S2770RT IS – 0102094

Table of Contents

Electrical Danger ............................ Inside Front Cover

California Proposition 65 ................ Inside Front Cover

Chapter 1 – Introduction

Aerial Platform Features.............................................1

Operator’s Manual......................................................1

Safety Alerts ...............................................................1

Operation....................................................................1

Maintenance...............................................................2

Manual of Responsibilities..........................................2

Additional Information.................................................2

Chapter 2 – Specications

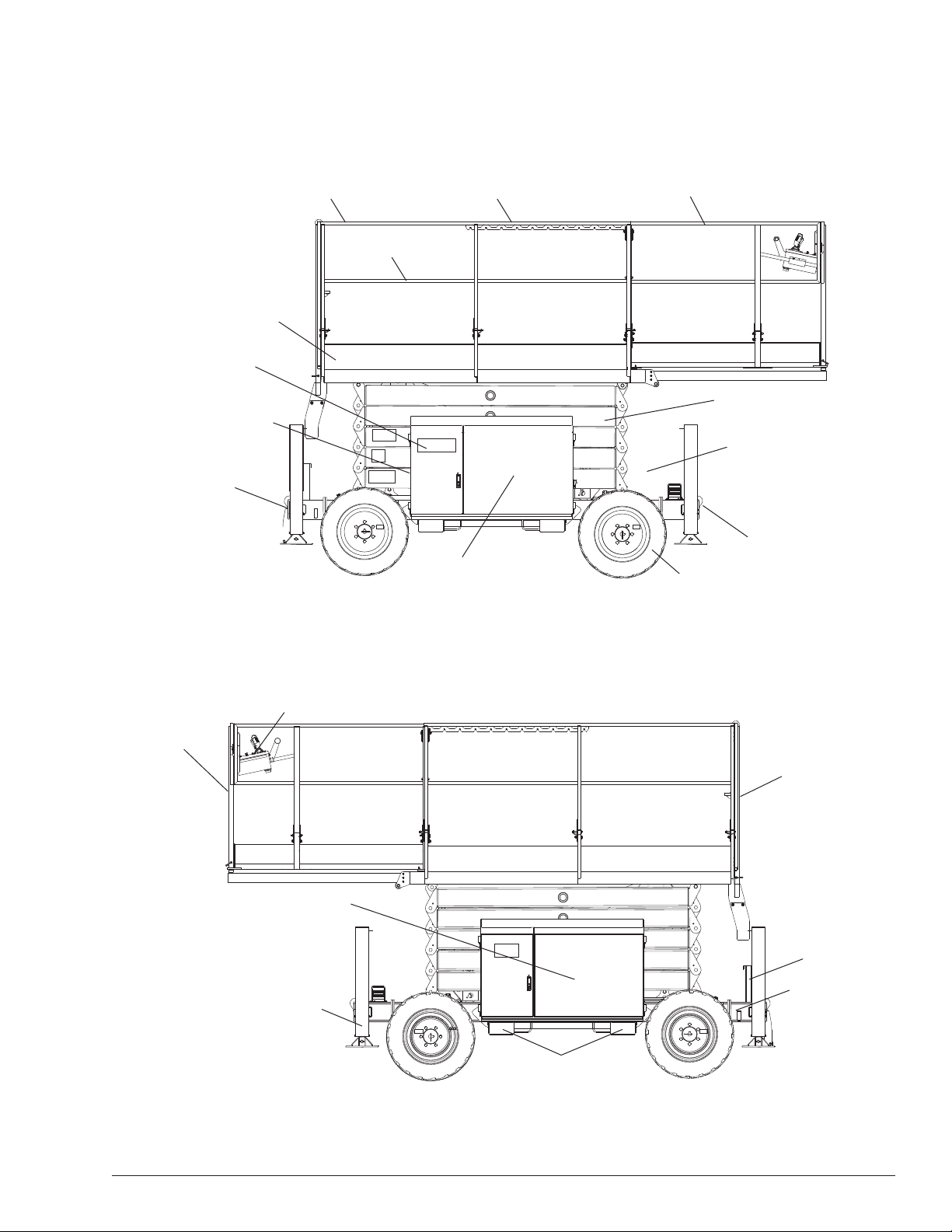

Component Identication............................................3

General Specications................................................4

Aerial Platform.........................................................4

Platform...................................................................4

Function Speed .......................................................4

Drive System...........................................................4

Tires ........................................................................4

Hydraulic System ....................................................4

Ambient Air Temperature Operating Range ............4

Maximum Wind Speed ............................................4

Chapter 3 – Safety

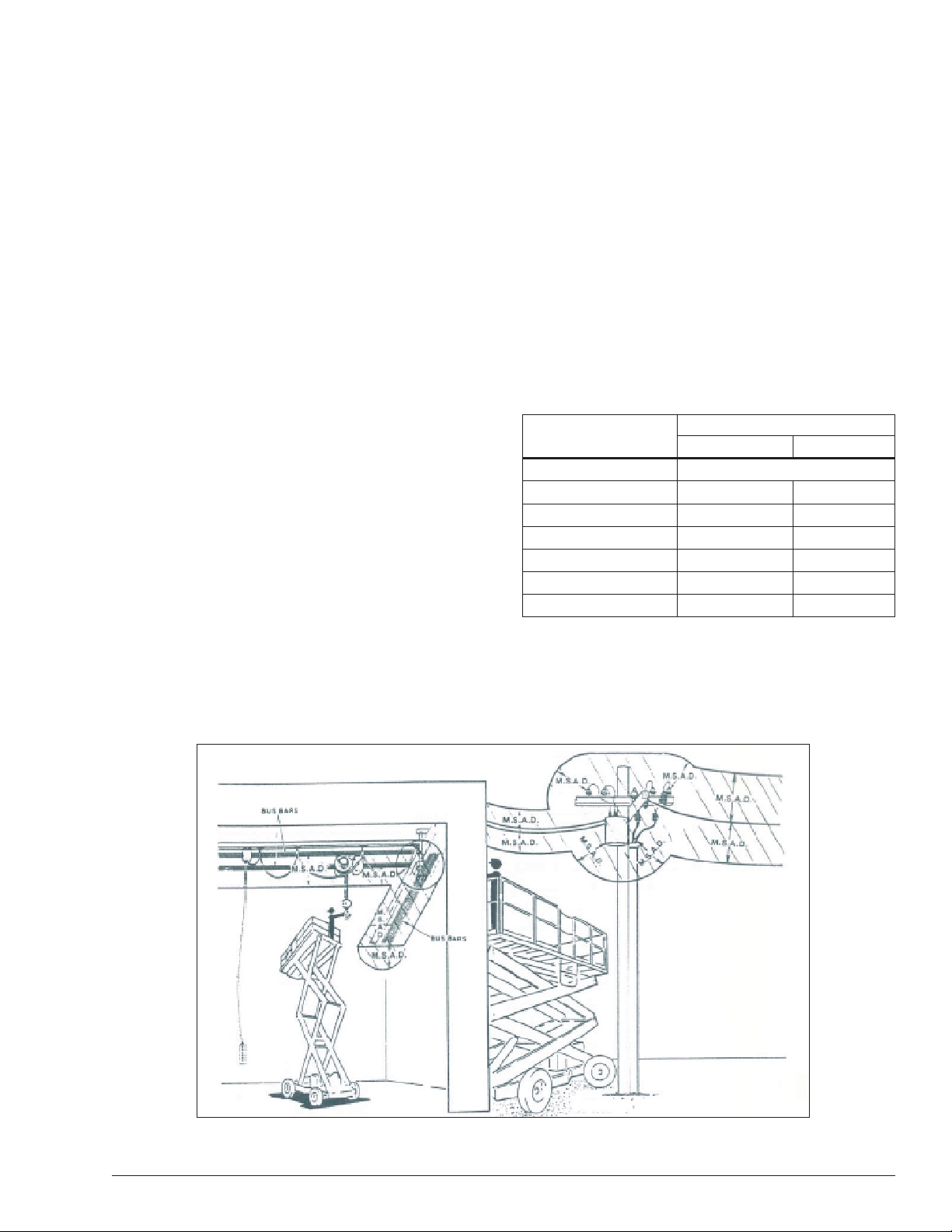

Electrocution Hazards ................................................5

Minimum Safe Approach Distance .............................5

Prestart Inspection......................................................6

Work Place Inspection and Practices.........................6

Operation....................................................................6

Tip-Over and Falling Hazards.....................................7

Hydraulic System........................................................7

Engine and Fuel Handling Precautions ......................7

Placards and Decals...................................................8

Chapter 4 – Safety Devices

Emergency Stop Controls...........................................9

Manual Emergency Lowering Pump...........................9

Ground Operation Button ...........................................9

Outriggers.................................................................10

Bubble Levels...........................................................10

Platform Foot Valve ..................................................10

Tilt Alarm...................................................................10

Guardrails.................................................................10

Lanyard Anchors.......................................................10

Horn Button .............................................................. 11

Safety Prop............................................................... 11

Chapter 5 – Gauges and Displays

Fuel...........................................................................13

Engine Oil.................................................................13

Hydraulic Fluid Filter Gauge.....................................13

Hydraulic Fluid Level Gauge ....................................13

Bubble Levels...........................................................13

Chapter 6 – Controls

Outrigger Controls ....................................................15

Lower Controls .........................................................15

Emergency Stop Button ........................................15

Control Selector ....................................................15

Ground Operation Button ......................................15

Platform Raise Button ...........................................15

Platform Lower Button...........................................15

Upper Controls .........................................................16

Emergency Stop Button ........................................16

Lift/Drive Handle....................................................16

Steer Handle .........................................................16

Drive Speed Handle ..............................................16

High Speed Drive – Rabbit....................................16

Low Speed Drive – Turtle......................................16

Joystick .................................................................16

Horn Button ...........................................................17

Platform Foot Valve ..................................................17

Chapter 7 – Prestart Inspection

Operator’s Manual....................................................19

Engine ......................................................................19

Oil Level ................................................................19

Air Intake ...............................................................19

Fuel Tank...............................................................19

Fuel Line ...............................................................20

Hydraulic System......................................................20

Fluid Level.............................................................20

Fluid Filter .............................................................20

Hoses, Tubes, and Fittings....................................20

Tires and Wheels......................................................21

Outrigger Controls ....................................................21

Bubble Levels...........................................................21

Lower Control Station...............................................21

Operating Controls ................................................21

Emergency Stop....................................................22

Manual Emergency Lowering Pump.........................22

Structures .................................................................22

Weldments ............................................................22

Rollers and Slide Blocks .......................................22

Fasteners ..............................................................23

Upper Control Station...............................................23

Guardrail System ..................................................23

Lanyard Anchors.......................................................23

Platform Extension Deck ..........................................24

Operating Controls ................................................24

Emergency Stop....................................................25

Horn Button ...........................................................25

Placards and Decals.................................................25

Prestart Inspection Checklist....................................29

Chapter 8 – Operation

Hydraulic System Cold Weather Warm-Up .............31

Manually Warming The Hydraulic System ............31

Preparing for Operation............................................31

Outriggers.................................................................31

Operating with Outriggers Lowered on Slopes .....32

Lower Controls .........................................................33