1

Content

1 Introduction������������������������������������������������������������������������1

2 Safety tips����������������������������������������������������������������������������1

3 Technical specifications ����������������������������������������������������2

4 Snowdog purpose��������������������������������������������������������������2

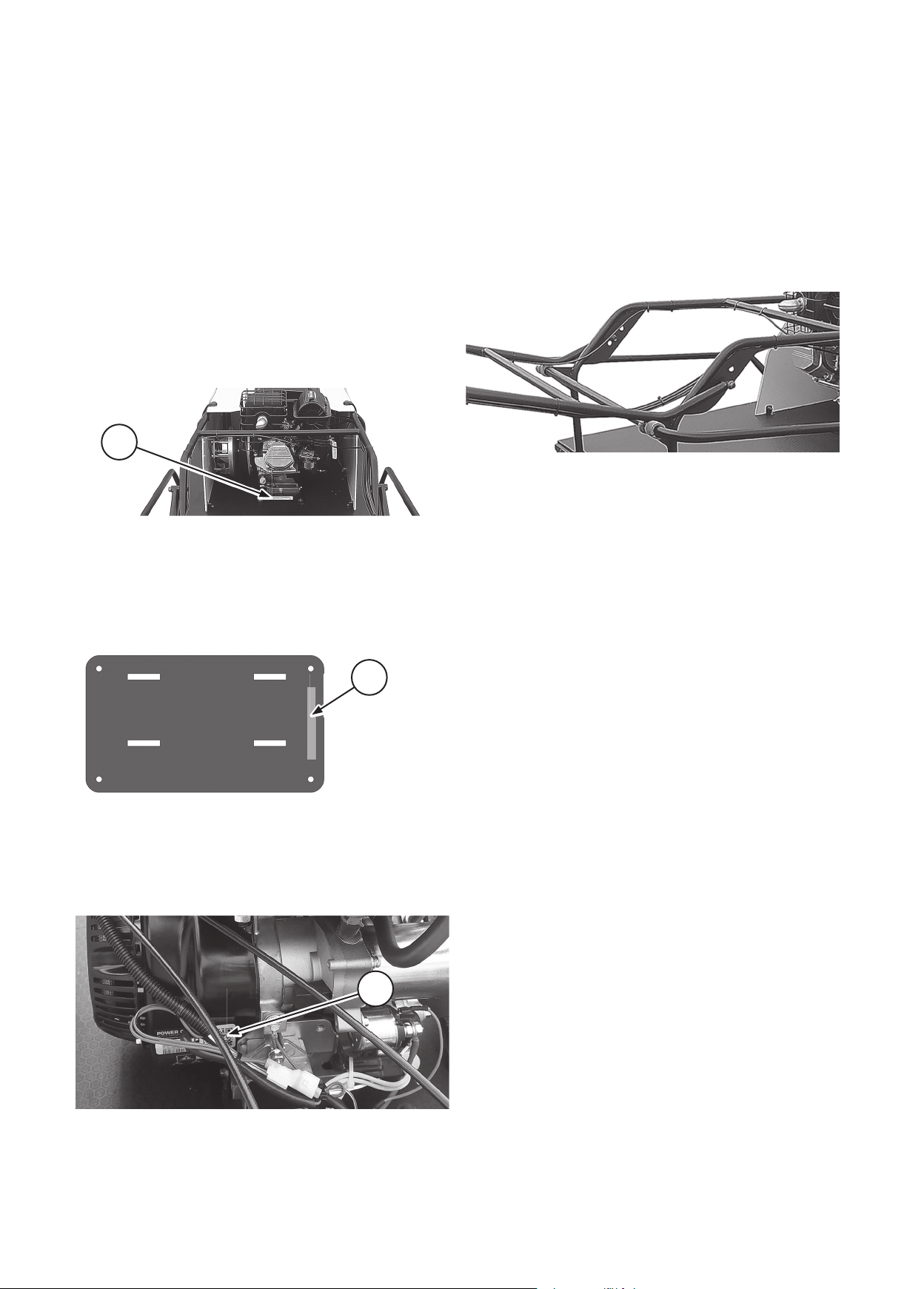

5 Overview �����������������������������������������������������������������������������2

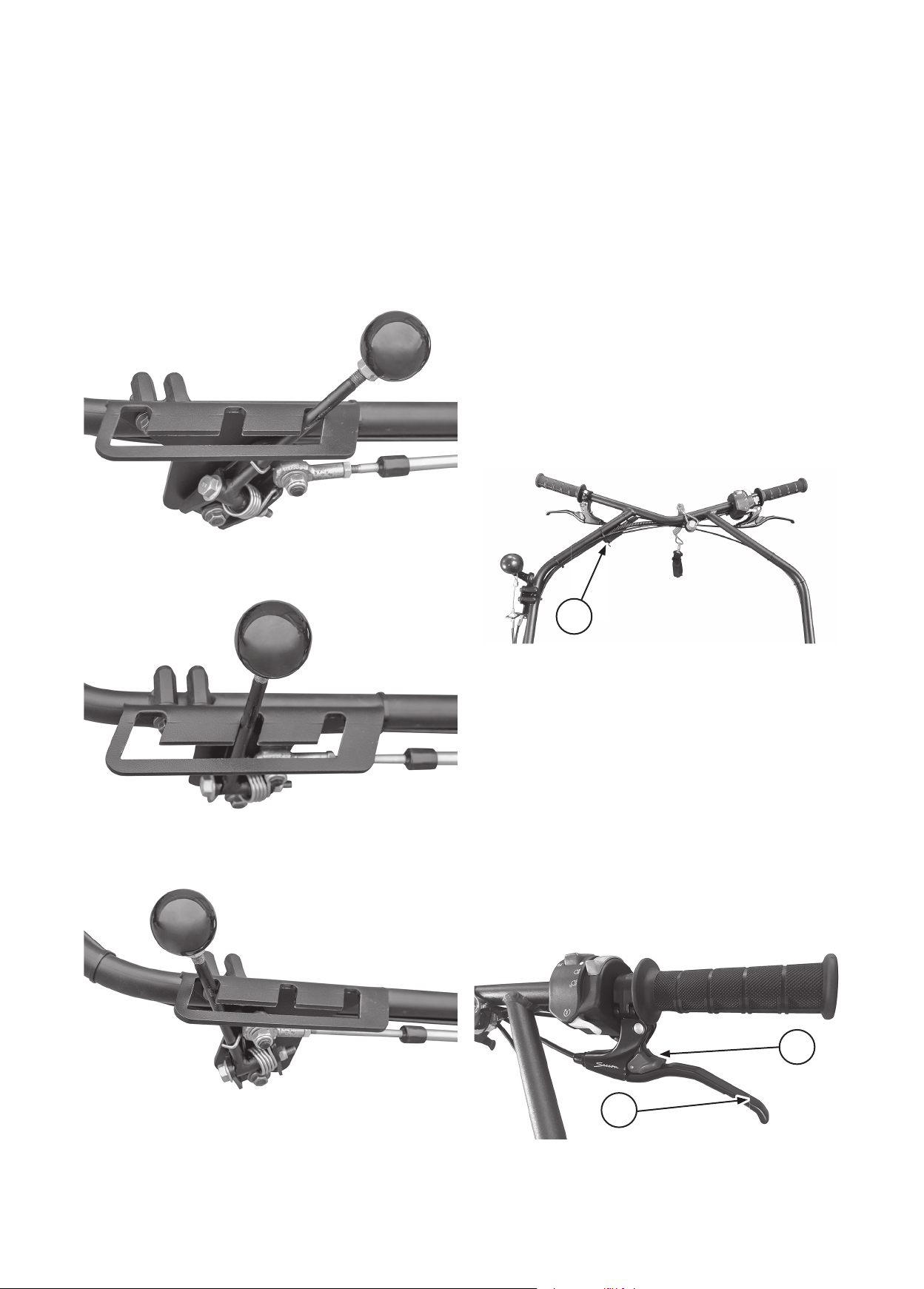

6 Snowdog setup�������������������������������������������������������������������5

7 Operating the Snowdog ���������������������������������������������������5

8 Severe operation conditions ������������������������������������������13

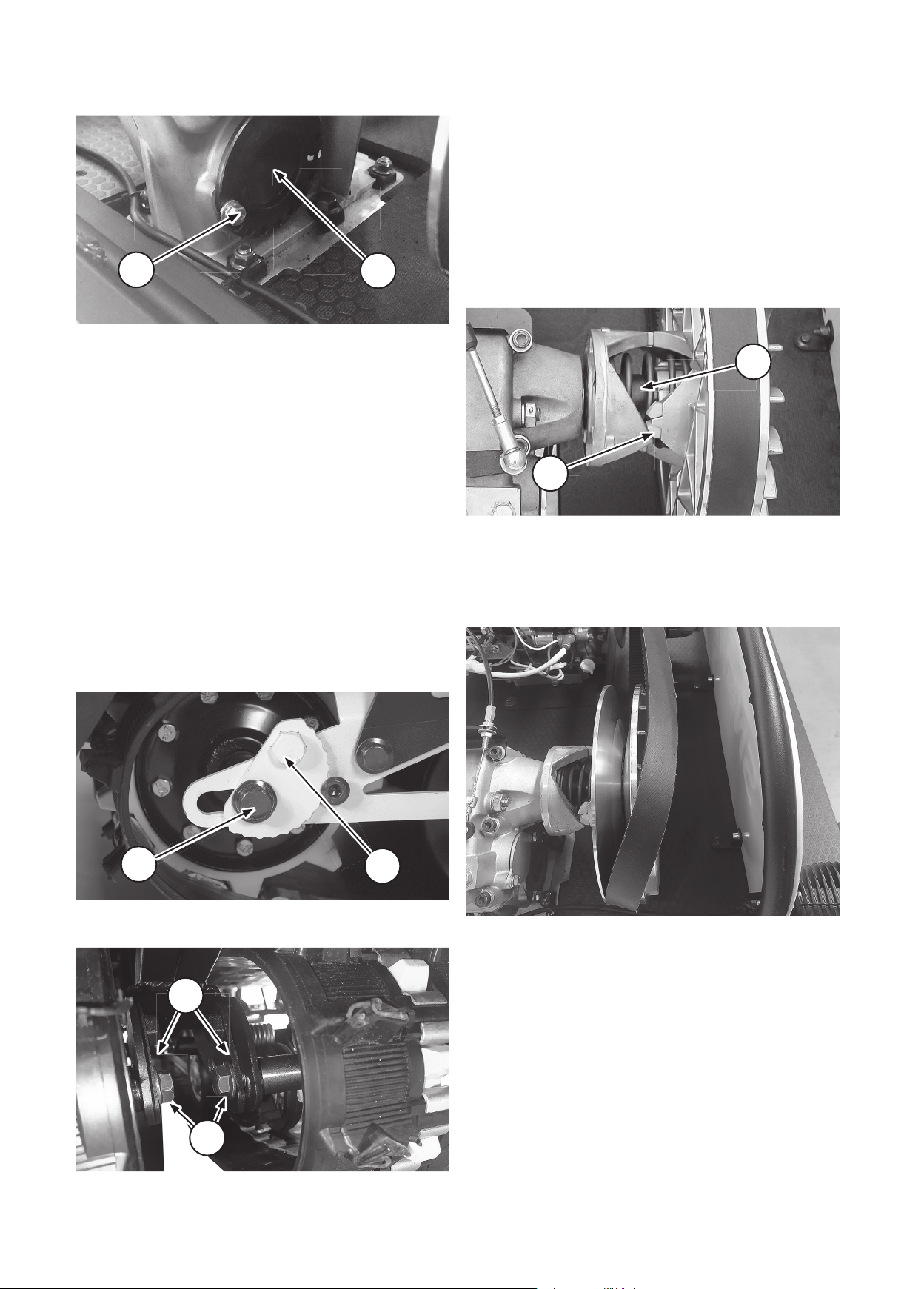

9 Scheduled maintenance �������������������������������������������������14

10 Transportation������������������������������������������������������������������14

11 Snowdog maintenance table������������������������������������������14

12 Storage�������������������������������������������������������������������������������16

13 Manufacturer’s warranty Snowdog �����������������������������16

14 Warranty card*�����������������������������������������������������������������18

15 Service list �������������������������������������������������������������������������18

17 Electrical drawing ������������������������������������������������������������19

1 Introduction

Thank you for purchasing the Snowdog!

Before using Snowdog, please read this manual carefully�

Following technical instructions and safety tips ensure

continuous years of reliable product usage�

Snowdog is a compactly designed and reliable highly

tracksled, equipped with a high-quality Briggs & Stratton

engine and ready for off-road trips or fun�

All information in this manual corresponds to the state of the

product at the date of signing and printing the document�

The manufacturer reserves the right to make changes to

design without prior notice and without any obligations� If a

difference is found between this Manual and your machine,

please contact your Snowdog dealer to get the latest

information�

Service life of Snowdog is 5 years�

2 Safety tips

This Owner’s manual contains important information on

safety tips and operating instructions for Snowdog� In

case of resale, please share this document and the engine

service manual with the next Snowdog owner due to the

importance of the information contained�

Please read this manual carefully before operating the

Snowdog� Non-compliance with the operation instructions

and non-acquaintance with the information in the user’s

manual may cause serious damage and even injuries�

Snowdog operating safety tips and instructions are marked

with “Warning” tag listed herein�

All the information on operating safety tips and instructions

for Briggs & Stratton engine is in the engine user’s manual�

Please read the manual carefully before using the Snowdog�

!Warning

Before operating the Snowdog you must read the

user’s manual and engine user’s manual.

• It is prohibited to operate the Snowdog for minors

under 16 years old, and not recommended to

operate Snowdog for people who are not capable

to operate it safely for different reasons.

• It is prohibited to operate the Snowdog under the

influence of alcohol and/or drugs.

• It is prohibited to use Snowdog without the mud

flaps and emergency engine shutdown switch.

• Operating a faulty or defective Snowdog machine

is prohibited.

• Operating the Snowdog on public roads and trails

is strictly prohibited.

• Snowdog is designed for outdoor use only. Indoor

use is prohibited.

• Park the Snowdog at a safe distance from people

and animals.

• Before starting the engine make sure there are no

people, animals or objects near the Snowdog that

may be damaged or injured.

• Strap the engine security switch on your hand

before starting the engine.

• Before starting the engine make sure the throttle

control lever moves freely and is not fixed.

• Do not start the engine if the handlebar is folded.

• Do not fold the handlebar while the engine is

running.

• Always check out the parking brakes.

• Stay clear of the drive shafts!

• Any maintenance of the Snowdog and the engine

must be carried out only after the engine is shut

off, unless otherwise required for maintenance.

• Make sure all the screws on shafts are tightened

before operating the Snowdog.

• In case of any control malfunctions you should

stop, locate the problem, and fix it.

• Wear protective gloves when operating the

Snowdog.

• Wear protective helmet when operating the

Snowdog.

• Wear ear protectors to reduce the harmful effects

of noise caused by the Snowdog.