Software House RM-4T Manual

1

RM-4T

Hardware Installation

Version A0

Part Number UM-302

April 2014

The RM-4T is the board, and the RM-4TE is the RM-CAN enclosure with an

RM-4T mounted in it. The RM-4T can be connected to any Software House

iSTAR series control panel or apC series control panel.

SPECIFICATIONS

STANDARDS RM-4T readers must be wired in accordance with the National Electrical Code

(ANSI/NFPA 70), local code.

Table 1: Specifications

RM-4T Specifications

Environmental

Indoor 32° F to 120° F (0° C to 49° C)

Storage -31° F to 151 ° F (-35 ° C to 66° C)

Humidity 0 to 85%

Electrical

Input

Reader Bus 12 VDC, 175mA without reader

12 VDC, 550mA with reader

Output

Reader 10.9 to 11.18 VDC / 5 VDC

LED output control 4.0 VDC to 5.25 VDC, 20mA

Installation

2

INSTALLATION

Static Electricity

Precautions

Before handling any internal components, discharge static electricity by

touching a grounded surface.

Wear a grounding wrist strap and stand on a grounded static protection mat.

Limit movement during installation to reduce static buildup.

Power

RM-4T

The RM-4T can be powered either from a local, UL listed, access control

(UL294) or burglar alarm (UL603), Class 2 power-limited power source with

4-hour standby capability, or from a Software House UL listed, access

control (Ul294) or burglar alarm (UL1076) panel which has 4-hour standby

capability.

Readers

Readers connected to the RM-4T can either be powered from a local UL

listed access control (UL294), or burglar alarm *Ul603), Class 2 power-

limited power source with 4-hour standby capability, or from the RM-4T.

Wall Mount Dimensions

The RM-4T must be installed in the RM-CAN and within the protected

premise in accordance with the National Electrical Code (NFPA70), and the

local authorities having jurisdiction.

Table 2: Enclosure (Wall Mount Dimensions)

Item Dimension/Location

Weight 2.5 lbs (1.2 KG)

Height 7 in. (17.78 cm)

Width 8 in. (20.32 cm)

Depth 3 1/4 in. (8.255 cm)

Two Upper

Mounting Holes

1/4 in. (.635 cm), keyhole type

Two Bottom

Mounting Holes

Circular type

Knockouts 1/2 in. (1.27 cm.), eight

Tamper Switch for cover supervision.

Installation

3

Wall Mount Hardware The hardware listed in Tabl e 3 on page 3 is not included with the RM-4T.

Installation Tools Antistatic floor mat, tabletop mat, and wrist strap.

Standard tool kit.

3/32" (2.4 mm) screwdriver (supplied with iSTAR Ultra).

Security screwdriver (contact Software House).

Small needle nose pliers; small Phillips screwdriver; wire strippers.

5/16" (#10) nut driver (for securing shield wires to a ground stud).

Mounting To Mount the RM-4T

1. Ensure that the mounting site has been prepared. The product must be

installed indoors.

2. Carefully unpack the RM-4T. Observe the “Static Electricity Precautions” on

page 2.

3. Remove the appropriate knockouts. See Figure 1 on page 4.

4. Align the upper mounting keyhole slots at the upper back of the enclosure

with the two upper mounting screws and then lower the encloser into

position.

Table 3: Wall Mount Hardware Recommendations

Screw Size (Minimum)

Anchor Type

Screw Type

(Pan Head)

Wood Studs,

Plywood Wall

Drywall Plaster

Board

Concrete,

Brick, or Block

Wall

No Anchor Wood Screws #10 x 1-1/4 inch

No Anchor Concrete Screws #10 x 1-1/4 inch

Super Hold

Plastic Anchors

Wood, sheet

metal screws

#10 x 1-1/4 inch #10 x 1-1/4 inch

Toggle Bolts (bolt included) (only for keyholes) 10-24 x 1-1/4 inch 10-24 x 1-1/4 inch

Hollow Wall

Anchor

(screw included) 10-24 x 1-1/4 inch 10-24 x 1-1/4 inch

Sleeve Anchor (screw and nut

included)

1/4-20 x 1-3/8 inch

Wedge Anchor (screw and nut

included)

1/4-20 x 1-3/8 inch

Machine Screw

Anchor

Machine screw 10-24 x 1 inch

Lag Shield

Anchor

Lag screws 1/4 x 1 inch

Wiring

4

5. Install the two bottom mounting screws.

Figure 1. Wall Mounting

WIRING

Figure 2. Wiring

Readers

5

READERS The following readers are supported:

RM-4T Reader Setup 1. Set the Reader Address Switch, SW1 (a 16 position rotary switch, see

Figure 2 on page 4), to a number from one to eight. Each Reader along the

bus must have a unique address.

2. Set the SW-3 configuration switch to the desired setting as shown in Tab l e 4.

NOTE To comply with UL requirements, use shielded, minimum 22 AWG

stranded, twisted pair cable for monitor points, DSMs, and REXs.

Deister:

SWH-4000

SWH-4100

SWH-4200

HID:

iClass

iClass SE R40

Multitech Readers RP40

SWH-5100 Proximity Reader RK40

SWH-2100

SWH-3100

SWH-5200

RPK40

R15

RP15

P345MTR

P345KPMTR

5365 Series

Table 4: SW3 Switch Configuration Settings

SW3 # Function Off (Open) On (Closed)

SW3-1 Reader type Magnetic Wiegand

SW3-2 LCD

NOTE: Not used in the RM-4T.

LCD Present No LCD

SW3-3 LED Option Normal External Bi-color

SW3-4 Tamper Normal Bypass

SW3-5

(See Caution on page 5

EOL-Termination Not last Last unit in bus

SW3-6 LED Option Normal One Wire (A,B,C)

SW3-7 Beeper Control Enable RM-4T

Beeper

Disable RM-4T Beeper

SW3-8 Beep on Read Control No Beep on Read Beep on Read

Readers

6

3. Connect P5 input and output wiring, as shown in Figure 2 on page 4 and

Figure 3 on page 6.

Figure 3. RM-4T Reader Connections

Tab l e 5 on page 6 shows the P3 Read Head wiring connections.

To properly terminate an RS-485 line, only the last unit on the bus should

have SW3-5 in the On (closed) position.

Table 5: Read Head Wiring

P3 Magnetic Stripe (ABA 2) Wiegand (Swipe or Proximity)

1 Card Load Data 1 (white)

2 Clock Data 0 (green)

3 Data No Connection

4 +5V +5 V (red)

5 Ground Ground (black)

6 No connection +12 V (red)

Readers

7

RM3 LED Connections Wire Black, Red, Yellow, and Green as shown in Figure 4 on page 7.

Figure 4. RM3 LED Connections

7 Red LED Red LED

8 Yellow LED Yellow LED

9 Green LED Green LED

10 No connection RS-485 TXD/RXD+

11 No connection RS-485 TXD/RXD–

12 No connection Read Head Beep Control

Table 5: Read Head Wiring (Continued)

P3 Magnetic Stripe (ABA 2) Wiegand (Swipe or Proximity)

LED and Beep Control

8

Reader Wiring

Specifications

LED AND BEEP

CONTROL

Switch SW3 controls the reader LED display and whether the reader beeps on a

card read.

Beep on Read RoHS RM-4Ts can be set to Beep on a card read. The beep is local to the RM-

4T and does not indicate admit or reject status. It simply means that a credential

of the correct technology and frequency was presented to the reader. It could

actually be a misread if the corresponding card format is not set for the number

of bits in the card.

1. Set SW3-7 to OFF (Open)

2. Set SW3-8 to ON (Closed)

If there is a read head beeper connected to P3-12, set SW3-7 and SW3-8 to ON

(Closed).

LED Control

If SW3-3 is on and SW3-6 is OFF, the Function is External Bi-color. It is referred

to as Bi-color because there are two LEDs (red and Green) in the reader;

however, it is essentially Tri-color because in some cases the LEDs will appear

as Yellow.

Table 6: Reader Wiring Specifications

Signal From To Gauge Shielded Max Length

Reader

Data

RM-4T Wiegand read head 22

20

18

Yes 200 ft.

(60.96 m)

300 ft.

(91.4 m)

500 ft.

(152.4 m)

Reader

Data

RM-4T Magnetic read head 22 No 10 ft.

Table 7: SW3 LED Control Settings for SW3-3 and SW3-6

SW3-3 SW3-6 Function

OFF OFF 3-wire (R,G,Y)

ON OFF External Bi-Color

OFF ON 1 Wire (A,B,C)

ON ON 1 Wire (A,B,C)

Keypad Wiring

9

KEYPAD WIRING Tab l e 8 indicates the wiring for units with keypads.

GROUNDING AND

SHIELDING

Single RM-4T

1. When connecting the RM-4T to the reader bus use twisted pair, shielded

minimum 24 AWG cable. Attach the shield at one end only, usually at the

apC or iSTAR end.

2. Attach a local earth ground (18 or 22 gauge) wire to the J5 component on

the RM-4T.

Multiple RM Bus devices

When wiring an RM-4T reader to a bus with multiple devices, such as other RM-

4Ts, I/8s, or R/8s:

1. Attach the shields along the bus together (insulate each connection). Snip

off the shield wire at the end of the bus. See Figure 5 on page 10.

2. Attach the shield to the ground at only one point – at the ground stud inside

the iSTAR or apC cabinet adjacent to the knockout.

3. Attach a local earth ground (18 or 22 gauge) wire to the J5 component on

the RM-4T.

Table 8: Wiring for Units with Keypads

J2 Pin Function

1Col3

2 Col 2

3 Col 1

4Col0

5 Row 3

6 Row 2

7Row1

8Row0

123

456

789

0CE

CMD

ENT

C3 C2 C1

R3

R2

R1

R0

Please note that

on a 3 x 4 matrix

keypad, Pin 4 (C0)

is not used.

Grounding and Shielding

10

Figure 5. Reader Shield Wiring

Setting Module

Address and

EOL Termination

To set the module address, set SW1 (16 position rotary switch) to a number

from one to eight. Every RM-4T series reader on a bus must have a unique

address.

To set RS-485 EOL (End of Line) termination, set SW3-5 to the On (closed)

position if the module is the last unit on the bus. If the module is not the last unit

on the bus, SW3-5 should be Off (open).

Figure 6 on page 11 shows how to connect ARM-1 relay modules to the RM-4T

outputs and how to wire NO (Normally Open) and NC (Normally Closed)

supervised inputs.

ACM module

RS-485 connector on a reader

Knockout

Twist shield wires together and insulate

(do not ground)

Ground stud

(bus configuration)

Shield wire

Enclosure/cabinet

Shield wire Snip off shield

wire at end of

bus

Grounding and Shielding

11

Figure 6. RM-4T Input/Output Connections

Installing the ARM-1

Relay Module

Two ARM-1 relay components can be connected to the RM-4T reader through

the P5 connector (Table 9).

RM P5-1 is the common (+12 VDC) pin for either ARM-1.

RM P5-2 is the output drive (GND) for the first relay.

RM P5-3 is the output drive (GND) for the second relay.

NOTE The maximum distance from P5 to the ARM-1 is 25 feet.

The maximum distance from P5 to the inputs is 2000 feet.

Locate the 1Kresistors for the NO and NC supervised inputs as close

as possible to the switch.

NOTE The ARM-1 relay has not been evaluated by UL.

Table 9: ARM-1 Wiring

Module Wiring

ARM-1 Relay ARM P2-1 to RM P5-1

ARM P2-2 to RM P5-2

Testing RM-4T Readers

12

TESTING RM-4T

READERS

To Test RM-4T Treaders

1. Properly configure Readers, Inputs, and Outputs using the C•CURE 9000

Administration application and put the reader Online.

2. Measure the supply voltage to the RM-4T.

The voltage can be measured between pin 1 (+12 VDC supply) and pin 4

(ground) on the P4 connector. The voltage must be +12 VDC (+/-5%).

3. Check the RM reader address setting.

The RM must be set to an unused address, between 1 and 8, when

connected to the apC or iSTAR. Use rotary switch SW1 to set the reader

address.

4. Check the RM-4T for communications to the apC or iSTAR by observing

LED2 and LED3.

5. Check the supervised inputs. Configure the inputs on the apC or iSTAR

using the C•CURE 9000 Administration application.

With no switches or resistors connected to the supervised input 1 and 2

lines, the C•CURE 9000 Monitoring application should report inputs as

“Open Loop”.

When you connect the 1,000-ohm resistor to the input terminals, the

C• CURE 9000 Monitoring application should report that the input as

“Deactivated”. Supervised inputs #1 is found at pins 4 and 5 of P5.

Supervised input #2 is found at pins 6 and 7 of P5.

6. Check the outputs.

The outputs can be functionally tested by using the “momentary activate”

feature in the C• CURE 9000 Monitoring application. When the outputs are

momentarily activated, the signal will change state for a few seconds.

7. Check the reader interface.

The reader interface can only be tested by presenting a card with the

appropriate technology to the reader. Reading a card will cause the display

to show “Access Granted” or “Access Denied,” depending on the clearance

of the card.

ARM-2 Relay ARM P2-1 to RM P5-1

ARM P2-2 to RM P5-3

Table 9: ARM-1 Wiring (Continued)

Module Wiring

Copyright and Trademarks

13

COPYRIGHT AND

TRADEMARKS

C•CURE and Software House are registered trademarks of Tyco Security Products.

The trademarks, logos, and service marks displayed on this document are registered in the United States [or other

countries]. Any misuse of the trademarks is strictly prohibited and Tyco will aggressively enforce its intellectual

property rights to the fullest extent of the law, including pursuit of criminal prosecution wherever necessary. All

trademarks not owned by Tyco are the property of their respective owners, and are used with permission or

allowed under applicable laws.

Product offerings and specifications are subject to change without notice. Actual products may vary from photos.

Not all products include all features. Availability varies by region; contact your sales representative.

© 2014 Tyco Security Products.

All Rights Reserved.

Table of contents

Popular Switch manuals by other brands

Belden

Belden Hirschmann OCTOPUS 8TX PoE-EEC user manual

Veris Industries

Veris Industries Hawkeye 949 installation guide

Murphy

Murphy PowerView PVM Series Specification sheet

Velleman

Velleman K8015 Illustrated assembly manual

QNAP

QNAP QSW-M3212R-8S4T Quick installation guide

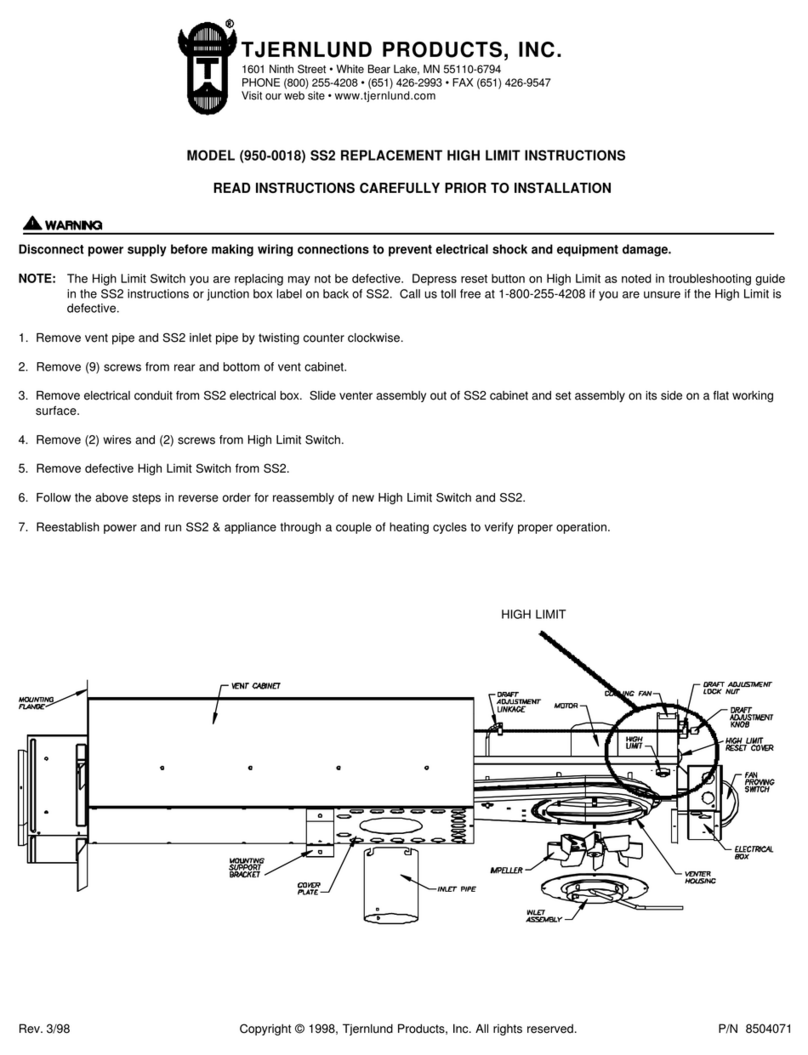

TJERNLUND

TJERNLUND SIDESHOT SS2 manual

D-Link

D-Link DES-1008P Quick installation guide

Planet Networking & Communication

Planet Networking & Communication GSD-1222VHP user manual

ENSIM SENSORS

ENSIM SENSORS DX-ELF 101 operating manual

Hored

Hored IS104GS-2F user manual

SP Controls

SP Controls SP-SW5200-VUHBT user guide

HP

HP ProCurve 8212zl Series datasheet