Software House RM-DCM-2 Instruction Manual

1

RM-DCM-2

Quick Start

Installation Guide

Version H0

Document Part Number UM-215

March 2018

OVERVIEW The RM-DCM-2 is a UL294 Listed and UL1076 Listed door control

module that includes the RM-4E Reader Module (RM-4E) and enclosure.

The RM-DCM-2 is designed to support up to two RM-4E modules,

providing a single enclosure for doors with IN and OUT readers.

The enclosure also has space for up to three I/8 and/or R/8 boards, for a

total of four boards. The RM-DCM-2 supports an optional battery (12

VDC, 4A), which will be recharged by the RM-4E battery charging circuit.

The RM-4E board provides the hardware interface between Magnetic

signaling read heads or Wiegand signaling read heads and the apC/8X,

iSTAR, and iSTAR Pro hardware. The RM-4E also provides inputs and

outputs that communicate between door components and the apC/8X,

iSTAR, and iSTAR Pro hardware.

The I/8 module provides eight supervised inputs and the R/8 module

provides eight dry contact, Form C relay outputs.

The RM-DCM-2 system consists of two subassemblies:

Model RM-DCM-CAN enclosure

Model RM-4E board

NOTE For information about the RM-4E, I/8, or R/8 modules, refer to the Quick

Start guides listed in Table 13.

NOTE All interconnecting products or devices must be UL Listed.

Overview

2

Table 1 lists the RM-DCM-2 board and enclosure offered by Software

House. You can install an RM-DCM-2 up to 4000 feet (1219 meters) from

the apC/8X, iStar or iSTAR Pro hardware.

TABLE 1. RM-DCM-2 Product Offering

Product Description Enclosure

RM-DCM-2 RM-4E module, with

connectors, LEDs, on-

board relays, and battery

charger

Factory mounted in metal junction box

with mountings for optional hardware

available from Software House.

TABLE 2. UL294 Levels

Feature Level

Destructive Attack 1

Line Security 1

Endurance 4

Standby Power 1

RM-DCM-2 Unit

3

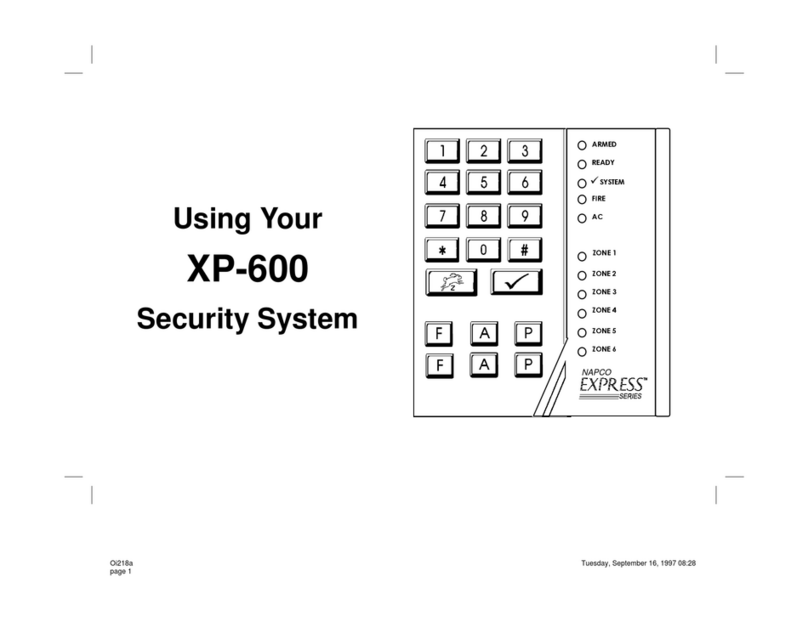

RM-DCM-2 UNIT Figure 1 shows the RM-DCM-2 unit with one RM-4E board, an optional

battery, and LCD.

NOTE UL has evaluated this configuration only.

FIGURE 1. RM-DCM-2 with Battery and LCD

FEATURES RM-DCM-2 features include:

LED status indicators – display RS-485, inputs, outputs, and power

status.

Maglock component – for use with door objects.

Bypass component – connects to a release switch on a door secured

by a magnetic lock.

On-board battery charger – supplies power to an optional battery for

memory retention in the event of a power failure.

NOTE The on-board battery is for memory retention only. UL has not evaluated

the battery for the Standby Power requirements of the UL294 Standard.

RM-4E

Battery

LCD

Features

4

Optional Equipment

Optional equipment for the RM-DCM-2 includes:

Backup battery kit – provides the RM-4E with backup power for

memory retention in the event of a power failure. The kit includes a

cable assembly that connects the battery to the RM-DCM-2 battery

component.

LCD component – displays diagnostic information and status

messages for readers attached to the RM-4E. The optional LCD is

attached to the J1 (LCD) connector on the RM-4E board.

Read Head Interfaces

The RM-4E supports Wiegand signaling or Magnetic read heads. Select

the interface you want by setting S5 position 1 on the RM-4E board.

Set S5-1 to the On (Closed) position for Wiegand read heads

Set S5-1 to the Off (Open) position for Magnetic read heads

NOTE The RM-DCM-2 has been evaluated by Underwriters Laboratories Inc.

(UL) for compatibility with HID Model 30387 and HID 5355 readers only.

RM-DCM-2 with RM-4E,

I/8, R/8, and Battery

The RM-4E Reader Module (RM-4E) simplifies installation by providing

clearly labeled termination points to identify functionality and device

information. The RM-4E also features LEDs for output, RS-485, power,

and input status to make it easier to install and service the system.

The RM-4E board is installed and mounted at the top of the door.

Another RM-4E board and any combination of I/8 and R/8 modules, up

to a total of four boards, can be mounted on the door and within the

enclosure.

Figure 2 shows an RM-DCM-2 unit with one RM-4E, R/8, I/8, and

battery. There could also be another RM-4E board, I/8, or R/8 mounted

in the space provided within the enclosure.

Features

5

FIGURE 2. RM-DCM-2 with RM-4E, R/8, I/8, and Battery

Tamper Switch

The RM-DCM-2 provides a tamper switch as part of the enclosure.

1. Verify or connect the normally closed tamper switch in the enclosure to the

2-pin connector labeled TAMPER (SW2) on the RM-4E board. See Figure 2.

2. Verify or set DIP switch SW5-4 (Tamper Override) to Off (Closed) on the

RM-4E. See Figure 5.

3. To configure the tamper:

C•CURE 800 - use the Reader Configuration Advanced dialog box.

C•CURE 9000 - use the Reader I/O tab.

NOTE The switch is normally closed so that when the door is closed the tamper

is secure. If the door is forced, the switch will open causing an alarm

event.

NOTE The tamper switch must be connected to comply with UL requirements.

Tamper Input (SW2)

Tamper Switch

RM-4E Reader Interface

6

RM-4E READER

INTERFACE

You can interface read heads that supply Wiegand signaling or magnetic

(ABA) signaling to the apC/8X, iSTAR, and iSTAR Pro using RM-4E

boards.

Figure 3 indicates how an RM-4E board interfaces with Wiegand and

Magnetic signaling read heads.

FIGURE 3. RM-4E Interface

NOTE UL has not evaluated magnetic (ABA) signaling read heads.

RM-4E Reader Interface

7

RM-4E Layout Figure 4 shows the photograph of an RM-4E board with LCD.

FIGURE 4. Photograph of RM-4E Board

RM-4E Components

8

RM-4E

COMPONENTS

Figure 5 shows the location of connection points, switches, and LEDs on

the RM-4E board.

RM-4E Board Layout

FIGURE 5. RM-4E Board Layout

This section lists the RM-4E components — starting from the upper right

corner of Figure 5 and moving in a clockwise direction.

Tamper

The RM-DCM-2 tamper input twisted pair wires, shown in Figure 2, are

connected to the TAMPER (SW2) input pins.

RM-4E Components

9

Power In There are two ways to power an RM-4E:

Method A - from the Power In connector using an external power

supply, which also charges the battery through the BATTERY

connector.

Method B - from the RS 485 connector using the apC or iSTAR power

supply.

NOTE: Do not use both power connection methods at the same time.

NOTE A UL Listed power-limited access control or burglar alarm power supply,

capable of four hours standby, must be used when the unit is powered

from a source other than the apC or iSTAR.

FIGURE 6. RM-4E Power Wiring - Method A

Method A - via Power In

Connect +12 or +24 VDC to Pin 2 of the Power IN connector.

Connect the ground side of the supply to either Pin 1, 3, or 4. Because

the three grounds are all tied together, you can connect the negative

side of the supply to any of the three pins.

Do not use +24 VDC unless all devices on the bus are RM-4Es.

RM-4s, I/8s, R/8s and MRMs must be powered with +12 VDC.

NOTE The battery charger only works if you power through the Power IN

connector.

+12/24 VDC

RM-4E Components

10

Method B - via RS-485 (RM Bus Connector)

Connect +12 VDC to Pin 1 of the RS-485 connector on the bottom

right side.

Connect Ground (Gnd) to Pin 4 of the RS-485 connector.

NOTE The +12 VDC input on Pin 1 has a protection diode that prevents you

from using the RS-485 connector as a source of +12 VDC if you power

through the Power IN connector.

Battery

Connect the plus and minus sides of the 12 VDC battery to the Battery

connector. The battery provides power for memory retention in the event

of a power failure. When power is restored, the battery is charged by the

power supplied through the Power In connector.

LED Connector Table 2 lists LED Connector Signals and Functions on the RM-4E board.

NOTE UL has not evaluated using Pin 5 to drive an external beeper.

Typical LED Scenarios

One wire Bi-Color - Attach the brown wire from the read head to the

Yellow LED drive on the RM-4E.

Two wire Red and Green - Attach the brown wire from the read

head to Red LED drive. Attach the orange wire from the read head to

the Green LED drive.

Three wire Red, Green, Yellow - Attach each LED drive to the

associated color LED.

See “LED Control” on page 22 for information.

TABLE 3. LED Connector Signals and Functions

Pin Signal Function

6 Gnd Ground

5 Beep Used to drive an external beeper on a

reader connected to the unit.

4 Grn Green LED drive

3 Yel Yellow LED drive

2 Red Red LED drive

1 +5 VDC + 5 VDC, if required

RM-4E Components

11

NOTE When the wiring gauge is too small or the wiring runs are too long, the

Yellow LED drive oscillation can cause cross-talk and result in misreads.

RS 485 Reader Bus RS 485 is the reader bus connection to the apC or iSTAR.

It is two wire, half duplex RS 485.

Connect Tx+ / Rx+ to Pin 2 and connect Tx- / Rx- to Pin 3.

The pins are numbered right to left on the connector.

Connecting Read

Heads

Connect read heads to the Read Head connector.

Connect either a Wiegand signaling device or a magnetic (ABA)

signaling device. Wiegand signaling uses Data 1 and Data 0 lines and

magnetic signaling uses Clock and Data.

Wiegand Signaling

For Wiegand signaling, use the following pinout; set SW5-1 to ON.

TABLE 4. RS 485 Reader Bus Connections

Pin Signal Function

4 Gnd Ground

3 D- Tx- / Rx- (usually green)

2 D+ Tx+ / Rx+ (usually white)

1 +12 +12 VDC (if required)

TABLE 5. Wiegand Signaling Pinout

Pin Signal Function

1 D1 Data 1 line (white)

2 D0 Data 0 line (green)

3 N/C No connection

4 +5 VDC +5 VDC if required

5 GND Ground

6 +12 VDC +12 VDC if required

RM-4E Components

12

Magnetic (ABA) Signaling

For Magnetic (ABA) signaling, use the following pinout; set SW5-1 to

OFF.

NOTE UL has not evaluated magnetic (ABA) signaling read heads.

Relay 1, Relay 2,

MagLock, and Bypass

The RM-4E provides lock components that facilitate connecting magnetic

and electric strike locks.

Relay 1 is a standard Form C, dry contact relay, identical to the relays

found on the iSTAR ACM.

Relay 2, along with the MagLock and Bypass connectors have

internal etch connections for wiring magnetic and electric strike locks

Tie Point (TP1/TP2) connector pins are not connected to the circuitry.

They are used as connection points to avoid field splices when

connecting locks to Relay1. TP1-1 is tied to TP1-2, and TP2-1 is tied to

TP2-2.

Lock Connectors The Lock Connector pinouts are shown below.

TABLE 6. Magnetic (ABA) Signaling Pinout

Pin Signal Function

1 CRD N/A

2 STRB Strobe signal

3DATData signal

4 +5 VDC +5 VDC if required

5 GND Ground

6 +12 VDC +12 VDC if required (not

used by Software House

magnetic read heads)

Lock Wiring Configurations

13

FIGURE 7. Lock Connectors

LOCK WIRING

CONFIGURATIONS

RM-4E lock connectors support the following wiring configurations:

Magnetic Lock using Relay 2

Electric Strike using Relay 2

Electric Strike using Relay 1

The following sections describe how to connect each configuration. The

electric strike examples are shown as Fail-Secure.

Magnetic Locks The normal state of a magnetic lock has current flowing through an

electromagnet on the lock that pulls a strike plate with a force of 500-2000

lbs.

Safety codes usually require a bypass switch for emergency egress. This

is not the Request to Exit (REX) switch.

Note the internal etch connections between Relay 2, Maglock, and the

Bypass connector.

Connecting a Magnetic

Lock

The following figure shows an example of connecting the power supply,

magnetic lock, and bypass switch.

Lock Wiring Configurations

14

FIGURE 8. Magnetic Lock Wiring with Jumper Options

Lock Wiring Configurations

15

Magnetic Lock

Components

This section describes the components and connections for magnetic lock

wiring.

Power Supply

The power for a magnetic lock must be filtered, regulated direct current

(DC) voltage. Alternating current (AC) does not work and half wave

rectified DC does not work reliably.

Most magnetic locks consume about 3 watts, which is about 125

milli-amps @ 24 VDC or 250 milli-amps @ 12 VDC.

18 AWG wire is generally recommended. If the wire runs exceed 100 feet,

use 16AWG wire instead.

The power supply to a magnetic lock must be isolated. Do not connect the

output of the power supply or the negative side of the lock to earth

ground. The connection from the minus side of the power supply must

go to Maglock pin 3.

Bypass Switch

Connect a normally closed (NC) emergency Bypass switch as shown.

Remove the J15 Bypass jumper for normal operation.

It will be necessary to connect the J15 Bypass jumper (closed) if you install

an electric strike on Relay 2.

Diode Protection

An optional inductive kickback suppression diode is available by

connecting the J13 Diode jumper (closed).

Some magnetic locks have the suppression circuitry built-in so in some

cases the J13 Diode jumper should be removed (open).

RM-4E Power Failure

When using the configuration shown, the magnetic lock remains locked

if the RM-4E loses connection to the apC or iSTAR because the normally

closed (NC) connection of Relay 2 is used. The magnetic lock also remains

locked if the RM-4E loses power.

Lock Wiring Configurations

16

You have the option of wiring to the normally open (NO) connector of

Relay 2 if you want to have the Magnetic lock unlock under those

conditions. If you use the normally open (NO) connector then Relay 2

will have to be normally energized using the C•CURE Administration

application.

If the power supply fails, the magnetic lock will unlock regardless of

whether the normally closed (NC) or normally open (NO) is used.

Electric Strikes Unlike magnetic locks, electric strike locks typically lock when not

powered and unlock when powered.

You must decide if you want to wire for “fail-secure” or “fail-safe.” Fail-

secure means that if there is a power failure, the door goes to a secure or

locked state. Fail-safe (fail-open) means that the door is open if there is a

failure. It is important that local codes be followed to avoid people

getting trapped in an emergency situation. Usually fail-secure doors have

crash bars to allow emergency egress.

Using Relay 2 for an

Electric Strike

The same internal connections that are used for a magnetic lock can be

used to wire an electric strike. Connect the plus side of the power supply

to the normally open (NO) connection of Relay 2 and connect the

remaining external connections the same as the magnetic lock

Lock Wiring Configurations

17

FIGURE 9. Relay 2 Fail Secure Wiring

Lock Wiring Configurations

18

Electric Strike

Components

This section describes components and connections for electric strike

wiring using Relay 2.

Bypass Switch

Connect the J15 Bypass jumper (closed) to provide the internal

connection from Maglock Pin 1 to the C contact of Relay 2. Do not connect

an external bypass switch.

Diode Protection

An optional surge suppression diode is available by connecting the J13

Diode jumper (closed). If the electric strike has a suppression diode built-

in, disconnect the J13 Diode jumper (open).

Using Relay 1 for an

Electric Strike

Relay 1 is a standard Form-C dry contact relay. Wiring door strikes using

this relay on the RM-4E is the same as wiring them to apCs, iSTARs, R/

8s etc.

Two pair of isolated tie points have been added to minimize splices.

Connect the strike and the power supply as shown. There is no

internal etch to consider when using Relay 1.

In the example below, a fail-secure door is shown with the normally open

(NO) contact. You can add an optional external suppression diode, if

desired.

Inputs

19

FIGURE 10. Relay 1 - Fail Secure Wiring

INPUTS

Input 1 and Input 2 Connect inputs using the standard Software House supervision for either

NO or NC. Figure 11 shows an example of wiring Normally Open (NO)

and Normally Closed (NC) inputs.

FIGURE 11. Input Wiring

Inputs

20

NOTE To comply with UL requirements, use shielded, minimum 22 AWG

stranded, twisted pair cable for monitor points, DSMS, and REXs. Use

Belden 9462 or equivalent.

LED Input Status

Each input uses a Red, Yellow, or Green LED to show the input status.

Only one color will be on at a time for each input.

Table 6 lists the LED color and the corresponding input status.

Red LED indicates alert (nominal 500 ohms or 2K ohms).

Green LED indicates secure hardware state (nominal 1k ohms).

Yellow LED indicates supervision error (open circuit, shorted, or line

fault).

The RM-4E input status LEDs show flashing status if the RM-4E is

communicating with the apC or iSTAR and at least one input or

output is configured, or the reader is being used on a door. (The apC

or iSTAR needs a configured reason to communicate.)

TABLE 7. LED Input Status

LED Color Input Status

Red Alert (nominal 500 ohms or 2K ohms).

Green Secure hardware state (nominal 1k ohms).

Yellow Supervision error (open circuit, shorted, or line fault)

Table of contents

Popular Security System manuals by other brands

Skyros

Skyros VideoNet 9.1 installation manual

Simu

Simu 5124491B Original manual

BW Technologies

BW Technologies Micro Clip XT Operator's manual

Ultra Start

Ultra Start 500 Series owner's guide

System Sensor

System Sensor P2R Installation and maintenance instructions

Audiovox

Audiovox Prestige 128-8614 owner's manual