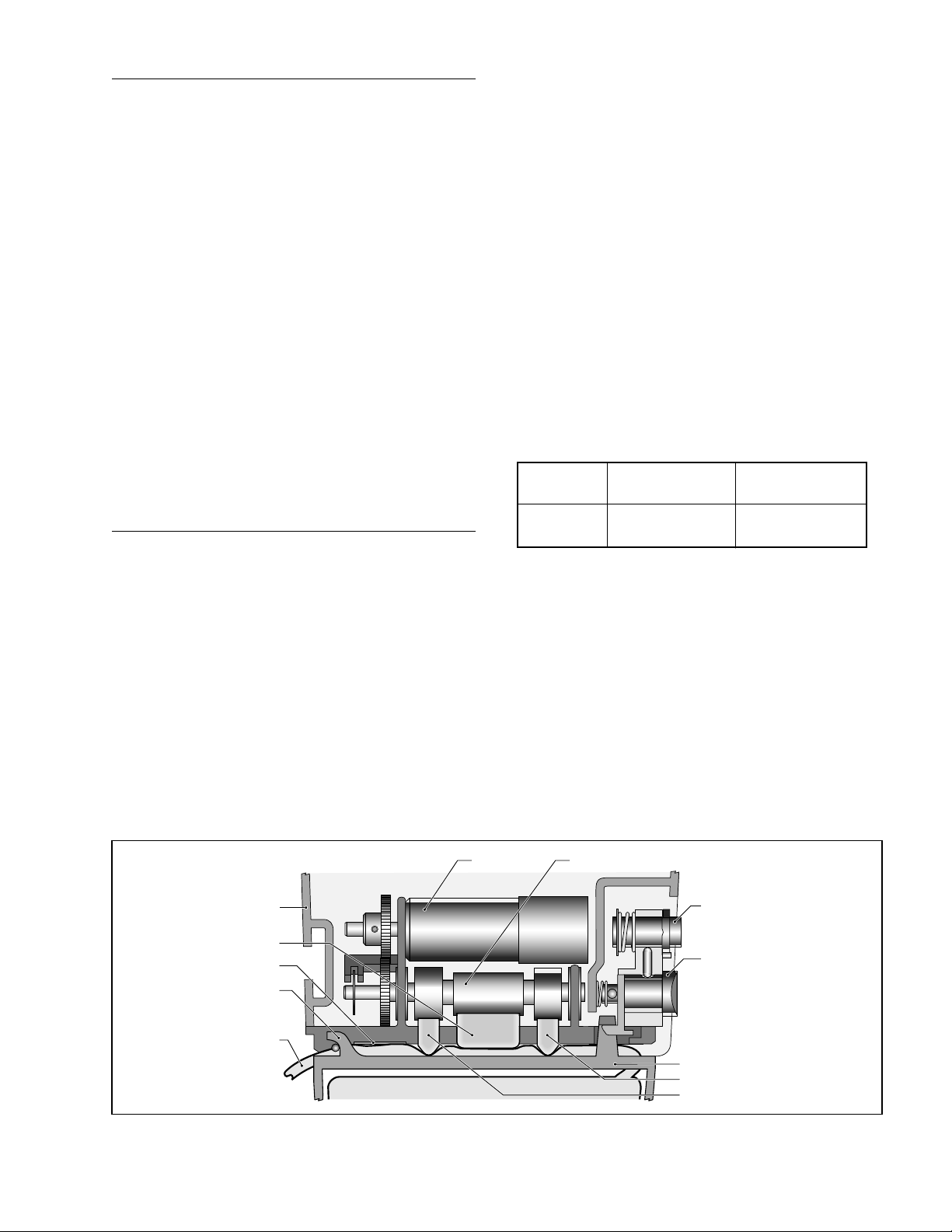

Rotation of the motor is sensed by the

microprocessor via an infrared‑sensitive

photo detector. An infrared light source is

mounted so that its light beam illuminates the

infrared detector. An opaque flag is mounted

concentrically to the camshaft and rotates

with it between the infrared light source and

detector. When the flag interrupts the light

beam, the output of the detector is sensed

by the microprocessor via an input port bit.

Power to the infrared LED light source is

controlled by the motor driver circuit and is

off when the motor is not running to conserve

battery life.

In the microprocessor software, multiple

checks are made on motion of the camshaft.

When the motor is commanded to start,

the infrared sensor must show that half a

revolution has occurred within five seconds

and that the motor has stopped when half

a rotation was completed. In addition, no

camshaft rotation can take place when the

motor has not been commanded to run.