ARC130S SECTION 0

ARC130S 060801 Version 1 Issue 1 0.5

Table of Contents

Section 1 Introduction

Section 2 Specification

Section 3 Installation

Power Connections .......................................................................................................... 3.1

Environment .....................................................................................................................3.1

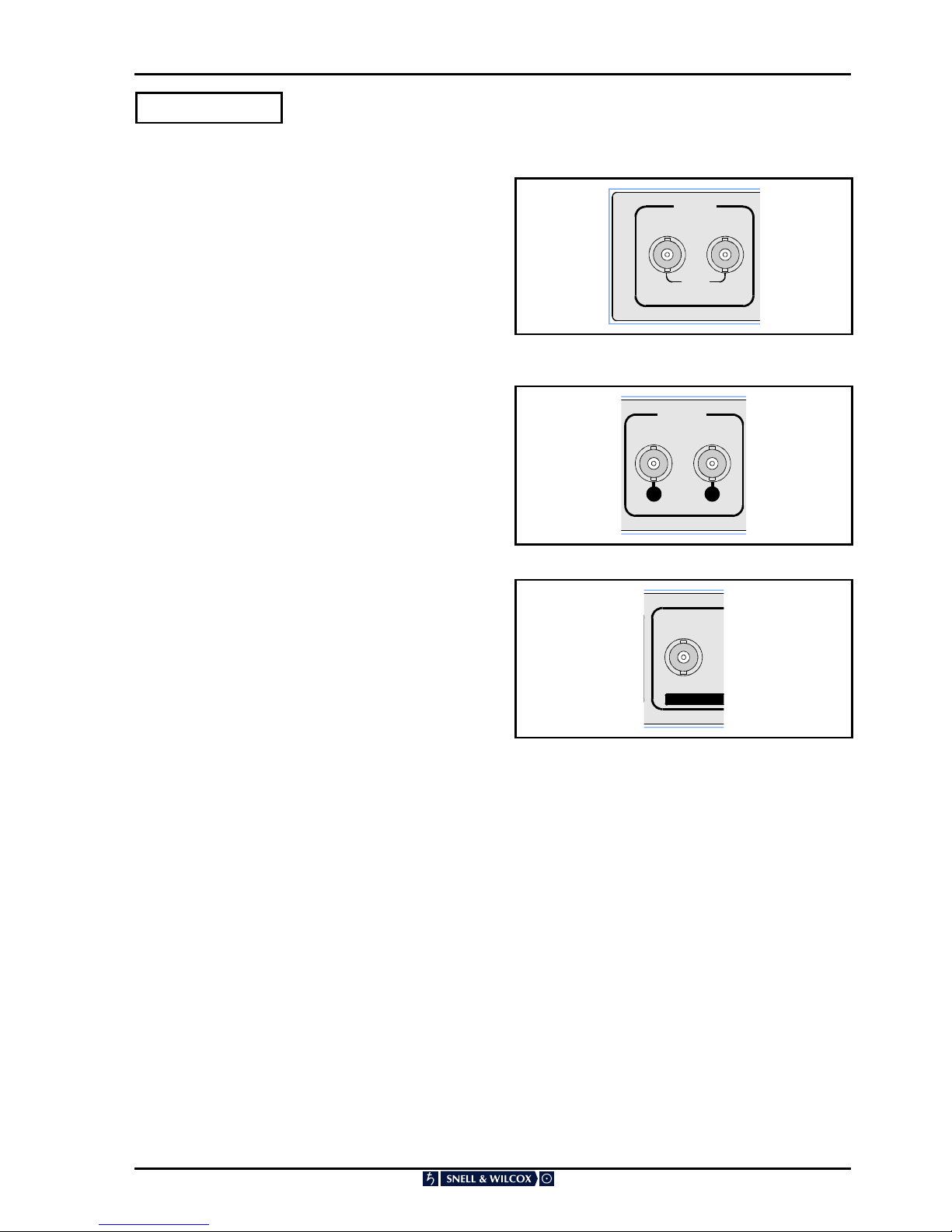

Rear Panel Connections .................................................................................................. 3.2

Using a Kudos Active Front Panel fitted to a Shoebox..................................................... 3.5

GPI Connections .............................................................................................................. 3.6

ARC Configuration Loader Program ................................................................................ 3.8

Switching On ....................................................................................................................3.10

Section 4 Operation

Introduction....................................................................................................................... 4.1

Switch Controls (Blank Front Panel) ................................................................................ 4.1

Top Menu ............................................................................................................... 4.2

Audio ...................................................................................................................... 4.3

Blanking ................................................................................................................. 4.4

Display ................................................................................................................... 4.5

GPI ......................................................................................................................... 4.10

Auto Setup ............................................................................................................. 4.11

Line 23 (PAL Standard Only) ................................................................................. 4.14

AFD Dat ................................................................................................................. 4.15

Memory .................................................................................................................. 4.17

Setup...................................................................................................................... 4.18

VITS ....................................................................................................................... 4.23

Option with Front Panel Controls ..................................................................................... 4.24

Function Select ...................................................................................................... 4.25

Display ................................................................................................................... 4.25

VITS ....................................................................................................................... 4.27

Auto........................................................................................................................ 4.27

Setup...................................................................................................................... 4.28

GPI ......................................................................................................................... 4.30

Bypass ................................................................................................................... 4.36

User........................................................................................................................ 4.36

Aspect Ratio Selection ........................................................................................... 4.37

Blanking Setup ....................................................................................................... 4.46

Line 23 Setup ......................................................................................................... 4.47

Video Index Setup.................................................................................................. 4.48

Appendix – Video Index and Enhanced Line 23 .................................................... 4.50

Operation via a Kudos Active Front Panel

Protocol .................................................................................................................. 4.53

RollCall Menu System Drawing.............................................................................. 4.54

Menu Details .......................................................................................................... 4.55

Section 5 System Overview ........................................................................................................... 5.1

Block Diagram Description............................................................................................... 5.2

Section 6 Aspect Ratio Technical Codes for Video and Picture Sources