Tradinco TRAQC-9 User manual

User Manual

TRAQC-9

TRAQC-9

Calibrators

User Manual

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 2

Content

1. General 5

1.1 Warranty .........................................................................................5

1.2 TRAQC-9 Description.........................................................................6

1.2.1 CE EMC Directive 2014/30/EU ........................................................6

1.2.2 CE Electrical Safety Directive 2014/35/EU........................................6

1.3 Symbols Used ..................................................................................7

1.4 Scope of this manual ........................................................................7

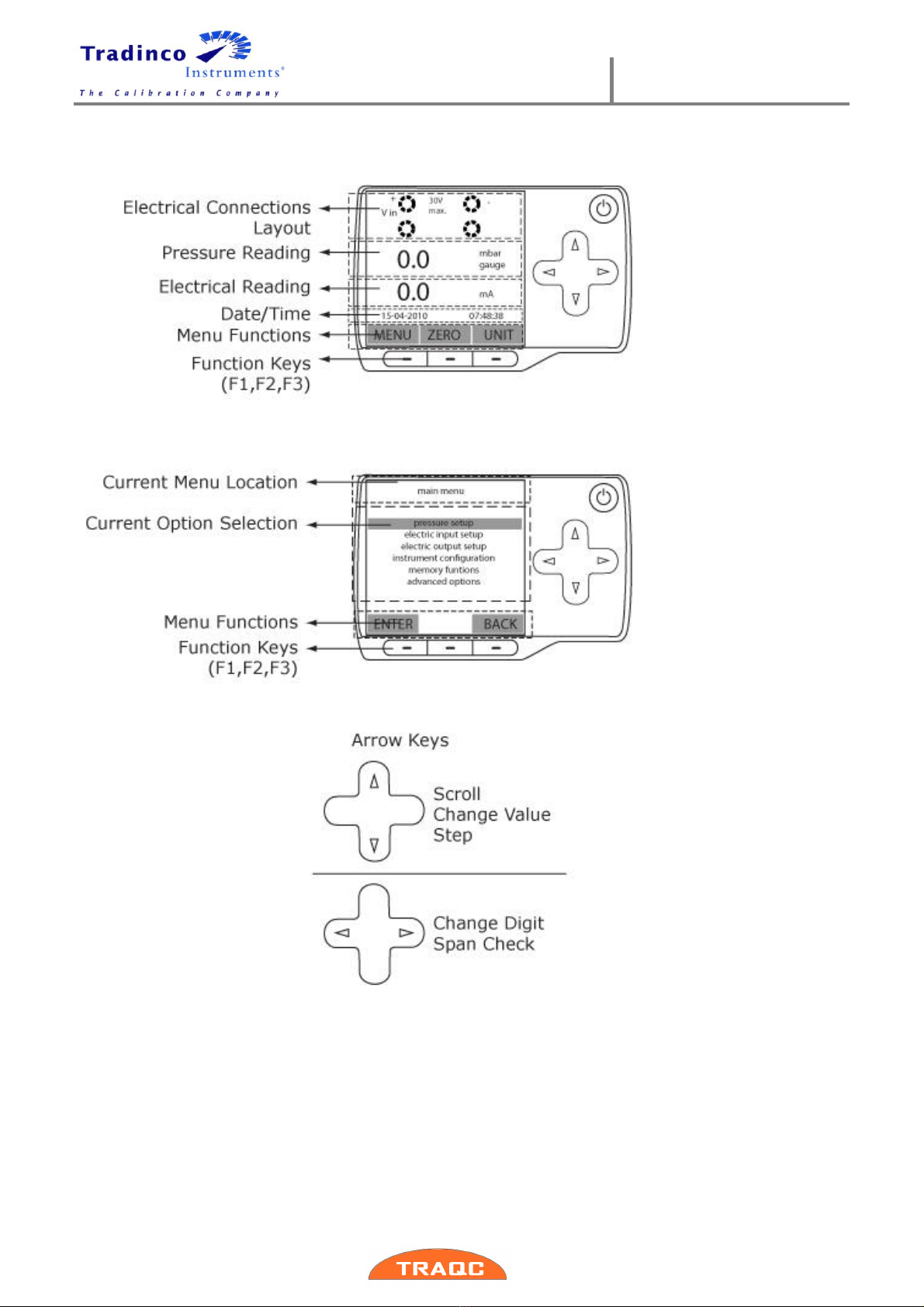

1.5 Indicator Interface............................................................................8

1.6 Navigation .......................................................................................9

1.7 Electrical Connections .....................................................................10

2. TRAQC-9 Types 11

2.1 TRAQC-9 Configurations ..................................................................11

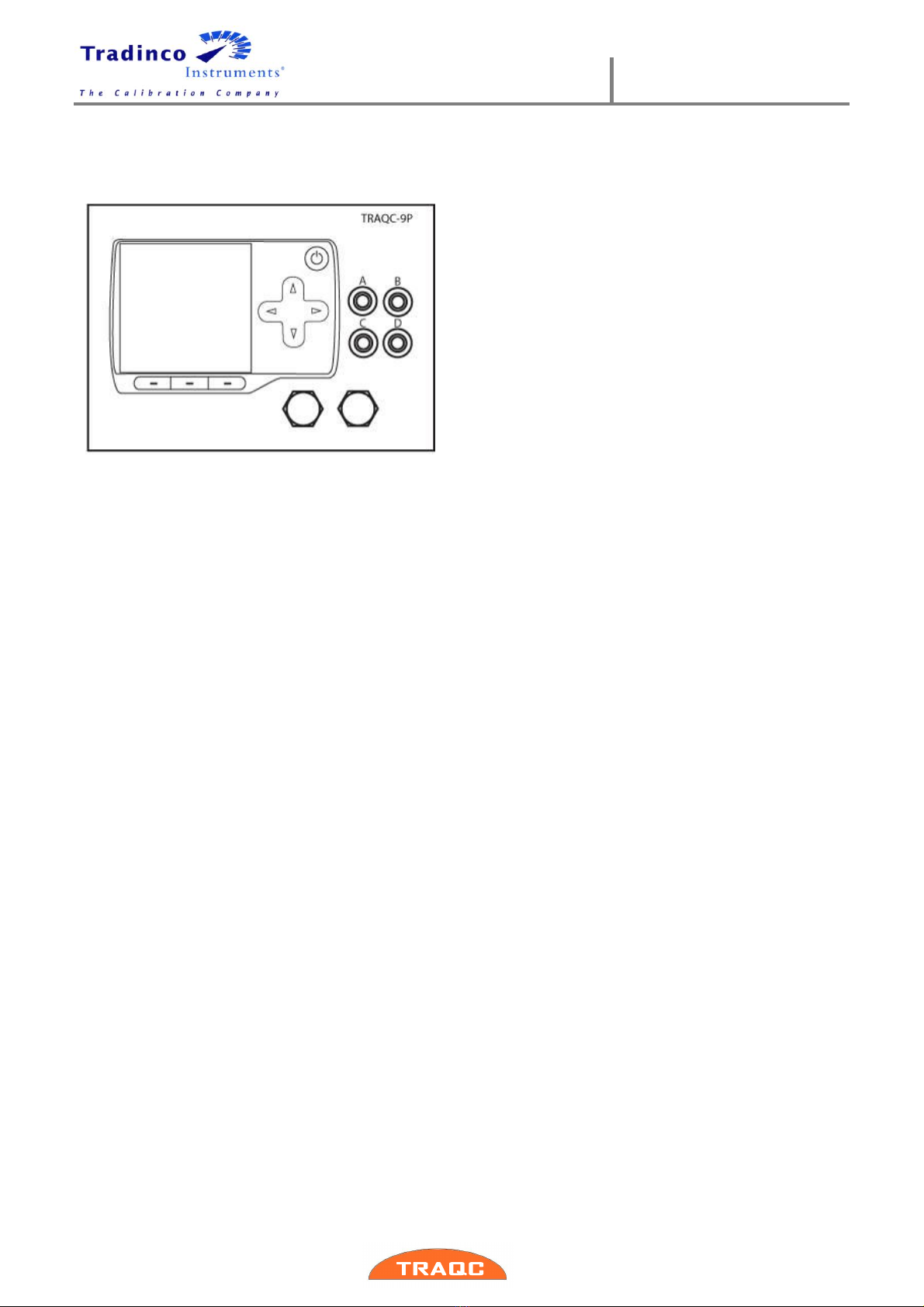

2.2 TRAQC-9 P Pressure........................................................................12

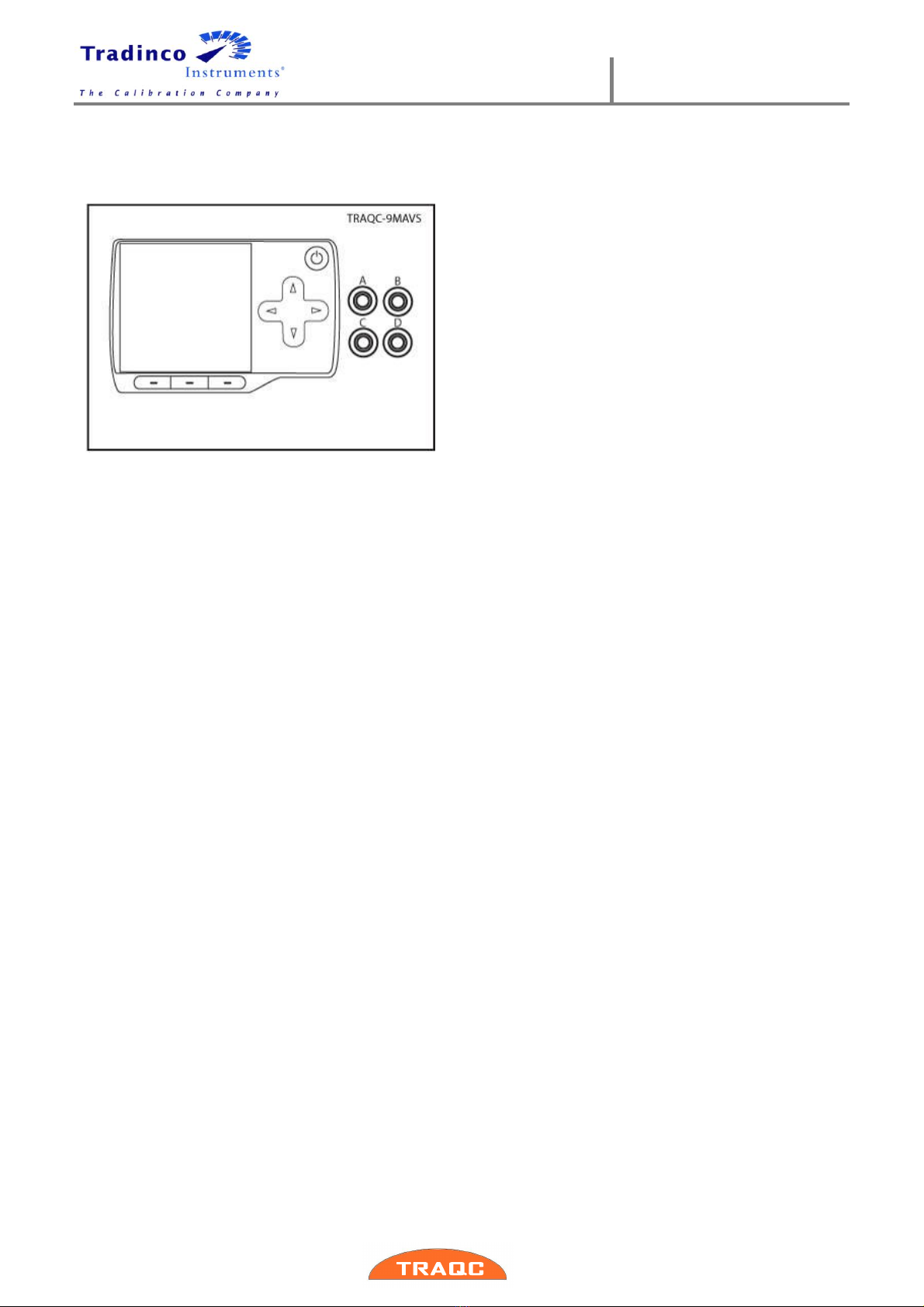

2.3 TRAQC-9 MAVS Milliamp ere and Volt Signals........................................13

2.4 TRAQC-9 CAC Absolute pressure Controller........................................14

2.4.1 TRAQC-9 CAC operating instructions:............................................14

2.5 TRAQC-9 CPC Pneumatic Controller ..................................................15

2.5.1 TRAQC-9 CPC operating instructions: ............................................15

2.6 TRAQC-9 CLPC Low Pressure Controller .............................................16

2.6.1 The TRAQC-9 CLPC operating instructions: ....................................16

2.7 TRAQC-9 CHPC High Pressure Controller............................................17

2.7.1 TRAQC-9 CHPC Operating instructions: .........................................17

2.8 TRAQC-9 CVC ................................................................................18

2.8.1 TRAQC-9 CVC operating instructions:............................................18

3. Operating Instructions 19

3.1 Power On/Off ................................................................................. 19

3.2 Menu ............................................................................................19

3.2.1 Main Menu Structure ...................................................................19

3.3 Zeroing ......................................................................................... 20

3.4 Selecting Pressure Units ..................................................................20

3.5 Pressure Range .............................................................................. 21

3.5.1 Selecting Pressure sensor Auto ranging .........................................21

3.6 Instrument Status ..........................................................................21

4. User Configuration 22

4.1 Pressure Setup...............................................................................22

4.1.1 Averaging on/off.........................................................................22

4.1.2 Averaging setup .........................................................................22

4.1.3 Resolution Setup ........................................................................22

4.1.4 Conversion Table ........................................................................23

4.1.5 Set customer unit .......................................................................23

4.1.6 Gauge mode ..............................................................................23

4.1.7 Absolute mode ...........................................................................23

4.1.8 Set abs interval ..........................................................................23

4.1.9 Set Baro.ref.int ..........................................................................23

4.2 Electrical Input Setup......................................................................24

4.2.1 mA Input ...................................................................................24

4.2.2 mA + Xmtr Supply (optional) .......................................................24

4.2.3 Xmtr Power Setup (optional)........................................................ 24

4.2.4 Switch Test................................................................................25

4.2.5 Switch Test Setup.......................................................................25

4.2.6 V Input......................................................................................25

4.2.7 Hart Resistor..............................................................................25

4.2.8 mA/V Scaling .............................................................................26

4.2.9 Set mA/V Scaling....................................................................... 26

4.3 Electrical Output Setup (Optional) ....................................................27

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 3

4.3.1 Pressure xmtr mode (Pressure transmitter mode)...........................27

4.3.2 Xmtr mode settings (Parameter Mode Settings)..............................28

4.3.3 Current Output...........................................................................28

4.3.4 Current Output Settings ..............................................................28

4.3.5 Voltage Output...........................................................................29

4.3.6 Voltage Output Settings .............................................................. 29

4.3.7 Auto Span Check Mode................................................................29

4.3.8 Ramp Mode ...............................................................................29

4.4 Instrument Configuration ................................................................30

4.5 Memory functions ...........................................................................32

4.6 Temperature ..................................................................................32

4.7 Advanced Options...........................................................................32

4.7.1 Set rtc time ...............................................................................32

4.7.2 Set rtc date ...............................................................................32

4.7.3 Set recal Date ............................................................................33

4.7.4 Erase data memory.....................................................................33

4.7.5 Show Product Data .....................................................................33

4.8 Calibration of TRAQC-9.................................................................... 34

4.8.1 Adjust instrument inputs. ............................................................34

4.8.1.1 Current input .........................................................................35

4.8.1.2 Current in + Loop supply (Optional) ..........................................35

4.8.1.3 Voltage input .........................................................................35

4.8.1.4 Adjust Vbat A/D .....................................................................36

4.8.1.5 P1: XX-YY BARG (Pressure Sensor Adjustment) .......................... 36

4.8.1.6 Clear user adjustments ...........................................................36

4.8.1.7 Resistance input .....................................................................36

4.8.2 Adjust instruments outputs (Optional)...........................................37

4.8.2.1 Current source ....................................................................... 37

4.8.2.2 Current simulator ...................................................................37

4.8.2.3 Voltage output .......................................................................38

4.8.3 Show calibration factors ..............................................................38

5. Data transfer 39

6. Computer Interface (Optional) 39

6.1 General Description ........................................................................39

6.2 Connections ................................................................................... 39

6.3 RS232 Settings ..............................................................................39

6.4 Ethernet Settings ...........................................................................39

7. Maintenance instructions 40

7.1.1 Housing.....................................................................................40

7.1.2 Test connections.........................................................................40

7.1.3 Regulating valves .......................................................................40

8. Product Specifications 41

8.1 General .........................................................................................41

8.2 Measurement .................................................................................41

8.3 Generation and control....................................................................41

8.3.1 Traqc-9 P ..................................................................................41

8.3.2 Traqc-9 CLPC Low Pressure Controller ........................................... 41

8.3.3 Traqc-9 CHPC High Pressure Controller..........................................41

8.3.4 Traqc-9 CPC Pressure Controller ...................................................41

8.3.5 Traqc-9 CVC Vacuum Controller ...................................................42

8.3.6 Traqc-9 CAC Absolute Pressure Controller...................................... 42

8.4 Options & Accessories .....................................................................43

8.4.1 Standard Supply includes ............................................................43

8.4.1.1 TRAQC-9 P /MAVS ..................................................................43

8.4.1.2 TRAQC-9 Controller.................................................................43

8.4.2 Optional Supply..........................................................................43

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 4

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 5

1. General

1.1 Warranty

During the design and manufacturing of this instrument the at most attention has been given to

quality and durability.

This manual contains information needed for the safe and effective use of the

capabilities of the instrument.

Please read the manual carefully before operating the instrument. By doing so

possible damage to the instrument or damage caused by the incorrect use of the

instrument can be avoided.

TRADINCO INSTRUMENTS warrantees the instrument in accordance with the Standard Terms

and Conditions of the Instrument Trade as issued by the Association bearing the name

"Federation Het Instrument" (The Instrument Federation, (filed with the Clerk of Utrecht District

Court on 13 January 1993 under number 16/93 and with the Chamber of Commerce and

Industry in Amersfoort on 18 January 1993. A copy is available on request.

TRADINCO INSTRUMENTS warrantees that this product will be free from defects in materials

and workmanship for a period of 5 years from the date of shipment. If any such product proves

defective during this warranty period, TRADINCO INSTRUMENTS, at its option, will either repair

the defective product without charge for parts or labour, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify TRADINCO INSTRUMENTS

of the defect before the expiration of the warranty period and make suitable arrangements for

the performance of the service.

Customer shall be responsible for packaging and shipping of the defective product to the service

centre designated by TRADINCO INSTRUMENTS, with shipping charges prepaid.

If no defect can be found Customer may be charged for costs of the investigation.

This warranty does not apply to any defect, failure or damage caused by:

a. Improper use of the instrument.

b. Battery leakage.

c. Normal wear of the product.

d. Modification or repair carried out by or on behalf of the owner or by a third party.

e. Implementation of modifications to the product that are not supplied or implemented by

TRADINCO INSTRUMENTS.

TRADINCO INSTRUMENTS and its vendors will not be liable for any indirect, special, incidental

or consequential damages irrespective of whether TRADINCO INSTRUMENTS or the vendor has

advance notice of the possibility of such damages.

The type number of the product, as listed on the instrument tag plate, should always be

mentioned in any correspondence concerning the product.

Tradinco Instrumenten-Apparaten b.v.

Radonstraat 250

2718 TB Zoetermeer

The Netherlands

+31 79 2033133

www.tradinco.com

info@tradinco.com

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 6

1.2 TRAQC-9 Description

The Tradinco pressure calibrator TRAQC-9 is a universal pressure calibrator with a measuring

range from -1 to 1000 barg, depending on the pressure sensors fitted in the instrument.

The calibrator comes in several types such as:

Absolute

Vacuum

Gauge

Compound

The TRAQC-9 consists of 3 main parts:

A high quality digital pressure display with curser and two function push buttons.

One or more pressure sensors plus related pneumatic circuit.

An electrical measuring circuit (standard mA + V DC)

The built-in central microprocessor has been programmed with the individual pressure and

temperature characteristics of each installed sensor and continuously calculates the correct test

pressure in a temperature range from 5 to 45 degrees C.

The internal electronics are also checked and compensated continuously.

The built-in measuring cells are protected against overpressure and the calibrator warns the

user if a measuring range is exceeded.

This manual includes the following TRAQC-9 types:

TRAQC-9 P

TRAQC-9 MAVS

TRAQC-9 CAC*

TRAQC-9 CPC*

TRAQC-9 CLPC*

TRAQC-9 CHPC*

*The TRAQC-9 Controller types will be used in combination with the TRAQC-9 P.

1.2.1 CE EMC Directive 2014/30/EU

The electrical part of the TRAQC-9 meets the regulations according to the standards listed

below:

EN-IEC 61000-4-2 : 2009

EN-IEC 61000-4-3 : 2009

EN-IEC 61000-4-4 : 2012

EN-IEC 61000-4-5 : 2009

EN-IEC 61000-3-2 : 2014

EN-IEC 61000-3-3 : 2013

The unit is CE marked accordingly

1.2.2 CE Electrical Safety Directive 2014/35/EU

The electrical part of the TRAQC-9 meets the regulations according to the standard listed below:

EN 61010-1 : 2010

The unit is CE marked accordingly

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 7

1.3 Symbols Used

Warning for conditions or practices that could result in personal injury, loss of life and/or

in damage to the product or other property.

Attention signal or remark

1.4 Scope of this manual

This manual contains information for instruments built after January 2011.

This manual is an user manual on how to operate the instrument; it is not a calibration

instruction manual.

As Tradinco Instruments continuously strives to improve its products, specifications of

instruments may be altered without further notice

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 8

1.5 Indicator Interface

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 9

1.6 Navigation

The menu can be accessed when the calibrator is in measuring mode (see figure).

Navigating through the menu is possible by pressing the function keys (F1, F2 and F3) and the

‘ARROW’ keys. Above the function keys in the display, the meaning of the function keys is

indicated. By pressing one of the function keys below the display, the menu opens.

By pressing the ‘BACK’ key (F3) results in going one level back.

The menu consists of multiple options to choose from. The option in the black bar is the one

selected. By pressing the navigation keys up or down, another option in the menu can be

selected.

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 10

1.7 Electrical Connections

The “Electric Connections Layout” in the display references

the physical layout of these 4 banana socket. (Example see

figure).

The letters A,B,C and D are for identification purposes and

will be of reference, in this manual only.

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 11

2.TRAQC-9 Types

2.1 TRAQC-9 Configurations

These are:

Model

Pneumatic version

Range

TRAQC-9 P

No regulation

-1 - 1000 barg

DC Volt measurement:

0 –30 V

DC Ampere measurement:

0 –24 mA.

TRAQC-9 MAVS

No regulation

DC Volt measurement:

0 –30 V

DC Ampere measurement:

0 –24 mA

TRAQC-9 CAC

Reducer and Needle valve

0 - 10 bara

TRAQC-9 CPC

Reducer and Volume regulator

0 - 10 barg

TRRAQ-9 CLPC

Pump with volume control

0 - 1000 mbarg

TRAQC-9 CHPC

Reducer with needle valve.

0 - 350 barg

The various versions and their operating instructions are described on the following pages.

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 12

2.2 TRAQC-9 P Pressure

The TRAQC-9 P is the pressure indicator.

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 13

2.3 TRAQC-9 MAVS Milliamp ere and Volt Signals

The TRAQC-9 MAVS is the electrical calibrator for the TRAQC-9 series.

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 14

2.4 TRAQC-9 CAC Absolute pressure Controller

The TRAQC-9 CAC absolute pressure controller, ranging 0 to 10 bar absolute depending on the

range of the selected reducer and is suitable for a so-called "dead end" system.

The calibrator is equipped with three fine regulating needle valves and a Polyflo test coupling.

The TRAQC-9 CAC has to be connected externally to a vacuum-and a pressure supply.

2.4.1 TRAQC-9 CAC operating instructions:

Connect the “test” coupling to the unit to be calibrated.

Connect the “gauge” coupling to the TRACQ-9 P.

Close the “bleed valve”(1) and the “pressure shut off valve”(2). Slowly open the “vacuum shut

of valve” (3) to the maximum admissible pressure for the "unit under test". Then close the

“vacuum shut off valve” again.

While the system is under vacuum pressure, check with the TRAQC-9 P if there is any leakage;

this becomes apparent by an extreme change of pressure.

Let air into the system by opening the “bleed valve” (1), then close the “bleed valve” (1).

Eliminate any leaks and repeat the test as described above until all leaks are eliminated.

-To generate sub barometric pressures, close the “pressure shut off valve” (2), slowly open the

“vacuum shut off valve” (3) wile observing the indicated pressure. Once the “vacuum shut off

valve” (3) is open, further regulate the vacuum pressure with the “bleed valve”(1) until the

correct pressure is obtained.

-To generate a test pressure above the barometric pressure, close the “vacuum shut off

valve”(3), open the “pressure shut off valve”(2) and regulate with the “reducer” until the desired

test pressure is obtained.

If the test pressure is to be decreased towards the barometric pressure, the “bleed valve” (1)

has to be slowly opened until the correct test pressure is reached.

Repeat the procedure as often as a new test pressure is desired.

When all test pressures have been generated, open the “bleed valve” (1), close the “vacuum

shut off valve”(2) and/or “pressure shut off valve”(3) and disconnect the test hoses.

The installed needle valves have a soft seat. It is not necessary to close these with a

great deal of force.

1

2

3

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 15

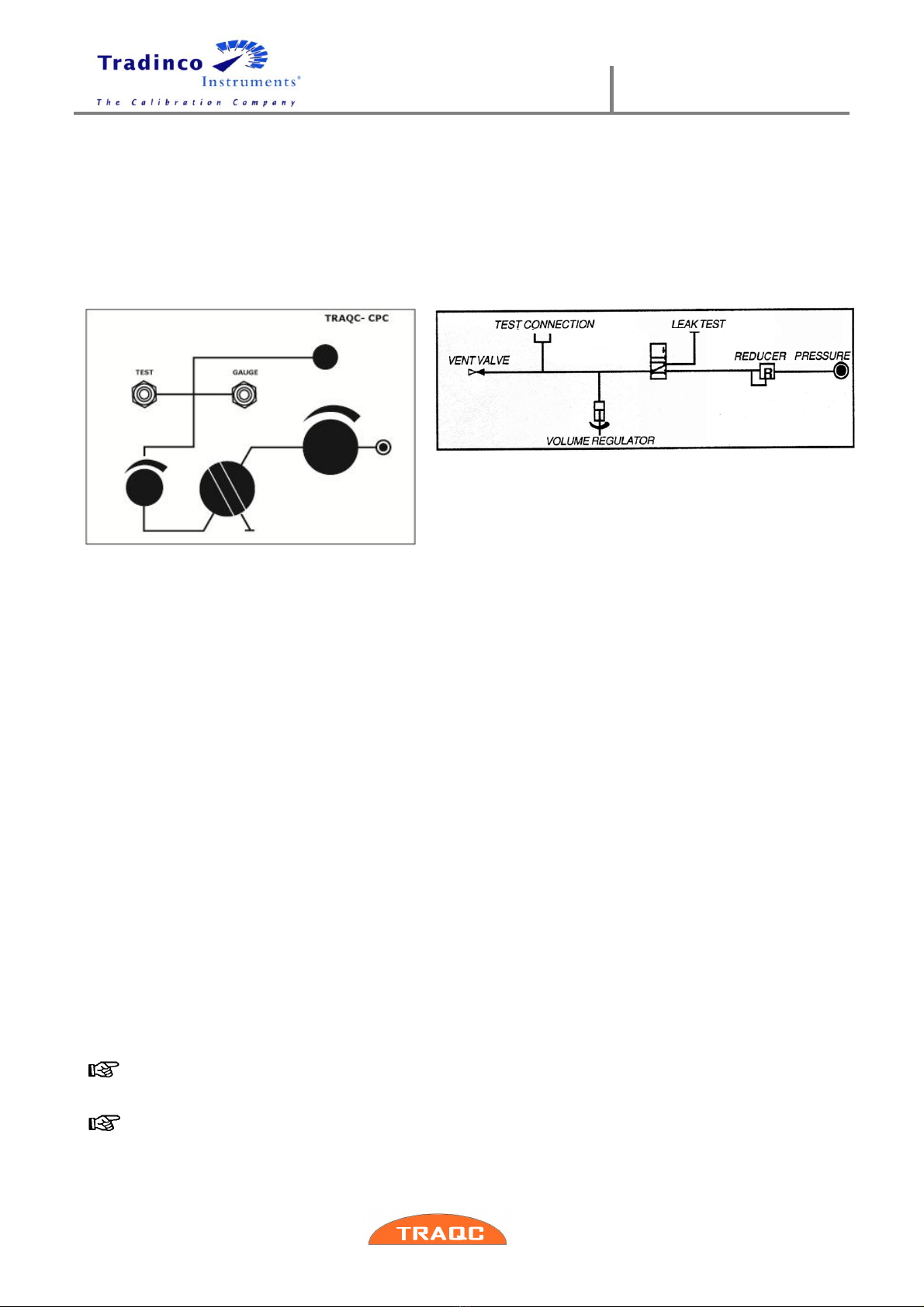

2.5 TRAQC-9 CPC Pneumatic Controller

The TRAQC-9 CPC is a pressure controller, ranging from 0 to 10 bar depending on the range of

the selected reducer and is suitable for a so-called "dead end" system.

The controller is equipped with a fine regulating reducer. The reducer has to be fed from an

external pneumatic pressure supply with a maximum pressure of 10 bar.

A leakage-free pneumatic switch is intergraded in the controller in order to be able to perform

leakage tests. Also a volume regulator has been installed for fine regulating the test pressure.

2.5.1 TRAQC-9 CPC operating instructions:

Decrease the “reducer”(4) by turning it fully counterclockwise so that the test pressure is zero,

set the “volume regulator”(2) in the middle position and close the “bleed valve”(1).

Connect the “TEST” coupling to the unit to be calibrated.

Connect “GAUGE” coupling to the TRAQC-9 P.

Open the “selector switch”(3) (knob in line).

Slowly increase the pressure by operating the “reducer”(4) clockwise, until the maximum

admissible pressure for the unit under test is reached. Close the “selector switch”(3).

Check with the TRAQC-9 P if there is any leakage, this becomes apparent by an extreme change

of the test pressure. Open the selector switch. Remove the pressure from the system by

decreasing the “reducer”(4) to minimum and by opening the “bleed valve”(1).

Eliminate any leaks and repeat the test as described above until all leaks are eliminated.

Close the “bleed valve”. Slowly increase pressure with the “reducer”(4) until the desired test

pressure has been reached; close the “selector switch”(3) and fine tune the test pressure with

the “volume regulator”(2).

The first test pressure has now been generated. After the measurement value has now been

recorded, the selector switch has to be opened again and the following test pressure can be

created.

Repeat the procedure as often as a new test pressure is desired. When all test pressures have

been generated, the selector switch must be opened, the “reducer”(4) must decreased set to

minimum (fully ccw),open the “bleed valve”(1), the test hoses must be disconnected and turn in

“volume regulator”(2) completely.

It is recommended to regulate the decrease of the test pressure by means of the “bleed

valve”(1) instead of the reducer; this avoids fouling of the reducer

The installed needle valve has a soft seat. It is not necessary to close these with a great

deal of force.

1

4

3

2

1

User Manual

TRAQC-9

TRAQC-9 12/2011 EN Rev.1 page : 16

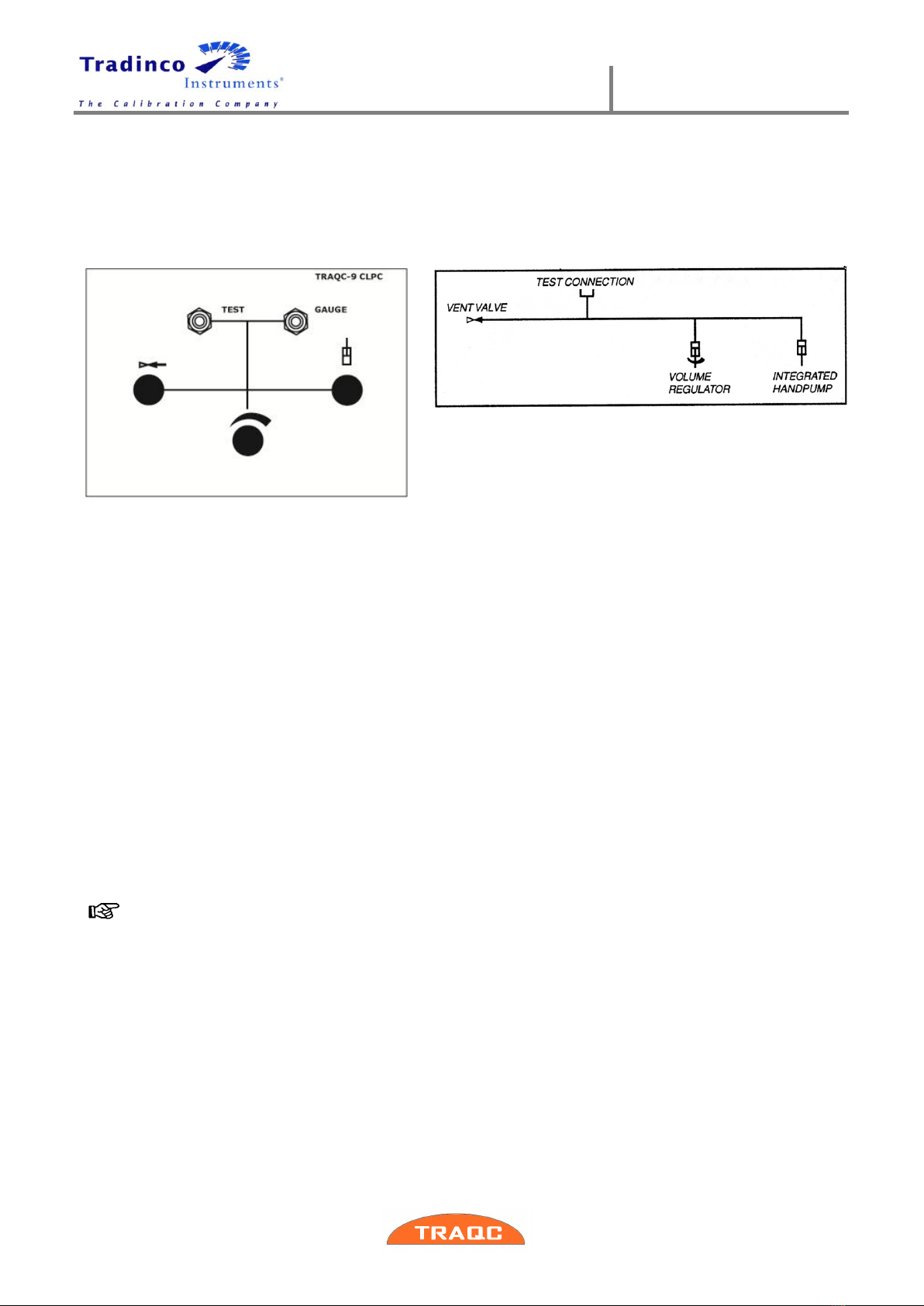

2.6 TRAQC-9 CLPC Low Pressure Controller

The TRAQC-9 CLPC is a low pressure controller, ranging from 0 to 1000 mbar and is suitable for

a so-called "dead end" system.

Integrated in the controller are a small manually operated pump and a volume regulator for

generating and regulating the test pressure.

The TRAQC-9 CLPC needs no external pneumatic supply.

2.6.1 The TRAQC-9 CLPC operating instructions:

Connect the “TEST” coupling to the unit to be calibrated.

Connect the “GAUGE” coupling to the TRAQC-9 P.

Close the “bleed valve” (1). Use the “manual pump”(3) to create the maximum admissible

pressure for the "unit under test".

Check with the TRAQC-9 P if there is any leakage, this becomes apparent by an extreme change

of the test pressure. Release air from the system by opening the “bleed valve” (1). Set the

“volume regulator”(2) in the middle position.

Eliminate any leaks and repeat the test as described above until all leaks are eliminated.

Close the “bleed valve” (1). Use the “manual pump” (3) to get close to the desired test

pressure. Now use the “volume regulator” (3) to fine trim the test pressure to the desired value.

Repeat the procedure as often as a new test pressure is desired. When all test pressures have

been generated, open the “bleed valve” (1), disconnect the test hoses and turn in the “volume

regulator” (2) completely.

The installed needle valve has a soft seat. It is not necessary to close this with a great

deal of force.

3

1

2

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 17

2.7 TRAQC-9 CHPC High Pressure Controller

The TRAQC-9 CHPC is a high pressure controller, ranging from 0 to 350 bar, depending on the

range of the selected reducer and is suitable for a so-called "dead end" system.

The calibrator is equipped with a high pressure reducer. The reducer has to be fed from an

external high pressure supply with a maximum pressure of 350 bar.

2.7.1 TRAQC-9 CHPC Operating instructions:

Decease the “reducer”(3) to minimum by turning it fully counterclockwise.

Close the “pressure shut off valve”(2) by turning it fully clockwise.

Connect the “test” coupling to the unit to be calibrated.

Connect the “Gauge” coupling to the TRAQC-9 P.

Close the “bleed valve”(1) and open the “pressure shut off valve”(2). Slowly increase the

pressure with the “reducer”(3) until the maximum admissible pressure for the unit under test is

reached. Close the “pressure shut off valve”(2) and decrease the “reducer”(3) to minimum.

Check with the TRAQC-9 P if there is any leakage; this becomes apparent by an extreme

change of the test pressure. Then remove the pressure from the system by opening the “bleed

valve”(1).

Eliminate any leaks and repeat the test as described above until all leaks are eliminated.

Close the “bleed valve”(1). Open the “pressure shut off valve”(2) and increase the “reducer”(3)

to approximately 110% of the desired test pressure. Than close the “pressure shut off

valve”(2).

For regulating the test pressure:

-Slowly opening and closing the “pressure shut off valve”(2) will result in a pressure increase.

-Slowly opening and closing the “bleed valve”will result in a pressure decrease.

A measurement can be performed when both the “pressure shut off valve”(2) and the “bleed

valve”(1) are closed.

Repeat the procedure as often as a new test pressure is desired. When all test pressures have

been generated, decrease the “reducer”(3) to a minimum, close the “pressure shut off

valve”(2), open the “bleed valve” (1) and disconnect the test hoses.

The installed needle valves have a soft seat. It is not necessary to close these with a

great deal of force.

3

2

1

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 18

2.8 TRAQC-9 CVC

The TRAQC-9 CVC vacuum pressure controller, ranging -1 to 0 bar gauge and is suitable for a

so-called "dead end" system.

The calibrator is equipped with two fine regulating needle valves and a Polyflo test couplings.

The TRAQC-9 CAC has to be connected externally to a vacuum supply.

2.8.1 TRAQC-9 CVC operating instructions:

Connect the “test” coupling to the unit to be calibrated.

Connect the “gauge” coupling to the TRACQ-9 P.

Close the “vacuum shut off valve” (2) and then the “bleed valve” (1). Slowly open the “vacuum

shut of valve” (2) to the maximum admissible vacuum pressure for the "unit under test". Then

close the “vacuum shut off valve” (2) again.

While the system is under vacuum pressure, check with the TRAQC-9 P if there is any leakage;

this becomes apparent by an extreme change of pressure.

Let air into the system by opening the “bleed valve” (1).

Eliminate any leaks and repeat the test as described above until all leaks are eliminated.

-To generate vacuum pressures, close the “vacuum shut off valve” (2) and then “bleed valve”(1),

slowly open the “vacuum shut off valve” (2) wile observing the indicated pressure. Once the

“vacuum shut off valve” (2) is open, further regulate the vacuum pressure with the “bleed

valve”(1) until the correct pressure is obtained.

Repeat the procedure as often as a new test pressure is desired.

When all test pressures have been generated, open the “bleed valve” (1), close the “vacuum

shut off valve”(2) and disconnect the test hoses.

The installed needle valves have a soft seat. It is not necessary to close these with a

great deal of force.

1

2

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 19

3.Operating Instructions

3.1 Power On/Off

The TRAQC-9 is switched on and off by pressing the on/off key. The TRAQC-9 will go through a

short startup self-check routine. During that routine the display shows the current firmware.

After completing the startup procedures the device switches into the measuring mode and

displays the measured value(s), and the measuring unit(s) from last time. When turning off the

device, the display shows ‘Shutting Down’.

If the calibrator needs to be recalibrated at short notice, a message with the date that the

instrument should be re-calibrated is displayed for several seconds before the startup

procedure continues. If the recalibration date has expired a message is displayed as a

warning. By pressing ‘ENTER’ key (F1) the start-up procedure is continued.

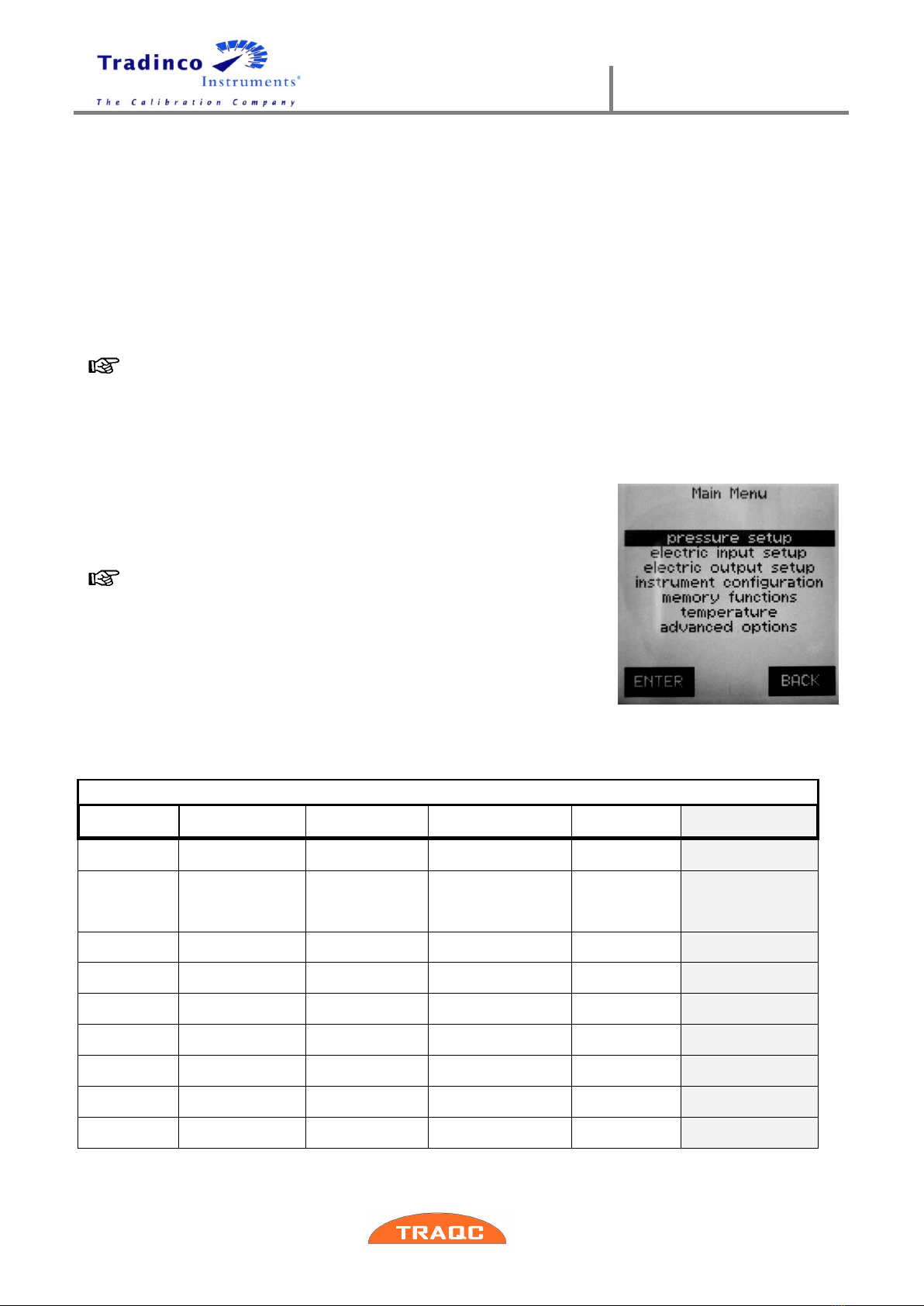

3.2 Menu

The main menu is accessed by pressing the ‘MENU’ key (F1). On

top in the display the current location in the menu structure is

shown.

Most of the functions in the menu structure are optional.

Therefore it is possible the TRAQC-9 included with this

manual has less functions than explained in this user

manual.

3.2.1 Main Menu Structure

Main Menu

pressure

setup

electric input

setup

electric output

setup

instrument

configuration

memory

functions

advanced options

averaging

on/off

mA input

pressure xmtr

mode

backlight setup

list by tagnr.

Set rtc time

averaging

setup

mA + Xmtr supply

xmtr mode

settings

select language

list by serialnr.

Set rtc date

resolution

setup

Xmtr power setup

current output

date/time display

view definitions

Set recall date

conversion

table

switch test

current output

settings

show settings

Erase data memory

Set customer

unit

switch test setup

voltage output

factory defaults

Show instrument

data

gauge mode

V input

voltage output

settings

Adjust instrument

inputs

absolute

mode

Hart resistor

auto span check

mode

Adjust instrument

output

set abs

interval

mA/V scaling

ramp mode

Show calibration

factors

set

Baro.ref.int

set mA/V scaling

User Manual

TRAQC-9

TRAQC-9 04/2017 EN Rev.4 page : 20

3.3 Zeroing

To zero an input signal press ‘ZERO’ key (F2) in the “measuring

mode” display. The menu shows the different inputs that can be

zeroed, consisting of pressure inputs and the electrical inputs.

Select the desired input using the ‘ARROW’ keys.

By pressing the ‘BACK’ key (F3) the zeroing procedure is

stopped without making modifications.

By pressing ‘ENTER’ key (F1) the zeroing procedure is

continued and there is asked to confirm the zeroing

procedure after which the calibrator returns to measuring

mode.

When zeroing the ‘Pressure Input’, ensure that the

pressure ports are open to atmospheric pressure.

The TRAQC-9 P comes standard with a quick connect coupling with

integraded shut off valve. This can be opened by:

Connect/insert the other half of the coupling to the

pressure coupling (-port) of the TRAQC-9 P

Connect one side of a pressure hose to the pressure

coupling (-port) of the TRAQC-9 P and leave the other side

of the hose unconnected.

With these procedures the pressure in the system of the

TRAQC-9 P can get equal with the atmospheric pressure.

To zero another test pressure and/or electrical signal, first generate the required test signal

(tare value) and carry out the above-described zeroing procedure. The test value displayed is

the difference between the actual test value and the entered tare value.

3.4 Selecting Pressure Units

When in “measuring mode”screen press the ‘UNIT’ key (F3) to

change the unit. Use the ‘ARROW’ keys to select the desired unit

and press ‘ENTER’ key (F1) to confirm and go back to “measuring

mode”.

The following units can be selected:

bar kgf/cm2inHg

mbar mmH2O torr

Pa cmH20 %

hPa mH2O mSeaw

kPa inH20

MPa ftH2O

psi mmHg

This manual suits for next models

6

Table of contents

Other Tradinco Test Equipment manuals