Soilmoisture Equipment 3000F01 User manual

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

OPERATING

INSTRUCTIONS

Plant Water Status Console February 2011

Model 3000F01

The Plant Water Status Console, Model 3000F01, is supplied without the compressed gas cylinder or the pres-

sure regulator, but does come with a 5-foot long, exible, high pressure (3,000 psi working pressure) stainless

steel connecting hose to connect to your pressure source. One end of the connecting hose is sealed to the

pressure inlet of the console. The other end can be tting with standard 1/4-inch pipe ttings to connect to your

regulated pressure source. We recommend you use brass pipe and tube ttings that have a 3,000 psi working

pressure. The regulated pressure that you supply to the console must not exceed the maximum pressure reading

of the pressure readout gauge of the console. For standard units this pressure is 600 psi.

Model 3005F01

The Plant Water Status Console, Model 3005F01, is supplied with a compressed gas cylinder and connected

pressure regulator for eld operation. The pressure regulator has been set at the factory for the maximum operat-

ing pressure of the unit which, for standard units, is 600 psi.

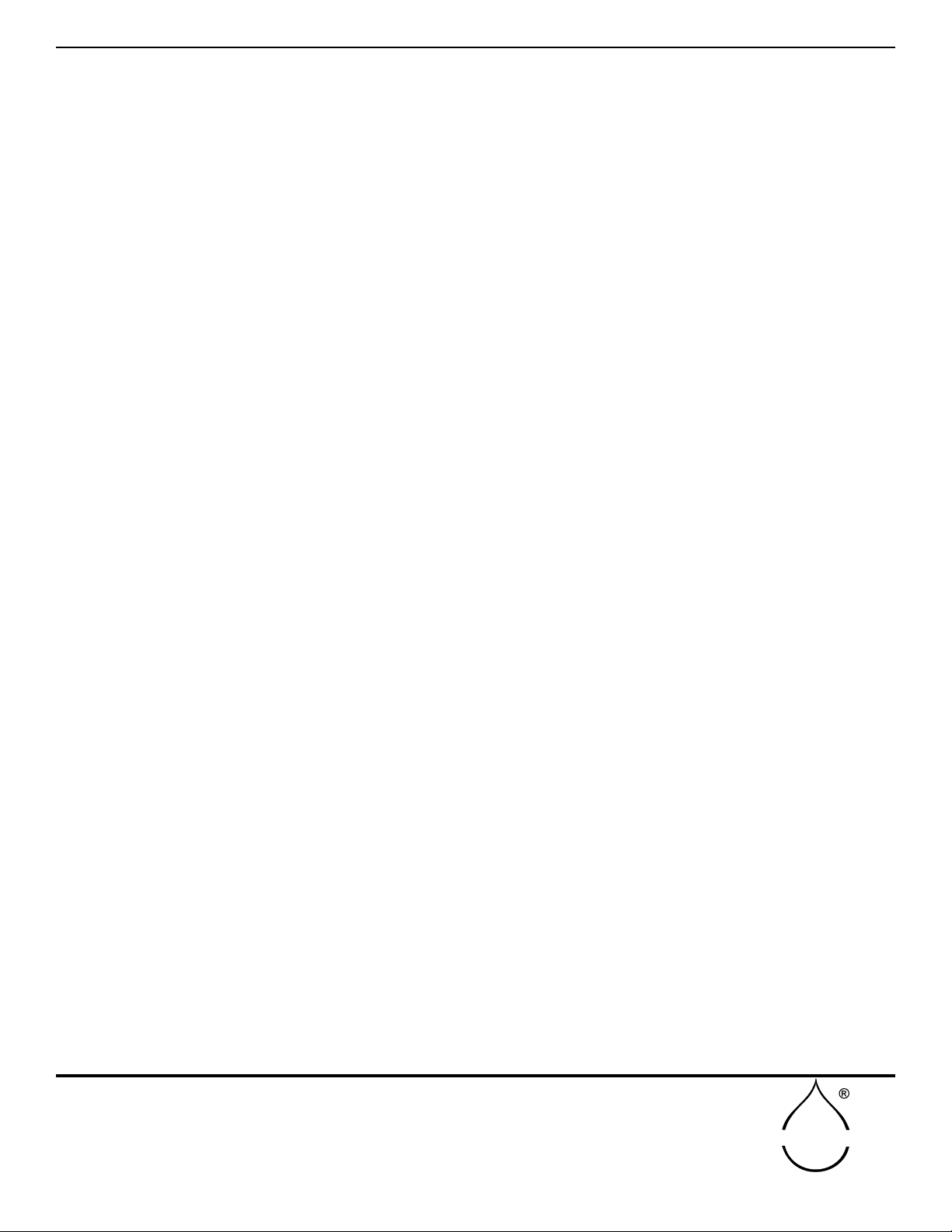

Fig. 01 - Model 3005F01 Plant Water Status Console - Table top

Fig. 02- Model 3005F01 Plant Water Status Console

(EXTENSION LEGS ATTACHED)

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

2

Soilmoisture Equipment Corp. (SEC) warrants all products manufactured by SEC to be free from defects

in materials and workmanship under normal use and service for twelve (12) months from the date of

invoice provided the section below has been met.

Soilmoisture Equipment Corp. (SEC) is not liable for any damages, actual or inferred, caused by misuse

or improper handling of its products. SEC products are designed to be used solely as described in these

product operating instructions by a prudent individual under normal operating conditions in applications

intended for use by this product.

WARRANTY & LIABILITY

TABLE OF CONTENTS

UNPACKING

The Plant Water Status Console was thoroughly tested before shipment. When packed, it was in per-

fect working order. Unpack with care being sure to remove all packing material. Follow the instructions

carefully in order to ensure long, trouble-free service.

Any damage found upon receipt should be reported immediately to the transport carrier for

claim. It is important to save the shipping container and all evidence to support your claim.

Be sure to read all operating instructions thoroughly before operating the unit.

The Plant Water Status Console comes fully assembled. See page 4 for instructions on how to as-

semble the leg extensions for laboratory use.

As with any pressure system, use reasonable caution. Be sure all valves are off before trans-

porting. Do not lean directly over the specimen holder. Leave it to a qualied technician to do

the repairs. Have the unit serviced at least once a year. DOT standards on aluminum pressure

vessels require hydrostatic testing every 5 years.

CAUTIONS & WARNINGS

Unpacking .............................................................................................................................................2

Cautions & Warnings..............................................................................................................................2

Warranty & Liability.................................................................................................................................2

General specications............................................................................................................................3

Theory of operation................................................................................................................................3

Acquaint Yourself with the parts.............................................................................................................4

Leg Extension Assembly...........................................................................................................5

Speciman holder and Pressure Vessel.....................................................................................5

Gauge.......................................................................................................................................6

Prep Board................................................................................................................................7

Valve Controls........................................................................................................................7-8

How to use and/or operate unit.........................................................................................................9-11

General care and maintenance............................................................................................................12

How to replace the compressed gas cylinder..........................................................................12

How to rell the compressed gas cylinder...............................................................................13

Helpful hints during normal use............................................................................................................14

Troubleshooting....................................................................................................................................14

Minor Adjustments................................................................................................................................14

Use and application of product options................................................................................................15

Specimen Holders and Grommets..................................................................................................15-18

Notes....................................................................................................................................................19

Replacement parts and accessories list.........................................................................................20-21

3

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

22 cubic foot aluminum DOT-3AL aluminum cylinder with CGA-580 tting rated for 2216 psi – requires •

hydrostatic testing every 5 years.

Single stage, step-down regulator set to 600 psi at the factory (can be reset by user if necessary).•

Standard pressure vessel 7˝, 0.5 liter volume, 2.4 kg, 40 or 80 bars. Cam lock. Specimen holder •

with safety valve. Internal diameter 2.73˝ with vertical useable height 5.837˝.

12˝ and 20˝ vessels also available. 12˝, 3.8 kg, 1 liter volume, 10.837” height. 20”, 6.3 kg, 1.8 liter, •

19.837˝ height.

All vessels 2.73˝ diameter and rated for 80 bars with cam lock and safety valve features. Made of •

stainless steel for a lifetime of use.

6˝ scientic test gauge with beryllium copper movement and stainless steel case, ¼ of 1% full scale •

accuracy and the highest quality you can buy for many years of service.

600 psi gauge, 40 bars. Subdivisions 2 psi, 0.2Bars, 20 kPa.•

Resolution ½ a division. Dual scale psi + kPa, Parallax mirror and adjustable needle to re-zero if •

necessary.

1500 psi gauge, 80 bars. Subdivisions 10 psi, 0.5 Bars, 50 kPa.•

Resolution ½ a division. Dual scale psi + kPa, Parallax mirror and adjustable needle to re-zero if •

necessary.

THEORY OF OPERATION

GENERAL SPECIFICATIONS

The roots of a plant are using reverse osmotic forces to overcome the matrix potential of the soil. The

stomates on the leaves of a plant are transpiring at different rates throughout the day. The resulting

tension in the xylem column can be measured using a plant water status console device.

The petiole of a leaf or stem is placed in a rubber grommet so the leaves are inside the pressure chamber

and the stem is outside at atmospheric pressure. By pressurizing the chamber and watching the point

where the sap oozes out of the stem at atmospheric pressure the 2 forces are in balance – the reading

on the gauge and the tension in the xylem column. This value can vary from the bottom to the top of the

plant and at different times of the day due to temperature, humidity, sunlight, and wind. By stressing

the plant, better crops can be produced and water use better managed.

4

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

44

AQUAINT YOURSELF WITH THE PARTS

SIDE VIEW Model 3005

PRESSURE GAUGE

COMPRESSED

GAS CYLINDER

(Model 3005 only)

PREPARATION

BOARD

3-WAY

CONTROL VALVE

METERING VALVE

TEST GAUGE

PRESSURE VESSEL

SPECIMEN

HOLDER

TANK

MOUNT BRACKET

(Model 3005 only)

Model 3005 PLANT WATER STATUS CONSOLE

SEALING VALVE

PRESSURE REGULATOR

SUPPORT BAR LEG EXTENSIONS (2 FRONT / 2 BACK)

ROUND HEAD BOLTS

(FOR LEG EXTENSION

ASSEMBLY - 8 PER UNIT)

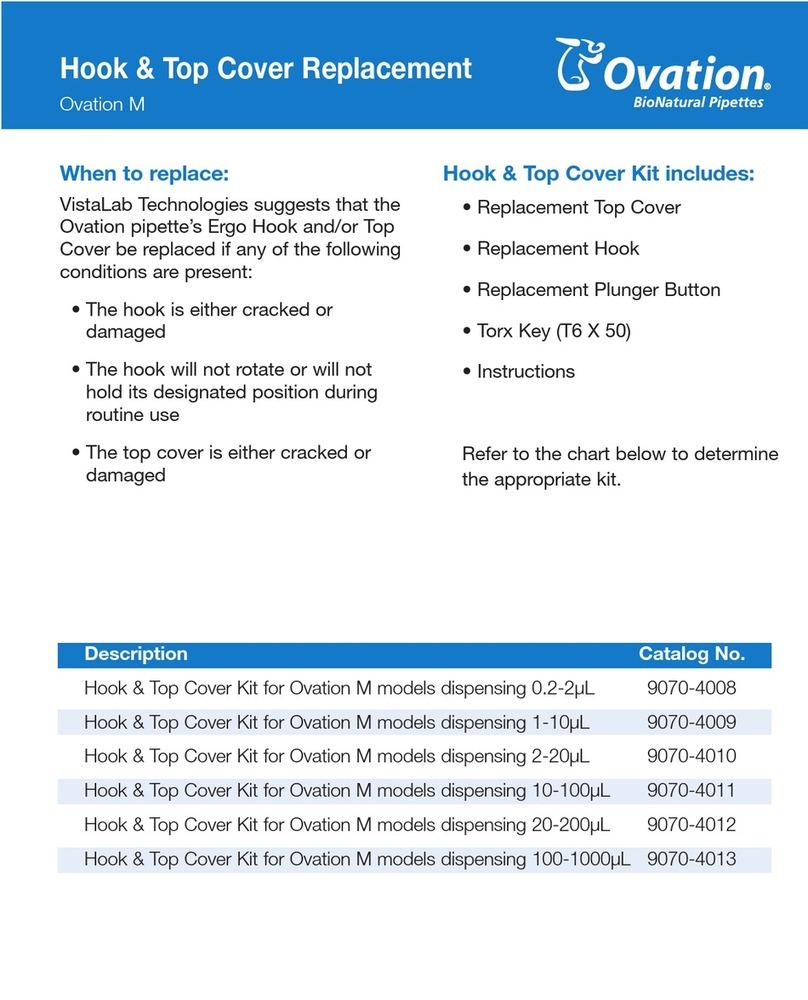

Fig. 03 - Plant Water Status Console primary parts

5

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

Assembly may require assistance depending on the size of

pressure vessel and total weight of unit.

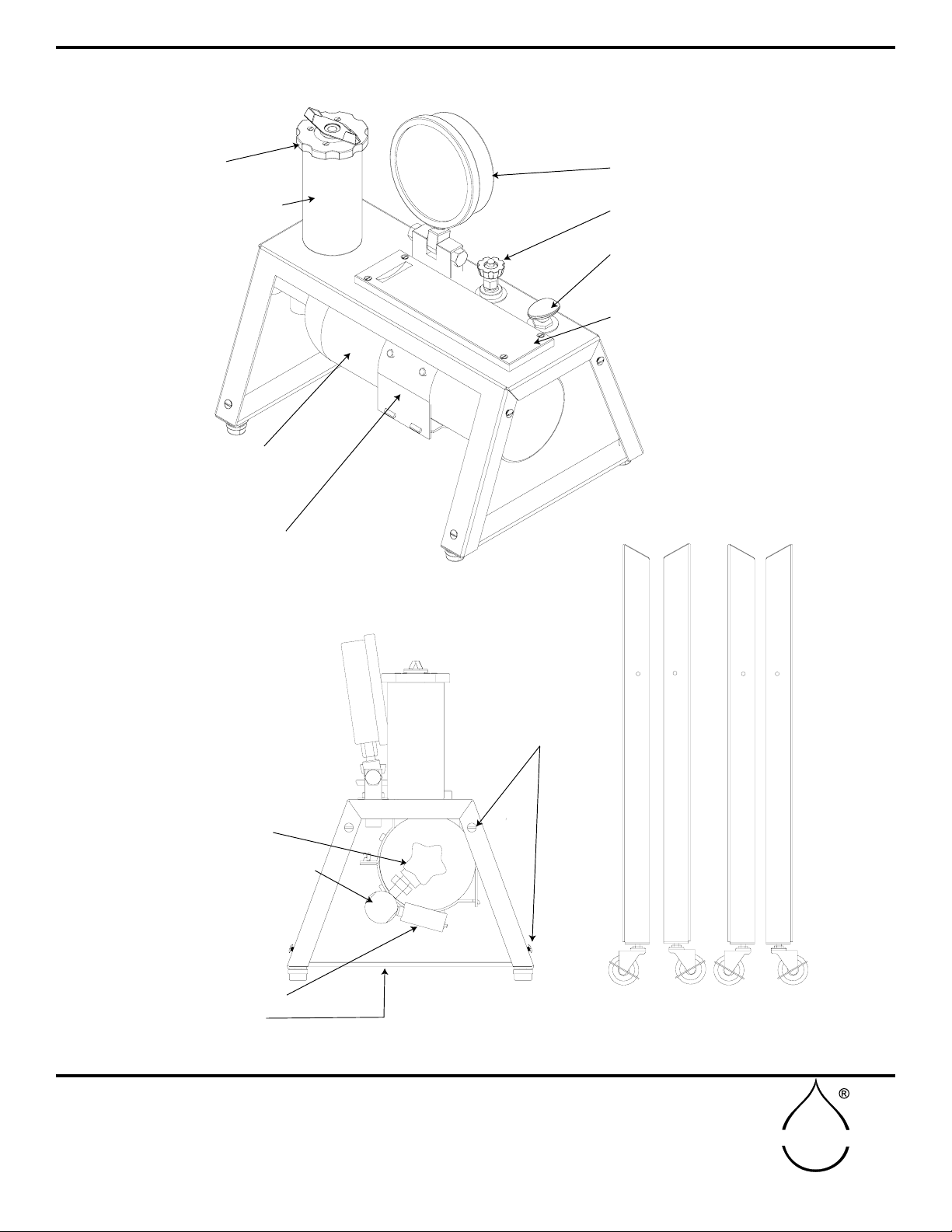

(Fig.04)

Unscrew round head bolts on each leg. (Total of 8 bolts 1.

included solely for the leg extensions)

Gently lay unit on front or back side. The unit may be 2.

resting on the pressure vessel. Although the pressure

vessel is bolted securely on the chassis, be careful not

to add any additional pressure.

Match legs to bolt holes. Re-insert bolts through bolt3.

holes and tighten.

Gently turn unit over and repeat steps 2 & 3 with the nal 4.

two legs.

The specimen holder is held securely in place with four internal

cams at the top of the vessel. The vessel’s high pressure gas inlet

is in the center of the vessel base. Remove the specimen holder by

turning the closing cap counterclockwise 45° and pulling the holder

upward (Fig. 05). To insert the specimen holder for a run, turn the

specimen holder 45° clockwise to lock it in place.

When the specimen holder is removed the rst time, it may require

considerable force. The “O” ring used to make the pressure seal

tends to “seize” to the metal surface if it is allowed to remain in

the compressed position for a considerable time. To minimize this

problem, apply a thin coat of light grease, such as stopcock grease

or Vaseline, to the “O” ring. Then, after the specimen holder is re-

moved for the rst time, it will enter and close.

AQUAINT YOURSELF WITH THE PARTS (cont.)

LEG EXTENSION ASSEMBLY

SPECIMEN HOLDER AND PRESSURE VESSEL

ROUND HEAD BOLTS

(2 EACH LEG)

FRONT LEG EXTENSION

BACK LEG EXTENSION

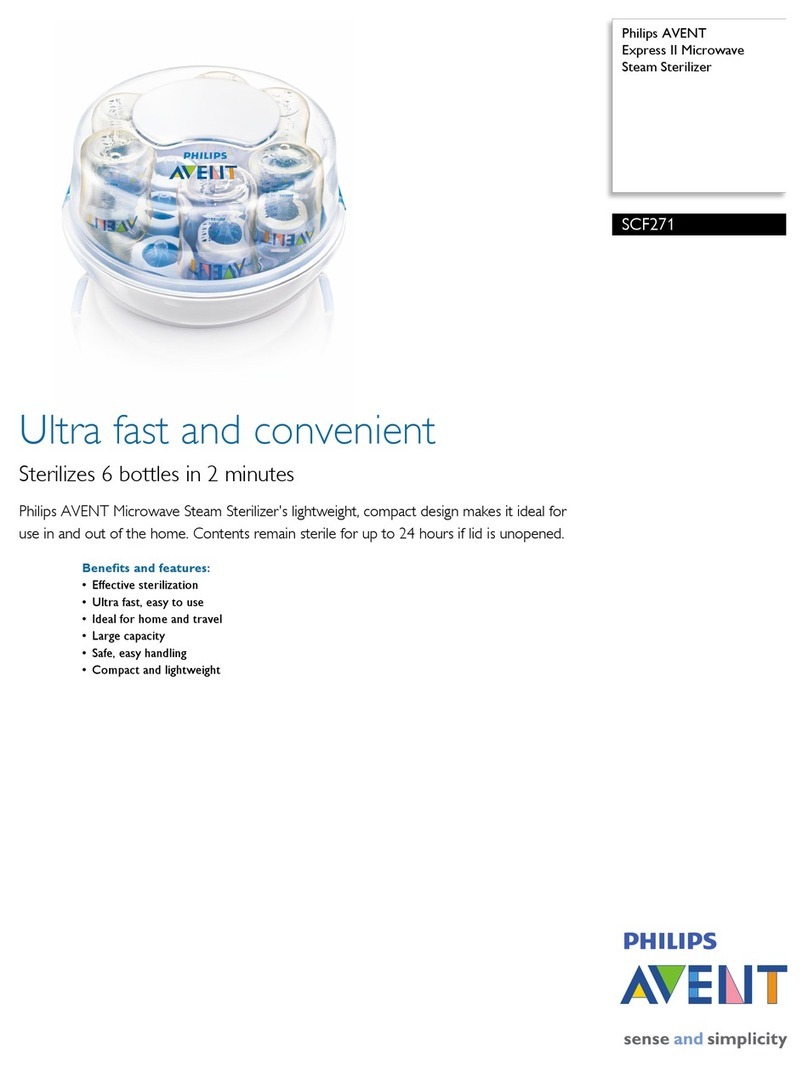

Fig. 04 - Leg extension assembly

Fig. 05- Specimen Holder

6

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

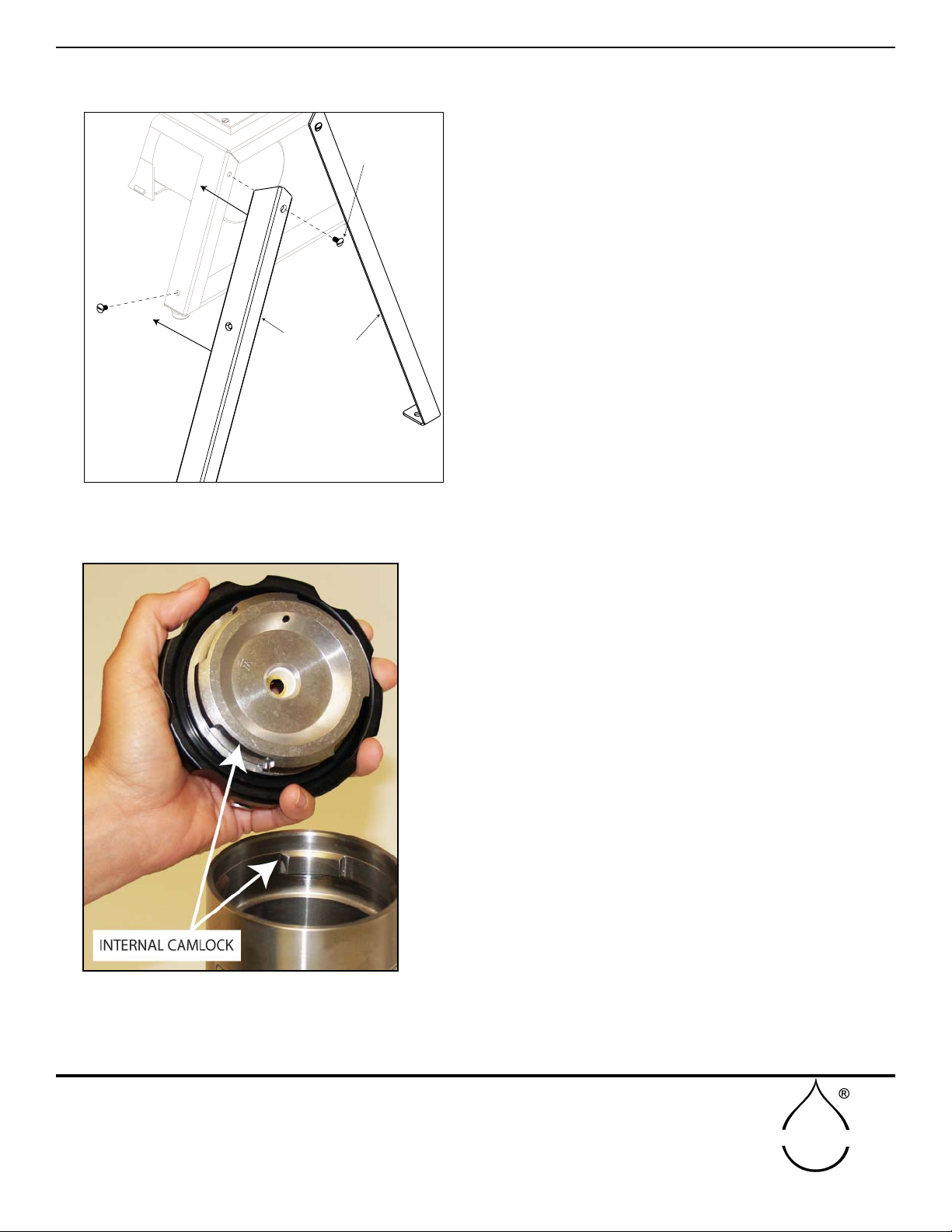

The fail safe valve (Fig. 6), in line with the pressure vessel cams, prevents build up of pressure in the

pressure vessel unless the specimen holder is completely locked in place.

The sealing knob (Fig. 6) on the specimen holder actuates the collet-type closure that pressure seals

the specimen and sealing sleeves during a run. Turning the sealing knob clockwise seals the specimen.

Turning counterclockwise releases the seal. (Sealing sleeves and grommets are discussed on pages

15-18.)

GAUGE

The 6 inch dial face, 1/4 +/- of 1% accuracy test gauge, graduated in both psi (pounds per square inch)

and in bars, indicates the pressure within the pressure vessel at all times. The swivel support base pro-

vides a detent to hold the gauge in two reading positions and one position for transport (Fig.07). A zero

pointer position adjusting screw is provided for zeroing the pointer in the event it is jarred out of place.

AQUAINT YOURSELF WITH THE PARTS (cont.)

Fig. 06- Specimen Holder

FAIL SAFE VALVE

SEALING KNOB

SEALING SLEEVE

GROMMET

Fig. 07- Test gauge with swivel base

7

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

The metering valve controls the rate at which pressure is built up in the pressure vessel. The valve is

usually adjusted so that the rate of pressure increase is in the range of 5-10 psi per second. Turning the

valve counterclockwise increases the rate of ow. During routine tests, this valve can be left at one xed

position to give uniform pressure building up on all samples. When the metering valve is closed (by

turning clockwise) care should be taken not to exert excessive closing force since this tends to damage

the valve seat and the long tapered valve which provides the sensitive gas ow control (Fig. 09).

The control valve directs the ow of gas into or out of the pressure vessel or seals the gas within the

pressure vessel (Fig. 10). When the control valve is in the “OFF” position, high pressure gas within the

pressure vessel is sealed in and no gas can enter or leave. When the control valve is in the “PRESSUR-

IZE” position, high pressure supply air from the pressure regulator ows through the metering valve,

through the control valve and into the pressure vessel. When the control valve is in the “EXHAUST”

position, the high pressure gas within the pressure vessel exhausts immediately to the atmosphere.

VALVE CONTROLS

PREPBOARD

The high density polyethylene preparation board provides a convenient cutting block for the prepara-

tion of leaf samples. The notch at the end holds the specimen holder during the loading operation to

minimize possibilities of damage (Fig. 08).

P

R

E

S

S

U

R

I

Z

E

O

F

F

P

R

E

S

S

U

R

I

Z

E

O

F

F

E

X

H

A

U

S

T

O

F

F

E

X

H

A

U

S

T

PRESSURIZE OFF EXHAUST

AQUAINT YOURSELF WITH THE PARTS (cont.)

Fig. 08- Specimen holder on prep board

Fig. 09- Metering valve settings

T

O

I

N

C

R

E

A

S

E

F

L

O

W

M

E

T

E

R

I

N

G

V

A

L

V

E

C

L

O

S

E

Fig. 10- Control valve settings

8

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

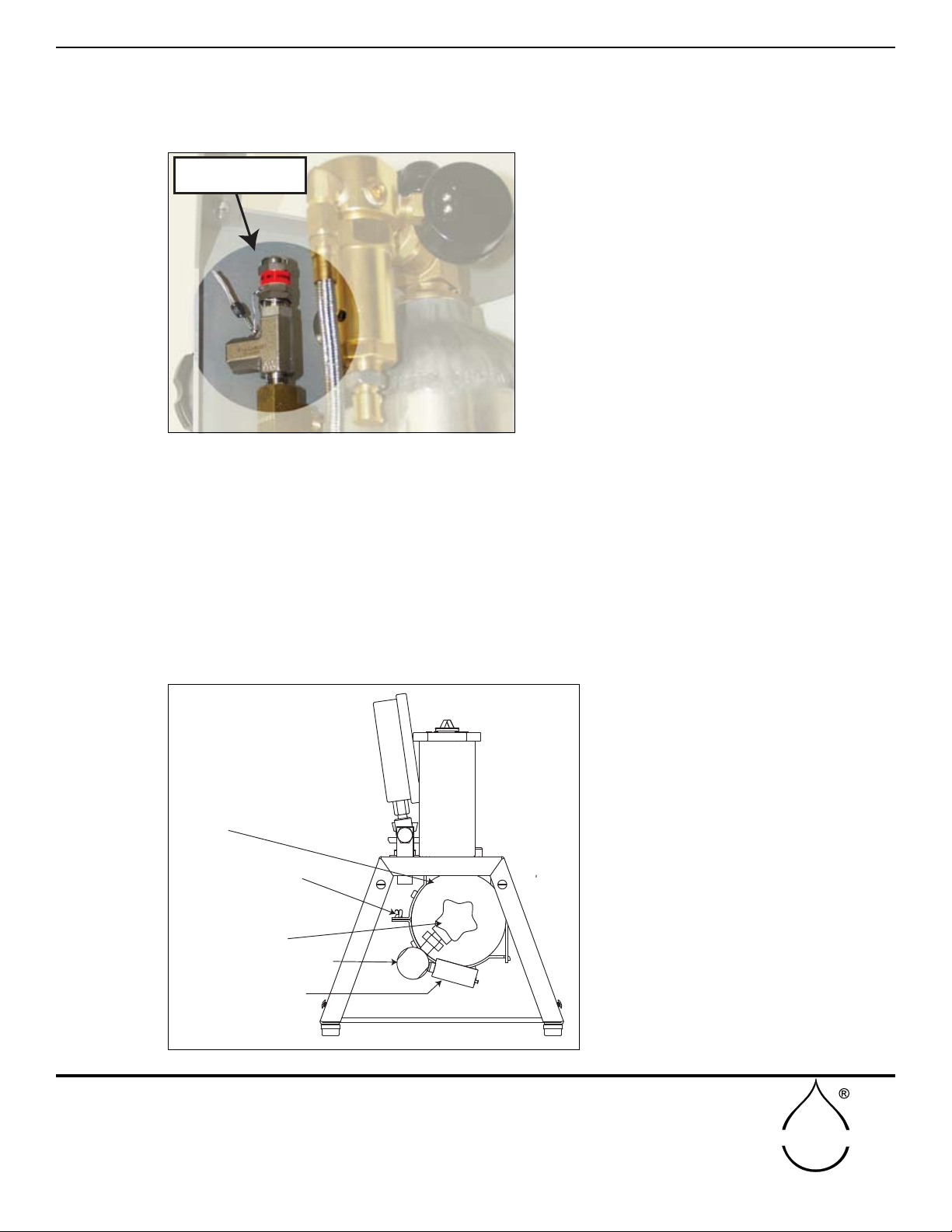

Underneath the panel a safety relief valve is incorporated in the system to prevent damage from any

excess buildup of pressure. The relief valve is set at the factory so that pressure will be released when

it exceeds the maximum operating range of the console (Fig. 11).

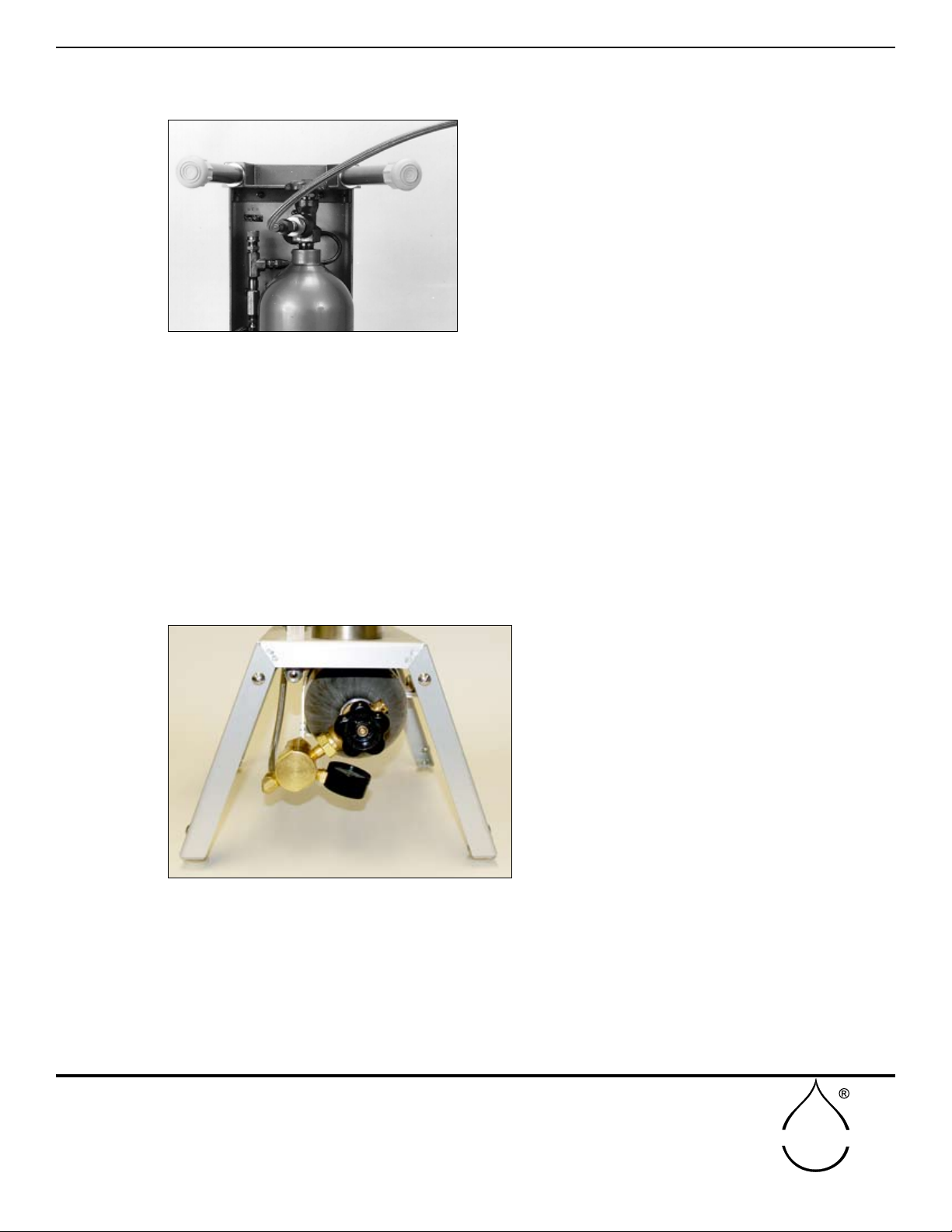

The pressure regulator is connected to the compressed gas cylinder. It can readily be removed for re-

placement or relling of the cylinder. The output pressure on the regulator has been set at the factory

at 600 psi for standard consoles.

The small pressure gauge, screwed into one of the ports of the regulator indicates the pressure within

the compressed gas cylinder and is used as a guide to indicate when the cylinder needs relling

(Fig. 12).

The rellable 2,216 psi, 22 cubic feet capacity, compressed gas cylinder is held securely by the tank

mounting bracket beneath the chassis. When empty, it can be lled in place without removing it from the

chassis. The sealing valve at the end of the tank should be kept closed (turn clockwise) except when

the console is in use.

AQUAINT YOURSELF WITH THE PARTS (cont.)

Fig. 11 - Safety relief valve

Fig. 12 - Parts under chassis

SAFETY RELIEF VALVE

(BOTTOM OF UNIT VIEW)

PRESSURE GAUGE

SEALING VALVE

PRESSURE REGULATOR

TANK MOUNTING

BRACKET

TANK

9

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

Step 1

Close the metering valve, turning clockwise (Fig. 09).

Step 2

The rellable 2,216 psi, 22 cubic feet capacity, compressed gas cylinder is held securely by the bottle

bracket beneath the chassis. When empty, it can be lled in place without removing it from the chassis.

The sealing valve at the end of the tank should be kept closed (turn clockwise) except when the console

is in use (Fig. 12).

Step 3

Open compressed gas cylinder sealing valve, by turning counterclockwise (Fig. 12).

Step 4

Remove specimen holder from pressure vessel, as described earlier, and place in notch of sample

preparation board (Fig. 08).

Step 5

Select sample leaf to run.

On initial run to check the unit and to acquaint yourself with its operation, you can substitute a round

rod for the leaf sample in order to seal the specimen holder. A nail, rivet, dowel pin, or round 1/8-inch to

1/4 inch in diameter may be used. If the diameter to be sealed is less than 1/8-inch, select the sup-port

washer with the 9/64-inch hole. If the diameter to be sealed is greater than 1/8 inch select the support

washer with the 1/4 inch hole. Next, select one of the rubber sealing sleeves that best ts the stem

diameter.

Step 6

Arrange the sealing sleeve on the stem, as shown,

and insert into the specimen holder, as shown. Turn

the sealing knob clockwise until the compressing

grommet squeezes the sealing sleeve sufciently

around the stem to hold it securely (Fig. 13).

Step 7

Holding the specimen holder by the closing cap, in-

sert the leaf sample into the pressure vessel and

then push the specimen holder down into place in

the pressure vessel. Pushing down with both thumbs

(one thumb on either side of the specimen holder, is

a good way to secure the specimen holder in place.)

Then, turn the specimen holder 45° clockwise, us-

ing the closing caps to lock it under the cams of the

pressure vessel.

Step 8

Tighten the sealing knob further, if necessary, to

be sure that the sealing sleeve is sealing properly

around the stem.

HOW TO USE AND/OR OPERATE THE UNIT

Fig. 13 - Stem insertion into the specimen holder

10

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

Step 9

Turn the control valve to the PRESSURIZE position (Fig. 10).

Step 10

Slowly open the metering valve, by turning it counterclockwise, and observe the pressure buildup on

the readout gauge (Fig. 09). Adjust valve until rate of increase is in the range of 5-10 psi per second or

at the rate you desire for the test.

Step 11

To stop the build up of pressure within the vessel at any time, simply turn the control valve (Fig.10) to

the “OFF” position. To resume build up of pressure, turn the control valve slowly to the “PRESSURIZE”

position.

Note: if the control valve is turned quickly to the “PRESSURIZE” position after an interruption in pres-

sure build up, as above, there will be a quick jump in pressure of a few pounds within the pressure

vessel. This is caused by the high pressure gas that builds up in the connecting tube between the

metering valve and the control valve while the control valve is in the “OFF” position. When the control

valve is opened quickly, this small volume of high pressure gas (supply pressure -600 psi) discharges

immediately into the pressure vessel. Thereafter, the metering valve limits the ow.

Step 12

The build up of pressure within the vessel can also be stopped or reduced at any time by turning the

metering valve in a clock-wise direction. Once you know the approximate value for the equilibrium

pressure for the plant specimen being tested, it is usually desirable to reduce the rate of pressure build

up as you approach the equilibrium pressure so that the equilibrium value can more accurately be

determined.

Step 13

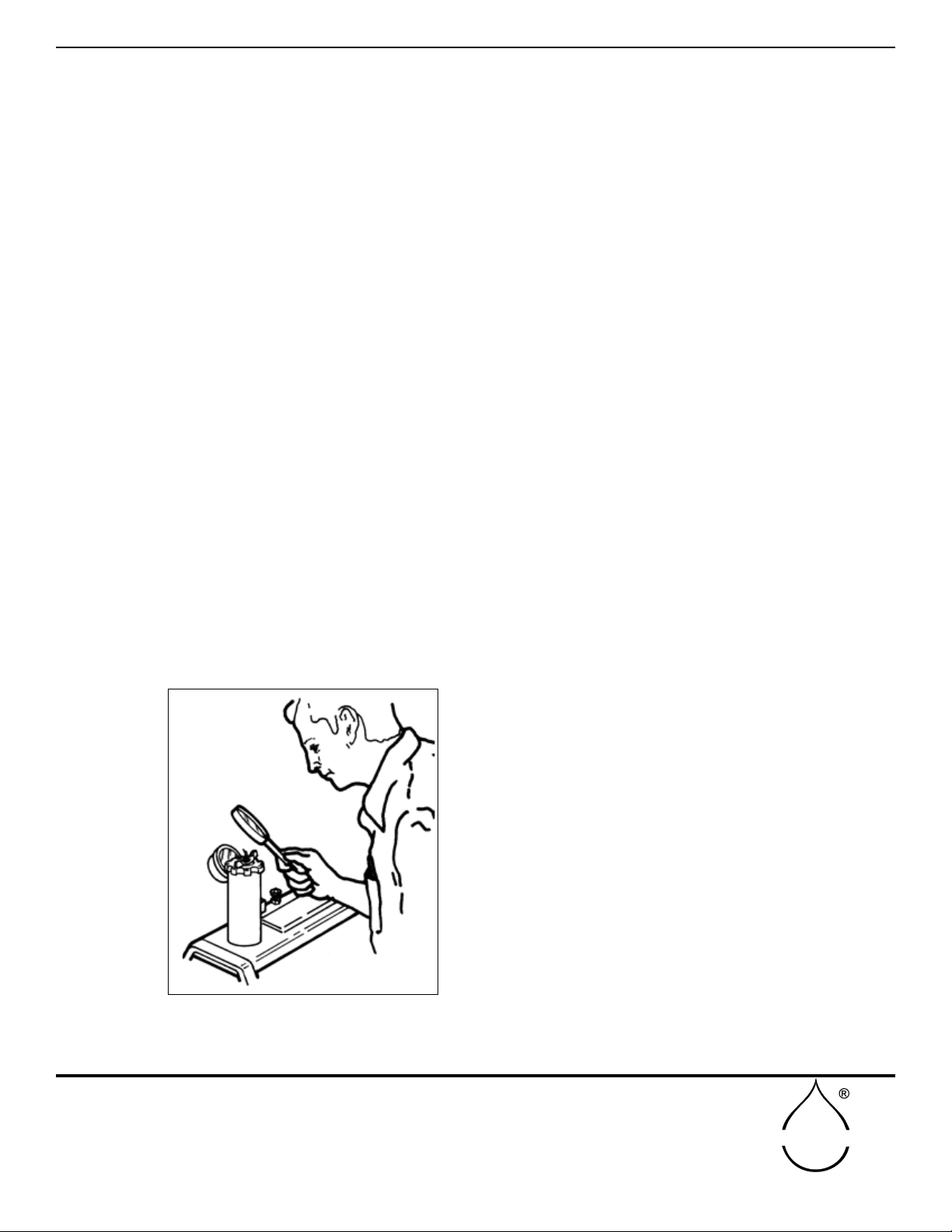

As pressure builds up in the pressure vessel, carefully observe the cut end of the petiole of the sample.

(Fig. 14)

If you hear air escaping around the sealing area of the sam-

ple, or if the stem seems to be “extruding” or moving up out of

the sealing sleeve, simply tighten the sealing knob further to

exert higher sealing pressure to stop the leak or movement.

CAUTION: Never put your eye directly over the center

of the pressure vessel during a run. Always observe the

sample stem from the side. Remember you are dealing

with high pressures and it is possible that a sample -

such as an individual needle from a pine tree - can be

ejected from the holder. It is recommended that the end

of the cut petiole be observed through a low-power mag-

nifying glass. The glass will give a better view and also

offers protection for the eyes.

Step 14.

The equilibrium pressure for the individual sample is reached

when sap starts to ow from the exposed cut end of the sam-

ple.

Fig. 14 - Observing the cut petiole of the sample

HOW TO USE AND/OR OPERATE THE UNIT (cont.)

11

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

After the sample has been mounted in the Plant Water Status Console(PWSC), and during the initial

stages of the pressure build up within the PWSC, the cut end will appear relatively dry. However, when

the equilibrium pressure is reached, the end will slicken up and be shiny and wet in appearance as sap

starts to ow from the end of the sample. If pressure is further increased, small bubbles may be formed

and arise in the extruded sap.

The build up of pressure should be stopped immediately when the cut end of the sample starts to

slicken in appearance by the extrusion of sap. The pressure reading at this point is the equivalent to

the negative force with which the plant water is held within that particular sample. After the equilibrium

pressure has been reached, one can verify the pressure immediately by dropping the pressure in the

pressure vessel below the equilibrium value. When this is done, you will note that the sap stops owing

immediately, pulls back into the stem of the sample, and the cut surface acquires the relatively dry ap-

pearance again. The build up can then be resumed again at a slow rate until sap again begins to ow.

You will note that the second equilibrium obtained matches very closely the rst reading.

Step 15

After this equilibrium value, sometimes referred to as plant

water potential or plant water stress, has been determined

and noted, pressure in the pressure vessel is exhausted

through the control valve by turning it to the “EXHAUST”

position.

The exhausting gas will make an appreciable noise de-

pending upon the pressure in the extraction vessel. The

exhaust port is underneath the control panel (Fig. 15) and

bafed by the end castings that hold the leg. The exhaust-

ing gas presents no hazard to the operator.

Step 16

Remove the sample by loosening the sealing knob slightly when the specimen holder is still in the pres-

sure vessel. Then, turn the closing cap of the specimen holder 1/8 turn (45 °) in a counterclockwise

direction.

Pull the specimen holder, with the specimen still in place, directly up out of the pressure vessel. Further

release the sealing pressure on the specimen by turning the sealing knob counter-clockwise until the

specimen and sealing sleeve can be readily removed.

The thrust washer will tend to remain in place in the specimen holder and can be left there to accept a

subsequent sample.

Step 17

If no further samples are to be run, shut off the compressed gas cylinder sealing valve. Remaining high

pressure gas within the system beyond the storage tank valve can be cleared, if desired, by turning the

control valve to the “PRESSURIZE” position with the metering valve opened somewhat. Under these

conditions, the gas in the system beyond the storage tank will exhaust through the pressure vessel.

After exhausting the pressure, turn the control valve again to the ‘OFF” position.

EXHAUST PORT

Fig. 15 - Exhaust Port

HOW TO USE AND/OR OPERATE THE UNIT (cont.)

12

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

HOW TO REPLACE THE COMPRESSED GAS CYLINDER

The compressed gas cylinder can be easily replaced with a full

tank or the tank can be lled from a larger supply tank without

removing it from the console.

Step 1

Set the console on end and support it so that it doesn’t fall over.

Step 2

Loosen and undo the 1-1/8 inch lock nut that holds the tank. A

1-1/8 inch open-end wrench or a crescent wrench of sufcient size

is required for this operation (Fig. 16). This lock nut has a right-

hand thread and therefore the nut must be turned in a counter-

clockwise direction to undo it.

When the lock nut is completely removed from the storage tank t-

ting, the pressure regulator will separate from the gas cylinder and

can be left hanging from its stainless steel connecting tube.

If the storage tank needs to be removed completely, loosen the

bottle bracket wing nut, then swing the closure bolt free from the

hinged bracket (Fig. 17).

The compressed gas cylinder can be relled with gas while it is

still mounted to the console after the regulator has been removed.

GENERAL CARE AND MAINTENANCE

Fig. 16 - Removing the tank by

loosening the bolt.

Fig. 17 - Disconnect the bracket

13

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

HOW TO REFILL THE COMPRESSED GAS CYLINDER

To ll the storage tank from a larger supply tank, our Model

0777L60 valved ller hose is used (Fig.18). The lock nuts

on the ends of the exible hose are tightened securely in

place on both tanks, using a 1-1/8” open-end wrench or

the equivalent. The tank valve on the small storage tank is

now opened rst.

The valve on the larger pressure supply tank is then

opened slowly so that the high pressure air from the large

tank can ow to the small tank. After a period of time, when

no further ow noise of gas is observed, the valve on the

large tank is sealed shut. The valve on the smaller tank is then closed securely. After the valves on both

tanks are closed, the lock nut on one end of the hose is loosened slowly. High pressure gas within the

exible hose will drain out of the loosened end. Thereafter, the exible high pressure hose is removed

from both tanks. After lling, the pressure regulator is again connected to the compressed gas cylin-

der. The round nose on the connection tting of the pressure regulator makes the pressure seal to the

compressed gas cylinder. The lock nut serves only to hold this round nose securely in contact with the

mating tting on the tank. The threads of the lock nuts themselves do not make a pressure seal.

Tighten the lock nut securely.

NOTE: If the compressed gas cylinder has

been removed from the console, be sure that

it is oriented in the proper position (Fig. 19), so

that the regulator ts correctly below the con-

sole.

The pressure gauge on the pressure regula-

tor should be in a "face up" position when the

storage tank is oriented properly.

Fig. 18 - Valve ller hose

Fig. 19 - Angle of the pressure regulator

GENERAL CARE AND MAINTENANCE (cont.)

14

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

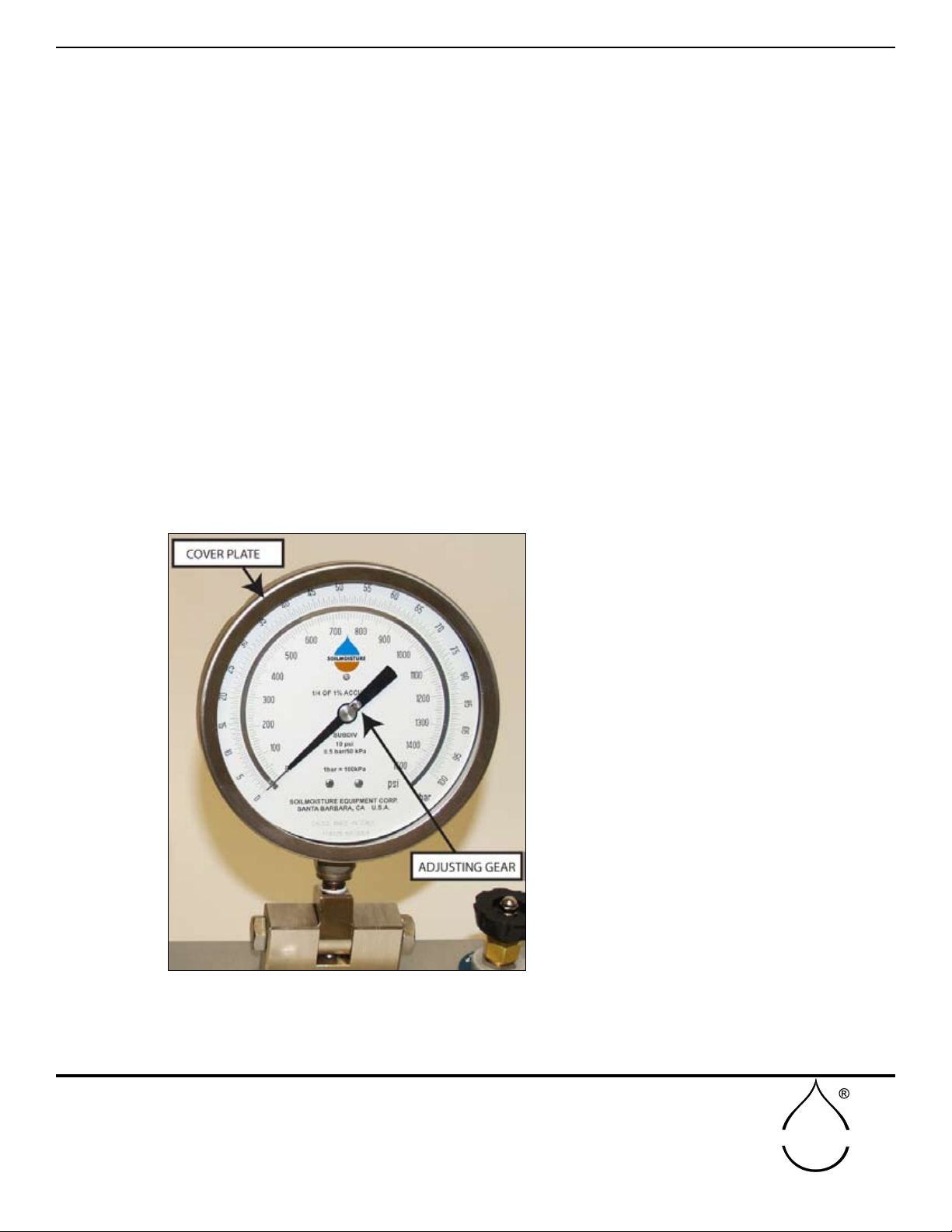

TO ADJUST THE ZERO POSITION OF THE PRESSURE READOUT GAUGE

In the event the pointer is jarred off of the zero position during transportation and handling, it can be

re-zeroed easily. To do this, unscrew the cover plate of the test gauge by turning it counterclockwise.

The zero adjusting gear (Fig. 20) on the gauge

pointer is then turned clockwise or counter-

clockwise with the adjusting tool supplied with

the unit to bring the pointer back to the zero po-

sition.

Replace the cover plate by screwing it on in a

clockwise position. Tighten securely to prevent

inltration of dust into the gauge.

Note: On special units the readout pressure

gauge is sometimes supplied with a friction-type

adjustable pointer. If this type of gauge is on

your unit, the zero position of the pointer is ad-

justed by grasping the knurled disc at the center

of the pointer and moving the pointer itself with

respect to this disc until the desired zero posi-

tion is obtained.

MINOR ADJUSTMENTS

Fig. 20 - Zero adjust

Keep the cam area and specimen holder "O" ring area and relief valve areas clean and free of •

dirt.

Do not block the bottom of the pressure vessel that could prevent air exhaust.•

Do not leave the pressure vessel pressurized while not in use.•

HELPFUL HINTS IN NORMAL USE

TROUBLESHOOTING

Leaking at the valve stem on the 3-way ball valve or metering valve

Remove handle and either remove stem nut to remove the stem assembly for cleaning, lubricating with

light oil and re-assembly or just tightening of the valve stem nut to stop the leaking. You may want to

just tighten the nut rst to see if that is all that is needed to stop the leak.

Locating leaks elsewhere when the unit is not holding pressure

Use soapy water and a small brush and check every joint in the system for leaks. Fix where possible.

15

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

Specimen Holders and Specified Grommets

SEALING

SLEEVES

STEM GROMMETS

(use with petioles)

LEAF GROMMETS

(use with leaves or grasses)

SUPPORT

WASHERS

3018G4BLKPKG05

1/2”OD,

BLANK

3018G4D062PKG05

1/2”OD,

1/16”DIAM. HOLE

3018G4D125PKG05

1/2”OD,

1/8”DIAM. HOLE

3018G4D187PKG05

1/2”OD,

3/16”DIAM. HOLE

3018G4D250PKG05

1/2”OD,

1/4”DIAM. HOLE

3019G4DBLKPK5

BLANK

3019G4D062PK5

1/16”DIAM. HOLE

3019G4D093PK5

3/32”DIAM. HOLE

3019G4D125PK5

1/8”DIAM. HOLE

3019G4D187PK5

3/16”DIAM. HOLE

3019G4D375PK5

3/8”DIAM. HOLE

3019G4D500PK5

1/2”DIAM. HOLE

3019G4UTE01PK5

1/16”WIDE x 1/4” ELIPSE

3019G4UTS01PK5

.050”WIDE x 1/2” SLOT

3019G4UTE02PK5

1/8”WIDE x 1/2” ELIPSE

3019G4UTA01PK5

1/8”WIDE x 1/2” ARC

3020G4BLKPK5

BLANK

3020G4D141PK5

9/64” DIAM. HOLE

3020G4D250PK5

1/4” DIAM. HOLE

3020G4D375PK5

3/8” DIAM. HOLE

3020G4D500PK5

1/2” DIAM. HOLE

3020G4UTE01PK5

1/16”WIDE x

1/2” SLOT

3020G4UTE02PK5

1/8”WIDE x

1/2” SLOT

3019G4D250PK5

1/4”DIAM. HOLE

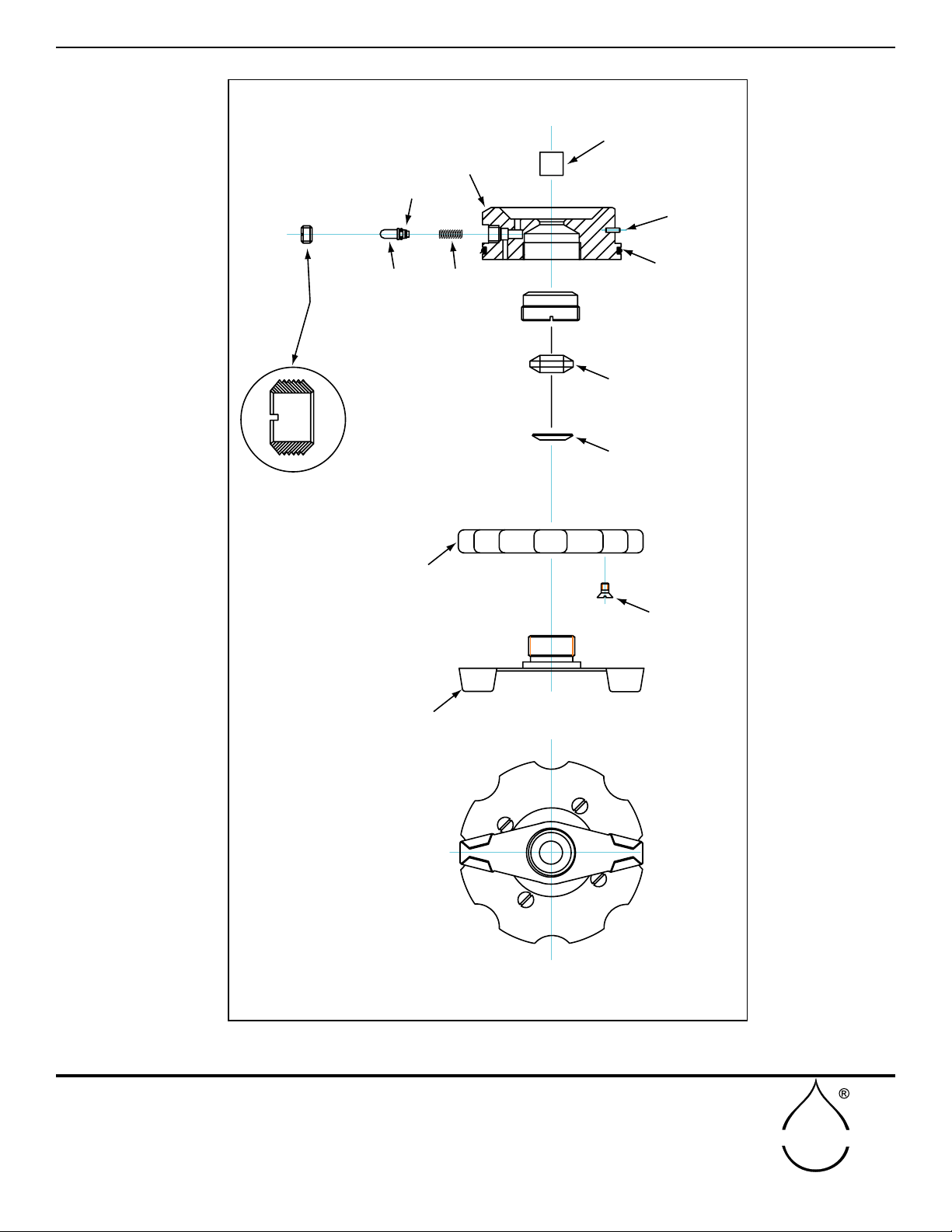

(Fig. 22) - Complete G4 Grommet kit (3019G4K3) shown above

The G4 Specimen Holder (Fig. 21) is a General Purpose Holder. It can be

set up to accept round petioles from 1/32 inch diameter to 1/2 inch diameter;

for short petioles from 1 cm long; and for blade-type leaves up to 1/2 inch

wide and on mid-vein of larger leaves. Above, (Fig. 22) are the range of

Grommets, Sealing Sleeves, and Support Washers used with the Plant Water Status Console using

the G4 Specimen Holder.

The rst stem Grommet, second column, (Fig. 22),a solid Grommet (no hole), can be used for testing

the system for leakage or to make your own Grommet. The next ve Grommets in the same column,

are used for testing petioles from the size of pine needles up to thick leaves, selection based on the size

of the petiole to be tested. The last item in the row, with the very large hole, is a Grommet that accepts

the sealing sleeves shown in the rst column (Fig. 22).

Rather than disassembling the specimen holder for each test, the sealing sleeves can be quickly taken

in and out of the Grommet for fast sampling.

The Grommets with slits in them, third column, (Fig. 22), are usually used for testing large leaves or

grass blades.

The G4 Series Brass Support Washers, fourth column, (Fig. 22), are used in conjunction with the

Grommets to protect the Grommet when the knob is tightened, thereby providing equal pressure over

the entire surface of the Grommet. The Support Washers also prevent the Grommet from being pushed

out of the specimen holder when pressurized.

(Fig.21) Model 3015G4

Specimen Holder

16

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

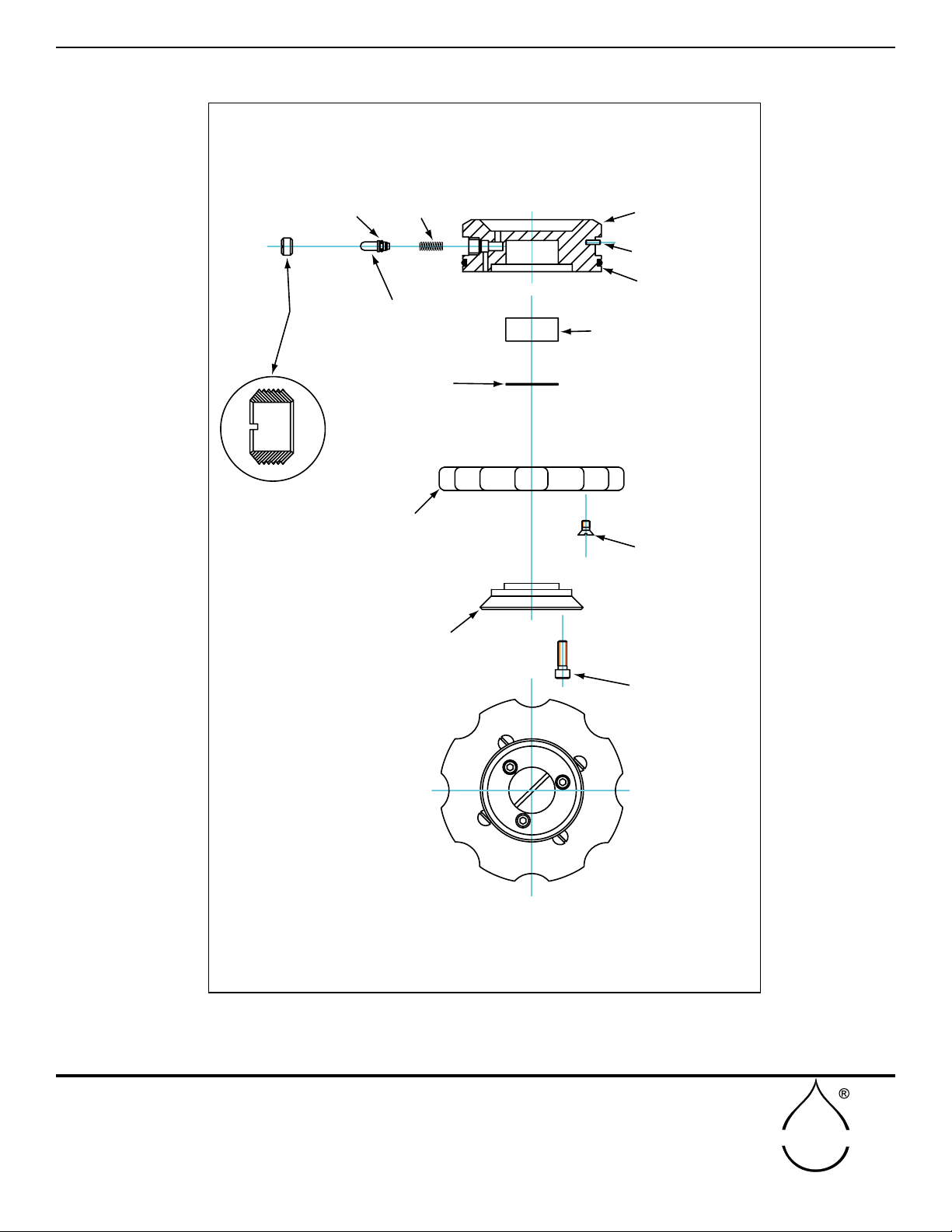

3015G4-100

M802X003

M802X149PKG04

MSL014-005

MSM002-002

Q0832CAQ05

3015G1-004

3015G4-001

3015G4-003

3015G4-002

SEALING KNOB

O-RING

PIN 3/32 DIA x 5/16

SCREW, FLT HD 8-32 x 5/16

SPRING

O-RING

SUPPORT WASHER

SEALING SLEEVE

GROMMET

HOUSING

CLOSING RING

INSERT

PISTON

DESIGNED TO ACCEPT ROUND PETIOLES FROM 1/32”DIA. TO 1/2” DIA.

Model 3015G4 Specimen Holder Assembly

Z3015G1-005

RETAINING COLLAR

(LARGER VIEW)

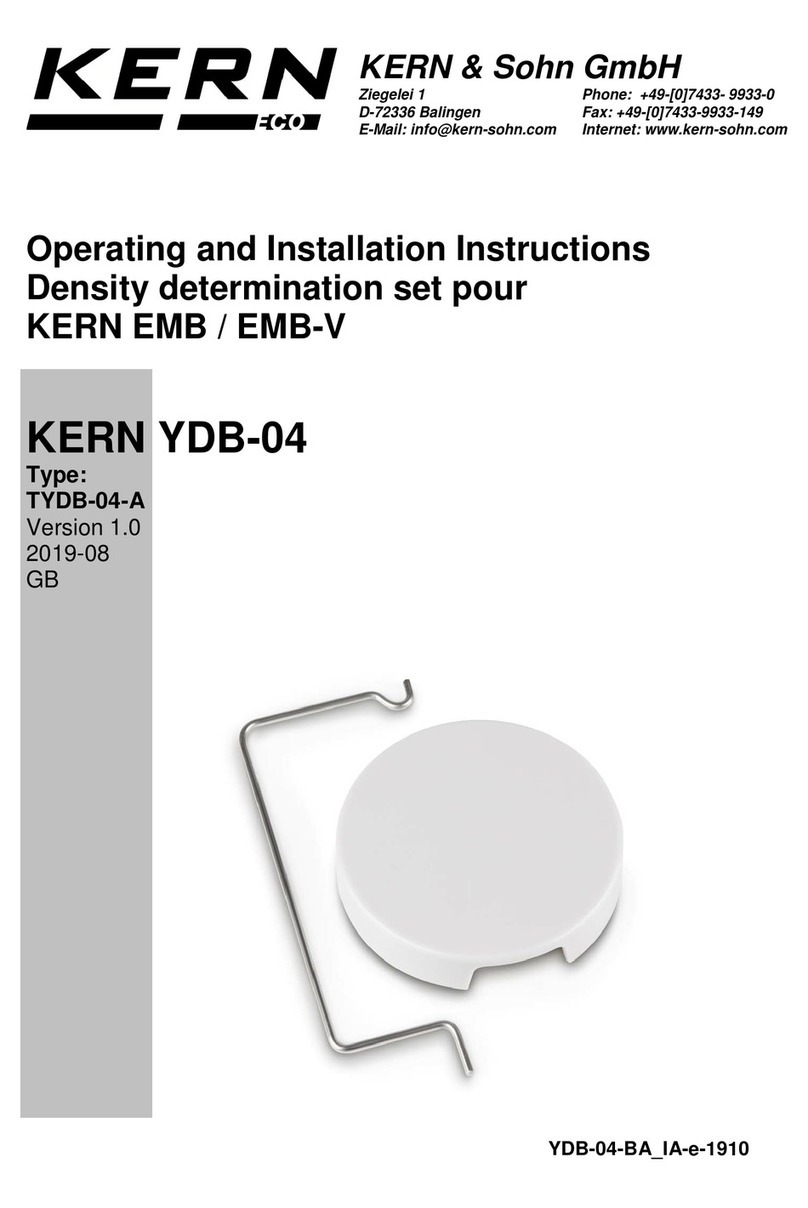

Fig. 23 - Replacement parts for Model 3015G4

Specimen Holder Assembly

G4 Specimen Holder REPLACEMENT PARTS

17

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

3017G2WBLKPKG05

BLANK

3017G2WRZRPKG05

RAZOR CUT

3017G2W090PKG05

SLOT 1.5” X .094

3017G2W050PKG05

SLOT 1.15” X .050

3021G2-000K1

BLANK

3021G2-001K1

1/16” SLOT

GROMMETS

SUPPORT

WASHERS

The G2 Specimen Holder (Fig. 25) is used specically for blade-type leaves up to 1 inch in width.

The items shown in the left column of (Fig. 24), are called Grommets. They are for use with broad

leaves or grasses; and the brass items shown, in the right column, are called Support Washers.

NOTE: The 3017G2 Series Grommets can only be used with the G2 Specimen Holder.

(Fig.24) MODEL 3017G2K1

G2 Series Complete Grommet Kit

G2 Specimen Holder (used for Blade-type Leaves)

(Fig.25) Model 3015G2

Specimen Holder

18

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

3015G4-003

MSM002-002

Q1024CAF10

Q0832CAQ05

M802X003PKG05

M802X149PKG04

MSL014-005

3015G1-004

Z3015G1-005

3015G2-002

3015G2-001

CLOSING RING

SCREW, FLT. HD. 8-32 X 5/16

SCREW, SOC.HD.CAP

10-24 X 5/8

SPRING

SEALING SLEEVE

SUPPORT WASHER

0-RING

O-RING

ROLL PIN

COMPRESSION RING

RETAINING COLLAR PISTON

HOUSING

DESIGNED TO ACCEPT BLADE-TYPE LEAVES UP TO 1” IN WIDTH.

Model 3015G2 Specimen Holder Assembly

(LARGER VIEW)

Fig. 26 - Replacement parts for Model 3015G2

Specimen Holder Assembly

G2 Specimen Holder REPLACEMENT PARTS

19

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

NOTES

20

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

sales@soilmoisture.com - www.soilmoisture.com

SOILMOISTURE

NOTES

This manual suits for next models

1

Table of contents

Other Soilmoisture Equipment Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

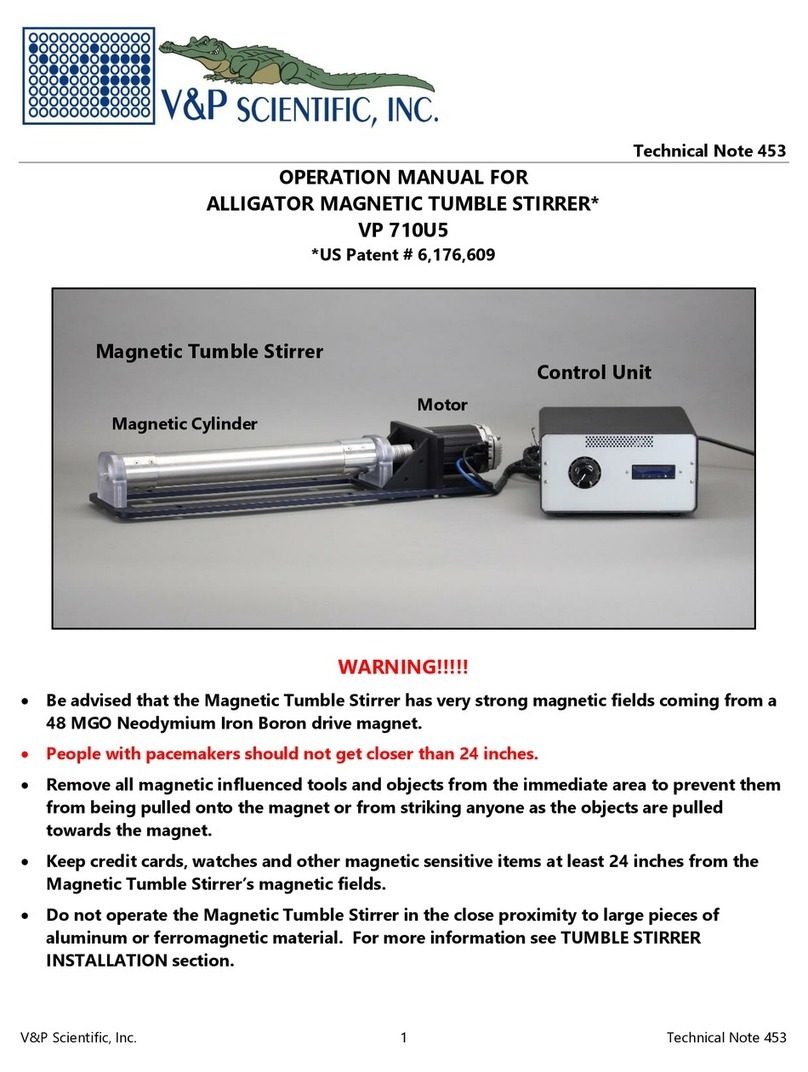

V&P Scientific

V&P Scientific VP 710U5 Operation manual

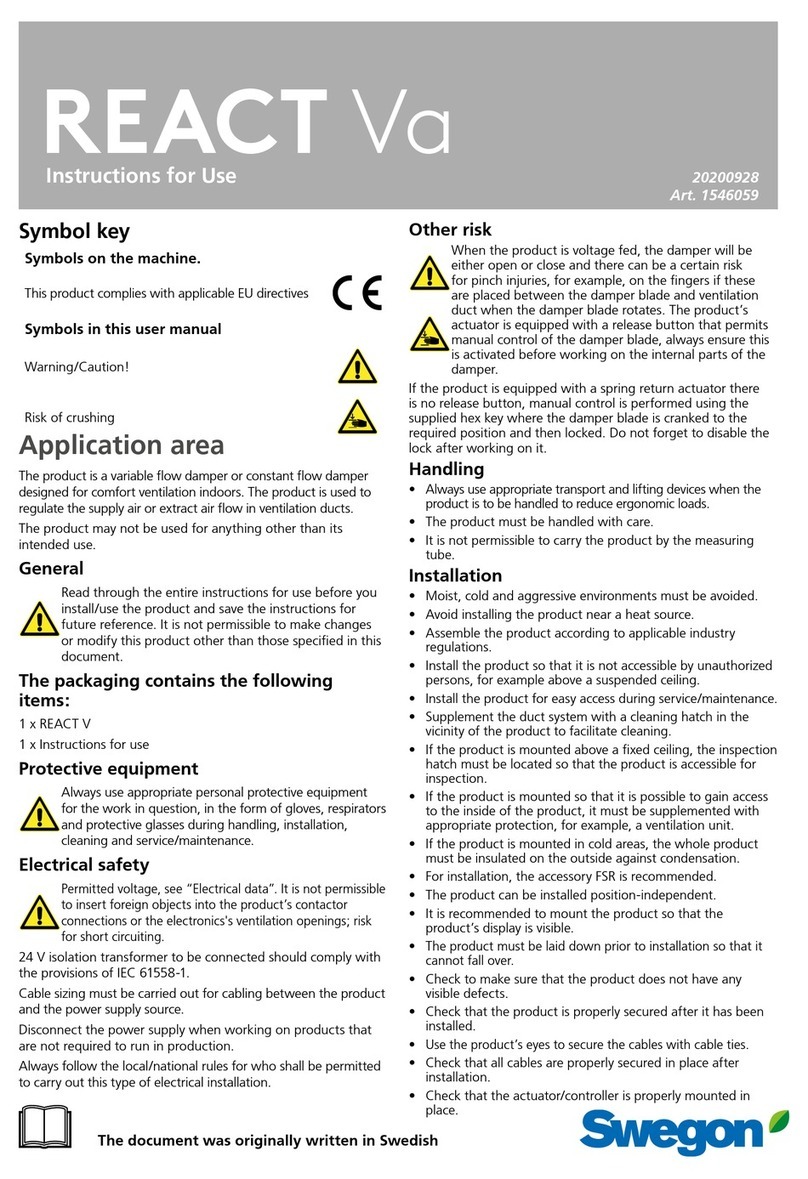

Swegon

Swegon REACT Va Instructions for use

Sartorius

Sartorius Vivaspin 500 operating instructions

PreOmics

PreOmics BeatBox user manual

Nickel-Electro

Nickel-Electro NE4-T Series manual

Thermo Electron

Thermo Electron 3911 Operating and maintenance manual

Welch Allyn

Welch Allyn RetinaVue 100 Imager Directions for use

Binder

Binder C 170 operating manual

Hettich

Hettich MIKRO 200 operating instructions

Cole Parmer

Cole Parmer Geno/Grinder HG-600 quick start guide

VERDER

VERDER Carbolite Gero HTMA 7/220 Installation, operation and maintenance instructions

Drawell

Drawell Gentier 96E user manual