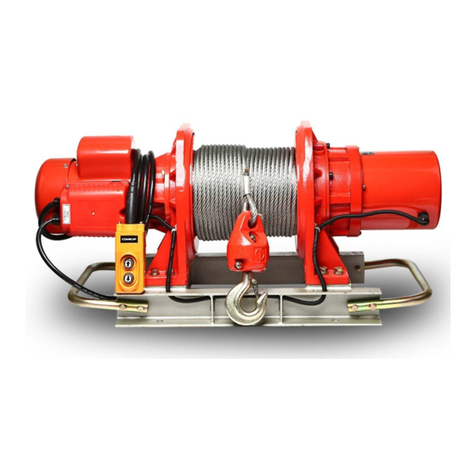

Smittybilt XRC8 User manual

Installation Manual

SAFETY PRECAUTIONS

Warning! Observe safety precautions for personal safety and the safety of others. Improper equipment operation may

cause personal injury and equipment damage.

Read the following carefully before attempting to operate your winch and keep the instructions for future reference.

1. Dress Properly:

- Don’t wear loose clothing or jewelry. They can be caught in moving parts.

- Wear leather gloves when handling winch cable. Do not handle cable with bare hands as broken wires can cause

injuries.

- Non-skid footwear is recommended.

- Protective hair covering to contain long hair.

2. Keep a Safe Distance:

- Ensure that all persons stand well clear of winch cable and load during winch operation, 1.5 times the cable length

recommended. If a cable pulls loose or breaks under load it can lash back and cause serious personal injury or death.

- Don’t step over the cable.

- All visitors and onlookers should be kept away from the work area.

- Keep proper footing and balance at all times.

3. Don’t Abuse the Cord:

- Never carry your winch by the cord or yank it to disconnect it from the receptacle.

- Keep cord from heat, oil and sharp edges.

4. Don’t Overwork the winch:

- If the motor becomes uncomfortably hot to touch, stop and let it cool for a few minutes.

- Don’t maintain power to the winch if the motor stalls.

- Don’t exceed maximum line pull ratings shown in tables. Shock loads must not exceed these ratings.

5. Avoid Unintentional Starting:

- Winch clutch should be disengaged when not in use and fully engaged when in use.

6. Check Damaged Parts:

- Before using, you should check your winch carefully. Any part that is damaged should be properly repaired or

replaced by an authorized service center.

7. Repair Your Winch:

- When repairing, use only identical replacement parts or it may cause considerable danger to the user.

8. Re-spool the cable:

- Leather gloves must be worn while re-spooling. To re-spool correctly, it is necessary to keep a slight load on the

cable. Hold the cable with one hand and the remote control switch with the other. Start as far back and in the center

as you can .Walk up keeping load on the cable as the winch is powered in.

- Do not allow the cable to slop through your hand and do not approach the winch too closely.

- Turn off the winch and repeat the procedure until all the cable except 1m is left.

- Disconnect the remote control switch and finish spooling in cable by rotating the drum by hand with clutch

disengaged.

- On hidden winches, spool in cable under power but keep hands clear.

PARTS INCLUDED QTY PARTS INCLUDED QTY

Winch 1 Roller Fairlead 1

Solenoid Box 1 Clevis Hook 1

Hardware Bag 1 Remote Control 1

Installation Manual

Warning: The use of any other accessory or attachment other than those recommended in the Fitting Instructions may

present a risk of personal injury.

WINCH OPERATION WARNINGS

Read the following carefully before attempting to operate your winch and keep the instructions for future reference.

1. The uneven spooling of cable, while pulling a load, is not a problem, unless there is a cable pile up on one end of

the drum. If this happens reverse the winch to relieve the load and move your anchor point further to the center of the

vehicle. After the job is done,you can un-spool and rewind for a neat lay of the cable.

2. Store the remote control switch inside your vehicle where it will not become damaged, inspect it before you plug it

in.

3. When ready to begin spooling in, plug in remote control switch with clutch disengaged, do not engage clutch with

motor running.

4. Never connect the hook back to the cable. This causes cable damage. Always use a sling or chain of suitable

strength.

5. Observe your winch while winching, if possible while standing at a safe distance. Stop the winching process every

meter or so to assure the cable is not piling up in one corner. Jamming the cable can break your winch.

6. Do not attach tow hooks to winch mounting apparatus. They must be attached to vehicle frame.

7. The use of a snatch block will aid recovery operations by providing a doubling of the winch capacity and a halving

of the winching speed, and the means to maintain a direct line pull to the center of the rollers. When double loading

during stationary winching, the winch hook should be attached to the chassis of the vehicle.

8. Ensure rated “D” or bow shackles are used in conjunction with an approved tree trunk protector to provide a safe

anchor point.

9. When extending winch cable, ensure that at least FIVE (5) wraps of cable remain on drum at all times. Failure to do

this could result in the cable parting from the drum under load. Serious personal injury or property damage may result.

10. All winches are provided with a Red Cable marking to identify that 5 cable wraps remain on the winch drum when

this mark appears at the rollers. No recovery should be attempted beyond this marking.

11. Since the greatest pulling power is achieved on the innermost layer of your winch, it is desirable to pull off as much

line as you can for heavy pulls (you must leave 5 wraps minimum on the drum-red cable). If this is not practical use a

snatch block and double line arrangement.

12. Draping a heavy blanket or similar object over the extended winch cable is recommended as it will dampen any

back lash should a failure occur.

13. Neat, tight spooling avoids cable blinding, which is caused when a load is applied and the cable is pinched between

the others. If this happens, alternatively power the winch in and out. Do not attempt to work a bound cable under load,

free by hand.

14. Apply blocks to wheels when vehicles are on an incline.

15. Battery:

- Be sure that the battery is in good condition. Avoid contact with battery acid or other containments.

- Always wear eye protection when working around a battery.

- Have the engine running when using the winch, to avoid flattening the battery.

16. Winch cable:

- Be sure that the cable is in good condition and is attached properly.

- Do not use the winch if cable is frayed.

- Do not move the vehicle to pull a load.

Installation Manual

-Do not replace the cable with a cable of lesser strength.

- The life of cable is directly related to the use and care it receives. Following its first and subsequent uses, a cable

must be wound onto the drum under a load of at least 500lbs (230kg) or the outer wraps will draw into the inner

wraps and severely damage the cable during winching. The first winch use should be a familiar run while in a

relaxed, non-recovery situation. Spool out the cable until the red cable mark appears (about five wraps on the

drum), when rewind the cable onto the drum under a load of 500lbs (230kg) or more. This will slightly tension and

stretch the new cable and create a tight cable wrap around the drum. Failure to do so may result in cable damage

and reduced cable life.

- When the cable is replaced, be sure to apply locktite, or the cable clamp thread. Tighten the clamp screw properly

but do not over-tighten. The lockkite will prevent loosening of the screw in arduous conditions. Locktite 7471

primer and 222 Thread Locker are recommended.

17. Do not attempt to exceed the pulling limits of this winch.

18. Do not drive your vehicle to assist the winch in any way. Vehicle movement in combination with winch operation

may overload the cable, the winch itself or cause damaging shock loads.

19. Shock loads when winching are dangerous! A shock load occurs when an increased force is suddenly applied to the

cable. A vehicle rolling back on a slack cable may induce a damaging shock load.

20. The winches shown in this manual are solely for vehicle and boat mount, non-industrial applications.

21. Do not use winch in hoisting applications due to required hoist safety factors and features.

22. Do not use the winch to lift, support or otherwise transport personnel.

23. Do not move your winch by lifting the cable leads or the clutch handle lever.

Installation Manual

INSTALLATION

MOUNTING YOUR WINCH

1 a) The winch is to be mounted into a suitable steel mounting frame using the 4 point foot mounting system in either a

horizontal or vertical plane.

b) It is very important that the winch be mounted on a flat surface so that the three sections (motor, cable drum and gear

housing) are properly aligned.

c) Before commencing installation, ensure the mounting facility being used is capable of withstanding the rated capacity

of the winch.

d) The fitment of winches and / or a frontal protection system may affect the triggering of SRS air bags. Check that the

mounting system has been tested and approved for winch fitment in the air bag equipped vehicle.

2. Smittybilt manufactures winch mounting frames and / or Frontal Protection Systems to suit most popular vehicles.

Winch frames are packaged with detailed instructions.

3. Should you wish to manufacture your own mounting plate the dimensions below will assist. A steel mount plate of

6mm thickness is recommended. Fasteners should be steel high tensile grade 5 or better. A poorly designed mount may

void warranty.

4. The winch should be secured to the mounting with 3/8” UNC* 1-1/4” steel bolts and spring washers provided.

5. The roller fairlead is to be mounted so as to guide the rope onto the drum evenly.

6. Special mounting requirements for XRC15.

a) XRC15 is to be mounted into a suitable steel mounting frame using the 8 point foot mounting system in either a

horizontal or vertical plane.

b) A steel mount plate of 10 to 12mm thickness is recommended. Fasteners should be steel high tensile grade 8.8 or

better (8 pieces grade 8.8 M12X40 fasteners are provided with the XRC15winch).

Mounting Figure for XRC15

Installation Manual

Installation Manual

LUBRICATION INSTALLATION

All moving parts in the winch are permanently lubricated with high temperature lithium grease at the time of assembly.

Under normal conditions factory lubrication will suffice. Lubricate cable periodically using light penetrating oil. Inspect

for broken strands and replace if necessary. If the cable becomes worn or damaged, it must be replaced.

CABLE INSTALLATION

Unwind the new cable by rolling it along the ground, to prevent kinking. Remove old cable and observe the manner in

which it is attached to the drum flange.

ELETRICAL CONNECTION

For normal self-recovery work, your existing electrical system is adequate. A fully changed battery and proper

connections are essential. Run the vehicle engine during winching operations to keep charged.

Pay close attention to proper electrical cable connection as follows (refer to Diagram 1)

Be sure to observe the following steps for a correct and safe electrical connection:

1. Short Red cable (B’) connecting to the red terminal (B) of winch motor.

2. Short black cable with yellow jacket (C’) connecting to the yellow terminal (C) of the motor.

3. Short black cable with black jacket (D’) connecting to the black terminal (D) of the motor.

4. Thin black cable (A’) connecting to bottom terminal (A) of the motor.

5. Long black cable (1.8m), one terminal (a) connecting to the bottom terminal (A) of the motor, and the other terminal

negative (-) connecting to negative (-) terminal of battery.

6. Long red cable positive (+) connecting to positive (+) of battery.

Installation Manual

NOTE:

1. Your battery must be kept in good condition.

2. Be sure battery cables are not drawn taught across any surfaces, which could possibly damage them.

3. Corrosion on electrical connections will reduce performance or may cause a short.

4. Clean all connections especially in remote control switch and receptacle.

5. In salty environments use a silicone sealer to protect from corrosion.

6. Index the heads of the plate studs into the keyhole slots on the back of the winch.

7. Attached the winch/Adaptor plate assembly to your trailer hitch, by inserting the trailer hitch ball through the

shaped hole in the Adaptor plate.

Installation Manual

WINCH OPERATION

SUGGESTION: The best way to get acquainted with how your winch operates is to make a few test runs before you

actually need to use it. Plan your test in advance. Remember you can hear your winch as well as you can see it

operate. Get to recognize the sound of a light steady pull, a heavy pull, and sounds caused by load jerking or shifting.

Soon you will gain confidence in operating your winch and its use will become second nature to you.

OPERATING:

1. Ensure the vehicle is secured by applying the parking brake or chocking the wheels.

2. Pull out the winch cable the desired length and connect to an anchor point. The winch clutch allows rapid uncoiling

of the cable for hooking onto the load or anchor point. The shifter tab located on the gear housing of the winch

operates the clutch as follows:

a) To disengage the clutch, move the clutch shifter tab to the “OUT” position. Cable may be free spooled off the drum.

b) To engage the clutch, move the clutch shifter tab into the “IN” position. The winch is now ready for pulling.

3. Recheck all cable rigging before proceeding.

4. Plug in the winch hand control. It is recommended that the winching operation takes place from the driver’s position

to ensure safe operation. Turn control base clockwise until it locks into place.

5. To commence winching operation, start vehicle engine, select in transmission, maintain engine speed at idle.

6. Operate the remote control switch to IN or OUT until the vehicle has been retrieved. Regularly check the winch to

ensure cable is winding onto the drum evenly.

Note:

1. Never winch with your vehicle in gear or in park, which would damage your vehicle’s transmission.

2. Never wrap the cable around the object and hook onto the cable itself, this can cause damage to the object being

pulled, and kink or fray the cable.

3. Keep hands, clothing, hair and jewelry clear of the drum area and cable when winching.

4. Never use the winch if the cable is frayed, kinked or damaged.

5. Never allow anyone to stand near the cable, or in line with the cable behind the winch while it is under power, if the

cable should slip or brake, it can suddenly whip back towards the winch, causing a hazard for anyone in the area.

Always stand well to the side while winding.

6. Don’t leave the switch plugged in when winch is not in use.

CHECK THE WINCH CAREFULLY AND THOROUGTLY BEFORE OPERATING!

Installation Manual

MAINTENANCE

It is highly recommended that the winch be used regularly (once a month). Simply power the cable out 15m, free spool

5m and then power back in. This will keep all components in good working condition so that the winch can be relied on

when needed. Contact your authorized outlet for technical assistance and repairs.

SPARE PARTS: A comprehensive range of spare parts is available. For further information please contact Smittybilt

Automotive Products.

NOTE:

The safety precautions and instructions discussed in this manual can’t cover all possible conditions and

situations that may occur. It must be understood by the operator that common sense and caution are

factors, which cannot be built into this product, but must be applied by the operator.

Installation Manual

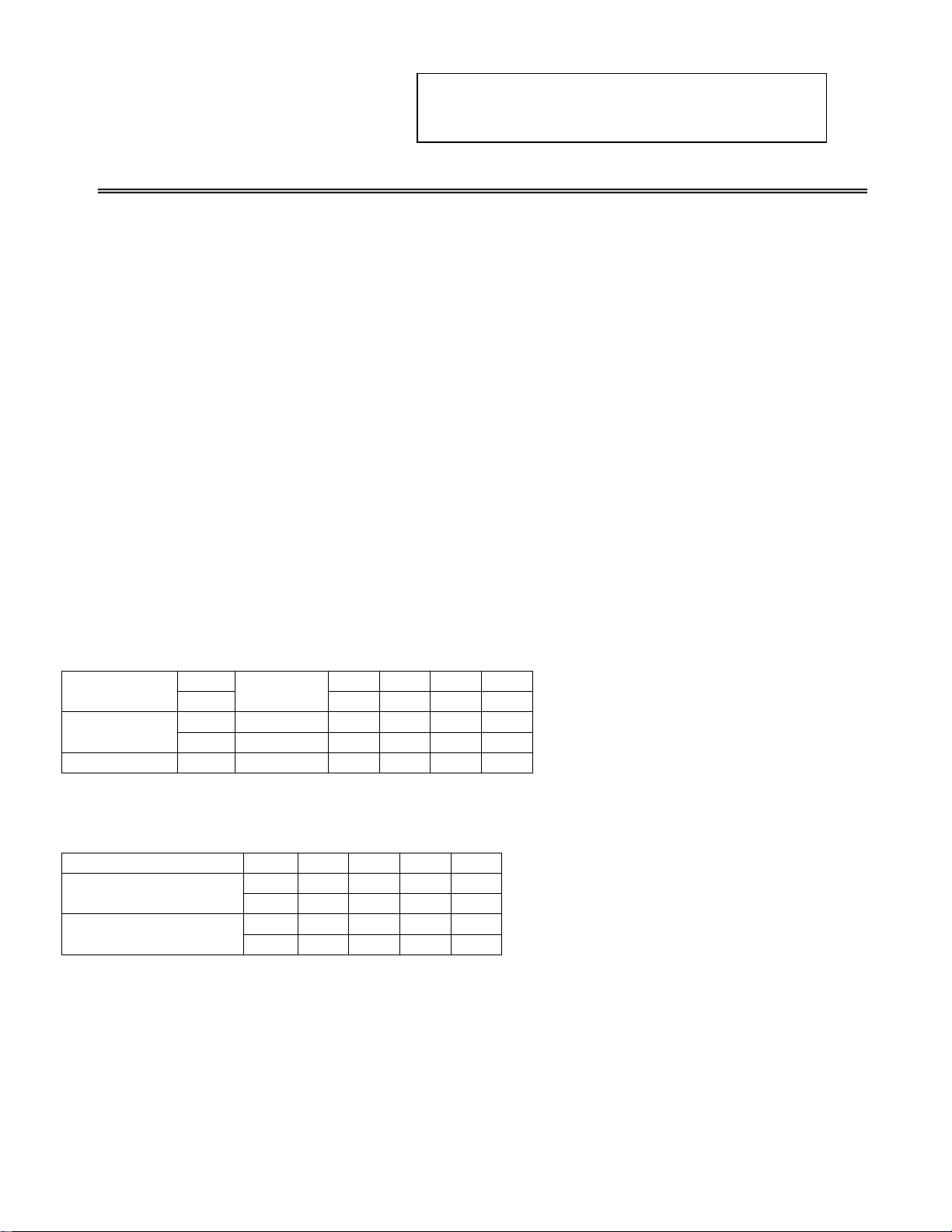

XRC 8 Specifications

Rated Line Pull: 8000Lbs (3630kgs) single-line

Motor: 5.5hp /12V, Series Wound

Control: Remote Switch, 12’ (3.7m) lead

Gear Train: 3-Stage Planetary

Gear Ratio: 172.8:1

Clutch: Rotating Ring Gear

Brake: Automatic In-The-Drum

Drum Size: (Diameter x Length) 2.5” x 8.82” (63.5mm x 224mm) Wire

Rope: (Diameter x Length) 21/64” x 94’ (8.2mm x 28.5m) Fairlead: 4-

Way Roller

Remote Control: Included

Recommended Battery: 650CCA Minimum for Winching

Battery Leads: 25mm2, 72” (1.8m)

Finish: Black

Gross Weight: 94.0lbs (42.5Kgs)

Mounting Bolt Pattern: 10.0” x 4.50”

Line speed and amp draw (first layer)

Line Pull Lbs NO LOAD

2000

4000

6000

8000

Kgs 910 1814

2720

3630

Line Speed Fpm 37.2 18 13.1 10.2 8.2

Mpm 11.4 5.5 4.1 3.2 2.6

Motor Current

Amps

75 195 260 335 410

Line pull and cable capacity

Layer of cable 1 2 3 4

Rated line pull per layer

Lbs 8000

6900

5850

5100

Kgs 3630

3130

2650

2310

Cable capacity per layer

Ft 16 42 72 94

Mpm

5 12 21 28

Installation Manual

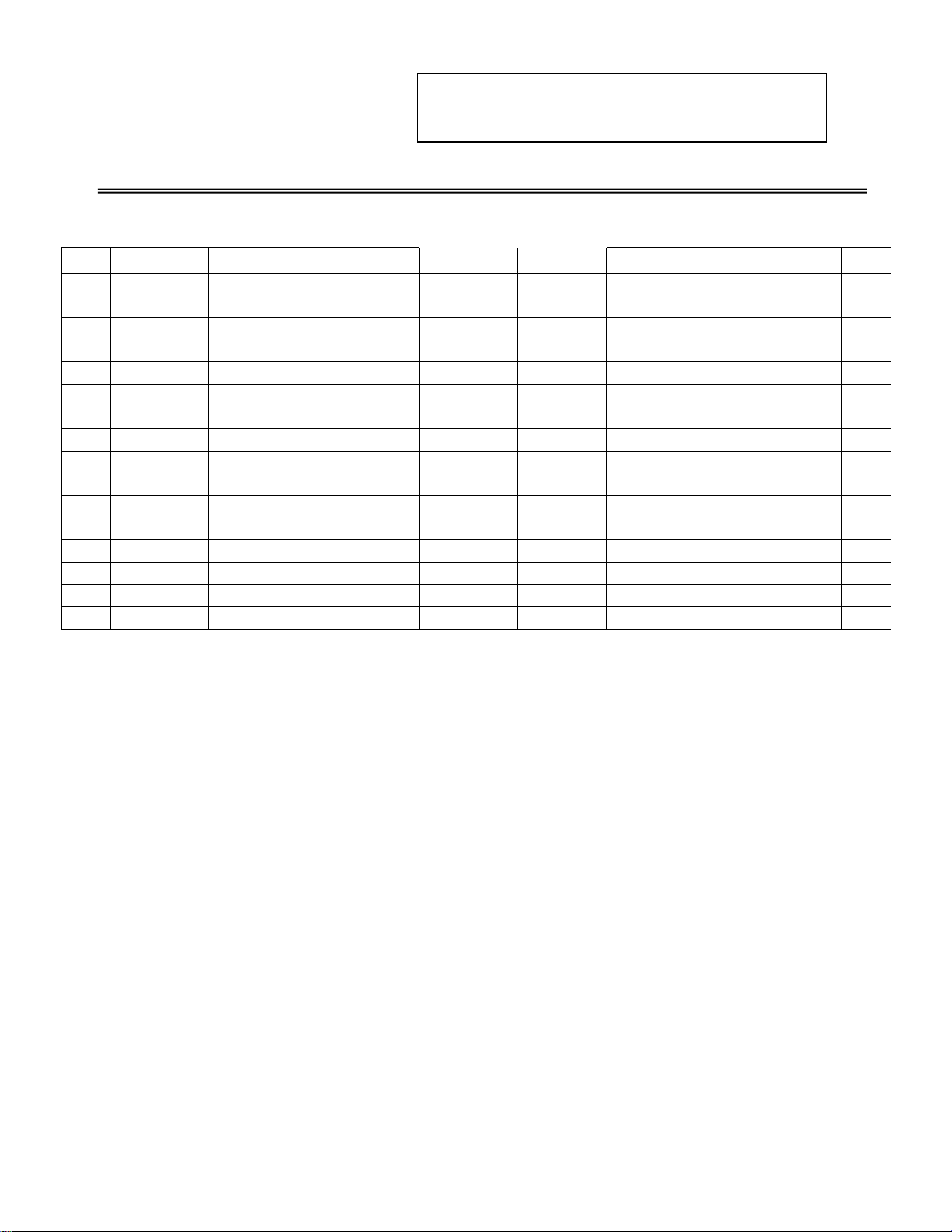

XRC 8 WINCH PARTS LIST

No.

Parts No.

Description Qty

No.

Part No. Description Qty

01 97281-01 Sun Gear-Input 1 27 97281-27

Inner Gear 1

02 97281-02 Gear Carrier-Input 1 28 97281-28

Clutch Gear 1

03 97281-03 Gear Carrier-Intermediate 1 29 97281-29

Gear Box Tube 1

04 97281-04 Washer-1.2mm thickness 2 30 97281-30

Gasket 1

05 97281-05 Gear Carrier-Output 1 32 97281-32

Gear Box End Cover 1

06 97281-06 Outer Spline 1 33 97281-33

Bolt + Spring Washer 10

07 97281-07 Spline Positioning Bolt 1 34 97281-34

Shaft Sleeve 1

08 97281-08 Drum 1 35 97281-35

Washer 1

09 97281-09 Brake Positioning Bolt 1 36 97281-36

Bearing 1

10 97281-10 Brake System 1 37 97281-37

Clutch Spring 1

11 97281-11 Coupling Joint 1 38 97281-38

Locking Pin 1

12 97281-12 Rotor 1 39 97281-39

Clutch Lever 1

15 97281-15 Motor Long Bolts 2 40 97281-40

Clutch Steel Ball 1

16 97281-16 Motor End Cover 1 41 97281-41

Wire Rope 1

17 97281-17 Carbon Frame & Brush Assy

1 42 97281-42

Wire Rope Fix Bolt 1

18 97281-18 Stator 1 43 97281-43

Screw 4

19 97281-19 Tie Rod Bolt 4 44 97281-44

Spring Washer 4

20 97281-20 Motor Base 1 45 97281-45

Winch Mount Bolt 4

21 97281-21 Nylon Bearing 2 46 97281-46

Clevis Hook 1

22 97281-22 Tie Rod 2 47 97281-47

Roller Fairlead 1

23 97281-23 Bolt 10 48 97281-48

Fairlead Mount Bolt/Nut

2

24 97281-24 Spring Washer 10 49 97281-49

Control Box 1

25 97281-25 Gear Box Base 1 50 97281-50

Remote Control 1

26 97281-26 Gasket 1

Installation Manual

XRC 8 DRAWING

Installation Manual

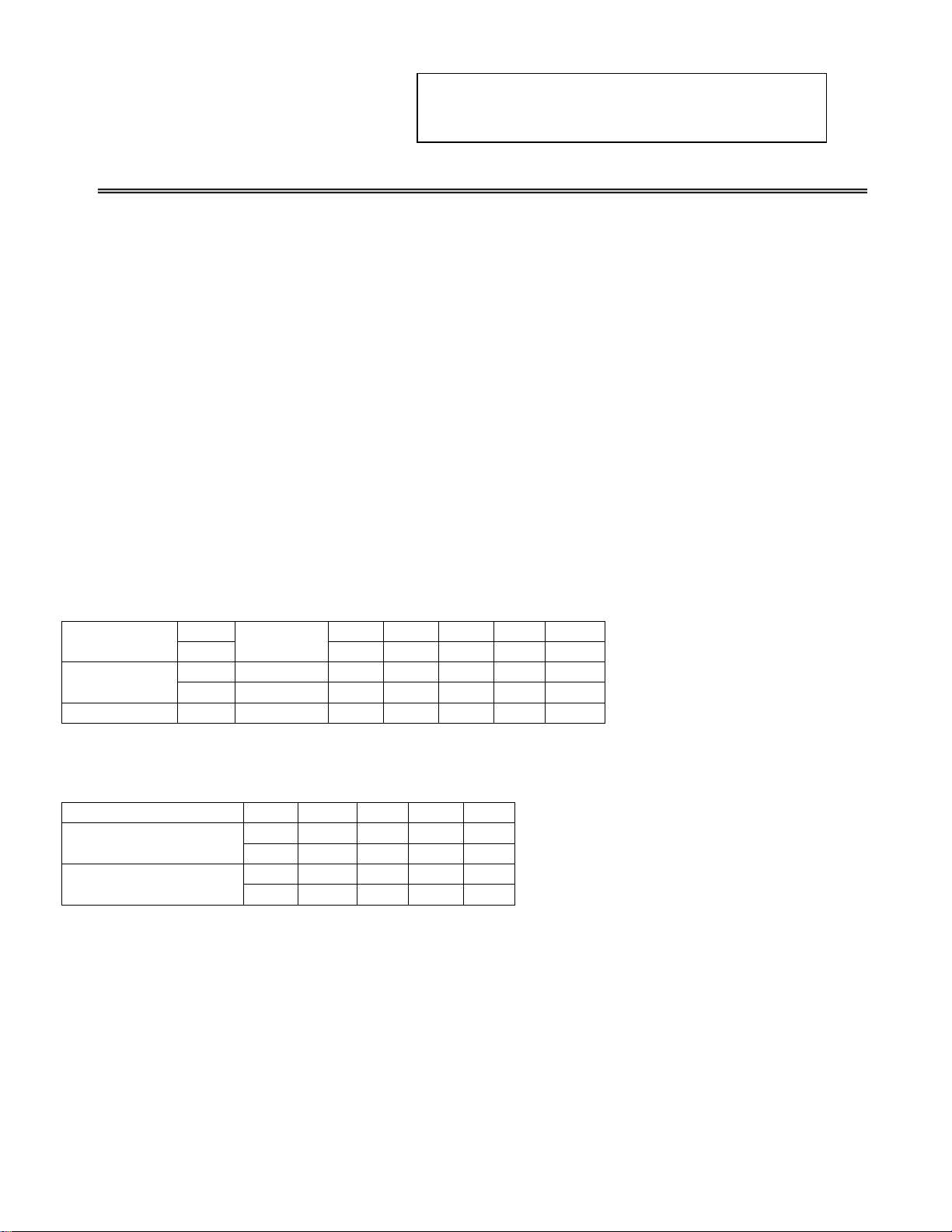

XRC 10 Specifications

Rated Line Pull: 10000Lbs (4532kgs) single-line

Motor: 5.5hp/12V, Series Wound

Control: Remote Switch, 12’ (3.7m) lead

Gear Train: 3-Stage Planetary

Gear Ratio: 218:1

Clutch: Rotating Ring Gear

Brake: Automatic In-The-Drum

Drum Size: (Diameter x Length) 2.5” x 8.82” (63.5mm x 224mm)

Wire Rope: (Diameter x Length) 23/64” x 94’ (9.2mm x 28.5m)

Fairlead: 4-Way Roller

Remote Control: Included

Recommended Battery: 650CCA Minimum for Winching

Battery Leads: 25mm2, 72” (1.8m)

Finish: Black

Weight: 99.0lbs (42.5Kgs)

Mounting Bolt Pattern: 10.0” x 4.50”

Line speed and amp draw (first layer)

Line Pull Lbs NO LOAD

2000 4000 6000 8000

10000

Kgs 910 1814 2720 3630

4535

Line Speed Fpm 29.53 14.44

12.14

10.17

8.86 7.38

Mpm 9 4.4 3.7 3.1 2.7 2.25

Motor Current

Amps

70 170 240 310 380 425

Line pull and cable capacity

Layer of cable 1 2 3 4

Rated line pull per layer

Lbs 10000

8633

7716 7089

Kgs 4535 3915

3499 3215

Cable capacity per layer

Ft 16 42 72 94

Mpm

4.88 12.8 21.95

28.5

Installation Manual

XRC 10 WINCH PARTS LIST

No.

Parts No.

Description Qty

No.

Part No.

Description Qty

01 97210-01 Gear Box End Cover 1 17 97210-17

Remote Control 1

02 97210-02 Gasket 1 18 97210-18

Control Box Assy 1

03 97210-03 Bearing 1 19 97210-19

Nylon Bearing 2

04 97210-04 Sun Gear-Input 1 20 97210-22

Tie Rod 2

05 97210-05 Inner Gear 1 21 97210-21

Drum 1

06 97210-06 Gasket 2 22 97210-22

Brake System 1

07 97210-07 Gear Carrier-Input 1 23 97210-23

Coupling Joint 1

08 97210-08 Gear Carrier-Intermediate

1 24 97210-24

Winch Mount Bolt 4

09 97210-09 Washer-1.2mm thickness 2 25 97210-25

Motor Base 1

10 97210-10 Clutch Gear 1 26 97210-26

Rotor 1

11 97210-11 Gear Carrier-Output 1 27 97210-27

Stator 1

12 97210-12 Gear Box Tube 1 28 97210-28

Carbon Frame & Brush Assy

1

13 97210-13 Clutch Handle Assy 1 29 97210-29

Motor End Cover 1

14 97210-05 Outer Spline 1 30 97210-30

Roller Fairlead 4

15 97210-15 Tie Rod Bolt 4 31 97210-31

Clevis Hook 1

16 97210-16 Gear Box Base 1 32 97210-32

Wire Rope 1

Installation Manual

XRC 10 DRAWING

Installation Manual

XRC 1 Specifications

Rated Line Pull: 12000Lbs (5440kgs) single-line

Motor: 6.6hp/12V, Series Wound

Control: Remote Switch, 12’ (3.7m) lead

Gear Train: 3-Stage Planetary

Gear Ratio: 265:1

Clutch: Rotating Ring Gear

Brake: Automatic In-The-Drum

Drum Size: (Diameter x Length) 2.5” x 8.82” (63.5mm x 224mm)

Wire Rope: (Diameter x Length) 23/64” x 94’ (9.2mm x 28.5m)

Fairlead: 4-Way Roller

Remote Control: Included

Recommended Battery: 650CCA Minimum for Winching

Battery Leads: 25mm2, 72” (1.8m)

Finish: Black

Weight: 99.0lbs (45.0Kgs)

Mounting Bolt Pattern: 10.0” x 4.50”

Line speed and amp draw (first layer)

Line Pull Lbs NO LOAD

2000

4000

6000

8000

10000

12000

Kgs 907 1814

2722

3630

4532 5440

Line Speed Fpm 23.5 12.8 10.5 9.4 7.4 6.3 5

Mpm 7.2 3.9 3.2 2.9 2.3 1.9 1.5

Motor Current

Amps

65 120 165 215 270 320 370

Line pull and cable capacity

Layer of cable 1 2 3 4

Rated line pull per layer

Lbs 12000

10270

9200

8500

Kgs 5440 4654 4169

3852

Cable capacity per layer

Ft 16 42 72 94

Mpm

5 12 21 28

Installation Manual

XRC 1 WINCH PARTS LIST

No.

Parts No.

Description Qty

No.

Part No. Description Qty

02 97212-02 Sun Gear-Input 1 26 97212-26

Gear Box Tube 1

03 97212-03 Gear Carrie-Input 1 27 97212-27

Clutch Gear 1

04 97212-04 Gear Carrier-Intermediate

1 28 97212-28

Inner Gear 1

05 97212-05 Washer-1.2mm thickness 2 29 97212-29

Gasket 9500 3

06 97212-06 Gear Carrier-Output 1 30 97212-30

Gear Box End Cover 1

07 97212-06 Outer Spline 1 31 97212-31

Bolt 10

08 97212-08 Spline Positioning Ring 1 33 97212-33

Shaft Sleeve 1

09 97212-09 Drum 1 34 97212-34

Clutch Spring 1

10 97212-10 Bolt 1 35 97212-35

Washer 1

11 97212-11 Brake Assy 1 36 97212-36

Washer 1

12 97212-12 Coupling Joint 1 37 97212-37

Clutch Steel Ball 1

13 97212-13 Rotor 1 38 97212-38

Connection of Clutch Handle

1

15 97212-15 Motor Long Bolt 2 40 97212-40

Wire Rope 1

16 97212-16 Motor End Cover 1 41 97212-41

Screw 4

17 97212-17 Carbon Assy 1 42 97212-42

Lock Washer 4

18 97212-18 Stator 1 43 97212-43

Mounting Bolt 4

19 97212-19 Tie Rod Bolt 4 44 97212-44

Clevis Hook 1

20 97212-20 Motor Base 1 45 97212-45

Roller Fairlead 1

21 97212-21 Nylon Bearing 2 46 97212-46

Fairlead Mount Nut 2

22 97212-22 Tie Bar 2 47 97212-47

Fairlead Mount Bolt 2

23 97212-23 Bolt 9 48 97212-48

Control Box Assy 1

24 97212-24 Lock Washer 19 49 97212-49

Handle Remote Control 1

25 97212-25 Gear Box Base 1

Installation Manual

XRC 1 DRAWING

Installation Manual

XRC 15 Specifications

Rated Line Pull: 15000Lbs (6800kgs) single-line

Motor: 6.6hp/12V, Series Wound

Control: Remote Switch, 12’ (3.7m) lead

Gear Train: 4-Stage Planetary

Gear Ratio: 395:1

Clutch: Rotating Ring Gear

Brake: Automatic In-The-Drum

Drum Size: (Diameter x Length) 3.7” x 8.54” (94mm x 217mm)

Wire Rope: (Diameter x Length) 25/64” x 94’ (10.0mm x 28.5m)

Fairlead: 4-Way Roller

Remote Control: Included

Recommended Battery: 650CCA Minimum for Winching

Battery Leads: 25mm2, 72” (1.8m)

Finish: Black

Weight: 143.0lbs (65.0Kgs)

Mounting Bolt Pattern: 10.0” x 4.50”; 10.0” x 6.50”

Line speed and amp draw (first layer)

Line Pull Lbs NO LOAD

3000

6000

9000

12000

15000

Kgs 1360

2720

4080

5440 6800

Line Speed Fpm 21.3 11.5 7.2 5.6 4.9 3.6

Mpm 6.5 3.5 2.2 1.7 1.5 1.1

Motor Current

Amps

65 140 270 295 360 420

Line pull and cable capacity

Layer of cable 1 2 3 4

Rated line pull per layer

Lbs 15000

12550

10638

9320

Kgs 6800 5688 4820 4200

Cable capacity per layer

Ft 19.7 46.0 75.5 91.8

Mpm

6 14 23 28

Installation Manual

XRC 15 WINCH PARTS LIST

No.

Parts No.

Description Qty

No.

Part No. Description Qty

01 97215-01 Sun Gear - Output 1 26 97215-26 Gasket 2

02 97215-02 Gear Carrier Assy - Output 1 27 97215-27 Inner Gear 1

03 97215-03 Gear Carrier Assy - Intermediate

1 28 97215-28 Clutch Gear 1

04 97215-04 Washer 1 29 97215-29 Gear Box Tube 1

05 97215-05 Planet Gears - Output 1 30 97215-30 Gear Box Graft Stan 1

07 97215-07 Washer 1 32 97212-32 Gear Box End Cover 1

08 97215-08 Drum Assy 1 33a 97215-33a Washer 4 20

09 97215-09 Bolt for Brake 1 33b 97215-33b

Bolt M4*25 20

10 97215-10 Brake Assy 1 36 97215-36 Bearing 1

11 97215-11 fixing sleeve 1 37a 97215-37a Shaft Sleeve 1

12 97215-12 Rotor (12V) 1 37b 97215-37b

Washer 1

13 97215-13 Bolt M5*20 4 37c 97215-37c Clutch 1

14 97212-14 Washer 18 2 37d 97215-37d

Clutch Bolt 1

15 97215-15 Tie Rod Bolt 6 37e 97215-37e Clutch Spring 1

16 97215-16 Motor End Cover 1 39 97215-39 Bolt 8

17 97215-17 4.5”Carbon Assy 1 41 97215-41 Wire Rope 1

18 97215-18 Stator (12V) 1 42 97215-42 Wire Rope Mount Bolt M6*8

1

19 97215-19 Long Bolt 1 43 97215-43 Bolt M12*40 8

20 97215-20 Motor Base 1 44 97215-44 Washer 12 10

21 97215-21 Nylon Bearing 2 46 97215-46 Clevis Hook 1

22 97215-22 Tie Rod 2 47 97215-47 Roller Fairlead 1

23 97215-23 Bolt M5*20 10 48 97215-48 Bolt M12*25 2

24 97215-24 Washer 5 2 49 97215-49 Control Box Assy (12V) 1

25 97215-25 Gear Box Base 1 53 97215-50 Remote Control 1

Other manuals for XRC8

1

This manual suits for next models

3

Table of contents

Other Smittybilt Winch manuals

Popular Winch manuals by other brands

Come.up Winch

Come.up Winch DV-9si quick start guide

Strongline

Strongline ATW6005 instruction manual

Comeup

Comeup CWG-10151 Installation

Harbor Freight Tools

Harbor Freight Tools Badland 57607 Owner's manual & safety instructions

Kolpin Outdoors

Kolpin Outdoors KAWASAKI MULE PRO-FX Assembly & owners manual

Comeup

Comeup Cub3 manual