Contents

1INTRODUCTION .................................................................................................................... 2

1.1 About this product ............................................................................................................ 3

1.2 Intended use.....................................................................Fehler! Textmarke nicht definiert.

1.3 Examples of incorrect use.................................................................................................. 4

1.4 EU Declaration of conformity............................................................................................. 5

1.5 Guarantee statement ........................................................Fehler! Textmarke nicht definiert.

1.6 Technical specifications ..................................................................................................... 6

1.7 Data plate.........................................................................Fehler! Textmarke nicht definiert.

1.8 Structure and area of applicability of the operating instructions......................................... 6

1.8.1 Structure.............................................................................Fehler! Textmarke nicht definiert.

1.8.2 Target group.......................................................................Fehler! Textmarke nicht definiert.

1.8.3 Changes to these operating instructions ................................................................................ 7

1.8.4 Safe keeping of the operating instructions ............................................................................. 7

1.8.5 Spatial limits .......................................................................Fehler! Textmarke nicht definiert.

1.8.6 Time limits..........................................................................Fehler! Textmarke nicht definiert.

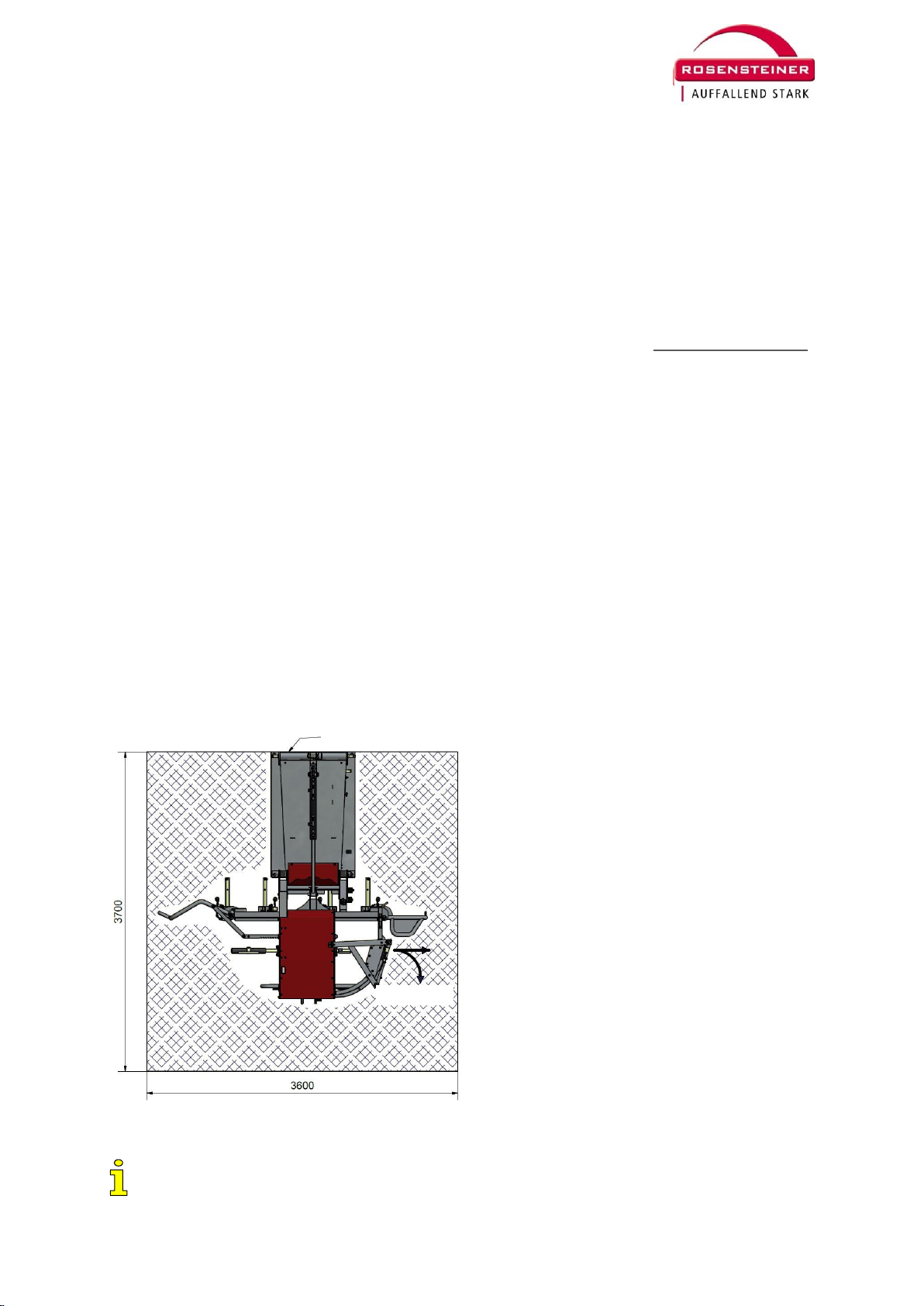

1.8.7 Operational working space.................................................Fehler! Textmarke nicht definiert.

1.8.8 Explanation of information and hazard notices...................................................................... 7

1.8.9 Pictograms in the operating instructions and on the machine............................................... 8

2TRANSPORT.......................................................................................................................... 9

2.1 Hitching the hoof trimming crush to a tractor..................................................................... 9

2.2 Towing the hoof trimming crush with a tractor .................................................................. 9

2.3 Removal of the hoof trimming crush from the tractor and setting down........................... 10

3STARTING / OPERATION...................................................................................................... 11

3.1 View of appliance / Main operating elements Kipp Top II Comfort.................................... 11

3.2 Safety instructions before starting................................................................................... 12

3.3 Procedure for starting the hoof trimming crush................................................................ 13

4DE-COMMISSIONING / CESSATION OF WORK ...................................................................... 15

5CLEANING.................................................................... FEHLER! TEXTMARKE NICHT DEFINIERT.

6SERVICING / MAINTENANCE / REPAIR ................................................................................. 16

6.1 Safety instructions.............................................................Fehler! Textmarke nicht definiert.

6.2 Electrical hazard.............................................................................................................. 16

6.3 Servicing and care ........................................................................................................... 17

7REPLACEMENT PARTS .................................................. FEHLER! TEXTMARKE NICHT DEFINIERT.

8REGULAR INSPECTION.................................................. FEHLER! TEXTMARKE NICHT DEFINIERT.

9SCOPE OF DELIVERY / ACCESSORIES..................................................................................... 19