HYDROVERT V20 USER MANUAL Version 2.1 dated 10-08-2017

3

1 – INTRODUCTION

HYDROVERT V20 is a new inverter model with built-in EMC filter in compliance with 2004/108/EC

(Electromagnetic Compatibility) and 2006/95/EC (Low Voltage) Directives, fitted with special software for

hydraulic systems, which can operate with both old and new control units.

Controls only the UPWARD run phase.

The following advantages are attained:

•No peak currents. The maximum start-up current is the nominal current.

•Possibility of setting a network maximum input power limit, to contain the contractual power.

•Reduction of consumptions.

•Optimisation of run comfort.

•Power factor correction of the network input power. Cosϕ

ϕϕ

ϕ0.98.

•Possibility of selecting the inspection speed value.

HYDROVERT V20 is available for motors with maximum input current up to 27A.

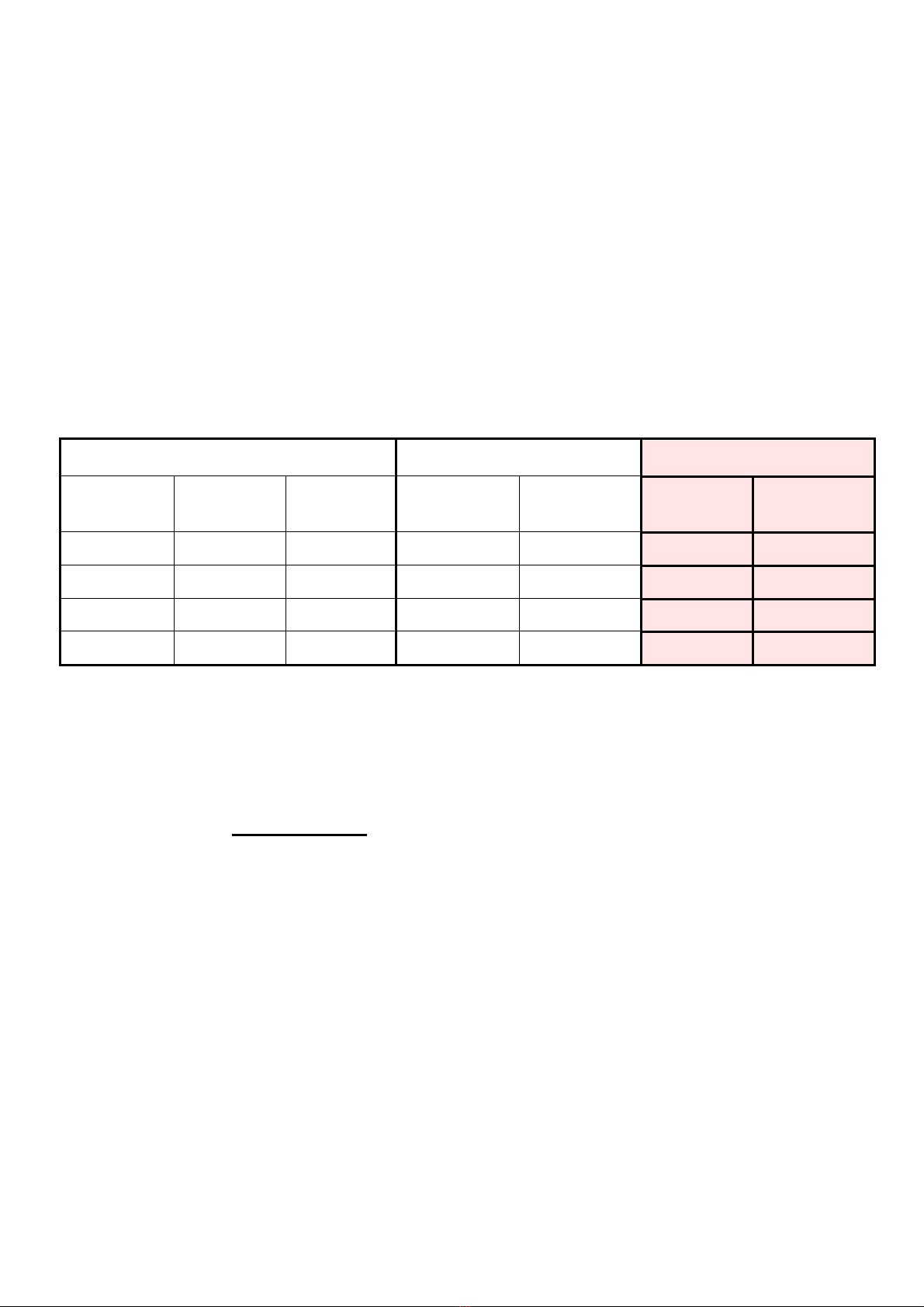

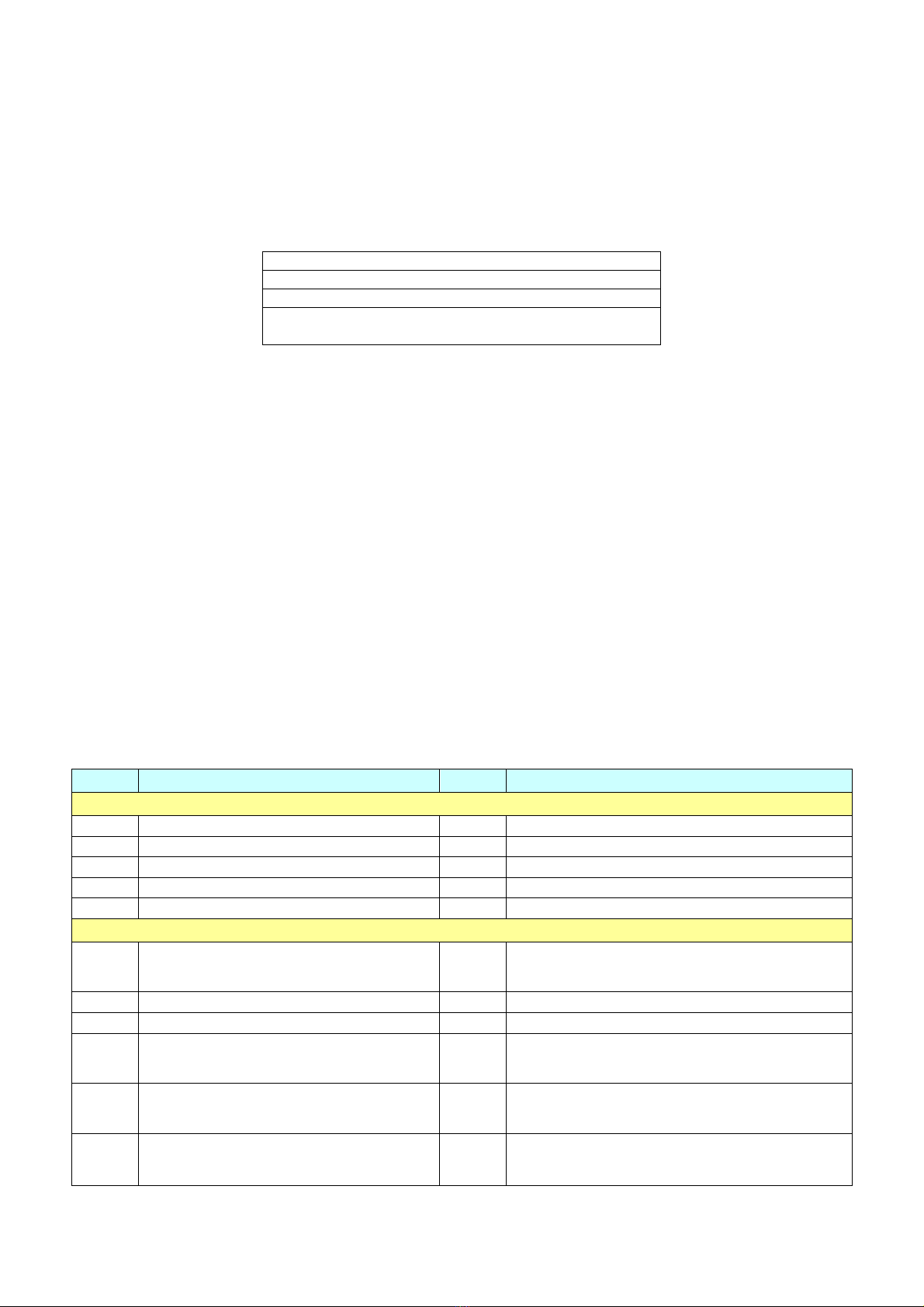

A TABLE is given successively, which states the indicative INPUT POWER and ENGAGED POWER values

that can be obtained with HYDROVERT V20, highlighting the possible saving with respect to the application

of a simple SOFT STARTER.

MOTOR DATA

(kW)

(kW)

PLATE

POWER

(kW)

NOMINAL

CURRENT

(A)

MAXIMUM

CURRENT

(A)

With

NOMINAL

current

With

MAXIMUM

current

SOFT

STARTER HYDROVERT

2.2 7.1 9 3.9 5 6 4.5

3 8.6 11 4.7 6 6 4.5

4.7 13 16 7.2 8.8 10 6

6 15 21 8.3 11.6 15 6

TABLE 1 – Input Power and Engaged Power

2 – RECOMMENDATIONS AND PRECAUTIONS

For everything that concerns the recommendations relative to personal safety and to prevent accidental

damage to the product or equipment connected to it, refer to the “SAFETY” chapter in the original

VACON INSTALLATION AND MAINTENANCE TECHNICAL MANUAL (VACON 20 Cold Plate series

inverter) available at www.it.vacon.com, where the “Declaration of Conformity”, given on the last page of

this document, is also present.

Read this manual completely before powering the appliance.

Regarding specific application on elevators, also carefully consider the following points:

1- The inverter leakage current to earth is over 30mA, a residual current device must therefore be

envisioned with I

d

no less than 300mA; type B or type A. For the earth connection, the regulations

prescribe a cable with minimum section of 10 mm².

If, on closing the master switch, the RCD intervenes, do not repeat the operation several times

successively because the inverter could undergo permanent damage.

2- To prevent damage to the inverter in the event of prolonged standstill without power supply,

before re-starting it is necessary:

- If the inverter is at a standstill for several months, power it for at least 1 hour in a way to

regenerate the bus condensers.

- If the inverter is at a standstill for more than 1 year, power it for 1 hour with voltage that is 50%

lower than the nominal voltage and then for 1 hour at nominal voltage.