8EN ATySController C35 - 549781A - SOCOMEC

5. QUICK START

106

1,5 - 3

144

(0/+1)

92

(0/+0 ,8)

12

312 313 314 315 316 317 63A64A24 14 04 13

- +

36 35 943751 54 52 F1 73 72F2 71 70

1413 15 16 17

103

102 101 302 301 202 201

104 105 106 203 204 205 206

93 92 91

L1

L2

L3

N

L1

L2

L3

N

318-520 ph-ph

184-300 ph-n

318-520 ph-ph

184-300 ph-n

NC + - 0 I I I C

Ctrl OFF I I

I I

I

I

0

0

C

C

-

+

I I

81 82

I 0 C

Aux supply

SOURCE 1

S1 IN S2 IN

DPS OUT

All fuses 4A type gG*

*Using a Socomec cable harness kit excludes the need for fuses

SOURCE 2

301302

X2

HMI Programming

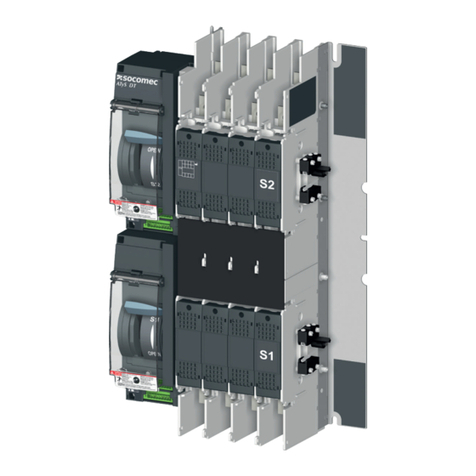

Connection with ATyS

Connectors

Dashbord orderTechnical characteristics

Mounting

To access the programming mode do a long press on button 14 and enter the password

(Default 1000).

Menu Submenu Adjustment range Default value Description

System NETWORK 1P+N, 2P, 3P, 3P+N 3P+N Select the installation network type.

NOM. VOLT. 220Vph-N, 230Vph-n,

240Vph-N, 380Vph-ph,

400Vph-ph, 415Vph-ph

400Vph-ph

(4)

Network nominal voltage.

NOM. FREQ. 50, 60 Hz 50Hz Network nominal frequency

APP S1-Mains S2-Gens,

S1-Gens S2 – Mains,

S1-Mains S2 – Mains

S1-Mains

S2-Gens

Type of application.

TECHNO

TYPE

PC Type, CC Type,

CB Type

PC Type Type of RTSE technology.

SIGNALTIME 0.1s-20s , MAINT 5.0s Duration of the signal time (when CC

type is selected the signal time is always

maintained).

PRIO NET S1, S2 S1 Priory source settings, the controller prioritize

the source selected.

RETURNS AUTO RESTRANS,

MANU RETRANS, NO

RETRANS

AUTO

RESTRANS

Retransfer mode, automatic, manual

retransfer (needs user validation before

transferring to priority source), or no

retransfer (controller will not retransfer

automatically to the priority source).

ROT PH L1L2L3, L3L2L1, OFF OFF Selection of the rotation order of phases,

when “OFF” is selected controller will not

check the phase rotation order.

COM Contains submenu for all RS485, Modbus settings cf. communication settings.

PASSWORD 0000-9999 1000 Password for required access settings

such as mode change, test launch and

programing.

BACKLIGHT Keep-Active, 30min-

1min

Keep-Active Duration of the backlight on LCD screen

(If the product is using 24VDC only to

power backlight will be off).

Language ENGLISH, 中文,English Controller language.

ABOUT NA NA Show software version, and serial

number.

RST.

FACTORY

NA N/A Press “OK” in this menu to reset all

settings to default values.

Voltage

(1)

S1-OVth 120-102% 115% Over voltage threshold for loss of source 1

(must be greater than hysteresis setting).

S1-OVhy 119-101% 110% Over voltage hysteresis for return of

source 1 (must be inferior to threshold

setting).

S1-UVth 98-80% 85% Under voltage threshold for loss of

source 1 (must be inferior to hysteresis

setting).

S1-UVhy 99-81% 95% Under voltage hysteresis for return

of source 1 (must be greater than to

threshold setting).

S2-OVth 120-102% 115% Over voltage threshold for loss of source

2 (must be greater than hysteresis

setting).

S2-OVhy 119-101% 110% Over voltage hysteresis for return of

source 2 (must be inferior to threshold

setting).

S2-UVth 98-80% 85% Under voltage threshold for loss of

source 2 (must be inferior to hysteresis

setting).

S2-UVhy 99-81% 95% Under voltage hysteresis for return

of source 2 (must be greater than to

threshold setting)

S2-UVhy 99-81% 95% Under voltage hysteresis for return

of source 2 (must be greater than to

threshold setting)

Frequency(2)

S1-OFth 120-102% 115% Over frequency threshold for loss

of source 1 (must be greater than

hysteresis setting).

S1-OFhy 119-101% 110% Over frequency hysteresis for return of

source 1 (must be inferior to threshold

setting).

S1-UFth 98-90% 90% Under frequency threshold for loss of

source 1 (must be inferior to hysteresis

setting).

S1-UFhy 99-91% 95% Under frequency hysteresis for return

of source 1 (must be greater than to

threshold setting).

S2-OFth 120-102% 115% Over Frequency threshold for loss

of source 2 (must be greater than

hysteresis setting).

S2-OFhy 119-101% 110% Over frequency hysteresis for return of

source 2 (must be inferior to threshold

setting).

S2-UFth 98-90% 90% Under frequency threshold for loss of

source 2 (must be inferior to hysteresis

setting).

S2-UFhy 99-91% 95% Under frequency hysteresis for return

of source 2 (must be greater than to

threshold setting).

Timers S1-FT 3-60s 5s Source 1 fail timer.

S2-FT 3-60s 5s Source 2 fail timer.

S1-RT 3-3600s 5s Source 1 return timer.

S2-RT 3-3600s 5s Source 2 return timer.

S1-S2 0DT 0-20s 0s Source 1 dead band timer.

S2-S1 0DT 0-20s 0s Source 2 dead band timer.

CT 0-3600s 180s Generator Cool down timer.

SD 0-6000s 0s Generator start delay.

ST 1-3600s 30s Generator start timeout timer.

Test BUTTON

TEST

Test on load,

Test off load

Test on load Test mode for the HMI test button.

LCD TEST Starts a lamp test and LCD test.

In/Out IN. FUN1 See full manual NOT IN AUTO Input function for input 1 (91-92).

IN. TYPE 1 NO, NC NC Input type.

IN. DELAY. 1 0.01-60.00s 0.05 Input delay timer.

IN. FUN 2 See full manual NONE Input function input 2 (91-93).

IN. TYPE 2 NO, NC NO Input type.

IN. DELAY. 2 0.01-60.00s 0.05 Input delay timer.

IN. FUN 3 See full manual NONE Input function input 3 (91-92).

IN. TYPE 3 NO, NC NO Input type.

IN. DELAY. 3 0.01-600.00s 0.05 Input delay timer.

OUT. FUN1

(3)

See full manual GENSET Output function for programmable output.

OUT. TYPE 1

(3)

NO, NC NC output type.

(1) % of Voltage set in “NOM VOLT” must be within the working limits of the controller 184-300 V.a.c P-N.

(2) % of Frequency set in “NOM FREQ”.

(3) Only congurable when “APP” is set to S1-Mains S2-Mains.

(4) If voltage is set to 1PH+N the default value for NOM. VOLT. Will automatically be set to 230Vph-n.

dimensions in mm.

Connectors top view

Connectors bottom view

Denomination Terminal Description Characteristics

Control signal

outputs (orders

to RTSE)

13 Not used / Source 2 open AC1 – General use – Ie: 5A , Ue: 250 V.a.c

DC1 – General use – Ie: 5A , Ue: 30 V.d.c

AC15 - Ie: 3A, Ue: 120 V.a.c

AC15 - Ie: 1.5A, Ue: 240 V.a.c

DC13 - Ie: 0.22A, Ue: 125 V.d.c

DC13 - le: 0.11A, Ue: 250 V.d.c

14 Position II order / Source 2 closed

15 Position I order / Source 1 open

16 Position 0 order / Source 1 closed

17 Common point for position output

RS485

35 NC – Not connected

RS485 Isolated bus36 Negative electrode

37 Positive electrode

Genset output

51 Common point

52 Closed to start the Genset (closed when

controller is powered off)

AC1 – General use – Ie: 3A , Ue: 250 V.a.c

DC1 – General use – Ie: 3A , Ue: 30 V.d.c

AC15 - Ie 54/51: 3A 52/51: 1.5A Ue: 120 V.a.c

AC15 - Ie 54/51: 1.5A 52/51: 0.75A Ue: 240 V.a.c

DC13 - Ie 54/51: 0.22A 52/51: 0.22 A 125 V.d.c

DC13 - Ie 54/51: 0.11A 52/51: 0.11 A 250 V.d.c

54 Open to start the genset

Controller

programmable

inputs

91 Common point for programmable inputs

Do not use external voltage

Power from common point

92 Programmable input 1 (Set as default to

«NOT IN AUTO»)

93 Programmable input 2

94 Programmable input 3

Return of

information from

RTSE (Position

inputs)

70 Common point for position inputs

Do not use external voltage

Power from common point

71 Position I RTSE

72 Position II RTSE

73 Position 0 RTSE

Fire input F1 Negative electrode of the d.c power source 12-24 V.d.c

F2 Positive electrode of the d.c power source

Optional Aux

supply 24V.d.c

81 Negative electrode of the d.c power source 10-30 V.d.c (Auxiliary supply for controller, does not

supply RTSE)

82 Positive electrode of the d.c power source

Source 1 and 2

voltage inputs

103 Source 1 N Sensing range:

90-520 V.a.c (ph-ph)

50-300 V.a.c (ph-n)

45-65 Hz

Supply:

184-300 V.a.c* (ph-n)

45-65 Hz

Max consumption 10 W

*200-300 V.a.c in maintained mode

104 Source 1 L1

105 Source 1 L2

106 Source 1 L3

203 Source 2 N

204 Source 2 L1

205 Source 2 L2

206 Source 2 L3

DPS output

(RTSE power

supply)

301 Phase output AC – General use – Ie: 6A , Ue: 250 V.a.c

DC – General use – Ie: 6A , Ue: 30 V.d.c

AC15 - Ie: 3A, Ue: 120 V.a.c

AC15 - Ie: 1.5A, Ue: 240 V.a.c

DC13 - Ie: 0.22A, Ue: 125 V.d.c

DC13 - le: 0.11A ,Ue: 250 V.d.c

302 Neutral output

Voltage / frequency settings

DIN rail mounting

1. Mounting

2. Unmounting

Door mounting (IP 40)

IEC 60715

DIN rail

1

Auto LED (Green fixed when in auto mode, green blinking when transfer or fault ongoing).

2

Source 1 availability information (green fixed when source 1 is present and available and within threshold

limits, green blinking when source 1 is present but outside of threshold limits, off when under 50VAC).

3

Switch 1 LED position indications (green fixed when in position 1).

4

Zero position LED indication (yellow when in position 0).

5

Load supplied information (green fixed when load is supplied by an available source) green blinking when

load is supplied with a source which is present but outside of threshold limits).

6

Switch 2 LED position indications (green fixed when in position 2).

7

Source 2 availability information (green fixed when source 2 is present and available and within threshold

limits, green blinking when source 2 is present but outside of threshold limits, off when under 50VAC).

8

Test LED (yellow fixed when a test ins ongoing or when in programming mode).

9

Run LED (Green when product is powered).

10

COM LED (yellow blinking when RS communications is ongoing).

11

Fault LED (red blinking – long blink when fault or inhibit is activated).

12

FIRE LED (red fixed when fire input is activated).

13

Multi line LCD screen.

14

AUTO/MANU/PROG button, short press (<3s) to switch between AUTO and MANU modes then add

operator password to confirm (1000 default value). Long press (>3s) on this button to enter the programming

mode.

15

DASHBOARD/TEST button, short press (<3s) to change the dashboard shown (7 screens) (after 30s will

reset to default dashboard. A long press (>3s) will start a TEST ON LOAD, to validate enter the operator

password (1000 default). To stop the test, long press on this button again.

16

DOWN/POS1 button, in MANU mode will switch to position 1. In programming mode or when password is

requested, go up in the menu screen.

17

OK/POS0 button, in MANU mode will switch to position 0. Use to validate selection in programming mode or

when a password is requested.

18

UP/POS2 button, in MANU mode will switch to position 2. In programming mode or when password is

requested, go down in the menu screen

Source available

U/F

OVth/OFth

OVhy/OFhy

Unom/Fnom

UVhy/UFhy

UVth/UFth

8

23

4

5 6 7

1

910 12

13

14 17 15

1816

11

S1=OVth=116%

S1=OVhy=110%

S1=UVth=85%

S1=UVhy=95%

S2=OVth=112%

S2=OVhy=110%

S2=UVth=85%

S2=UVhy=95%

POS. I COUNT

00016

POS. II COUNT

00010

S1-S2

Phase angle

-10°

S1=OFth=116%

S1=OFhy=110%

S1=UFth=90%

S1=UFhy=95%

S2=OFth=112%

S2=OFhy=110%

S2=UFth=90%

S2=UFhy=95%

S1=RT=0005s

S1=FT=05s

S2=RT=0005s

S2=FT=04s

S1-S2=0DT=00s

S2-S1=0DT=01s

SD=0000s

CT=0180s ST=0030s

INPUTS

71 POS I OFF

72 POS II ON

73 POS 0 OFF

92 OFF

93 OFF

94 OFF

OUTPUTS

16 POS I OFF

15 POS II ON

14 POS 0 OFF

13 OFF

52 OFF

S1 50.1Hz

U1n=232V

S2 50.2Hz

U1n=234V