Page 2 AB20002

Thank you for purchasing a Demco spray boom. We feel you have made a wise choice and hope you are completely

satisfied with your new boom. If you have any questions regarding the applications of certain solutions or chemicals,

contact your chemical supplier and follow chemical manufacturer recommendations as well as all licensing and use

restrictions or regulations.

GENERAL INFORMATION

1. Unless otherwise specified, high-strength (grade5)

(3 radial-line head markings) hex head bolts are used

throughout assembly of this sprayer.

2. Whenever terms “LEFT” and “RIGHT” are used in this

manual it means from a position behind sprayer and

facing forward.

3. When placing a parts order, refer to this manual for

proper part numbers and place order by PART NO.,

DESCRIPTION, and COLOR.

WARNING: TO AVOID PERSONAL INJURY OR PROPERTY DAMAGE, OBSERVE FOL-

LOWING INSTRUCTIONS:

Chemicals are dangerous.Know exactly what you’re going to do and what is going

to happen before attempting to work with these products. Improper selection or

use can injure people, animals, plants and soil.

Always wear protective clothing such as coveralls, goggles and gloves when work-

ing with chemicals or sprayer.

Be sure to dispose of all unused chemicals or solutions in a proper and ecologically

sound manner.

Table of Contents

General information................................................................................................................... 2

Warranty Policy, Operator Manuals & Registration................................................................ 2

Safety , Signal Words ................................................................................................................. 3

Equipment Safety Guidelines ................................................................................................... 4

Lighting and Marking ................................................................................................................ 4

Safety Sign Care ......................................................................................................................... 5

Tire Safety.................................................................................................................................... 5

Remember .................................................................................................................................. 5

Before Operation ......................................................................................................................5-6

During Operation......................................................................................................................6-7

Following Operation.................................................................................................................. 7

Highway and Transport Operations........................................................................................8-9

Performing Maintenance........................................................................................................... 9

Bolt Torque................................................................................................................................. 10

Spray Tip Assembly and Installation ....................................................................................... 11

Sprayer Calibration Procedures............................................................................................... 12

Spray Tip Charts ........................................................................................................................ 13

Nozzle Parts Breakdown and List ............................................................................................ 14

21’ - 30’ Truss-T Boom Parts Breakdown and List .................................................................. 15

40’ Truss-T Boom Parts Breakdown and List........................................................................... 16

Sprayer Checklist....................................................................................................................... 17

WARRANTY POLICY, OPERATOR MANUALS, PARTS MANUALS & REGISTRATION

Go online to www.demco-products.com to review Demco warranty policies, operator manuals and register your Demco

product.

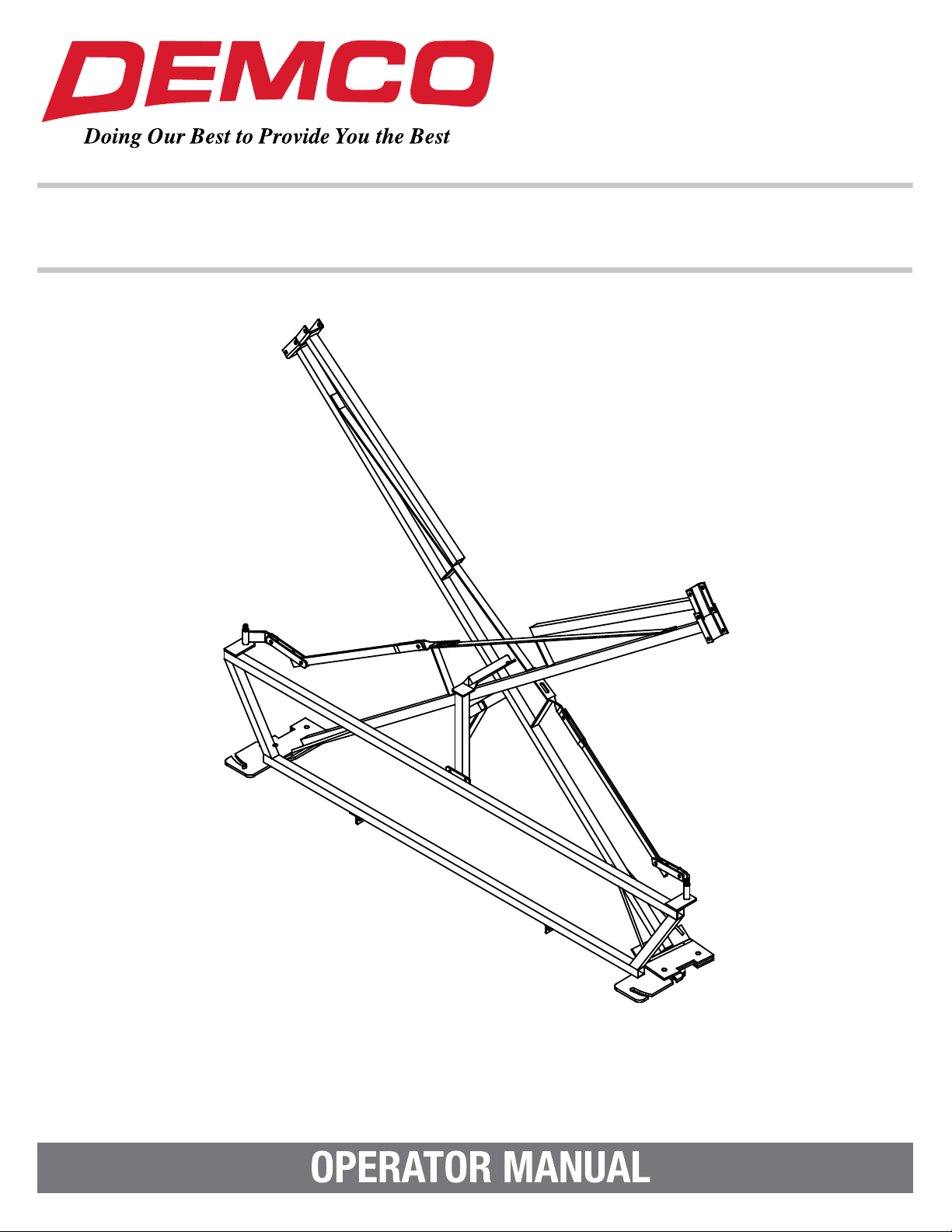

INTRODUCTION