8

Off Lock Bore/ Reg. / Deep:..................................................................................................................................... 21

BOLT DRILL ON: ................................................................................................................................................21

FACE PLATE REG /OFF /EXTEND TIME:.............................................................................................................21

FEED MODE OFF /AUTO /FEED THROUGH: .......................................................................................................21

FEED JOG FOR /JOG REV: .................................................................................................................................21

SLOW FEED:.......................................................................................................................................................21

DISABLE AUTO FEED: ........................................................................................................................................21

1-PASS FRONT ROUTERS 2PASS: .......................................................................................................................21

WIDTH-ADJUST OPEN /CLOSE:..........................................................................................................................21

DISABLE AUTO-ADJUST:....................................................................................................................................21

SHIFT ROUTERS OUT OF POCKET: ......................................................................................................................22

CENTER HINGE:..................................................................................................................................................22

START SEQUENCE: .............................................................................................................................................22

EMERGENCY STOP: ............................................................................................................................................22

OPTIONAL OPERATING CONTROLS:....................................................................................................................22

PRE-DRILL OFF/ON:...........................................................................................................................................22

PRE-DRILL ROUTER HORIZONTAL POP-UP STOP OVERRIDE:..............................................................................22

PRE-DRILL LOCK OUT: ......................................................................................................................................22

DEADBOLT SHIFT:..............................................................................................................................................22

DEADBOLT BORE:..............................................................................................................................................22

BOLT DRILL:......................................................................................................................................................22

FACE PLATE DEAD BOLT: ..................................................................................................................................23

SIDE DRILL (LATCH HOLE) ................................................................................................................................23

LOCK BORE DIAMETER:.....................................................................................................................................23

ROUTER OPERATING CONTROLS:.......................................................................................................................23

CENTER ROUTER:...............................................................................................................................................23

ROUTER ON /OFF: .............................................................................................................................................23

3- OR 4-POCKET CONFIGURATIONS:...................................................................................................................23

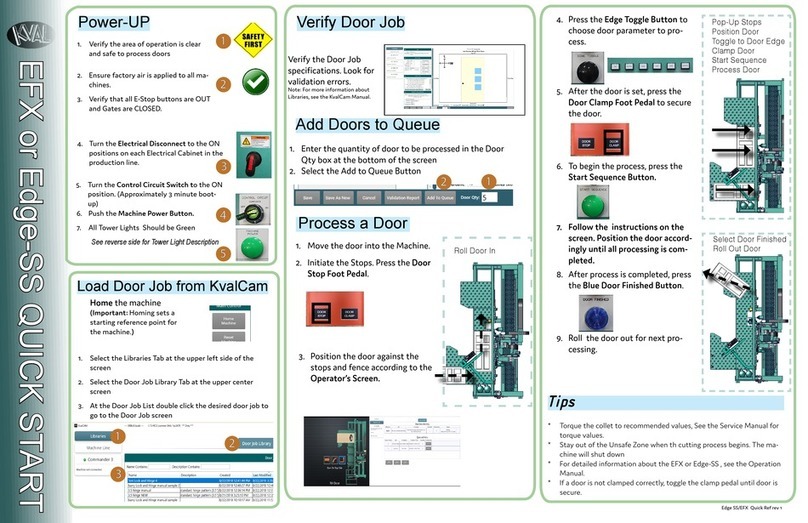

FOOT PEDAL OPERATING CONTROLS .................................................................................................................23

DOOR CLAMP:....................................................................................................................................................23

JAMB CLAMP:.....................................................................................................................................................23

CONTROLS ON THE ELECTRICAL BOX .................................................................................................................24

SPEED CONTROL FRONT SECTION:.....................................................................................................................24

BACK SECTION FACE PLATE CONTROL TIME: ....................................................................................................24

700-C RESET:.....................................................................................................................................................24

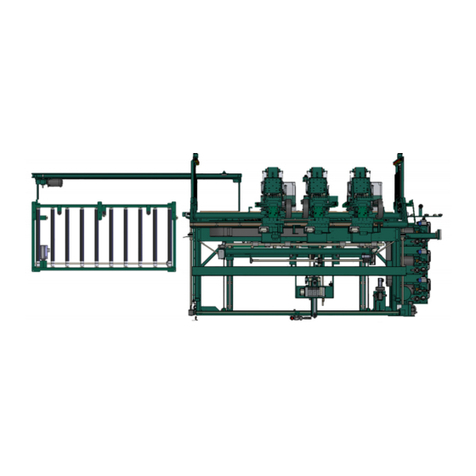

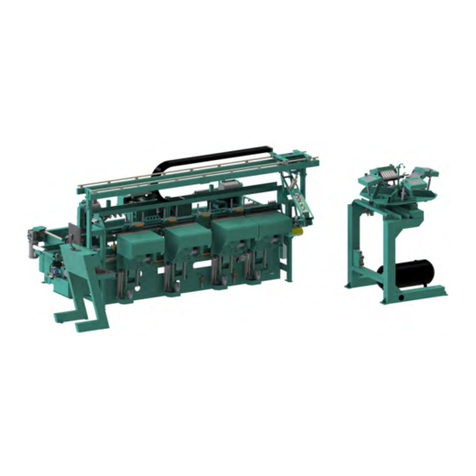

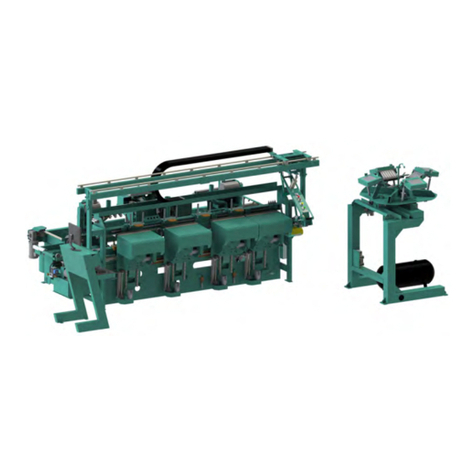

SIX-SHOOTER.....................................................................................................................................................24

SIX-SHOOTER OPERATING CONTROLS ...............................................................................................................25

INSERT SCREW:..................................................................................................................................................25

START SEQUENCE: .............................................................................................................................................25

RESET: ...............................................................................................................................................................25

UNCLAMP:..........................................................................................................................................................25

EMERGENCY STOP: ............................................................................................................................................25

HOPPER SLIDE VALVE:.......................................................................................................................................25

SAFETY INSERT SCREW SLIDE VALVE:...............................................................................................................25

SCREW DRIVER IN CLOSE TRAP ..........................................................................................................................25

OPTIONAL CONTROLS:.......................................................................................................................................26

LOAD /UNLOAD:................................................................................................................................................26

Six-Shooter Gear Installation and Maintenance:....................................................................................................... 26

Removing the Gear Motor: ....................................................................................................................................... 26

REMOVING THE PLUNGE CYLINDER:..................................................................................................................27

REMOVING GEARBOX: .......................................................................................................................................28

GEAR BOX MAINTENANCE:................................................................................................................................29

REINSTALLING THE GEARBOX:...........................................................................................................................31

RE-INSTALLING THE PLUNGE CYLINDER:...........................................................................................................31

RE-INSTALLING THE GEAR MOTOR:...................................................................................................................31

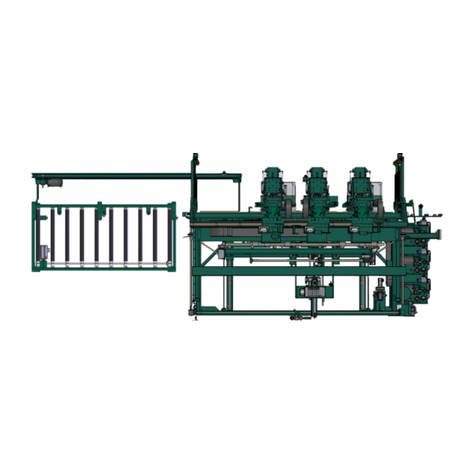

FRONT SECTION .................................................................................................................................................32