Lit. No. 76616, Rev. 02 3 November 15, 2018

TABLE OF CONTENTS

PREFACE.................................................................... 4

Warranty Registration ........................................... 4

Owner's Information Form .................................... 4

SAFETY ...................................................................... 5

Safety Definitions.................................................. 5

Warning/Caution Labels ....................................... 5

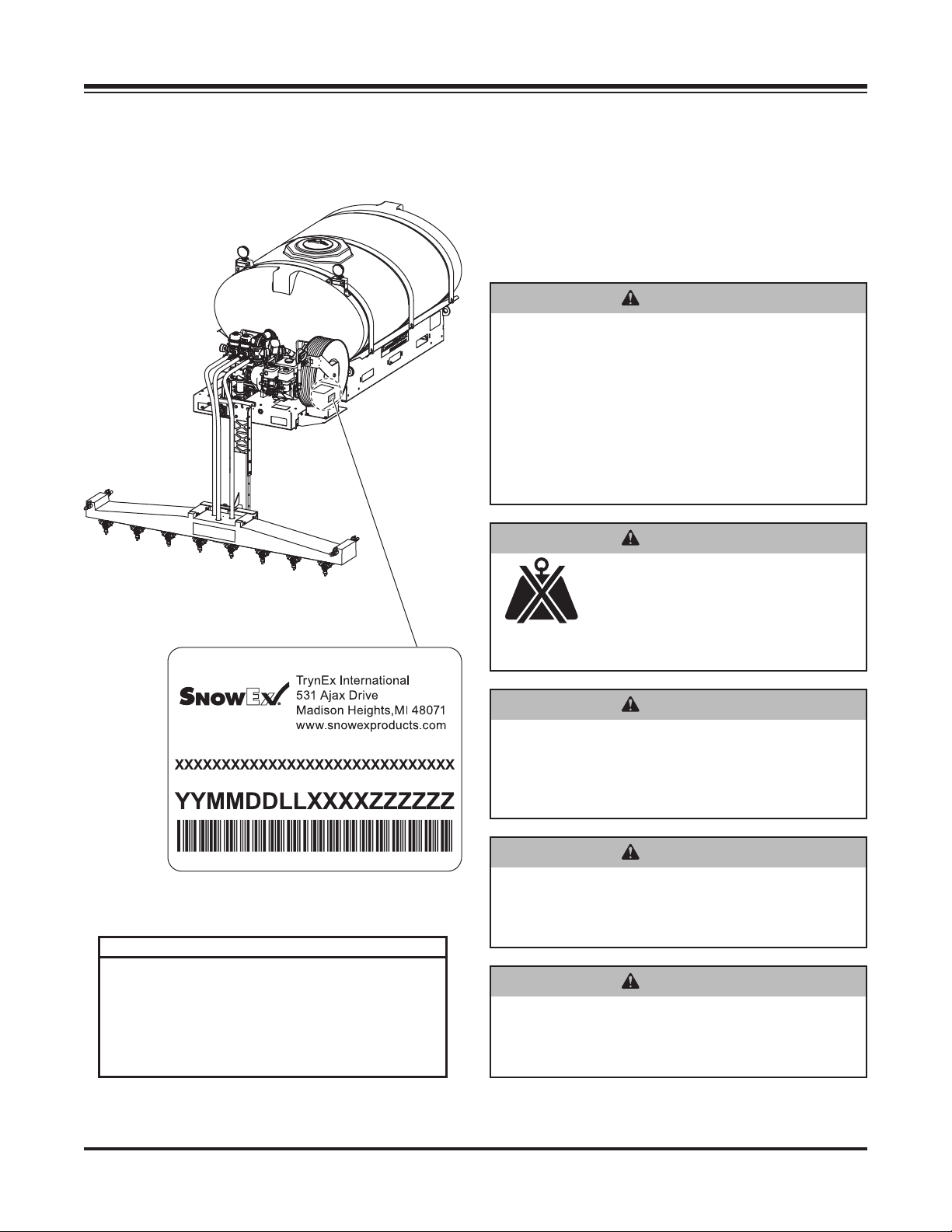

Serial Number Label ............................................. 6

Safety Precautions................................................ 6

Fuses .................................................................... 7

Personal Safety..................................................... 7

Fire and Explosion ................................................ 8

Cell Phones........................................................... 8

Ventilation ............................................................. 8

Battery Safety ....................................................... 8

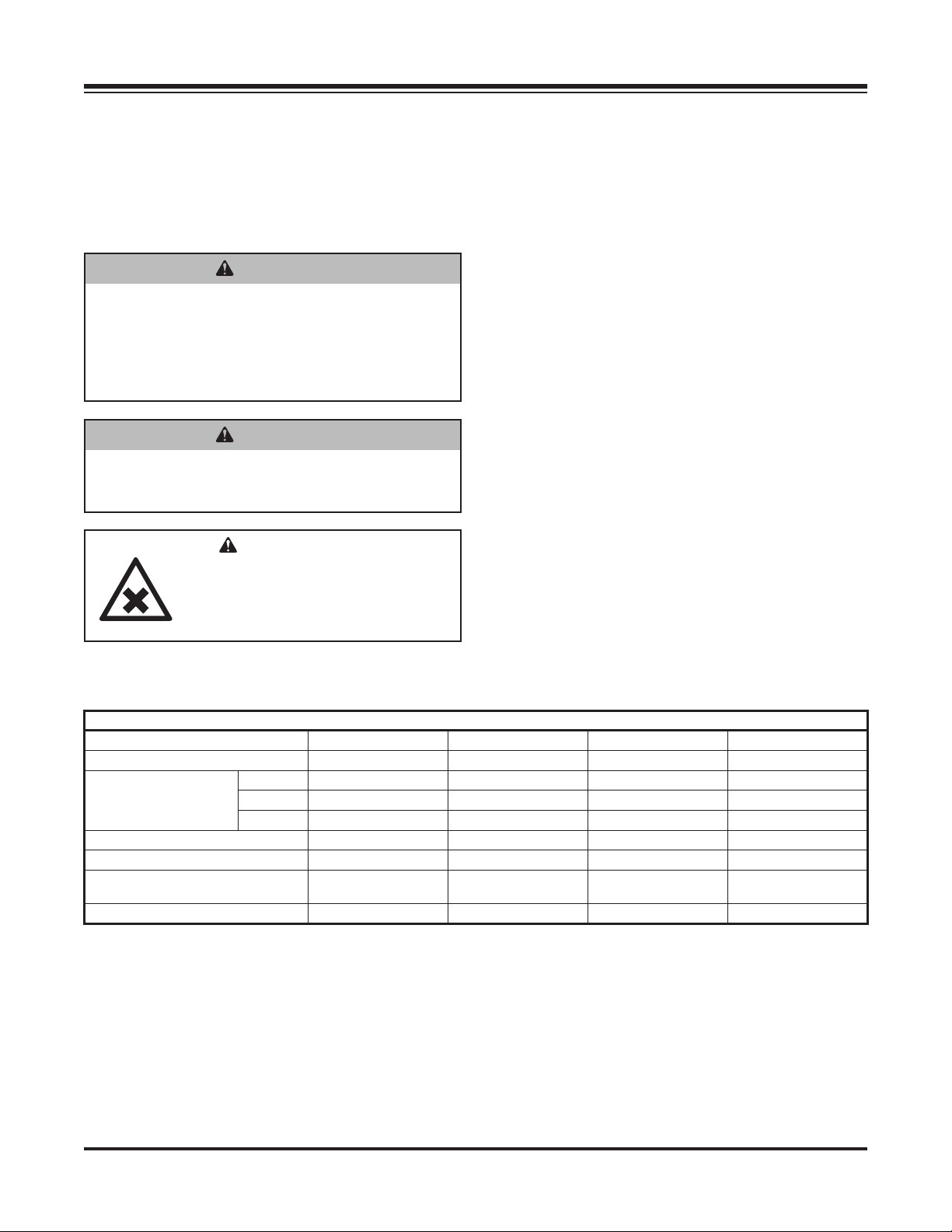

Torque Chart ......................................................... 8

LOADING.................................................................... 9

Certification........................................................... 9

Specifications........................................................ 9

INSTALLATION INSTRUCTIONS ............................ 10

Installation and Removal..................................... 10

Control Box Mounting ......................................... 12

Wiring Diagram ................................................... 13

Installation........................................................... 14

Mounting the Display Console & Switches... 14

Speed Sensor Installation ............................ 15

Standard Control Installation .............................. 15

Wiring Diagram............................................. 15

Battery Connections..................................... 15

FILLING .................................................................... 16

First Time Filling.................................................. 16

Routine Filling ..................................................... 16

Gasoline ....................................................... 16

Adding Brine................................................. 16

Oil ................................................................. 16

OPERATING & CALIBRATION INSTRUCTIONS ... 18

Control Operation ............................................... 18

Deluxe Control.............................................. 18

Standard Control .......................................... 19

Deluxe Console Functions .................................. 20

Rotary Switch Position Functions................. 20

Calibration Positions..................................... 20

Soft Key Functions ....................................... 20

Calibration........................................................... 21

Entering Calibration Values.......................... 21

"Special" Calibration ........................................... 24

Entering Calibration Values.......................... 24

Console Switches & Buttons............................... 28

Section Switches .......................................... 28

Resetting System Counters.......................... 29

Standard Sprayer Control ................................... 30

Sprayer Console........................................... 30

Spray Boom Operation .......................................30

Wing Spray Nozzle Selection....................... 30

Downward Spray Nozzle Selection .............. 31

Nozzle Alignment ......................................... 31

Default Control Settings...................................... 31

Deluxe Control.............................................. 31

Application Rates................................................ 32

Manual Mode................................................ 32

Calculations ........................................................33

Equations......................................................33

Conversions.................................................. 33

Example Calculation..................................... 34

MAINTENANCE........................................................35

Periodic Maintenance ......................................... 35

Cleaning.............................................................. 35

End of Season and Storage................................35

Nozzle Maintenance ...........................................35

Pump Maintenance ............................................. 35

TROUBLESHOOTING..............................................36

TROUBLESHOOTING – DELUXE CONTROL ........ 37

Wiring Diagram – Electric Start System ............. 38

Wiring Diagram – Hydraulic System ................... 39