9

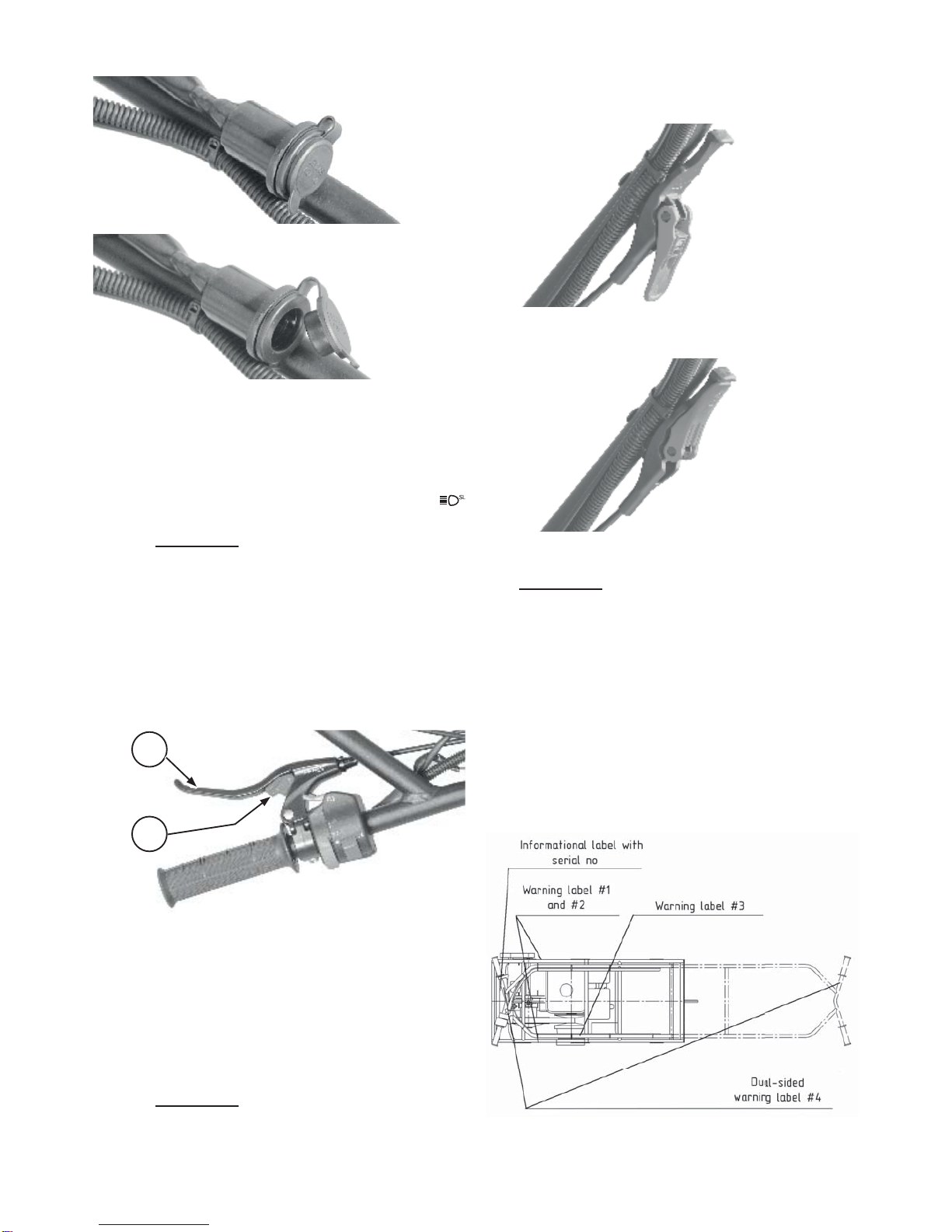

5. Visually check the driver and driven shafts of the CVT,

clean out of dirt if necessary. Be sure to check for

plastic inserts (1) in CVT driver shaft. If plastic inserts

are missing or worn out — insert new ones.

11.3 After the first 5 hours of SNOWDOG

operation

1. Lubricate the throttle and parking brake cables.

2. Lubricate the drive chain and sprockets with

an aerosol chain spray.

3. Adjust throttle and parking brake arms (free motion

should have a value of 0.19 – 0.27 in (5–7 mm)).

4. Adjust the chain tension.

5. Service the engine as specified in the operating

manual of the engine.

6. Visually check the track tension.

11.4 After each 20 hours of SNOWDOG running

1. Lubricate the throttle and parking brake cables.

2. Lubricate the drive chain and sprockets with an

aerosol chain spray.

3. Adjust throttle and parking brake arms (free motion

should have a value of 0.19 – 0.27 in (5–7 mm)).

4. Adjust the chain tension.

5. Check the track tension as described in paragraph

13.3.

6. Change the engine and transmission oils.

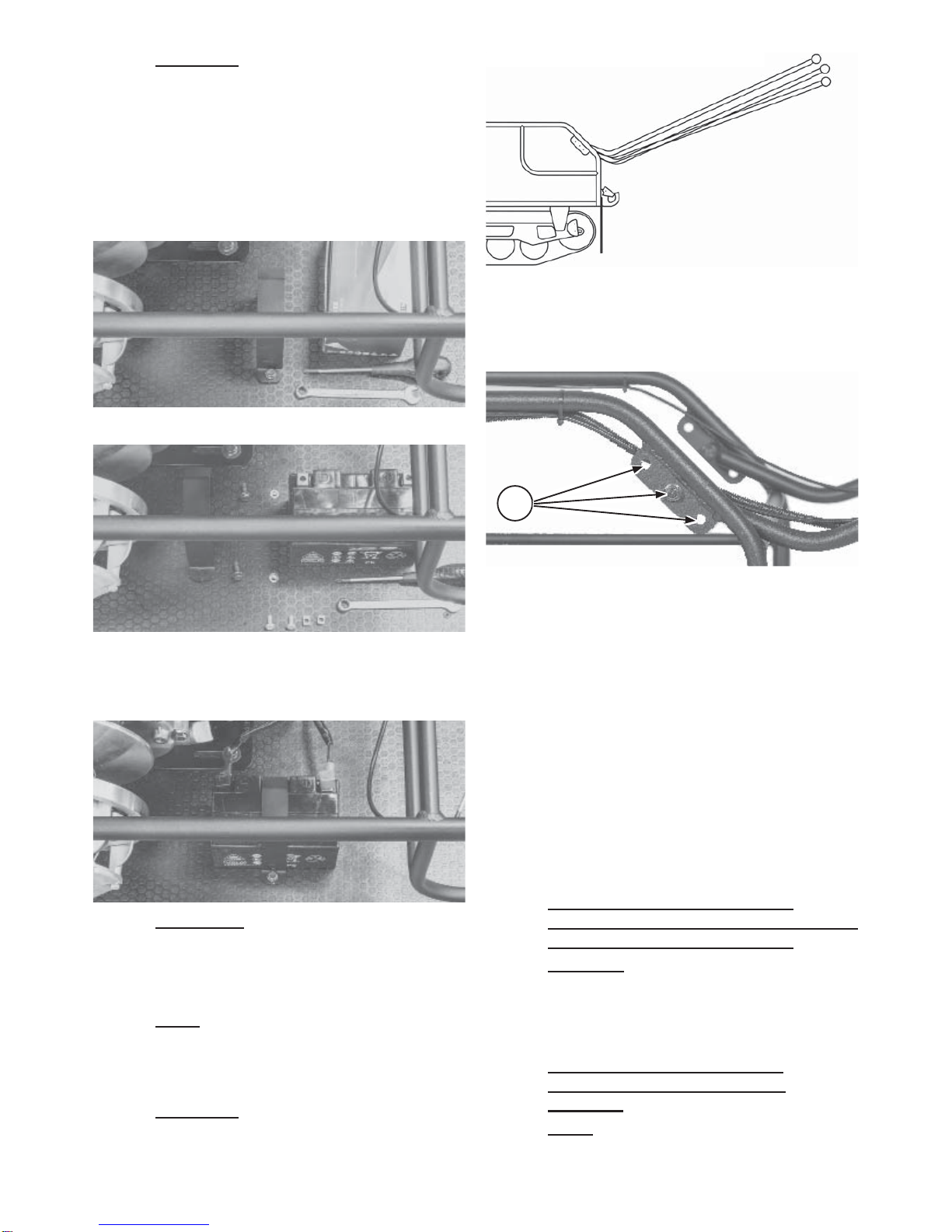

7. Lubricate the bearings in supporting rollers via service

hatch.

8. Service the engine as specified in the operating

manual of the engine.

!WARNING

• When operating under heavy duty conditions

the maintenance should be carried out more

often.

• Heavy duty operating conditions include:

- Moving on deep loose snow (more than 16 inches

in depth).

- Moving at temperature below -13 and above 50

degrees Fahrenheit.

- Moving on wet snow and on snow containing

water.- Moving on surfaces flooded by water.

- Moving on rocky terrain.

- Moving on snow crust which cannot withstand

the weight of the tracksled and sleds.

- Participation in races and competitions.

- Prolonged moving at low speed, “tightly

strained”.

- Moving with a towed load more than 330 lbs.

- Moving on hard-surfaced roads.

- Moving in mud.

- Moving in sand.

- Prolonged moving uphill, downhill, or on slopes.

- Short trips with frequent stops.

11.5 Washing and cleaning

Before washing and cleaning, remove the cover if

necessary. Wash cover, if necessary.

Do not use high pressure for washing, it may damage

some parts of SNOWDOG.

SNOWDOG should be washed with warm water and car

detergent. Thoroughly rinse the detergent.

Wash using a bucket with a sponge or small water pressure

hose. It is necessary to ensure that water is not suffused in

parts, connectors and switches on the engine, in (on) the air

filter and muffler. Do not use petrol or other solvents to clean

the plastic and painted surfaces. Powertrain and chassis must be

cleaned of twigs, leaves and other contaminants. Remove stains

of oil and other fluids.

Start up and warm up the SNOWDOG after washing.

!WARNING!

Do not allow corrosive substances on the

track, such as gasoline, solvents, acids, etc.

12 Storage

SNOWDOG should be stored in a dry ventilated room or

outdoors under a canopy with a waterproof cover.

In case of a short-term storage (up to one month), perform

the procedures specified in paragraph 11.4.

In case of a long-term storage (over a month) perform

all the procedures specified in paragraph 11.4 and lubricate

non-coated parts with a preserving agent, as well as the parts

where paint-and-lacquer coating is exposed. This ensures the

safe preservation of the SNOWDOG for up to 12 months when

stored normally. For the next 12 months of storage, reproduce

the steps above. To do so, follow the engine depreservation

procedures specified herein, remove the preserving agent from

the parts, fill the tank with gas, start the engine and let run for

5 minutes, then stop it, change the engine oil, and preserve the

SNOWDOG for another period.

Also follow the engine manufacturer recommendations for

long-term storage.

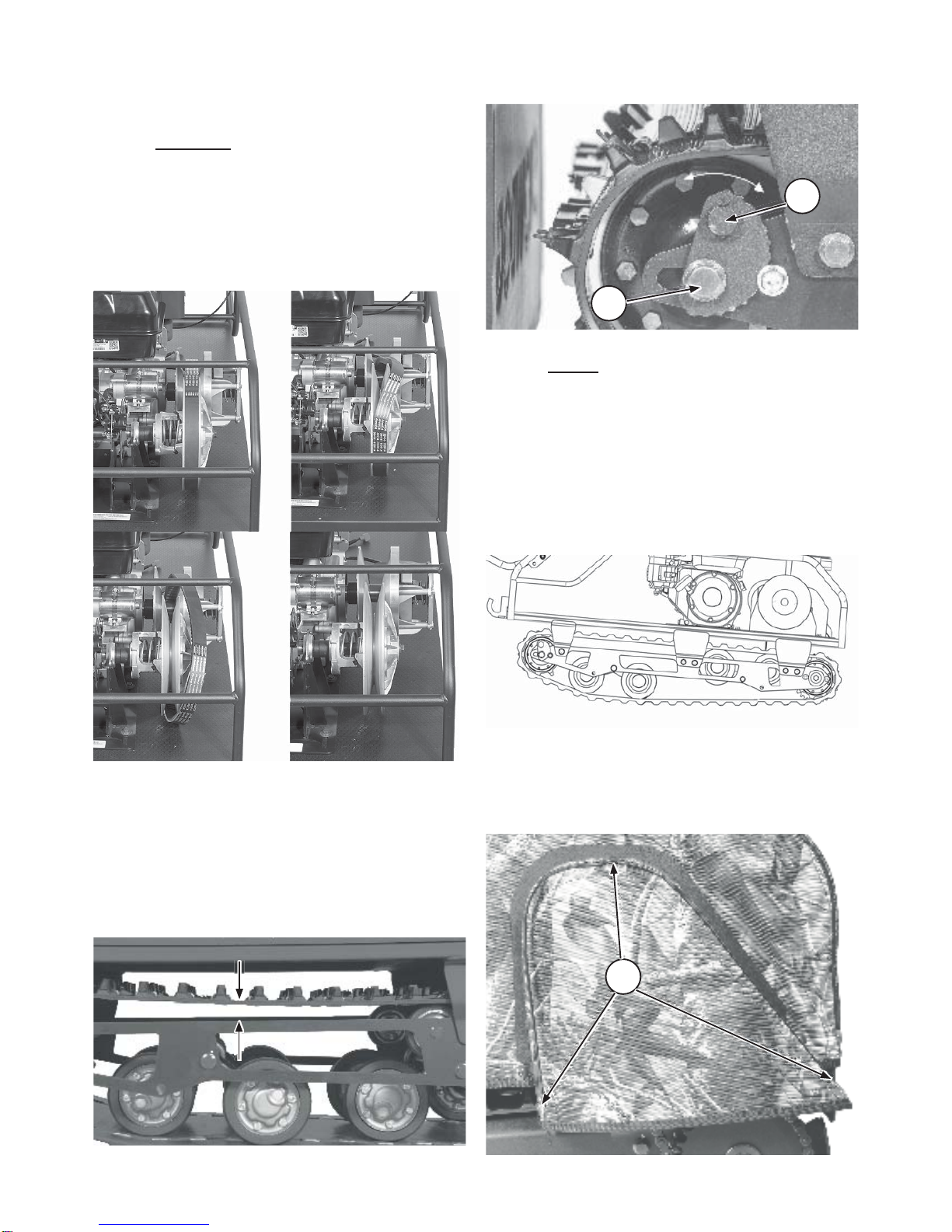

12.1 Track maintenance

Check the track condition and its tension after each trip.

Excessive track tension is often the reason for power loss and

causes engine overload.

Never operate the SNOWDOG with severe track damage.

In case of severe track damage, you should seal it to prevent

moisture from ruining the track’s cord.

The cord threads should not stick out of the track’s side.

If they do, cut them off.

Check the track’s metal brackets after each trip. If bent,

straighten. If a bracket is missing, replace it. Operating damaged

tracks leads to their rapid deterioration.

Inspect and clean the track after each trip.

When operating the SNOWDOG in the wet snow, clean the

track more often, especially before a prolonged stop. Do not

expose the track to oil and various chemicals.

Do not store the SNOWDOG under direct sunlight.

Loosen the track before storage.

We recommend storing the SNOWDOG in suspended

position. In case of a long-term storage the track must be

rotated to a new position once a month.

12.2 Transportation

Drain the fuel from the tank or shut down the fuel valve

before transporting. The SNOWDOG must be in a horizontal

position during loading and unloading. When transporting the

SNOWDOG, make sure it is secure.

SNOWDOG cannot be stacked during transportation.

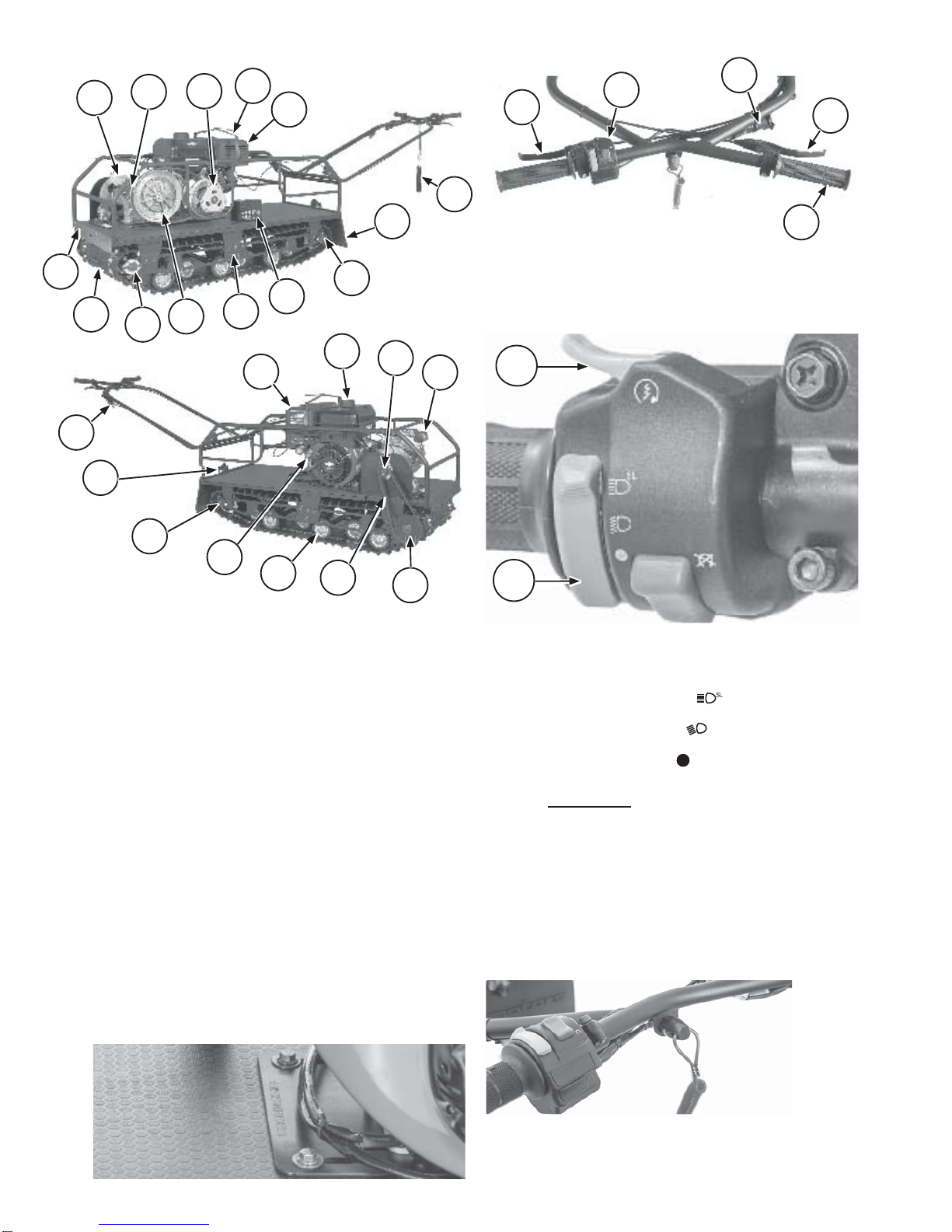

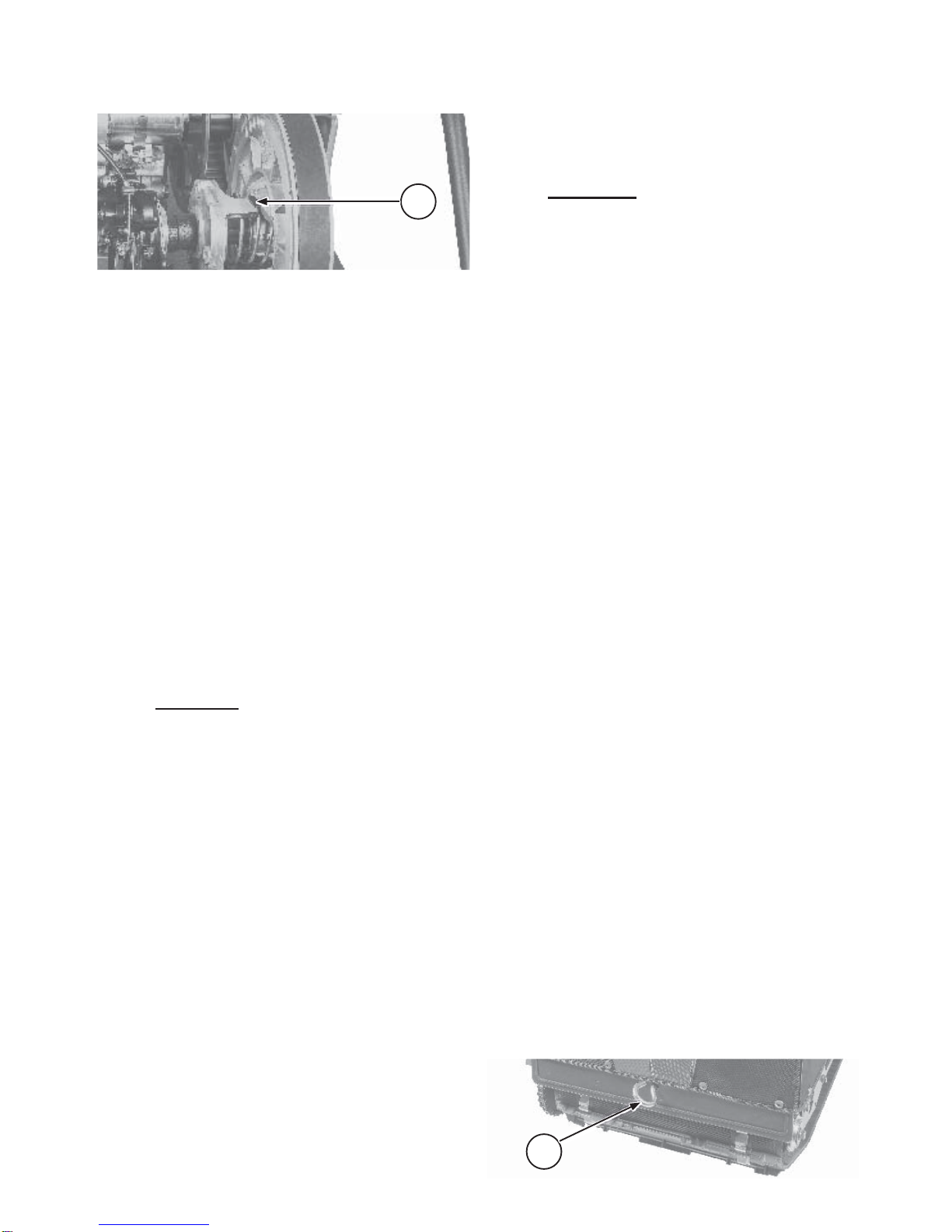

Snowdog is equipped with connector for towing eye bolt (1)

in the front part of the chassis on top part of the front mudflap.

It is designated to mount the Snowdog during transportations,

etc.

Eye bolt is provided with SNOWDOG.

1

1