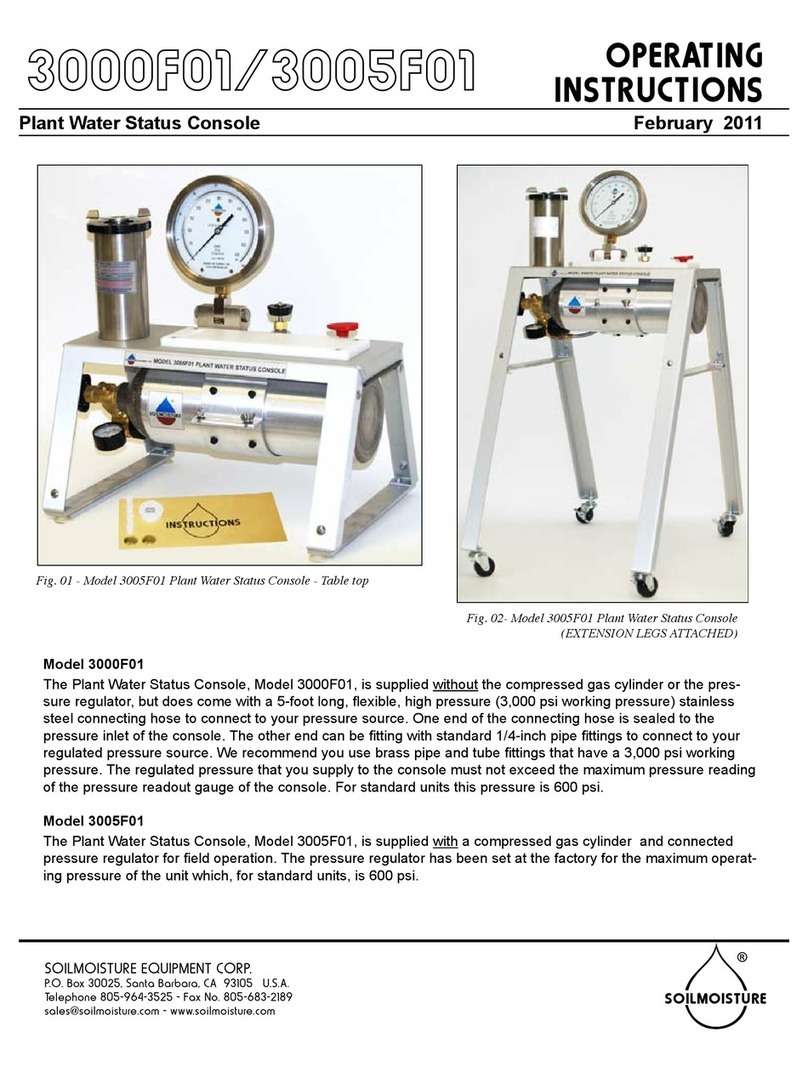

Soilmoisture Equipment 1768B-.15SYS1 User manual

This manual suits for next models

1

Table of contents

Other Soilmoisture Equipment Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

cetoni

cetoni BASE 120 Hardware manual

Velp Scientifica

Velp Scientifica DLH F201A0157 instruction manual

cytiva

cytiva F9-R operating instructions

Yoda

Yoda Bactiscan user manual

Labnet

Labnet Spectrafuge 16M instruction manual

ThermoFisher Scientific

ThermoFisher Scientific HERASAFE 2030i Series operating instructions

Beckman Coulter

Beckman Coulter FP 1000 manual

PST

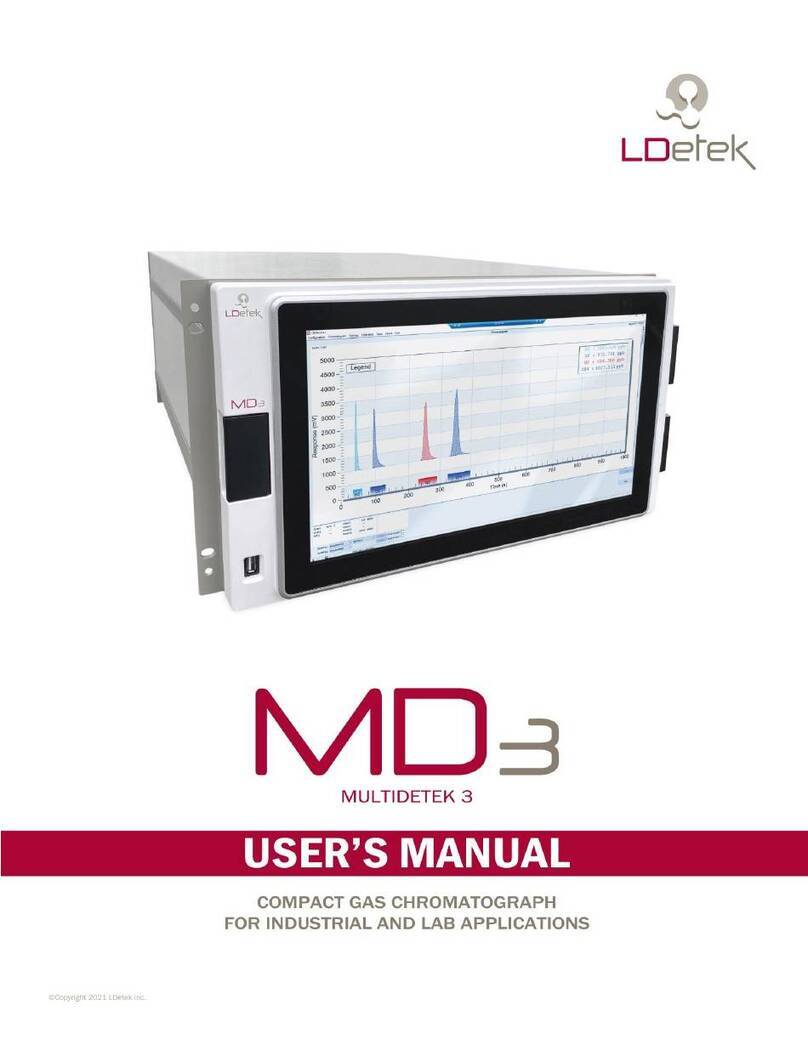

PST LDetek MULTIDETEK 3 user manual

Precisionary

Precisionary Compresstome VF-310-0Z user manual

Molecular Devices

Molecular Devices EMax Plus user guide

Leica

Leica RM2125RTS Standard operating procedure

Thermo Scientific

Thermo Scientific NS-FANT12-CH Quick setup guide

Topcon

Topcon TRC-NW300 instruction manual

Waters

Waters TA Instruments Sample/Temperature Stage Operator's guide

Keithley

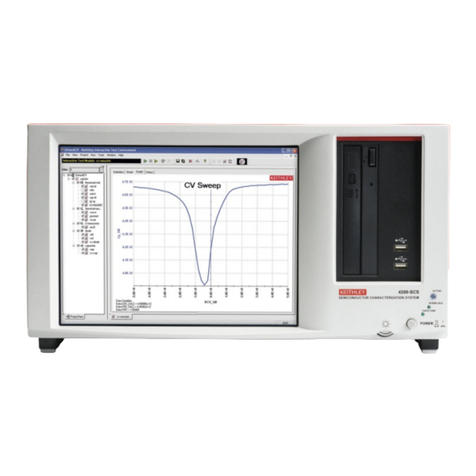

Keithley 4200-SCS-PK3-903-01 quick start guide

Labnet

Labnet VorTemp 1550 instruction manual

Qiagen

Qiagen QIAcuity 911000 user manual

EIJKELKAMP

EIJKELKAMP 08.02 SAND / KAOLIN BOX operating instructions