SOFTSTARTUK MV-DS User manual

Softstart UK Contents

Contents

1. About This Manual...............................................................................................................3

1.1. User Manual Version ............................................................................................................................................ 3

2. Caution Statements .............................................................................................................4

3. General Description.............................................................................................................5

3.1. Overview............................................................................................................................................................... 5

3.2. Feature List........................................................................................................................................................... 5

3.3. Key Features ........................................................................................................................................................ 6

3.4. Model Code .......................................................................................................................................................... 7

4. Specifications.......................................................................................................................8

4.1. Key Components .................................................................................................................................................. 8

4.2. Dimensions and Weights ...................................................................................................................................... 8

4.3. General Technical Data ........................................................................................................................................ 9

5. Installation ..........................................................................................................................11

5.1. Mounting Instructions - Power Assembly ............................................................................................................ 11

5.2. Mounting Instructions - Controller ....................................................................................................................... 12

5.3. Power Terminations ............................................................................................................................................ 13

5.4. Earth Terminations.............................................................................................................................................. 14

5.5. Control Terminations........................................................................................................................................... 14

5.6. Wiring Terminations on the Controller................................................................................................................. 14

5.7. Wiring Terminations on the Power Interface Board............................................................................................. 15

5.8. Ground Current CT Configuration ....................................................................................................................... 15

5.9. Current Transformer Internal Wiring ................................................................................................................... 17

5.10. Power Circuits..................................................................................................................................................... 19

6. Internal Wiring –X10...........................................................................................................21

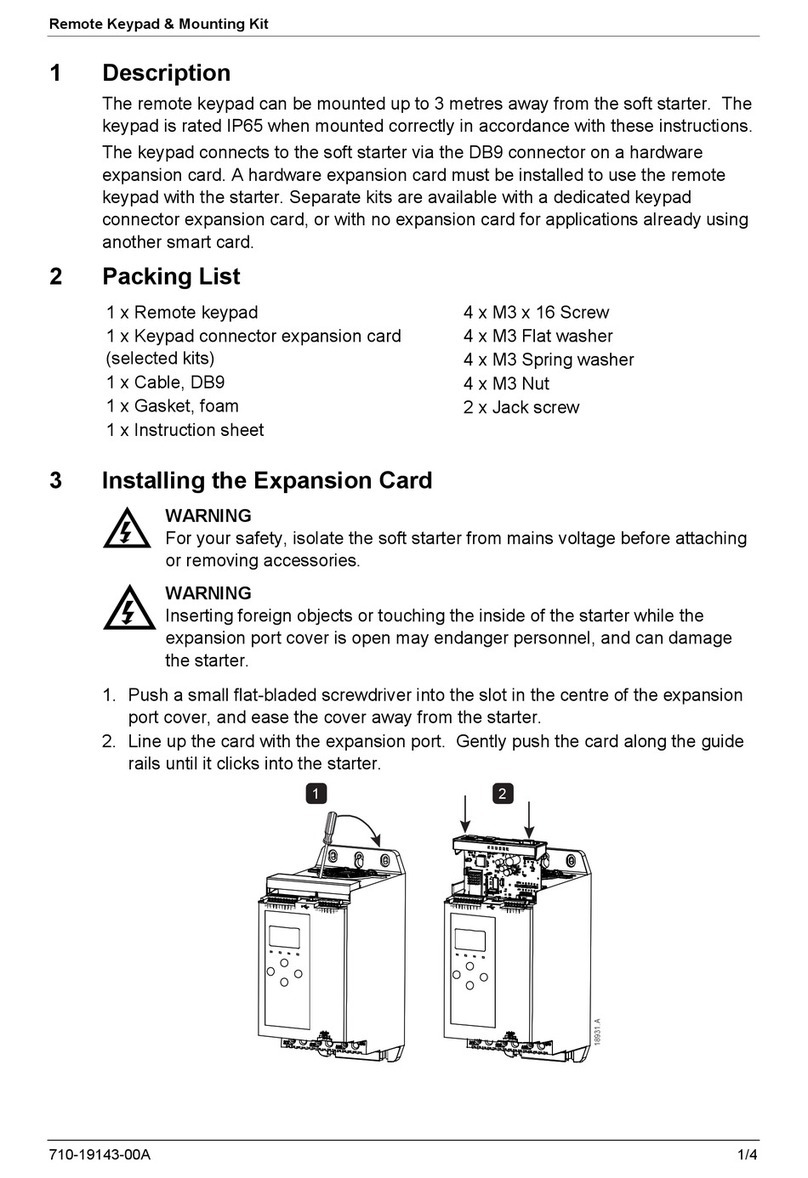

7. Keypad and Feedback .......................................................................................................22

7.1. The Controller ..................................................................................................................................................... 22

7.2. Menu Shortcuts................................................................................................................................................... 22

7.3. Displays .............................................................................................................................................................. 22

8. Configuration......................................................................................................................23

8.1. Programming Menu ............................................................................................................................................ 23

8.2. Standard Menu ................................................................................................................................................... 24

8.3. Extended Menu................................................................................................................................................... 25

8.4. Load/Save Settings............................................................................................................................................. 27

8.5. Parameter Descriptions ...................................................................................................................................... 28

9. Commissioning ..................................................................................................................41

9.1. Commissioning Menu (Tools) ............................................................................................................................. 41

9.2. Set Date and Time .............................................................................................................................................. 41

9.3. Simulation Tools ................................................................................................................................................. 41

9.4. Input/Output Status ............................................................................................................................................. 42

9.5. Reset Thermal Models........................................................................................................................................ 43

9.6. Low Voltage Test Mode ...................................................................................................................................... 44

10. Monitoring...........................................................................................................................45

10.1. Logs Menu .......................................................................................................................................................... 45

11. Operation ............................................................................................................................46

11.1. Start, Stop and Reset Commands ...................................................................................................................... 46

11.2. Using the Soft Starter to Control a Motor ............................................................................................................ 46

11.3. Using the MV-DS to Control a Slip-Ring Motor ................................................................................................... 46

11.4. Operating States ................................................................................................................................................. 49

11.5. Motor Protection.................................................................................................................................................. 50

11.6. Operating Feedback ........................................................................................................................................... 51

12. Troubleshooting.................................................................................................................53

12.1. Protection Responses......................................................................................................................................... 53

12.2. General Faults .................................................................................................................................................... 57

13. Maintenance .......................................................................................................................58

13.1. Safety.................................................................................................................................................................. 58

13.2. Maintenance Schedule ....................................................................................................................................... 58

13.3. Tools required ..................................................................................................................................................... 58

13.4. Thermal Image.................................................................................................................................................... 58

710-15811-00B – MV-DS User Manual (V02~V06) 1/64

Contents Softstart UK

14. Appendix.............................................................................................................................59

14.1. Parameter Defaults ............................................................................................................................................. 59

14.2. Accessories ........................................................................................................................................................ 62

2/64 710-15811-00B – MV-DS User Manual (V02~V06)

Softstart UK About This Manual

1. About This Manual

The examples and diagrams in this manual are included solely for illustrative purposes. The information

contained in this manual is subject to change at any time and without prior notice. In no event will responsibility

or liability be accepted for direct, indirect or consequential damages resulting from the use or application of this

equipment.

WARNING

Indicates a hazard that may cause personal injury or death.

CAUTION

Indicates a hazard that may damage the equipment or installation.

NOTE

Provides helpful information.

1.1. User Manual Version

This user manual (710-15811-00B) is compatible with MV-DS soft starters using version 1.29 control software

and version 2.3x interface software. For other software versions, please contact Softstart UK for the correct

user manual.

Software versions are displayed on the Controller screen at power up.

Ready Welcome

1.29 / 2.32 / 1.05 Software versions: Control software, Interface software, Controller

710-15811-00B – MV-DS User Manual (V02~V06) 3/64

Caution Statements Softstart UK

2. Caution Statements

Caution Statements cannot cover every potential cause of equipment damage but can highlight common

causes of damage. It is the installer's responsibility to read and understand all instructions in this manual prior

to installing, operating or maintaining the equipment, to follow good electrical practice including applying

appropriate personal protective equipment and to seek advice before operating this equipment in a manner

other than as described in this manual.

xRead and understand the entire manual before installing operating, or maintaining the MV-DS. Follow all

applicable local and national codes.

xApply appropriate personal protective equipment (PPE) and clothing, and follow safe electrical work

practices.

xUse only electrically insulated tools and clothing and insulated protective gear when working around

electrical equipment.

xDisconnect all power and ensure that the MV-DS is de-energised before servicing the equipment.

xDo not rely on visual indications such as switch position or fuse removal for determining a de-energised

condition. Always assume that a terminal is energised until it is checked and ensure that a terminal is de-

energised and grounded.

xIsolate the MV-DS completely from the power supply before attempting any work on the MV-DS or motor.

xAlways use a properly rated voltage sensing device to confirm power is off.

xBefore servicing the MV-DS, ensure that all static charge has been discharged by grounding it with an

appropriate grounding device.

xMetal swarf in the cabinet can cause equipment failure.

xThe control inputs are powered by the soft starter. Do not apply external voltage to the control input

terminals.

xContacts or switches operating the control inputs must be suitable for low voltage, low current switching (ie

gold flash or similar).

xCables to the control inputs must be segregated from mains voltage and motor cabling.

xSome contactor coils are not suitable for direct switching with PCB mount relays.

WARNING - ELECTRICAL SHOCK HAZARD

The MV-DS contains dangerous voltages when connected to mains voltage. Only a qualified

electrician should carry out the electrical installation. Improper installation of the motor or the MV-DS

may cause equipment failure, serious injury or death. Follow this manual and local electrical safety

codes.

SHORT CIRCUIT

The MV-DS is not short circuit proof. After severe overload or short circuit, the operation of the MV-DS

should be fully tested by an authorised service agent.

GROUNDING AND BRANCH CIRCUIT PROTECTION

It is the responsibility of the user or person installing the MV-DS to provide proper grounding and

branch circuit protection according to local electrical safety codes.

ARC FLASH HAZARD

Medium voltage equipment has a potential risk of arc flash. When insulation or isolation between

electrified conductors is breached or can no longer withstand the applied voltage, a short circuit occurs

through the air. This may cause a phase-to-ground and/or a phase-to-phase fault.

Although unlikely, arc fault can be caused by:

xContamination in the insulation caused by deterioration over time

xInadequate insulation system on cable terminals

xOvervoltage

xIncorrect protection coordination settings

xOverheating of the contact area, due to incorrect tightening of connections

xIntroduction of foreign matter, including swarf, vermin, tools or maintenance equipment left in the

starter

STORAGE

The MV-DS must be stored in its original packaging in a clean and dry environment. The MV-DS

should be unpacked only after the equipment room is ready for installation. Particular care should be

taken to avoid exposure of the electronics to cement and/or concrete dust.

4/64 710-15811-00B – MV-DS User Manual (V02~V06)

Softstart UK General Description

3. General Description

3.1. Overview

The MV-DS provides compact and robust soft start solutions for control of medium voltage motors. MV-DS soft

starters provide a complete range of motor and system protection features and have been designed for reliable

performance in the most demanding installation situations.

The two primary components of a MV-DS soft starter are:

xa power assembly

xa controller module

3.2. Feature List

Starting

xConstant Current

xCurrent Ramp

Stopping

xCoast To Stop

xSoft stop

Protection

xUndervoltage / Overvoltage

xMains frequency

xPhase sequence

xShorted SCR

xMotor Overload (thermal model)

xInstantaneous Overcurrent (two stages)

xTime-overcurrent

xGround Fault

xUndercurrent

xCurrent Imbalance

xMotor thermistor

xExcess Start Time

xPower circuit

xAuxiliary trip

Extensive input and output options

xRemote control inputs

(3 x fixed, 2 x programmable)

xRelay outputs

(3 x fixed, 3 x programmable)

xAnalog output

(1 x programmable)

xSerial port (with module)

Comprehensive feedback

xStarter status LEDs

xDate and time stamped event logging

xOperational counters (number of starts,

hours-run, kWh)

xPerformance monitoring (current, voltage,

power factor, kWh)

xUser-programmable monitoring screen

xMulti-level password protection

xEmergency stop pushbutton

Power connection

x50 A to 500 A, nominal

x2300 VAC to 6600 VAC

Accessories (optional)

xCommunication modules:

Ethernet (Profinet, Modbus TCP, Ethernet/IP),

Profibus, DeviceNet, Modbus RTU, and USB

xSynchronous motor control

xPC software

xOvervoltage protection

xControl supply transformer

xMV/LV Control transformer

710-15811-00B – MV-DS User Manual (V02~V06) 5/64

General Description Softstart UK

3.3. Key Features

MV-DS soft starters offer several special functions to ensure ease of use and to provide optimal motor control in

all environments and applications.

xCustomisable Protection

The MV-DS offers comprehensive protection to ensure safe operation of the motor and soft starter. The

protection characteristics can be customised extensively to match the exact requirements of the installation.

Use 4 Protection Settings on page 29 to set the conditions in which each protection mechanism will activate.

Example: Use parameter 4C Undercurrent to set the level for an undercurrent trip and parameter 4D

Undercurrent Delay to set a delay on the trip.

Use 16 Protection Action on page 40 to select the soft starter's response when a protection mechanism

activates. Each protection can be set to trip the starter, activate a warning flag, or be ignored. All protection

activations are recorded in the event log, regardless of the protection class setting.

Example: Use parameter 16C Undercurrent to select the response for an undercurrent trip (trip, warn

or write to log). The default response is trip.

NOTE

MV-DS soft starters have built-in trip points to ensure operation remains within the soft starter's

capability. These internal trips cannot be overridden. Certain faults within the MV-DS will also

prevent the soft starter from operating. Refer to Troubleshooting on page 53 for details.

xAdvanced Thermal Modelling

Intelligent thermal modelling allows the soft starter to predict whether the motor can successfully complete a

start. The MV-DS uses information from previous starts to calculate the motor's available thermal capacity, and

will only permit a start which is predicted to succeed.

This feature can be enabled or disabled using parameter 4N Motor Temperature Check.

xComprehensive Event and Trip Logging

The MV-DS has a 99-place event log to record information on soft starter operation. A separate trip log stores

detailed information about the last eight trips. Refer to Starter Trip and Event Logger Software on page 45 for

details. For further information, or to download the software, visit www.softstartuk.com.

xInformative Feedback Screens

A digital display screen allows the MV-DS to display important information clearly. Comprehensive metering

information, details of starter status and last start performance allow easy monitoring of the starter's

performance at all times.

xDual Parameter Set

The MV-DS can be programmed with two separate sets of operating parameters. This allows the soft starter to

control the motor in two different starting and stopping configurations.

The secondary motor settings (parameter groups 9 and 10) are ideal for conventional (squirrel-cage) motors

which may start in two different conditions (such as loaded and unloaded conveyors).

NOTE

MV-DS soft starters are not suitable for controlling two separate motors. The secondary parameter set

should only be used for a secondary configuration of the primary motor.

The MV-DS will use the secondary motor settings to control a start when instructed via a programmable input

(refer to parameters 6A and 6F, Input A or B Function).

xFibre Optics

The MV-DS uses two-line fibre optic connections between the low voltage control module and the high voltage

power assembly for electrical isolation. This fibre optic link simplifies installation of chassis mount MV-DS

starters into custom panels.

6/64 710-15811-00B – MV-DS User Manual (V02~V06)

Softstart UK General Description

3.4. Model Code

MV-DS- – –

Control Voltage

C12 = 110~130 Vac & 220~240 Vac

Supply Voltage

V02 = 2300 Vac 50/60 Hz

V03 = 3300 Vac 50/60 Hz

V04 = 4160 Vac 50/60 Hz

V06 = 6600 Vac 50/60 Hz

Current Rating

0080 = 80 A @ AC53b 4-20 : 1780

0159 = 159 A @ AC53b 4-20 : 1780

0200 = 200 A @ AC53b 4-20 : 1780

0230 = 230 A @ AC53b 4-20 : 1780

0321 = 321 A @ AC53b 4-20 : 1780

0500 = 500 A @ AC53b 4-20 : 1780

710-15811-00B – MV-DS User Manual (V02~V06) 7/64

Specifications Softstart UK

4. Specifications

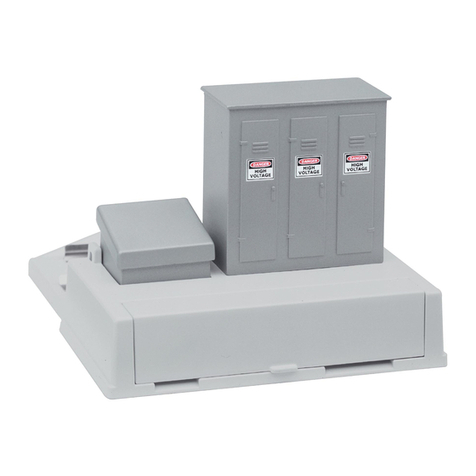

4.1. Key Components

03993.D

2

3

5

1

1Control transformer

2Control voltage terminal block

3Power interface board

4Phase arm (x3)

5Power assembly

4.2. Dimensions and Weights

Aa

b

B

c

C

d

e

Front view Side view Phase arm extended

A B C a b c d e Weight

(phase

arm)

Weight

(power

assembly)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

mm

(inch)

kg

(lb)

kg

(lb)

MV-DS-xxxx-V02 772

(30.4)

669

(26.3)

667

(26.3)

750

(29.5)

658

(25.9)

650

(25.6)

1302

(51.3)

531

(20.9)

29

(63.9)

165

(363.8)

MV-DS-xxxx-V03

MV-DS-xxxx-V04

MV-DS-xxxx-V06 832

(32.8)

875

(34.5)

817

(32.2)

810

(31.9)

864

(34.0)

800

(31.5)

1559

(61.4)

551

(21.7)

44

(97)

217

(478.4)

NOTE

For models MV-DS-xxxxV02 to MV-DS-xxxxV04, these dimensions apply up to 321 A. For the same

models with current ratings of 500 A, the MV-DS-xxxxV06 dimensions apply.

NOTE

In addition to the dimensions of the soft starter power assembly, an enclosure must allow space for the

following required components:

xMV-DS soft starters must always be installed with a main contactor and bypass contactor.

xMV-DS-0500-Vxx requires forced air ventilation when installed in an enclosure.

xController

The controller is suitable for use with all MV-DS soft starters.

340.0

(13.39)

220.0 (8.66)

80

(3.14)

1

INPUTB

INPUTA

RESET

STOP

START

Run Tri p LocalReady

Exit Menu

Store

Logs Alt Tools

Reset LCL

RM T

StopStart

Dimensions are shown in mm (inch).

Weight: 2.1 kg (4.63 lb)

1Control input LEDs

2Keypad

8/64 710-15811-00B – MV-DS User Manual (V02~V06)

Softstart UK Specifications

4.3. General Technical Data

Supply

Mains Voltage

MV-DS-xxxxV02 .......................................................................................................... 2.3 kV Phase-phase

MV-DS-xxxxV03 .......................................................................................................... 3.3 kV Phase-phase

MV-DS-xxxxV04 .......................................................................................................... 4.2 kV Phase-phase

MV-DS-xxxxV06 .......................................................................................................... 6.6 kV Phase-phase

Rated Frequency (fr) ............................................................................................................................. 50/60 Hz

Rated lightning impulse withstand voltage (Up)

MV-DS-xxxxV02 ~ V04 ....................................................................................................................... 45 kV

MV-DS-xxxxV06 ................................................................................................................................. 45 kV

Rated power frequency withstand voltage (Ud)

MV-DS-xxxxV02 ~ V04 .................................................................................................................... 11.5 kV

MV-DS-xxxxV06 ................................................................................................................................. 20 kV

Rated normal current (lr)

MV-DS-0080-Vxx .................................................................................................................................. 80 A

MV-DS-0159-Vxx ................................................................................................................................ 159 A

MV-DS-0200-Vxx ................................................................................................................................ 200 A

MV-DS-0230-Vxx ................................................................................................................................ 230 A

MV-DS-0321-Vxx ................................................................................................................................ 321 A

MV-DS-0500-Vxx ................................................................................................................................ 500 A

Rated short-time withstand current (symmetrical RMS) (lk)

MV-DS-xxxxV02 ~ V06 ..................................................................................................................... 48 kA 1

Form designation ........................................................................ Bypassed semiconductor motor starter form 1

Control Inputs

Start (C23, C24) ................................................................................................................ 24 VDC, 8 mA approx

Stop (C31, C32) ................................................................................................................ 24 VDC, 8 mA approx

Reset (C41, C42) .............................................................................................................. 24 VDC, 8 mA approx

Input A (C53, C54) ............................................................................................................. 24 VDC, 8 mA approx

Input B (C63, C64) ............................................................................................................ 24 VDC, 8 mA approx

Motor thermistor (B4, B5) ....................................................................................................... Trip point > 3.6 k:

Reset < 1.6 k:

NOTE

All control inputs are potential free. Do not apply external voltage to these inputs.

Rated Voltage ................................................................................................ 110 ~130 VAC or 220 ~ 240 VAC

Rated Frequency .................................................................................................................................. 50/60 Hz

Typical power consumption .................................................................................................... 70 W continuous 2

Outputs

Outputs on power interface board

Main contactor (13, 14) ........................................................................................................ Normally Open

Bypass contactor (23, 24) .................................................................................................... Normally Open

Run Output/ PFC (33, 34) .................................................................................................... Normally Open

Fan control output (43, 44) ................................................................................................... Normally Open

Outputs on Controller

Output Relay A (43, 44) ....................................................................................................... Normally Open

Output Relay B (51, 52, 54) ...................................................................................................... Changeover

Output Relay C (61, 62, 64) ...................................................................................................... Changeover

Analog output (B10, B11) ............................................................................................. 0-20 mA or 4-20 mA

Ratings of output relays on Controller

.............................................................................................................................. 10 A @ 250 VAC resistive

............................................................................................................................. 6 A @ 250 VAC 15 p.f. 0.3

................................................................................................................................ 10 A @ 30 VDC resistive

Environmental

Degree of Protection

Power Assembly ................................................................................................................................... IP00

Controller ............................................................................................................................. IP54/ NEMA 12

Operating temperature ....................................................................... - Û&WR&ZLWKGHUDWLQJWR&

Humidity ......................................................................................................... 5% to 95% Relative Humidity

Storage temperature ................................................................................................................ - Û&WRÛ&

Humidity ......................................................................................................... 5% to 95% Relative Humidity

Operating Altitude ................................................................................ 0 - 1000 m, above 1000 m with derating

Pollution degree ..................................................................................................................... Pollution Degree 3

Vibration ......................................................................................................................... Designed to IEC 60068

710-15811-00B – MV-DS User Manual (V02~V06) 9/64

Specifications Softstart UK

EMC Emission

Equipment class (EMC) .......................................................................................................................... Class A

Conducted radio frequency emission ........................................................ 10 kHz to 150 kHz: < 120 - 69 dB μV

.................................................................................................................. 0.15 MHz to 0.5 MHz: < 79 dB μV

..................................................................................................................... 0.5 MHz to 30 MHz: < 73 dB μV

Radiated radio frequency emission ........................................................ 0.15 MHz to 30 MHz: < 80-50 dB μV/m

........................................................................................................... 30 MHz to 100 MHz: < 60-54 dB μV/m

............................................................................................................ 100 MHz to 2000 MHz: < 54 dB μV/m

This product has been designed as Class A equipment. Use of this product in domestic environments may

cause radio interference, in which case the user may be required to employ additional mitigation methods.

EMC Immunity

Electrostatic Discharge ..................................................................... 6 kV contact discharge, 8 kV air discharge

Radio Frequency Electromagnetic Field .............................................................. 80 MHz to 1000 MHz: 10 V/m

Fast Transients 5/50 ns (main and control circuits) ......................................... 2 kV line to earth, 1 kV line to line

Surges 1.2/50 μs (main and control circuits) .................................................. 2 kV line to earth, 1 kV line to line

Voltage dip and short time interruption (safe shutdown) ........................................................................ 5000 ms

Standards Approvals

CE ........................................................................................................................................ EMC EU Directive

1Short circuit current, with appropriate R rated fuses fitted.

2Excludes contactors and/or circuit breakers.

10/64 710-15811-00B – MV-DS User Manual (V02~V06)

Softstart UK Installation

5. Installation

NOTE

The MV-DS soft starter should only be installed in a restricted access location suitable for electrical

equipment.

NOTE

Ensure that the equipment room is clean and relatively dust-free before unpacking and installing the

MV-DS soft starter. In particular, beware of concrete dust as it may cause corrosion.

5.1. Mounting Instructions - Power Assembly

xClearances

The MV-DS power assembly is rated IP00 and must be installed inside an enclosure.

No clearance is required below or at the sides. The power assembly should be installed with 100 mm clearance

above for isolation.

min 100 mm (3.93 inch)

NOTE

MV-DS-0500-Vxx requires forced air ventilation when installed in an enclosure.

xMounting Points

The power assembly is mounted in place using four M12 bolts. One bolt is required through each corner at the

base of the unit, tightened to a torque of 40 Nm. Individual phase arms are secured within the frame using one

M10 nut and two M10 high tensile grade 8.8 bolts complete with Belleville washers, all tightened to a torque of

28 ~ 30 Nm.

1

2 3

B

A

C

10130.C

1M10 bolts with Belleville washers

2M10 nut

3M12 mounting holes

Plan view

Front of unit

710-15811-00B – MV-DS User Manual (V02~V06) 11/64

Installation Softstart UK

xMeasurements A

mm (inch) B

mm (inch) C

mm (inch)

MV-DS-xxxxV02 636

(25.04)

513

(20.20)

68.5

(2.70)

MV-DS-xxxxV03

MV-DS-xxxxV04

MV-DS-xxxxV06 842

(33.15)

663

(26.10)

68.5

(2.70)

NOTE

For models MV-DS-xxxxV02 to MV-DS-xxxxV04, these dimensions apply up to 321 A. For the same

models with current ratings of 500 A, the MV-DS-xxxxV06 dimensions apply.

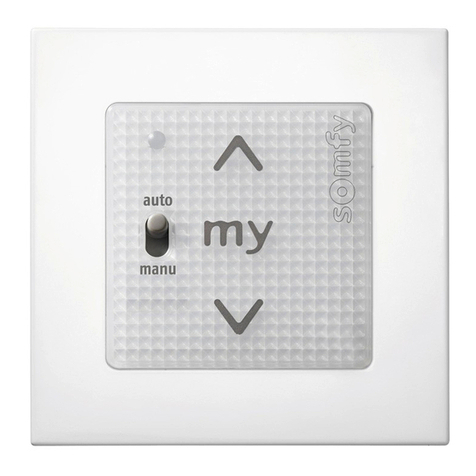

5.2. Mounting Instructions - Controller

The controller is secured into place using ten M4 nuts, affixed to the studs on the back of the controller.

112 (4.41)

300 (11.81)

310 (12.20)

340 (13.39)

220 (8.66)

196 (7.72)

186 (7.32)

11073.A

To mount the controller, make a 186 mm x 300 mm cutout at the desired mounting location. Ensure adequate

clearance (>85 mm) is available behind the mounting location. If you intend to use a communication module,

allow for a minimum clearance of 120 mm behind the mounting panel.

Drill 5 mm holes to accommodate the studs on the controller. Fit the Controller through the cutout and tighten

the nuts onto the studs.

12/64 710-15811-00B – MV-DS User Manual (V02~V06)

Softstart UK Installation

5.3. Power Terminations

T3B, T3, L3

T2B, T2, L2

L1

T1B

T1

6

(0.24)

25

(0.98)

13

(0.51)

Use only M10 high tensile grade 8.8 threaded fasteners for all terminations. Use a pre-load torque setting

between 28 ~ 30 Nm. Use only Belleville washers.

Side view Top view

03217.D

A

B

CD

10131.B

JJ

E

F

G

H

I

H

I

T1 T2 T3

L3L2L1 T3BT2BT1B

A

B

ABCDEFGH I J

mm

(inch) mm

(inch) mm

(inch) mm

(inch) mm

(inch) mm

(inch) mm

(inch) mm

(inch) mm

(inch) mm

(inch)

MV-DS-xxxxV02* 228

(8.98)

79

(3.11)

744

(29.29)

760

(29.92)

79

(3.11)

129

(5.08)

179

(7.05)

200

(7.87)

200

(7.87)

200

(7.87)

MV-DS-xxxxV03*

MV-DS-xxxxV04*

MV-DS-xxxxV06 228

(8.98)

79

(3.11)

792

(31.18)

806

(31.73)

107

(4.19)

164

(6.46)

222

(8.72)

268

(10.55)

268

(10.55)

268

(10.55)

NOTE

For models MV-DS-xxxxV02 to MV-DS-xxxxV04, these dimensions apply up to 321 A. For the same

models with current ratings of 500 A, the MV-DS-xxxxV06 dimensions apply.

710-15811-00B – MV-DS User Manual (V02~V06) 13/64

Installation Softstart UK

5.4. Earth Terminations

A 10 mm earth stud is located on each side of the power assembly, at the rear of the unit. Use only M10 high

tensile grade 8.8 threaded fasteners for all terminations. Use a pre-load torque setting between 28 ~ 30 Nm.

Use only Belleville washers.

5.5. Control Terminations

On the control voltage terminal block, control wiring is secured in place by 3 mm spring terminals. Use a

screwdriver to open the terminal clamp, then insert the wire into the terminal cage. Release the clamp by

removing the screwdriver.

C

A

C

B

A

(mm) B

(mm2)C

(mm)

32.53

5.6. Wiring Terminations on the Controller

xControl Wiring

The MV-DS has three fixed inputs for remote control. These inputs should be controlled by contacts rated for

low voltage, low current operation (gold flash or similar).

1

A

B

A B

C

A

B

C

C

23

C32

C31

C24

C23

C42

C41

03943.D

C32

C31

C24

C23

C42

C41

C32

C31

C24

C23

C42

C41

1Two-wire control

2Three-wire control

3Four-wire control

AStart

BStop

CReset

CAUTION

The control inputs are powered by the soft starter. Do not apply external voltage to the control input

terminals.

Cables to the control inputs must be segregated from mains voltage and motor cabling.

The reset input can be normally open or normally closed. Use parameter 6M to select the configuration.

NOTE

Reset input is normally closed by default.

14/64 710-15811-00B – MV-DS User Manual (V02~V06)

Softstart UK Installation

xTerminal Block (controller)

Terminations on the controller use plug-in terminals. Unplug the terminal blocks, complete the wiring, then re-

plug the terminal blocks into the controller.

Output A

Output B

Output C

Motor

Thermistor

24 VAC/DC

Relay Outputs

Control

Supply Control Inputs

Fibre Optic Connection

To P o wer Assembly

Analog

Output

Start

Stop

Reset

Prog A

Prog B

03948.B

5.7. Wiring Terminations on the Power Interface Board

07498.D

C74

C73

13

14

23

24

33

34

43

44

A1

A2

1 2 3

1 2 3

V0V1 V2V3

TX RX

CT3

CT2

CT1

1 4

9

2

10

7 8

1211

5 6

13

3

V IN

1Access for LV wiring

2Control terminals (refer to Power Circuit Configuration on page 20 for details)

3Non-conduction LEDs (green)

4Gate firing fibre optic connectors and firing LEDs (red)

5Voltage sensing input connector

6Ground fault CT connector

7Line CT connectors

8Access hole for CT wiring

9LV terminal block X10

10 CT ratio selector DIP switch S1

11 Fibre optic connections and LEDs to controller (Rx = Green, Tx = Red)

12 Non-conduction readback fibre optic connectors

13 LV terminal block X11

5.8. Ground Current CT Configuration

The ground current selector switch on the power interface board (S1) must be set to match the method for

calculating ground current and the ratio of the line current CTs.

NOTE

The soft starter will check the ground current settings when control power is applied. If the switch

settings are changed, control power must be cycled for the new setting to take effect.

xSummation method ground current measurement

Switch settings for summation method ground current measurement

Line CT ratio Switch setting

1000:1 1100

710-15811-00B – MV-DS User Manual (V02~V06) 15/64

Installation Softstart UK

Connection diagram: ground current summation CTs

L1 L2 L3

L21

L22

L11

L12

L32

L31

GF2

GF1

2

3

1

17971.C

1Line current transformers (1000:1)

2Ground current input to Power Interface PCB

3Individual phase inputs to Power Interface PCB

xZero sequence method ground current protection

Switch settings for zero sequence method ground current measurement

NOTE

Zero sequence ground current measurement requires a customer-supplied ground current CT.

The CT must be set to the relevant line CT ratio, 1 VA, minimum protection class rating 5P10.

Line CT ratio Switch setting

1000:1 1100

Connection diagram: ground current zero sequence CTs

L1 L2 L3

L21

L22

L11

L12

L32

L31

GF2

GF1

2

4

1

17972.C

3

1Line current transformers (1000:1)

2Individual phase inputs to Power Interface PCB (1000:1)

3Ground current input to Power Interface PCB

Example settings for S1

11

00

= 1100

16533.B

NOTE

Switch 1 is closest to the control terminal connectors. Switch 4 is closest to the CT connectors.

16/64 710-15811-00B – MV-DS User Manual (V02~V06)

Softstart UK Installation

5.9. Current Transformer Internal Wiring

xSummation Ground Fault Method (Standard)

The MV-DS current transformers (CTs) are installed and pre-wired on the power assembly. The CT wiring is

configured for summation of the ground fault current measurement.

Standard wiring for MV-DS current transformers, using summation ground fault method

T1 T2 T3T1B T1B T1B

GF2(B)

GF2(C)

GF2(D)

X11

GF2(A)

GF1(B)

GF1(C)

GF1(D)

X11

GF1(A)

CT11

CT12

CT21

CT22

CT31

CT32

CT13

CT23

CT33

X11

L11

X11

L21

X11

L31

X11

GF11 GF12

S1S2

P1P2

S1S2

P1P2

S1S2

P1P2

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(OG)

(OG)

A3

L11 L12 L21 L22 L31 L32 GF1 GF2

L11

L12

L21

L22

L31

L32

GF1

GF2

PH1 PH2 PH3 GND

CT1

CT2

CT3

L12

L22

L32

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

12 3

4

9

8

6

7

11

10

5

16702.A

1Busbars from output of bypass

contactor K2

7Orange/white twisted pair flying leads x3

2SCR stack assembly busbars 8Single-way terminal blocks x8

3Interface board line CT inputs 94-way terminal blocks x2

4Orange/white twisted pair looms x4 10 Busbars on power assembly

51000/1A 5P10, 5VA current

transformer

11 Busbars to motor output terminals

6Unused terminals for residual ground

fault CT

MV-DS IP00 terminal rail X11 layout and wiring (summation ground fault method)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(OG)

(OG)A3-L32 L32

A3-L31 L31

A3-L22 L22

A3-L21 L21

A3-L12 L12

A3-L11 L11 CT11

CT12

CT21

CT22

CT31

CT32

CT13

CT23

CT33

(A)

GF11

GF12

(B) (C) (D)

L11

L12

L21

L22

L31

L32

CT1-S1

CT1-S2

CT2-S1

CT2-S2

CT3-S1

CT3-S2

GF1

GF2

(A) (B) (C) (D)

(OG)

(WH)

A3-GF1

A3-GF2

GF1

GF2

1

2

3

6

4

9

8

10

5

7

16704.A

1Interface board line CT input (CT1) 6Unused terminals for residual ground fault CT

2Interface board line CT input (CT2) 7MV-DS line CT (CT1)

3Interface board line CT input (CT3) 8MV-DS line CT (CT2)

4Interface board ground fault CT inputs 9MV-DS line CT (CT3)

5Orange/white twisted pair looms x4 10 Orange/white twisted pair flying leads x3

710-15811-00B – MV-DS User Manual (V02~V06) 17/64

Installation Softstart UK

xResidual Ground Fault Method

To use a separate residual current ground fault CT, the standard wiring must be modified.

1. Mount a 1000/1A, 5P10, 1VA toroid style CT in a location where all three phases of the output motor cable

can be fed through it.

2. Wire the secondary of the toroid so that:

xCT terminal S1 connects to Rail X11 terminal GF11

xCT terminal S2 connects to Rail X11 terminal GF12

3. Remove wire GF1 from Rail X11 terminal GF1(A), and connect it to terminal GF11.

4. Remove wire GF2 from Rail X11 terminal GF2(A), and connect it to terminal GF12.

5. Place a wire link between terminals GF1(A), GF2(A) on Rail X11.

The CT wiring is now configured for residual ground fault current measurement.

Wiring for MV-DS current transformers, using residual ground fault method

T1 T2 T3T1B T1B T1B

GF2(B)

GF2(C)

GF2(D)

X11

GF2(A)

GF1(B)

GF1(C)

GF1(D)

X11

GF1(A)

CT11

CT12

CT21

CT22

CT31

CT32

CT13

CT23

CT33

X11

L11 L12

X11

L21 L22

X11

L31 L32

X11

GF11 GF12

T1 T2 T3

CTGF1

CTGF2

S1S2

P1P2

S1S2

P1P2

S1S2

P1P2

S1S2

P1P2

(OG)

(OG)

(WH)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(OG)

(OG)

A3

L11 L12 L21 L22 L31 L32 GF1 GF2

L11

L12

L21

L22

L31

L32

GF1

GF2

PH1 PH2 PH3 GND

(OG)

(WH)

CT1

CT2

CT3

1 2 3

45

10

9

87

14

11

12

13

6

16703.A

1Busbars from output of bypass

contactor K2

8Orange/white twisted pair flying leads x3

2SCR stack assembly busbars 9Single-way terminal blocks x8

3Interface board line CT inputs 10 4-way terminal blocks x2

4Orange/white twisted pair looms x4 11 Busbars on power assembly

5Wire link 12 Busbars to motor output terminals

61000/1A 5P10, 5VA current

transformer

13 Separate residual current ground fault CT

7Unused terminals for residual ground

fault CT

14 Cables to motor

18/64 710-15811-00B – MV-DS User Manual (V02~V06)

Softstart UK Installation

MV-DS IP00 terminal rail X11 layout and wiring (residual ground fault method)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(WH)

(OG)

(OG)

(OG)

A3-GF1

A3-GF2

GF1

GF2

A3-L32 L32

A3-L31 L31

A3-L22 L22

A3-L21 L21

A3-L12 L12

A3-L11 L11 CT11

CT12

CT21

CT22

CT31

CT32

CT13

CT23

CT33

CTGF1

CTGF2

(A)

GF11

GF12

(B) (C) (D)

L11

L12

L21

L22

L31

L32

CT1-S1

CT1-S2

CT2-S1

CT2-S2

CT3-S1

CT3-S2

GF1

GF2

(A) (B) (C) (D)

CTGF-S1

CTGF-S2

1

2

3

4

7

5

6

10

9

11

8

16705.A

1Interface board ground fault CT inputs 7MV-DS ground fault CT

2Interface board line CT input (CT1) 8MV-DS line CT (CT1)

3Interface board line CT input (CT2) 9MV-DS line CT (CT2)

4Interface board line CT input (CT3) 10 MV-DS line CT (CT3)

5Orange/white twisted pair looms x4 11 Orange/white twisted pair flying leads x3

6Wire link

5.10. Power Circuits

xOverview

MV-DS soft starters are designed to operate as part of a system including other components. A main contactor

and bypass contactor are required in all installations. All MV-DS soft starters must be installed with fuses.

The following additional components may also be required:

xmain isolator/ earth switch

xpower factor correction

xline inductors

xtransient/ overvoltage protection

xMV/LV control supply transformer

xMain Contactor

The MV-DS must always be installed with a main contactor. Select a contactor with an AC3 rating greater than

or equal to the full load current rating of the connected motor.

The main contactor is associated with terminals L1, L2, L3 on the supply side of the soft starter. The coil is

associated with output terminals 13, 14 of the MV-DS (refer to Power Circuit Configuration on page 20).

To ensure that the potentially dangerous medium voltage area is isolated from the low voltage control area,

power is supplied to the main contactor coil from the control voltage terminal block (refer to Internal Wiring –X10

on page 21).

xBypass Contactor

The MV-DS must always be installed with a bypass contactor. Select a contactor with an AC1 rating greater

than or equal to the full load current rating of the connected motor.

The bypass contactor is associated with terminals L1, L2, L3 on the supply side of the soft starter, and bypass

terminals T1B, T2B, T3B on the motor side. The coil is associated with output terminals 23, 24, and the

auxiliary Normally Open contact is associated with input terminals C73, C74 of the soft starter (refer to Power

Circuit Configuration on page 20).

To ensure that the potentially dangerous medium voltage area is isolated from the low voltage control area,

power is supplied to the bypass contactor coil from the control voltage terminal block (refer to Internal Wiring –

X10 on page 21).

710-15811-00B – MV-DS User Manual (V02~V06) 19/64

Table of contents

Other SOFTSTARTUK Controllers manuals