SOFTSTARTUK MIP-6 User manual

M

MI

IP

P-

-6

6

M

Mo

ot

to

or

r

I

In

ns

su

ul

la

at

ti

io

on

n

P

Pr

ro

ot

te

ec

ct

ti

io

on

n

I

In

ns

st

tr

ru

uc

ct

ti

io

on

n

M

Ma

an

nu

ua

al

l

Ver. 23/03/09

2 • Table of Content

________________________________________________________________________________________________

1. TABLE OF CONTENT

1. Table of Content ...................................................................................................................... 2

2. Safety & Warnings................................................................................................................... 3

2.1 Safety......................................................................................................................................... 3

2.2 Attention..................................................................................................................................... 3

2.3 Warnings.................................................................................................................................... 3

3. Technical Data ......................................................................................................................... 4

3.1 Introduction ................................................................................................................................ 4

3.2 Options....................................................................................................................................... 4

3.3 MIP selection ............................................................................................................................. 5

3.4 Protection features..................................................................................................................... 5

3.5 Input features ............................................................................................................................. 6

3.6 Supervision and communication features .................................................................................. 6

3.7 Optional serial link communication ............................................................................................ 6

4. Wiring Diagram ........................................................................................................................ 7

4.1 Low voltage wiring diagram ....................................................................................................... 7

4.2 Medium voltage wiring diagram ................................................................................................. 8

5. Terminals Description............................................................................................................. 9

6. Control Keypad...................................................................................................................... 11

6.1 LCD Arrangement .................................................................................................................... 11

6.2 Push-buttons............................................................................................................................ 11

6.3 Status LEDs. ............................................................................................................................ 12

6.4 Reviewing and modifying parameters...................................................................................... 12

6.5 Special actions performed by the key-pad............................................................................... 12

6.5.1 Run self test ..................................................................................................................12

6.5.2 Obtaining software version............................................................................................12

6.5.3 Obtaining default parameters ........................................................................................13

6.5.4 Clear statistical data ......................................................................................................13

6.5.4.1 Data cleared when STATISTICAL DATA is reset. .................................................13

6.5.5 Adjusting real time clock................................................................................................14

6.6 Mode pages ............................................................................................................................. 14

6.7 Blinking messages................................................................................................................... 15

6.8 Constant messages ................................................................................................................. 15

6.9 Mode pages and default values ............................................................................................... 16

6.9.1 Insulation parameters settings – page 1 .......................................................................18

6.9.2 I/O Parameters settings – page 2..................................................................................20

6.9.3 Tripping/alarm Options – page 3 ...................................................................................23

6.9.4 Comm. Parameters settings – page 4...........................................................................24

6.9.5 Measured data – page 5 ...............................................................................................25

6.9.6 Last 24 hour data – page 6 ...........................................................................................26

6.9.7 Last 31day data – page 7..............................................................................................26

6.9.8 256 months data – page 8.............................................................................................27

6.9.9 21 years data – page 9..................................................................................................27

6.9.10 Fault data – page 10 .....................................................................................................28

7. Case and Cutout Details ....................................................................................................... 29

8. Rear Panel Connection ......................................................................................................... 30

9. Resistor Units RU-7 & RU13 Dimensions............................................................................ 30

10. Technical Specifications....................................................................................................... 31

11. Ordering Information............................................................................................................. 32

3 • Safety & Warnings

2. SAFETY & WARNINGS

2.1 Safety

1 Read this manual carefully before operating the equipment and follow its

instructions.

2 Installation, operation and maintenance should be in strict accordance

with this manual, national codes and good practice.

3 Installation or operation not performed in strict accordance with these

instructions will void manufacturer warranty.

4 Disconnect all power inputs before servicing the MIP-6 and/or the load.

2.2 Attention

1 This product was designed for compliance with IEC 947-4-2 for class A

equipment.

2 Use of the product in domestic environments may cause radio

interference, in which case, the user may be required to employ

additional mitigation methods.

3 Utilization category is AC-53a or AC-53b, Form 1. For further information,

see Technical Specification

2.3 Warnings

1 Internal components and PCBs are at mains potential when the MIP-6 is

connected to mains. This voltage is extremely dangerous and will cause

death or severe injury if contacted.

2 When MIP-6 is connected to mains, even if control voltage is

disconnected, full voltage may appear on its internal PCBs.

3 The MIP-6 must be grounded to ensure correct operation, safety and to

prevent damage.

The company reserves the right to make any improvements or modifications to its products without

prior notice.

________________________________________________________________________________________________

4 • Technical Data

________________________________________________________________________________________________

3. TECHNICAL DATA

3.1 Introduction

Softstart UK’s MIP-6 is a sophisticated OFF-Line

Motor Insulation measure and Protection unit.

The MIP-6 is designed for testing the insulation resistance of both Low Voltage and Medium Voltage motors

(Low voltage model and Medium voltage models are different models).

For Low Voltage motors, the MIP-6 is a stand alone unit.

For Medium Voltage motors, external RU7 (up to 7200V) or RU13 (up to 13800V) should be used.

The MIP-6 is a fully digital unit and can be used for all types of AC motors.

The MIP-6 measures:

•Actual insulation resistance.

When the optional real time clock is installed, the optionMIP-6 is capable to calculate:

•Last hour average insulation resistance.

•Last twenty four hours average insulation resistance.

•Last (previous) month average insulation resistance.

•Last (previous) year average insulation resistance

Two types of Minimum and Maximum insulation resistance levels are recorded. One type is for

the present month and the other for minimum and maximum levels, since the last reset.

All above parameters can be displayed and read through the optional RS485 communication.

Built in programmable time delay, prevents wrong insulation measurement due to motor cable capacitances

and motor induced voltages.

The MIP-6 relay protects the system from abnormal low insulation resistance condition in the motor and

cabling. Upon fault, the MIP-6 can alarm or trip the motor or prohibit starting.

The MIP-6 uses automatically Adjustable DC voltage level for the optimal Insulation resistance measurement.

To increase system and user safety maximum DC voltage is 50V.

Insulation measurement range is 0 – 50Mohm for both low voltage and medium voltage types.

The MIP-6 measures the insulation level when the motor is off line. Measurement is performed only when the

upstream line contactor is open. A discrete (digital) input is used to inform the MIP-6 if it should measure the

insulation resistance or not.

The MIP-6 cannot measure the insulation resistance when motor is powered. No damage will occur if the MIP-

6 connected properly when the motor is powered.

To prevent mistake and high insulation resistance reading, as a result of a disconnected measurement line,

Line Test feature enables user to perform line test and verify that the insulation measurement line is properly

connected. This feature tests also that the MIP functions normally. This feature applicable only to M.V. units.

In addition, internal self test is running in the background and testing the MIP-6. Manual self test can be also

performed.

The MIP-6 is fully programmable with 8 protection functions, including Insulation Trip, Insulation Alarm, Line

Test fail (M.V. units only!), optional Communication Port failure, Internal Fault and three External Faults.

The MIP-6 has a two line, 16 character LCD display and a six buttons keyboard for programming, reading

actual values, statistical & maintenance data.

3.2 Options

1. Real time clock. More than 21 years of data can be stored in the MIP-6. Data will be lost if MIP-

6 is disconnected from the auxiliary power supply voltage, for more than 2 weeks.

The MIP-6 is capable of storing and displaying the following historical values:

•Average Insulation resistances, hour by hour, of the last 24 hours.

•Average Insulation resistances, day by day, of the last 31 days.

•Average Insulation resistances, month by month, of the last 256 months.

•Average Insulation resistances, year by year, of the last 21 years.

5 • Technical Data

________________________________________________________________________________________________

2. RS-485 communication for MIP-6 programming, remote data readings and controlling.

3. Analog output. The MIP-6 can output present insulation level, 1 hour average, 24 hours average or one

month average.

3.3 MIP selection

Select the MIP-6 according to mains rated voltage.

Low Voltage – Up to 690V line to line.

Medium Voltage 1 – up to 7200V line to line (together with RU7).

Medium Voltage 2 – up to 13800V line to line (together with RU13).

3.4 Protection features

The MIP-6 alarms if the motor ground insulation level decreases below a preset value. This relay should

protect the motor against too low insulation resistance between motor windings and ground (earth).

For low voltage, up to 690V, the MIP-6 is directly connected to one of the motor phases. For MV, all three

motor phases are connected to an external resistor and protection unit RU7/13. The output of the RU7/13 is

connected to the MIP-6.

The MIP-6 incorporates one programmable Analog Output (optional) as well as six programmable discrete

inputs and six programmable output relays. Four relays are of the N.O. type with one common line to all four.

The other two relays are change-over (form C) type.

All inputs and outputs are combined to provide a very flexible package.

All output relays can be programmed as: TEST COMMAND OFF (M.V. units only!), TEST COMMAND ON

(M.V. units only!),INS. TST NOT ACT., INS. TST ACTIVE, INSUL. IN RANGE D, INSUL. IN RANGE C,

INSUL. IN RANGE B, INSUL. IN RANGE A, FAULT-FAIL SAFE, FAULT, ALARM-FAIL SAFE, ALARM, TRIP-

FAIL SAFE, TRIP,

In addition to the above programming options for all relays, each of A, B or C relays can be configured as

TRIPPING/ALARM as shown on the following table:

(i.e. - It is possible to assign certain faults to each one of the relays A, B or C.)

The MIP-6 can handle 8 different trips / alarms.

INSULATION TRIP Programmable level normally used to prevent starting the motor.

INSULATION ALARM Programmable level normally used to alarm that the insulation level is

decreasin

g

.

COMM PORT FAILED Used to alert for a communication port fault.

LINE TEST FAILED Used to alert when insulation test line is faulty. Applicable only in MIP-6 for

Medium voltage application (with RU7 or RU13).

INTERNAL FAILURE Background running self test program continuously tests the hardware and

software of the MIP-6. This protection can signal if an internal error occurs.

EXTERNAL FAULT 1

EXTERNAL FAULT 2

EXTERNAL FAULT 3

Three external fault inputs can be programmed to alarm or trip the motor.

Protection levels and time delay settings are programmable using the key pad on the front panel or through

communication.

Note that other relays – D, E and F can not be programmed as a TRIPPING/ALARM relays.

Refer to section 6.9.3 on page 23 for more details.

6 • Technical Data

________________________________________________________________________________________________

3.5 Input features

Six optically isolated logic inputs are used. Each input can be programmed as: EXT FAULT 3 N.C., EXT

FAULT 3 N.O., EXT FAULT 2 N.C., EXT FAULT 2 N.O., EXT FAULT 1 N.C., EXT FAULT 1 N.O.,

EMERGENCY RESTART, AUTHORIZED KEY, REMOTE RESET, TEST LINE (M.V. units only!), TEST

INSUL. N.C., TEST INSUL. N.O.

3.6 Supervision and communication features

A Liquid Crystal Display (LCD), together with a keypad and LEDs enables “user friendly” interface, accurate

digital parameters setting, actual parameters readings, and detailed trip and alarm message displays.

Unauthorized setting changes can easily be prevented by the correct use of the Authorized key input terminals

and settings.

Measured Data Actual Insulation value, one hour average insulation value(1), 24 hours

insulation value(1), previous month average insulation(1), present month

minimum and maximum insulation values(1), minimum/maximum insulation

values since last reset, output and output contacts status

Last 24 Hours Data(1) Average insulation resistances, hour by hour, of the last 24 hours.

Lat 31 Day Data(1) Average insulation resistances, day by day, of the last 31 days.

256 Months Data(1) Average insulation resistances, month by month, of the last 256 months.

21 Years Data(1) Average insulation resistances, year by year, of the last 21 years.

Fault data Last Trip, Last Alarm, insulation resistance at time of trip, last 10 faults

with time and date stamp. (1)

Note:

(1) – Optional when real time clock option is installed.

3.7 Optional serial link communication

The MIP-6 is equipped with an optional powerful data communication system.

This communication system is unmatched in its reliability, flexibility and ease of use providing the ideal basis

for the design of a modern motor management system.

The MIP-6 incorporates a rear RS485 serial link that uses a MODBUS RTU protocol (The protocol description is not

included in this document) to provide high speed data acquisition to supervisory computers.

Data formats have been carefully structured to provide fast notification of alarms and continuous updates of performance

parameters.

The following information and control can be accessed through the communication.

(See MIP-6 Communication instruction manual.)

•All Actual data values

•All MIP-6 Parameter Settings (Read & Write)

•All the control commands for the MIP-6 (Measure command, Test line)

•Reset

The MIP-6 system is user expandable. No special engineering skills or tools are required.

For small systems, the host computer can communicate directly with the MIP-6 via a twisted shielded pair.

For larger systems a data highway enables multiple MIP-6 connection. Up to 32 MIP-6s can be added on

each twisted pair of the Host serial link with full access to all MIP-6's.

The system also performs high speed data acquisition. Users have a simple and friendly means of creating a

fully integrated monitoring and control systems.

System reliability is exceptionally high, meeting the highest standards of reliable communication in the

industry. Included in each message is a 16 bit CRC.

Notes:

•Protocols other than MODBUS RTU available upon consultation.

•Terminate serial link cable with 120 Ohm resistors at both ends.

7 • Wiring Diagram

4. WIRING DIAGRAM

4.1 Low voltage wiring diagram

Notes:

(1) – The optional communication RS485 output is an isolated output.

Use shielded twisted pair for RS485 communication.

It is recommended to ground the shield near the MIP-6.

(2) – The optional analog output is an isolated output.

Use shielded twisted pair for analog output.

It is recommended to ground the shield of the analog output cable at the receiver side.

(3) – All output relays are programmable. Refer to section 6.9.2 page 20 for more details.

(4) – All input relays are programmable. Refer to section 6.9.2 page 20 for more details.

(5) – Leave terminals 51, 52 not connected.

________________________________________________________________________________________________

8 • Wiring Diagram

________________________________________________________________________________________________

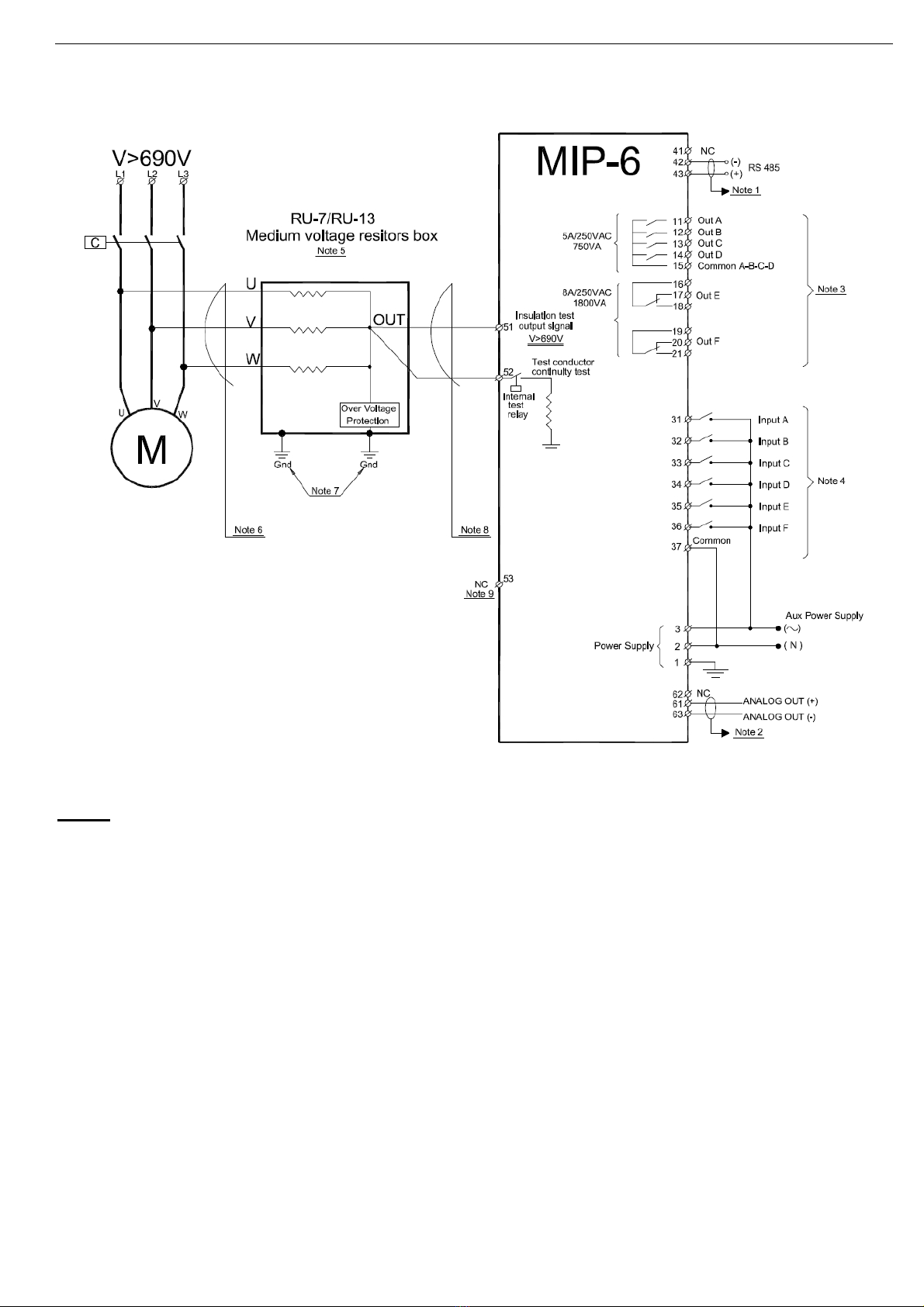

4.2 Medium voltage wiring diagram

Notes:

(1) – The optional communication RS485 output is an isolated output.

Use shielded twisted pair for RS485 communication.

It is recommended to ground the shield near the MIP-6.

(2) – The optional analog output is an isolated output.

Use shielded twisted pair for analog output.

It is recommended to ground the shield of the analog output cable at the receiver side.

(3) – All output relays are programmable. Refer to section 6.9.2 page 20 for more details.

(4) – All input relays are programmable. Refer to section 6.9.2 page 20 for more details.

(5) – RU7 is applicable for voltage up to 7.2kV.

RU13 is applicable for voltage up to 13.8kV.

(6) – Use medium voltage leads to connect the RU7/13 to the M.V. motor.

(7) –Use two ground connection to ground the RU7/13.

(8) – Use low voltage leads from RU7/13 to MIP-6 unless these leads run near M.V.

exposed equipment.

(9) – Leave terminal 53 not connected.

9 • Terminals Description

________________________________________________________________________________________________

5. TERMINALS DESCRIPTION

Indication Description Remarks

Terminal 3 – Phase or DC (+)

Terminal 2 – Neutral or DC (-)

Terminal 1 – Ground

Control voltage.

85-230VDC/AC (50/60Hz)

Same unit for all range of auxiliary

power supply. No need for

adjustments of any kind.

Terminal 31 – Input A

Terminal 32 – Input B

Terminal 33 – Input C

Terminal 34 – Input D

Terminal 35 – Input E

Terminal 36 – Input F

Terminal 37 – Common

Discrete Inputs.

6 programmable discrete

inputs.

To turn ON an input connect

control voltage between it’s

terminal and the common

terminal 37.

Each input can be programmed as:

EXT FAULT 3 N.C.

EXT FAULT 3 N.O.

EXT FAULT 2 N.C.

EXT FAULT 2 N.O.

EXT FAULT 1 N.C.

EXT FAULT 1 N.O.

EMERGENCY RESTART

AUTHORIZED KEY

REMOTE RESET

TEST LINE (M.V. units only!)

TEST INSUL. N.C.

TEST INSUL. N.O.

Refer to section 6.9.2 on page 20 for

more details.

Terminal 11 – Output relay A N.O

Terminal 12 – Output relay B N.O

Terminal 13 – Output relay C N.O

Terminal 14 – Output relay D N.O

Terminal 15 – Common of output

relays A, B, C & D.

Terminal 16 – Common of output

relay E

Terminal 17 – Output relay E N.C

Terminal 18 – Output relay E N.O

Terminal 19 – Common of output

relay F

Terminal 20 – Output relay F N.C

Terminal 21 – Output relay F N.O

Discrete Outputs.

6 programmable discrete

outputs.

Discrete outputs A, B, C, D

rated 5A/250VAC resistive,

750VA, NO configuration with

common terminal.

Discrete outputs E, F rated

8A/250VAC resistive,

1800VA inductive, change

over (form C) configuration.

Each output can be programmed as:

TRIPPING/ALARM (relays A, B and

C only!)

TEST COMMAND OFF

TEST COMMAND ON

INS. TST NOT ACT.

INS. TST ACTIVE

INSUL. IN RANGE D

INSUL. IN RANGE C

INSUL. IN RANGE B

INSUL. IN RANGE A

FAULT-FAIL SAFE

FAULT

ALARM-FAIL SAFE

ALARM

TRIP-FAIL SAFE

TRIP

Refer to section 6.9.2 on page 20 for

more details.

Terminal 43 – Serial port (+)

Terminal 42 – Serial port (-)

Serial link (Optional)

Standard RS485 half

duplex, with MODBUS

protocol.

Twisted shielded pair should

be used for wiring. Shield

should be connected to

chassis ground externally,

near the MIP-6.

Acceptable baud rates: 2400,

4800, 9600, 19200 and

38400 BPS.

Refer to section 3.7 on page 6for

more details.

Refer to section 6.9.4 on page 24 for

more programming details.

Note:

Connect 120 Ohm resistors

between (+) and (-) at both sides

of the line.

10 • Terminals Description

________________________________________________________________________________________________

Indication Description Remarks

Terminal 51 – Medium voltage

insulation input.

Terminal 52 – Medium voltage line

test input.

Terminal 53 – Low voltage

insulation input.

Insulation inputs

For Low voltage, up to 690V line to line, use terminal 53 only. Leave

terminals 51 and 52 open. Terminal 53 should be connected directly

to one of the motor phases. Terminal 53 can be connected to AC

voltage (when live) of 400V maximum (690/1.73), without damage.

There is no line test for low voltage.

WARNING! Terminal 53 is the only, terminal that can be

connected directly to mains live voltage of up to 690V

line to line. Connecting any live voltage to terminals 51

and/or 52 will cause immediate damage to the MIP-6

and can be dangerous!!!

Terminals 51 and/or 52 must be connected to

mains only through RU7 (up to 7200V) or RU13

(up to 13800V) unit. !

For Medium Voltage, use terminals 51 and 52. Terminal 51 is used

for the insulation measurement and terminal 52 is used for the line

test. Both terminals should be connected to motor via resistors unit

RU7/13. It is recommended to use two separate cables. One from

terminal 51 to the RU7/RU13 output and the other from terminal 52

to the RU7/RU13 output. Upon Line test, internal resistor is

connected to ground on terminal 52. Terminal 51 should measure

the parallel resistance of motor insulation and the internal resistance.

Terminal 61 – Analog out (+)

Terminal 63 – Analog out (-)

Analog output (Optional)

Analog output type can be

programmed to 4..20 mA or

0..20 mA. Load resistance

should be less than 400Ω.

Note:

The analog output electronics

is fully isolated electronic

circuitry.

Twisted and Shielded cable

must be used. Shield should

be connected to ground

externally, near the analog

output signal receiver.

The Analog output can be

programmed to represent one of

following parameters:

INS. R. AVG. -1MNTH(1)

INS. RES. AVG. -24H(1)

INS. RES. AVG. -1H(1)

INSULATION RES.

Refer to section 6.9.2 on page 20 for

more details.

Note:

(1) – Applicable only when real time

clock option is installed.

11 • Control Keypad

________________________________________________________________________________________________

6. CONTROL KEYPAD

The control keypad is the link between the MIP-6 and the user.

The MIP-6 control keypad features:

(1) Three indication LEDs (On, Stand by/Active, Fault/Alarm)

(2) Two lines of 16 alphanumeric characters each.

(3) Six push-buttons (Page, Select/Reset, Select, Store, Up (S) and down (T) keys.

(1)

(2)

(3)

6.1 LCD Arrangement

CONFIG. INPUT A

TEST INSUL. N.O.

Upper line displays function.

Lower line displays setting and\or measured values.

6.2 Push-buttons

Allows the operator to browse through the display and programming menus available in the

MIP-6.

Allows the operator to select a function within each Page.

Note: Pressing Select continuously changes shown parameters continuously.

Allows the operator to increase adjusted values shown in the display. Operator should press this

button momentarily, for slow value changes in the display, or continuously, for rapid value

changes in the display.

Allows the operator to decrease adjusted values shown in the display. Operator should press this

button momentarily, for slow value changes in the display, or continuously, for rapid value

changes in the display.

Page

Select

Allows the operator to store modified parameters in the non-volatile memory to save modified

parameters.

When Store is pressed while actual value is displayed, this display becomes the default display.

Store

12 • Control Keypad

________________________________________________________________________________________________

This key has two functions:

•Used to toggle between “backwards” and “forward” while pressing Select key.

When pressing Selectukey, an underline mark will show/not show on the first digit

of the second row of the display. While underline mark shows – Select key goes

“backwards”.

While underline mark does not show – Select key goes “forward”.

•When MIP-6 is in latched trip or in alarm status the Reset key allows the user to

reset the unit. The Reset key has to be pressed for 1 second in order to reset the

MIP-6.

Selectu

Reset

6.3 Status LEDs.

Green On Lights when control supply voltage is connected to the MIP-6.

Yellow Stand-by/

Active

Blinks when in stand-by.

Lights when measurement is active.

Red Alarm/

Fault

Blinks when in alarm.

Lights when in fault condition.

6.4 Reviewing and modifying parameters

Press Page key several times until you reach the required Mode page.

Press Select key to review parameters of this Mode.

When reaching the required parameter, modify its values with Tor Skeys.

Once value is set press Store key. Once data was properly stored in the non-volatile memory, the LCD will

display DATA SAVED OK for 2 seconds.

In addition the modified parameter/s can be stored at the end of every mode page.

Press Select until STORE ENABLE XXX PARAMETERS message appears, then press Store key. The LCD

will display DATA SAVED OK for 2 seconds.

6.5 Special actions performed by the key-pad.

6.5.1 Run self test

Press Page and Tkeys simultaneously.

The LCD will display:

TEST / MAINTENANCE

***OPTIONS***

Press Select key.

The LCD will display:

RUN SELF TEST?

PUSH ‘VALUE-UP’

To perform a self test push UP ARROW.

If self test OK, display will show:

SELF TEST PASSED

Press Mode key to exit test/maintenance mode.

6.5.2 Obtaining software version

Press Page and Tkeys simultaneously.

The LCD will display:

TEST / MAINTENANCE

******OPTIONS***********

Press Select key twice.

The LCD will display the software version:

13 • Control Keypad

________________________________________________________________________________________________

BTL-04/10/2006

MIP6-051006-Mb

Press Mode key to exit test/maintenance mode

6.5.3 Obtaining default parameters

Press Page and Tkeys simultaneously.

The LCD will display:

TEST / MAINTENANCE

******OPTIONS***********

Press Select key three times.

The LCD will display:

STORE NOW ?

DEFAULT SETTINGS

To obtain “default parameters” press Page+Store simultaneously.

The LCD will display:

DATA SAVED OK

At this point (If “default parameters” were obtained) the MIP-6 exit test/maintenance mode.

CAUTION! Obtaining Default Parameters erases all previously modified settings and

requires the operator to program all parameters values again.

6.5.4 Clear statistical data

Press Page and Tkeys simultaneously.

The LCD will display:

TEST / MAINTENANCE

******OPTIONS***********

Press Select key four times.

The LCD will display:

CLEAR NOW ?

STATISTICAL DATA

To clear “statistical data” press Reset+Store simultaneously.

The LCD will display:

DATA SAVED OK

At this point (If “statistical data” is cleared) the MIP-6 exit test/maintenance mode.

6.5.4.1 Data cleared when STATISTICAL DATA is reset.

The following data is cleared when STATISTICAL DATA is cleared:

•Total measure time

•Total # of trips

•Min. Insulation Resistances (general and of present month)

•Max. Insulation Resistances (general and of present month)

•Pre Trip Insulation value

•Last Trip

•Last Alarm

•Previous trips information and time stamps

•Hour, Date, Month, Year arrays with Insulation resistance history !

CAUTION! After clearing statistical data it is not possible to retrieve any cleared values.

14 • Control Keypad

________________________________________________________________________________________________

6.5.5 Adjusting real time clock

Press Page and Tkeys simultaneously.

The LCD will display:

TEST / MAINTENANCE

******OPTIONS***********

Press Select key five times.

The LCD will display:

hh.mm dd.mm.yy

09:10 29/11/06

Pay attention to the under line mark under the hour value.

modify the hour value with Tor Skeys.

Press Store key.

The LCD will display:

DATA SAVED OK

And after few seconds will change to:

hh.mm dd.mm.yy

09:10 29/11/06

Pay attention to the under line mark under the minutes value.

Repeat the same procedure as for the hour settings to seconds, day, month and year settings.

After Store key is pressed last time the LCD will display:

DATA SAVED OK

At this point the MIP-6 exit test/maintenance mode.

NOTE! For longer life, the Real Time Clock uses a backup capacitor and not a backup

battery. The backup capacitor retains data and keeps clock running for a few

days.

If the MIP-6 is not powered for a longer period, the clock has to be initialized.

Initialization can be done manually as described above or through a serial link.

6.6 Mode pages

Upon initiation of the MIP-6, the LCD displays:

INSULATION PARA.

***SETTINGS***

By pressing the Page key all mode pages can be reviewed:

I/O PARAMETERS

***SETTINGS***

TRIPPING/ALARM

***OPTIONS***

COMMUNICATION P.

***SETTINGS***

MEASURED DATA

-****-

LAST 24 HOUR DATA

-****-

LAST 31 DAY DATA

-****-

256 MONTHS DATA

-****-

21 YEARS DATA

-****-

FAULT DATA

-****-

15 • Control Keypad

________________________________________________________________________________________________

Notes:

1. Pressing Store key while the LCD displays an "Actual Data" parameter, will store this parameter as default

display. If no key is pressed for more than five minutes, this parameter will be constantly displayed.

2. Pressing Store key, while the LCD displays a header, will store this header as the default display. If no key

is pressed for more than five minutes this header will be constantly displayed.

6.7 Blinking messages

Blinking messages are displayed as a response to an event.

Blinking message is displayed for 2 seconds and then the display returns to the previous message.

Blinking messages are usually displayed as a response to an operator action.

The messages are either to confirm activation of the requested operation, or to indicate a reason for not doing

so.

Display Description

DATA SAVED OK

Displayed after pressing Store key. If an error is found during store

process, then next message is shown.

STORAGE ERROR

Displayed when an error is found in the store process.

WRONG PARAMETERS

Displayed after power-up, if the non-volatile parameter check sum is

found to be wrong.

UNAUTHRIZED ACCESS

When Authorized Key is open (locked), and a parameter change is

attempted. Also displayed after Unauthorized Store and Reset

action.

SELF TEST PASSED

Displayed as a response to running the built in test procedure,

provided that all tests were "OK".

SELF TEST FAILED

ERROR CODE=32

Displayed as a response to finding an error during the operation of

test procedure.

In case of test failure, reset and test again. If problem persists then

error code should be reported to an authorized factory

representative.

6.8 Constant messages

Constant messages are displayed upon a fault.

Display Description

ALARM

LINE TEST FAILED

Displayed when the Alarm LED illuminates. The lower line displays

the Alarm name.

TRIP

INSULATION TRIP

Displayed when the Trip LED illuminates. The lower line displays

the Trip name.

ALARM:

INT. FAILURE=XX

Displays in case of an internal failure.

Error code should be reported to an authorized factory

representative.

16 • Control Keypad

________________________________________________________________________________________________

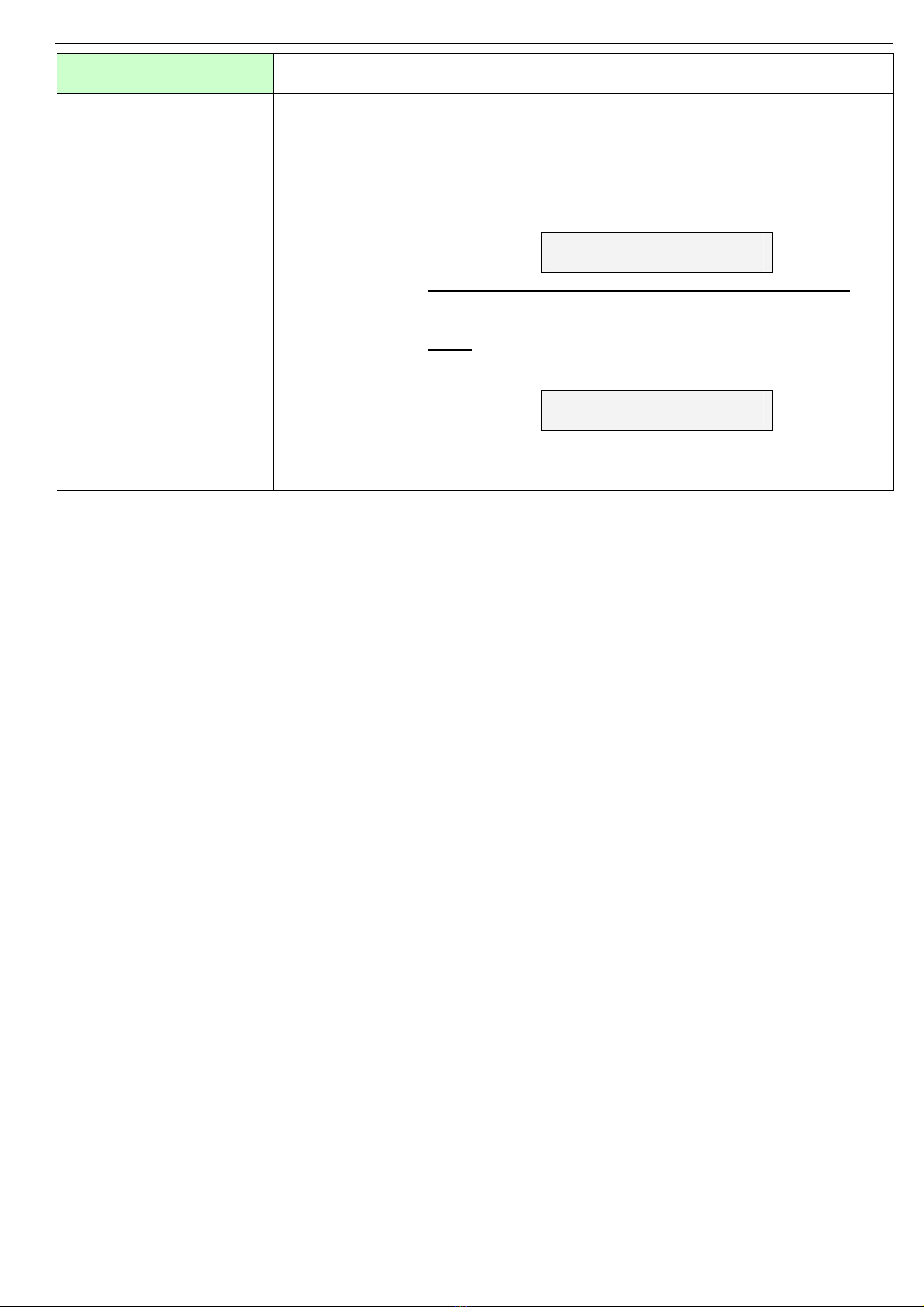

6.9 Mode pages and default values

INSULATION PARA.

***SETTINGS*** I/O PARAMETERS

***SETTINGS*** TRIPPING/ALARM

***OPTIONS*** COMMUNICATION P.

***SETTINGS*** MEASURED DATA

--****--

See page 18 See page 20 See page 23 See page 24 See page 25

Display and default

values Display and default

values Display Display

WAIT BEFORE TEST

2 MIN

CONFIG. INPUT A

TEST INSUL. N.O.

BAUD RATE

19200

INSULATION RES.

34377 KOHM

INSUL. TRIP LVL

1.0 MOHM

CONFIG. INPUT B

TEST LINE

ADDRESS NUMBER

OFF

1 HOUR AVG. INSUL

23456 KOHM

INSUL. TRIP DLY

10 MIN.

CONFIG. INPUT C

REMOTE RESET

S.LINK PAR. SAVE

DISABLE

24 HOUR AVG. INSUL

24456 KOHM

INSUL. ALARM LVL

2.0 MOHM

CONFIG. INPUT D

AUTHORIZED KEY

S.LINK CONTROL

DISABLE

PREV. MONTH AVG.

34566 KOHM

INSUL. ALARM DLY

10 MIN.

CONFIG. INPUT E

EXT FAULT 1 N.O.

FRONT COM ADDRES

OFF

THIS MONTH MIN.

12345 KOHM.

INSUL. RANGE A

4.0 MOHM

CONFIG. INPUT F

EXT FAULT 2 N.O.

STORE ENABLE

COMM. PARAMETERS

THIS MONTH MAX.

4321 KOHM.

INSUL. RANGE B

6.0 MOHM

PARAM. SETTINGS

NOT LOCKED

MINIMUM INSUL. R

34521 KOHM.

INSUL. RANGE C

8.0 MOHM

CONFIG. OUTPUT A

INSUL. IN RANGE D

MAXIMUM INSUL. R

99888 KOHM.

INSUL. RANGE D

10.0 MOHM

OUTPUT DELAY

600 SEC.

IN # 1 2 3 4 5 6

0 1 1 0 0 0

DISPLAY MODE

FULL DISPLAY

CONFIG. OUTPUT B

INSUL. IN RANGE C

OUT # 1 2 3 4 5 6

0 1 1 0 0 0

STORE ENABLE

INSULATION PARA.

OUTPUT DELAY

600 SEC.

TOTAL MEASURE T.

2 HOURS

CONFIG. OUTPUT C

INSUL. IN RANGE B

TOTAL # OF TRIPS

0

OUTPUT DELAY

600 SEC.

CONFIG. OUTPUT D

INSUL. IN RANGE A

OUTPUT DELAY

600 SEC.

CONFIG. OUTPUT E

ALARM

OUTPUT DELAY

300 SEC.

CONFIG. OUTPUT F

TRIP

ANALOG OUT TYPE

4 . . 20 mA

OUTPUT DELAY

120 SEC.

ANALOG OUT PARAM.

INS. RES. AVG. -1H

ANALOG OUT MIN.

0.0 MOHM

ANALOG OUT MAX.

20.0 MOHM

STORE ENABLE

I/O PARAMETERS

17 • Control Keypad

________________________________________________________________________________________________

LAST 24 HOUR DATA

--****-- LAST 31 DAY DATA

--****-- 256 MONTHS DATA

--****-- 21 YEARS DATA

--****-- FAULT DATA

--****--

See page 26 See page 26 See page 27 See page 27 See page 28

Display Display Display Display Display

PREVIOUS INSUL.:

AVARAGE VALUES

PREVIOUS INSUL.:

AVARAGE VALUES

PREVIOUS INSUL.:

MONTH/YEAR

PREVIOUS INSUL.:

MONTH/YEAR

LAST ALARM

INTERNAL FAILURE

HOUR=0….. 23

52.6 MOHM

DATE=1….. 31

51.3 MOHM

04/00 AVG, MIN, MX

60.0 60.0 60.0 M

04/00 AVG, MIN, MX

60.0 60.0 60.0 M

PRE TRIP INSUL.

0 KOHM

PREVIOUS INSUL.:

AVARAGE VALUES

LAST 10 TRIPS:

HH:MM DD/MM/YY

18 • Control Keypad

________________________________________________________________________________________________

6.9.1 Insulation parameters settings – page 1

INSULATION PARA.

***SETTINGS***

Display and default

values Range Description

WAIT BEFORE TEST

2 MIN

0 – 960 min. Idle time after measure command. Insulation measurement

starts after the WAIT BEFORE TEST TIME has elapsed.

INSUL. TRIP LVL

1.0 MOHM

0.2 – 25 MOhm. Trip occurs when present value of measured resistance is

lower than INSUL. TRIP LVL, for more than INSUL. TRIP

DLY (See next parameter)

Note:

In order to be activated, this parameter must be

programmed to:

I/O PARAMETERS SETTINGS – Parameters CONFIG.

OUTPUT X (Refer to section 6.9.2 page 20 for more details)

TRIPPING/ALARM OPTIONS (Refer to section 6.9.3 page

23 for more details)

INSUL. TRIP DLY

10 MIN.

0 – 960 min. Time Delay of Insulation trip.

INSUL. ALARM LVL

2.0 MOHM

0.2 – 25 MOhm. Alarm occurs when present value of measured resistance is

lower than INSUL. ALARM LVL, for more than INSUL.

ALARM DLY (See next parameter)

Note:

In order to be activated, this parameter must be

programmed to:

I/O PARAMETERS SETTINGS – Parameters CONFIG.

OUTPUT X (Refer to section 6.9.2 page 20 for more details)

TRIPPING/ALARM OPTIONS (Refer to section 6.9.3 page

23 for more details)

INSUL. ALARM DLY

10 MIN.

0 – 960 min. Time Delay of Insulation alarm.

INSUL. RANGE A

4.0 MOHM

0.2 – 25 MOhm. Insulation is inside range A (can operate a relay for

signalling) when measured Insulation resistance is lower

than INSUL. RANGE A setting.

INSUL. RANGE B

6.0 MOHM

0.2 – 25 MOhm. Insulation is inside range B (can operate a relay for

signalling) when measured Insulation resistance is lower

than INSUL. RANGE B setting.

INSUL. RANGE C

8.0 MOHM

0.2 – 25 MOhm. Insulation is inside range C (can operate a relay for

signalling) when measured Insulation resistance is lower

than INSUL. RANGE C setting.

INSUL. RANGE D

10.0 MOHM

0.2 – 25 MOhm. Insulation is inside range D (can operate a relay for

signalling) when measured Insulation resistance is lower

than INSUL. RANGE D setting.

DISPLAY MODE

FULL DISPLAY

FULL DISPLAY Future enhancement.

STORE ENABLE

INSULATION PARA.

Storing modified parameters

To store selected parameters, press Store key.

Note: Storing more than one parameter possible only when

19 • Control Keypad

________________________________________________________________________________________________

INSULATION PARA.

***SETTINGS***

Display and default

values Range Description

the MIP-6 is not running.

While MIP-6 is running each parameter can be changed

individually by pressing Store key after modifying the

parameter.

When parameters are correctly stored, the LCD will read:

DATA SAVED OK

This concludes INSULATION PARAMETER settings.

Pressing Select key after DATA SAVED OK returns to the

first display in this mode.

Note:

In case of a failure in parameter storing, the LCD

displays:

STORAGE ERROR

In this case load MIP-6 default parameters. Refer to section

6.5.3 on page 13 for more details on loading MIP-6 default

parameters.

20 • Control Keypad

________________________________________________________________________________________________

6.9.2 I/O Parameters settings – page 2

I/O PARAMETERS

***SETTINGS***

Display and default

values Range Description

CONFIG. INPUT A

TEST INSUL. N.O.

EXT FAULT 3 N.C.

EXT FAULT 3 N.O.

EXT FAULT 2 N.C.

EXT FAULT 2 N.O.

EXT FAULT 1 N.C.

EXT FAULT 1 N.O.

EMERGENCY

RESTART

AUTHORIZED KEY

REMOTE RESET

TEST LINE

TEST INSUL. N.C.

TEST INSUL. N.O.

Sets MIP-6 INPUT A.

EXT FAULT 3 N.C. (1) is programmed for open to trip.

EXT FAULT 3 N.O.(1) is programmed for close to trip.

EXT FAULT 2 N.C.(1) is programmed for open to trip.

EXT FAULT 2 N.O.(1) is programmed for close to trip.

EXT FAULT 1 N.C.(1) is programmed for open to trip.

EXT FAULT 1 N.O.(1) is programmed for close to trip.

EMERGENCY RESTART is programmed to reset and

prevent insulation trip by the MIP-6. (See also PARAM.

SETTING below)

AUTHORIZED KEY is programmed to prevent

parameter modifications. Closing the contact will

enable programming the MIP-6.

REMOTE RESET is programmed to remote reset the

MIP-6. To remote reset close contact momentarily.

TEST LINE is programmed to start the wiring test of the

cable from the resistor unit (RU7/RU13). Close the

contact to start the insulation measurement.

Applicable only in medium voltage applications.

TEST INSUL. N.C. is programmed to start the

insulation measurement. Open the contact to start the

insulation measurement.

TEST INSUL. N.O. is programmed to start the

insulation measurement. Close the contact to start the

insulation measurement

Note:

(1) In order to be activated, this parameter must be

programmed to:

I/O PARAMETERS SETTINGS – Parameters CONFIG.

OUTPUT X (Refer to section 6.9.2 page 20 for more

details)

TRIPPING/ALARM OPTIONS (Refer to section 6.9.3

page 23 for more details)

CONFIG. INPUT B

TEST LINE

Same as for CONFIG.

INPUT A.

CONFIG. INPUT C

REMOTE RESET

Same as for CONFIG.

INPUT A.

CONFIG. INPUT D

AUTHORIZED KEY

Same as for CONFIG.

INPUT A.

CONFIG. INPUT E

EXT FAULT 1 N.O.

Same as for CONFIG.

INPUT A.

CONFIG. INPUT F

EXT FAULT 2 N.O.

Same as for CONFIG.

INPUT A.

PARAM. SETTINGS

NOT LOCKED

LOCKED OUT

NOT LOCKED

When set to LOCKED OUT, AUTHORIZED KEY

programming in CONFIG INPUT A (See above)

functions normally.

Table of contents