SAFETY PRECAUTIONS

● Before turning on the power switch, make sure you fully understand the content in the Manual, and

make sure no personnel or obstructions in the hazardous area and work space

● After unpacking the machine when first operation or after a period of inactivity, the sliding mandrel need

to be put oil on it.

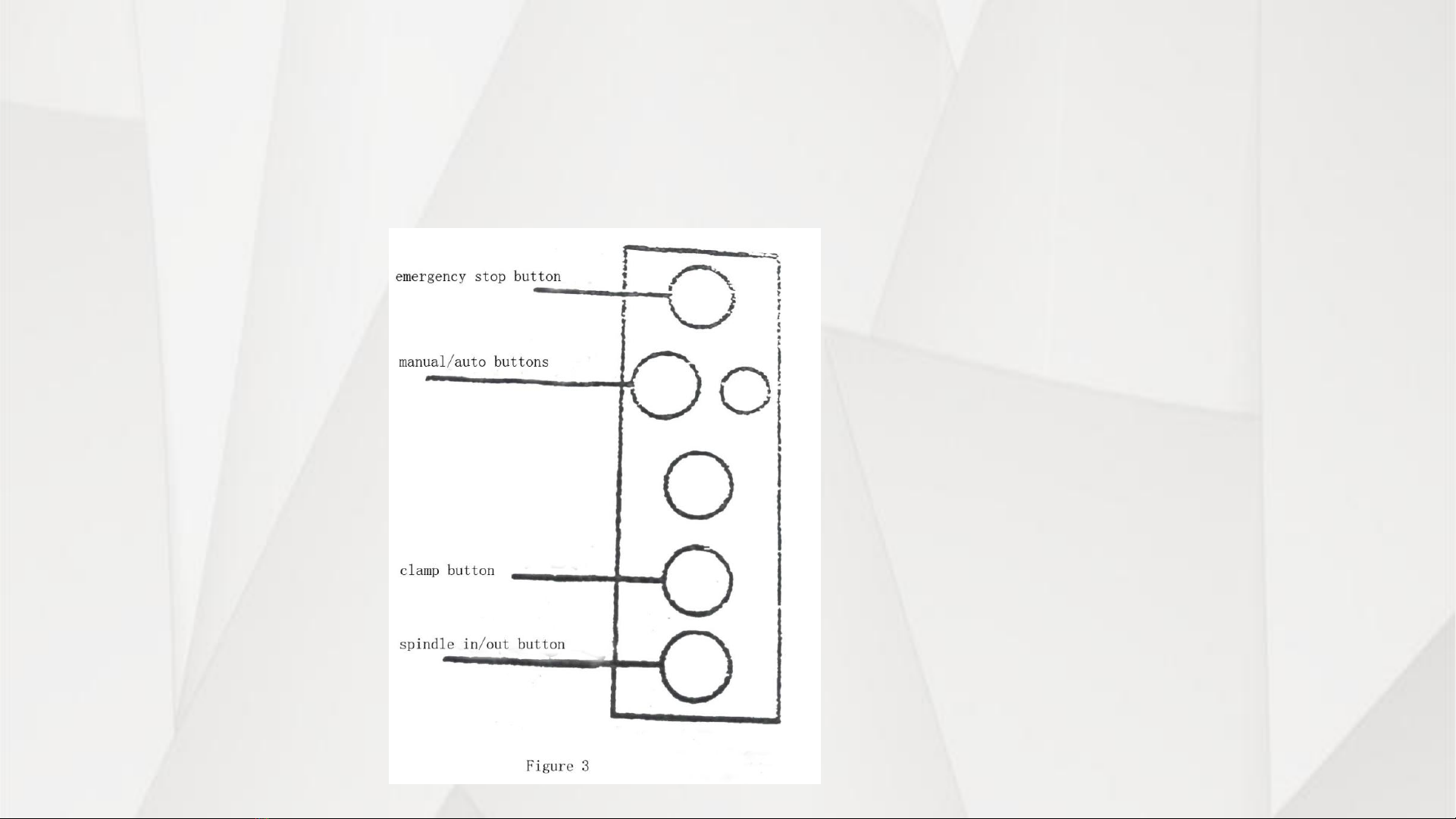

● Please memorize the position of emergency stop switch to ensure that when an emergency situation

occurs, the operator or other personnel to press the switch immediately, in order to avoid danger.

●The machining tool must meet the tool specifications or contact our sales department

●When replace the blade, please turn off the main power to ensure safety.

● Keep proper clamping when chamfering to avoid parts loose that make harm on the blade, the

machine or personal.

●Turn off the main power supply and clean environment around the machine and do the daily

maintenance of machinery when staff complete work and leave machine.

●Do not take off safety shield to avoid metal shavings flying to hurt people.

●Before starting machine or after shutdown machine, must add oil on it and keep it clean.