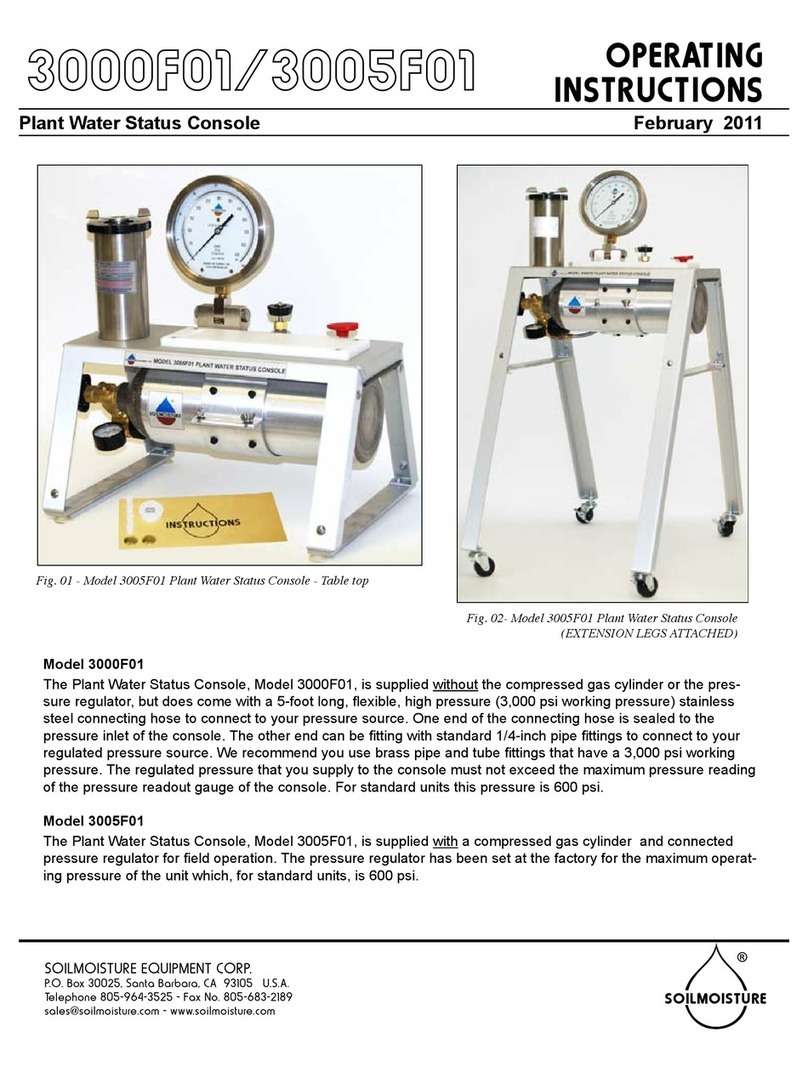

Soilmoisture Equipment 2900F1 User manual

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

SOILMOISTURE

INSTRUCTIONS

OPERATING

Model 2900F1 “QUICK DRAW” SOILMOISTURE PROBE May 2012

The 2900F1 QuickDraw Soilmoisture Probe is the most effective portable moisture measuring instrument

available. Designed for rugged eld use, the thermos construction utilizing capillary tube connections and super

porous ceramic tip assures fast response and accurate readings, independent of temperature differences. The self-

servicing feature, unique in tensiometer construction, eliminates the need for accessory service kits, and assures fast

response times after years of use.

The Probe is shipped in a dry condition for greater convenience in handling and storage over a period of time. Fol-

low the simple instructions to water ll your unit in preparation for use.

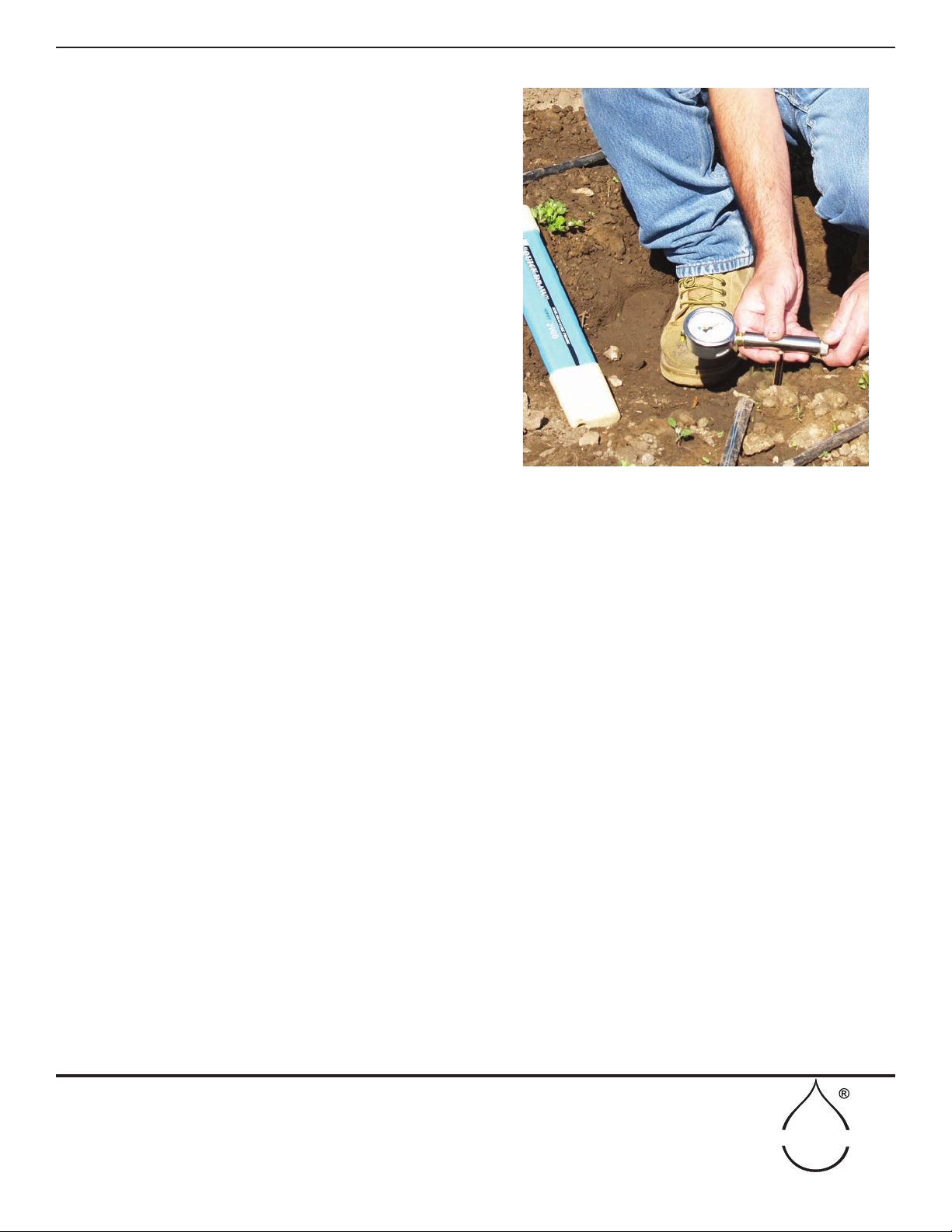

Figure 1 - 2900F1 Soilmoisture "Quick Draw" Probe

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

SOILMOISTURE

2

TABLE OF CONTENTS

Table of Contents.................................................................................................................................................... Page 2

Unpacking ...................................................................................................................................................... Page 3

Cautions & Warnings.............................................................................................................................................. Page 3

Warranty & Liability............................................................................................................................................... Page 3

Aquaint Yourself With The Parts ........................................................................................................................... Page 4

Theory of Operation................................................................................................................................................ Page 5

Requirements Prior to Use/Initial Filling................................................................................................................ Page 5

IMPORTANT NOTE ................................................................................................................... Page 5

Venting and Adjusting Dial Gauge............................................................................................... Page 6

Effects of Altitude on Operation of the Probe .............................................................................. Page 6

Initial Filling ................................................................................................................................. Page 7

Response Time too long .............................................................................................................. Page 10

About the Dial Gauge and Carrying Case ................................................................................... Page 10

Making a Soil Moisture Measurement................................................................................................................... Page 11

Coring a hole................................................................................................................................ Page 11

Inserting the Probe....................................................................................................................... Page 12

Making a Reading.................................................................................................................................................. Page 13

Dial Gauge Pressure Build-up ..................................................................................................... Page 14

Irrigation Scheduling ................................................................................................................... Page 15

Routine Measurements........................................................................................................................................... Page 16

Potted Plants ................................................................................................................................ Page 16

Using a number of probes at the same time................................................................................. Page 16

Troubleshooting......................................................................................................................................................Page16

Substantial change in the Vacuum Level..................................................................................... Page 16

Lack of response from Gauge...................................................................................................... Page 17

50 centibars cannot be reached.................................................................................................... Page 17

Replacing the Ceramic Tip .................................................................................................................................... Page 18

Replacing the Dial Gauge...................................................................................................................................... Page 20

Time Required to make a Reading......................................................................................................................... Page 22

Care and Maintenance............................................................................................................................................ Page 23

Tips for Scheduling Irrigations .............................................................................................................................. Page 24

Parts List ..................................................................................................................................................... Page 26

3

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

SOILMOISTURE

Soilmoisture Equipment Corp. (SEC) warrants all products manufactured by SEC to be free

from defects in materials and workmanship under normal use and service for twelve (12) months

from the date of invoice provided the section below has been met.

Soilmoisture Equipment Corp. (SEC) is not liable for any damages, actual or inferred, caused

by misuse or improper handling of its products. SEC products are designed to be used solely as

described in these product operating instructions by a prudent individual under normal operating

conditions in applications intended for use by this product.

WARRANTY & LIABILITY

UNPACKING

CAUTIONS & WARNINGS

The Soilmoisture "Quick Draw" Probe should be removed from the eld prior to the onset of

freezing conditions. Since the Probe is a water-lled system, it is essential that the unit be stored

and used at temperatures above freezing. Freezing temperatures, of course, will cause the water

within the unit to freeze and expand as ice is formed. This can cause breakage of the ceramic

tip and distort or rupture the thin-walled Bourdon tube within the dial gauge.

If the Bourdon tube is ruptured, the dial gauge cannot be repaired and will have to be replaced.

If the Bourdon tube is distorted but not ruptured, it may be possible to reset the pointer on the

gauge to correct the change in calibration caused by freezing.

Intense heat can cause the plastic Carrying Case to distort and can result in the evaporation of

all water from the sponge within the Carrying Case. This will be detrimental to the operation

of the Soilmoisture Probe. It will also result in frequent servicing for removal of air. Do not

subject the Soilmoisture Probe to intense heat while storing or transporting it. Very high tem-

peratures can develop within a closed cab of a truck or the trunk of a car.

Not Liable for improper use. Remove all packing materials and check the 2900F1 Soilmois-

ture "Quick Draw" Probe for any damage that may have occurred during shipment. If the

Sampler is damaged, call the carrier immediately to report it. Keep the shipping container and

all evidence to support your claim.

Do not bump or drop the dial gauge or ceramic sensing tip or they could break and will need to

be replaced. Take care not to let the sensing tip come in contact with grease or any other similar

material that could clog the pores of the ceramic.

Please verify that your shipment is complete.

4

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

Figure 2 - 2900K1 Parts

AQUAINT YOURSELF WITH THE PARTS

The Probe, Coring Tool, and Cleaning Rod are held in place by the molded plastic

retainers at the top of the Carrying Case.

NOTE: The Probe ts into the side of the Carrying Case marked “PROBE”, and

the Coring Tool ts into the side marked “CORING TOOL” (Fig. 3).

It is very important to keep the Probe in the side of the Carrying Case marked

“PROBE” when it is not actually being inserted in the soil, because this side of the

Carrying Case has a water storage reservoir, or sponge cartridge, at the bottom.

During the “Initial Filling” operation, pictured and described on pages 7 through

10, you will ll the water storage reservoir. Thereafter, the sensing tip of the Probe

will be kept moist.

An Accessory Kit (2900FK1) is provided with each Probe. It consists of a small

screwdriver, a 3/32” Allen Wrench, Replacement Ceramic Sensing Tips, O-Rings

and ¼ Oz. Silicone Grease Kit. The screwdriver is used to vent and adjust the dial

gauge and to replace the Sensing Tip. The Allen Wrench is used in the event the

Vacuum Dial Gauge needs replacement.

PROBE CORING

TOOL

CLEANING

ROD

PROBE

CASE

Figure 3 - Probe Case Tool Placement

DIAL GAUGE

NULL KNOB

POROUS CERAMIC

SENSING TIP

CLEANING RODCARRYING CASE PROBE CORING TOOL

WATER STORAGE

RESERVOIR

(SPONGE CARTRIDGE)

ACCESSORY

KIT

TOP

TOP

GREASE

SILICONE

MFJ012PK

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

55

THEORY OF OPERATION

The Model 2900F Soilmoisture Probe is a tensiometer-type instrument that reads soil

suction directly. The “soil suction” reading is a direct measure of the availability of

moisture for plant growth, and the standard unit of measurement is the “bar”. The bar*

is a unit of pressure in the metric system and is used to dene positive pressure (above

atmospheric pressure), or negative pressure or vacuum (below atmospheric pressure).

The gauge on the Probe is calibrated in hundredths of a bar (or centibars) of vacuum,

and is graduated from zero to 100.

In scientic work, it is becoming customary to express pressures and vacuums in a

unit of measure called a “Pascal”, and a “Kilopascal” which is 1000 times as large as

a Pascal. A “centibar”, as used above, is exactly equal to a Kilopascal. Therefore, the

dial gauge on the Probe also reads in Kilopascals and is graduated from zero to 100

Kilopascals (KPa).

Soil suction is actually created by the attraction that each soil particle has for the water

in the soil. Because of this attraction, water forms a lm around each particle of soil

and collects in the capillary spaces between the soil particles. As the soil becomes

drier, these lms become thinner and the attraction or soil suction increases. The plant

root has to over-come this soil suction, or attraction force, in order to withdraw mois-

ture from the soil. The measurement of soil suction then gives a direct indication of the

amount of work the plant root must do to get water from the soil. The only moisture

measuring instruments that accurately measure soil suction are those using the ten-

siometer principle. These instruments read centibars of soil suction directly without

calibration for soil type, salinity, or temperature.

When the Probe is inserted into the cored hole, there are various effects associated with

the movement of the porous ceramic sensing tip through the soil. The soil surrounding

the tip is slightly compacted and the wiping action of the porous ceramic through the

soil causes small thermal effects. It takes a few moments for these disturbances to dis-

perse, and this is the reason that it is not desirable to move the Null Knob for the rst

minute after insertion of the Probe.

In order to obtain a soil suction reading, it is necessary for a small amount of water

to transfer between the sensing tip of the Probe and the soil. When the Null Knob is

turned clockwise, water is forced out of the Probe sensing tip and into the surrounding

soil. When the Null Knob is turned counterclockwise, a vacuum is created within the

Probe, which causes moisture to move from the soil through the ceramic sensing tip

and into the Probe. In order to obtain an accurate reading within the minimum amount

of time, one must be careful not to disturb the moisture conditions surrounding the

Sensing Tip.

IMPORTANT NOTE: When examining the Probe, DO NOT leave the porous

ceramic sensing tip exposed to the air for prolonged periods.

When the Probe is removed from the Carrying Case and the Sensing Tip is not kept

moist, evaporation of moisture from the Tip will pull the dial gauge up to a very high

centibar reading. Under these conditions, air can diffuse through the water in the pores

of the Sensing Tip and enter the Probe, which can result in a decrease in sensitivity and

require a relling cycle.

REQUIREMENTS PRIOR TO USE

6

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

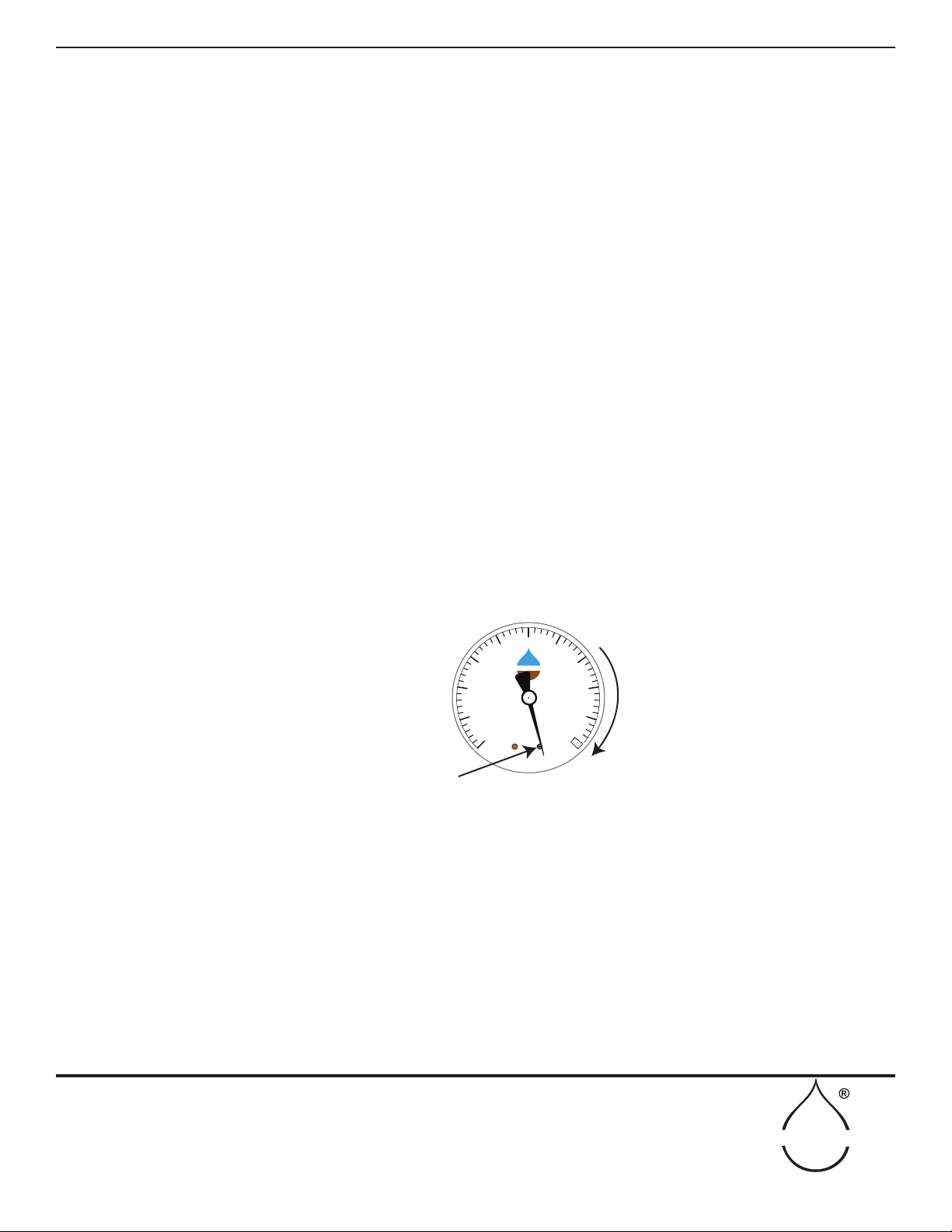

Venting and Adjusting

the Dial Gauge

The 2060FG dial gauge is hermetically sealed, therefore, the vent pin must be

pressed prior to use. Temperature or altitude changes could create internal pressure

which could give a less accurate reading.

First, simply press the vent pin located, at the top of the gauge, to release any col-

lected air. Located on the face of the gauge is an insertion point for a small at-

head screwdriver. If the gauge is reading high, turn the screwdriver clockwise an

estimated amount to correct the error. If the gauge reads low, turn the screwdriver

counterclockwise an estimated amount to correct the error. Repeat the process if

necessary until the pointer is on zero.

VENT PIN

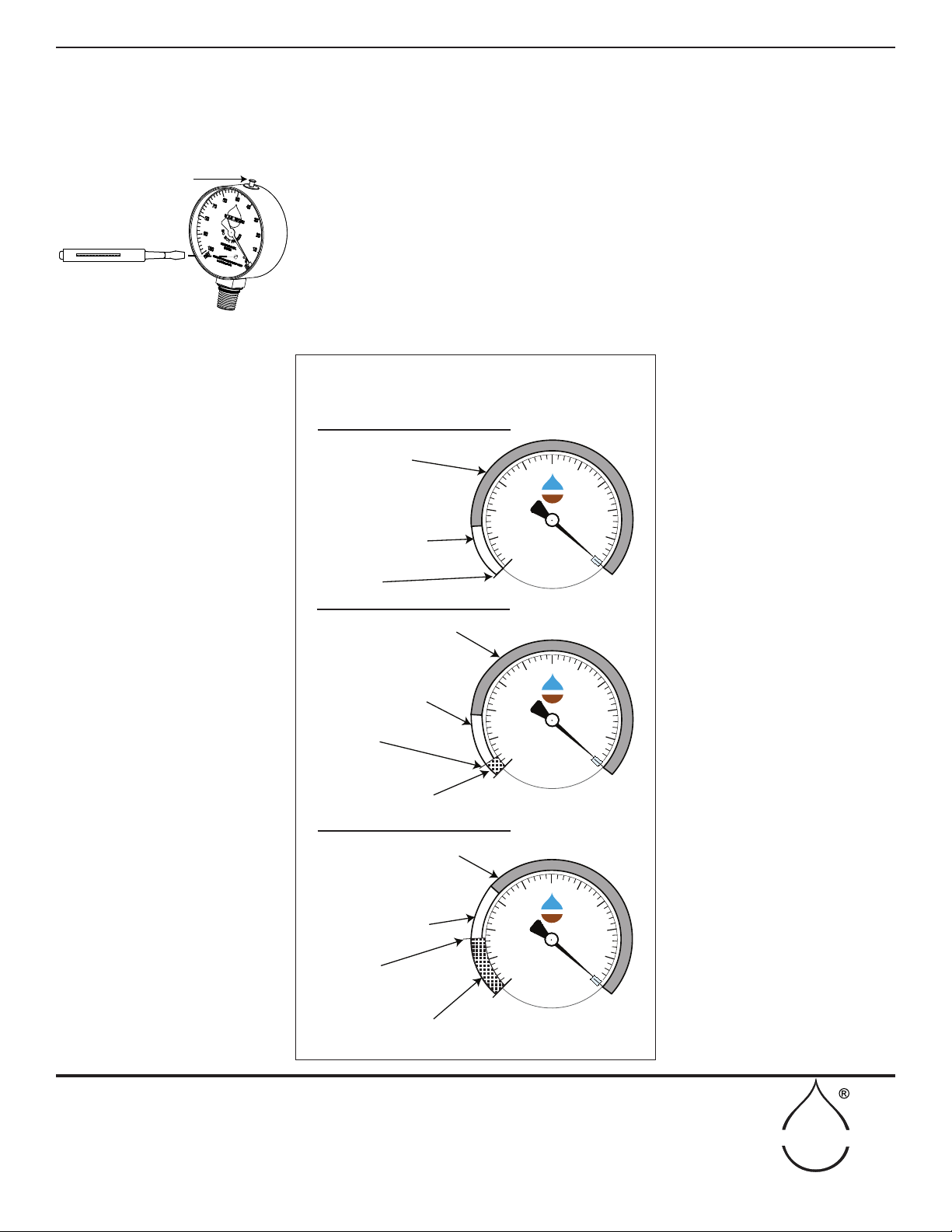

EFFECTS OF ALTITUDE ON OPERATION OF THE PROBE

PRACTICAL READING RANGE

0 TO 85 CENTIBARS

IN THIS RANGE AIR COMING

OUT OF SOLUTION MAKES

READING INACCURATE

THEORETICAL LIMIT

OF READING

AT SEA LEVEL

PRACTICAL READING RANGE

0 TO 81 CENTIBARS

IN THIS RANGE AIR COMING

OUT OF SOLUTION MAKES

READING INACCURATE

THEORETICAL LIMIT

OF READING

IN THIS RANGE WATER

BREAKS INTO A VAPOR

CAUSING UNIT TO LOSE

ALL OF ITS WATER

AT 1000 FT.

ABOVE SEA LEVEL

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

10

0

DRY

WET

100

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

10

0

DRY

WET

100

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

AT 5000 FT.

ABOVE SEA LEVEL

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

10

0

DRY

WET

100

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

PRACTICAL READING RANGE

0 TO 68 CENTIBARS

IN THIS RANGE AIR COMING

OUT OF SOLUTION MAKES

READING INAACURATE

THEORETICAL LIMIT

OF READING

IN THIS RANGE WATER

BREAKS INTO A VAPOR

CAUSING UNIT TO LOSE

ALL OF ITS WATER

The Reading Range is Reduced Approximately 3.5 Centibars

for Each 1000 Ft. Increase in Elevation

Figure 4 - Venting and adjusting the gauge

Figure 5 - Effects of Altitude

REQUIREMENTS PRIOR TO USE (CONT.)

7

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

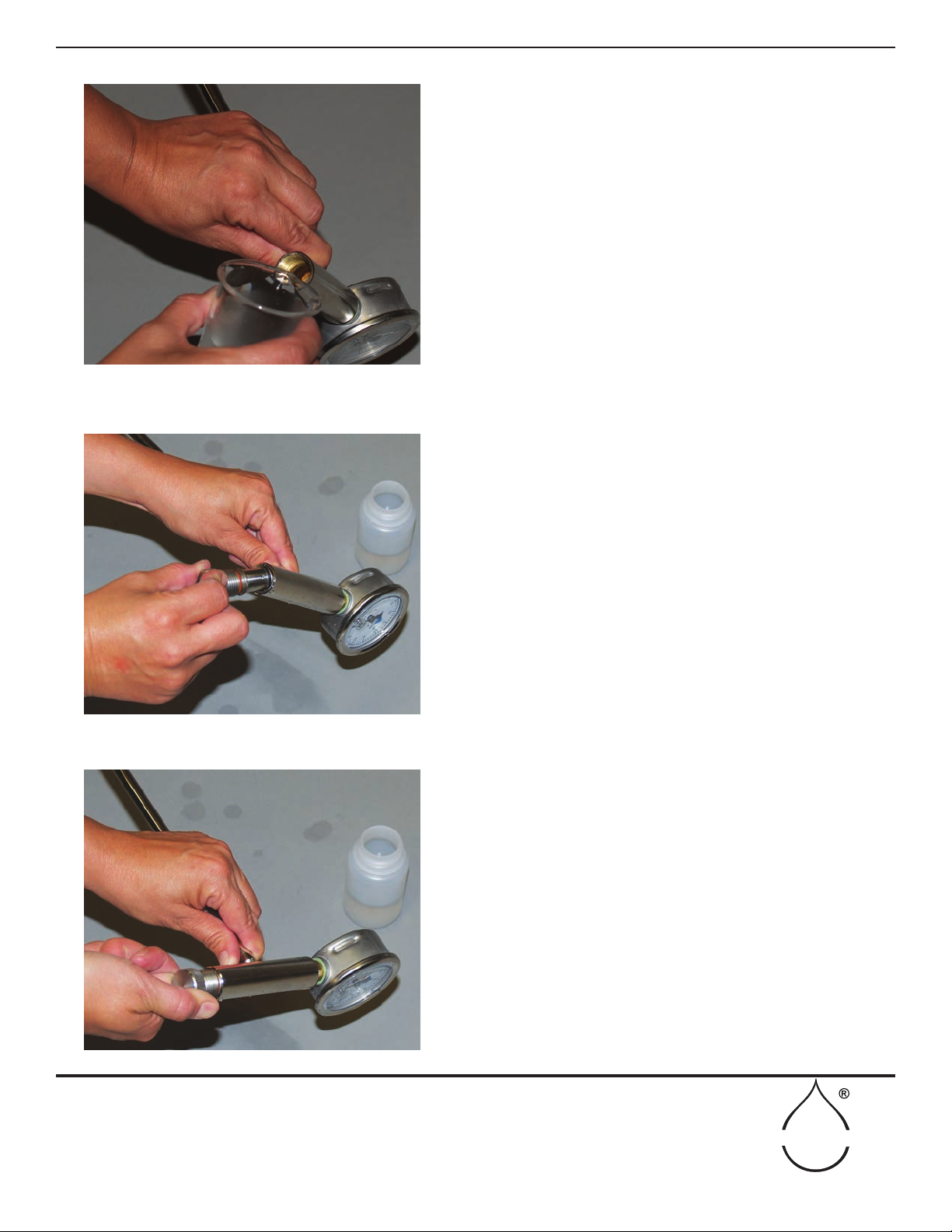

STEP 1

Turn Null Knob clockwise as far as it will go and then

insert the porous ceramic sensing tip in water.

STEP 2

Keep the sensing tip in water. Turn the Null Knob coun-

terclockwise until you just see the red ring.

On initial lling, the pointer will normally rise to a reading

of 40 to 50. Let the pointer drop to zero.

STEP 3

Keep the sensing tip in water. Continue to turn the Null

Knob slowly counterclockwise until it is loose and can be

removed.

REQUIREMENTS PRIOR TO USE / INITIAL FILLING

RED RING

Figure 8

Figure 7

Figure 6

8

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

STEP 4

Fill the handle with water. A teaspoon works well for this

operation. Water should be poured into the handle slowly

and carefully so that air bubbles are not trapped. If you see a

bubble clinging to the smooth wall or bottom of the handle

cavity, nudge it free with the sharp end of a pencil.

STEP 5

Screw the Null Knob completely back in the Handle, which

will push out excess water.

While you are doing this, water will ooze out through the

porous ceramic tip and drip off the end.

STEP 6

Turn the Null Knob clockwise as far as it will go.

REQUIREMENTS PRIOR TO USE / INITIAL FILLING (cont.)

Figure 10

Figure 11

Figure 9

9

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

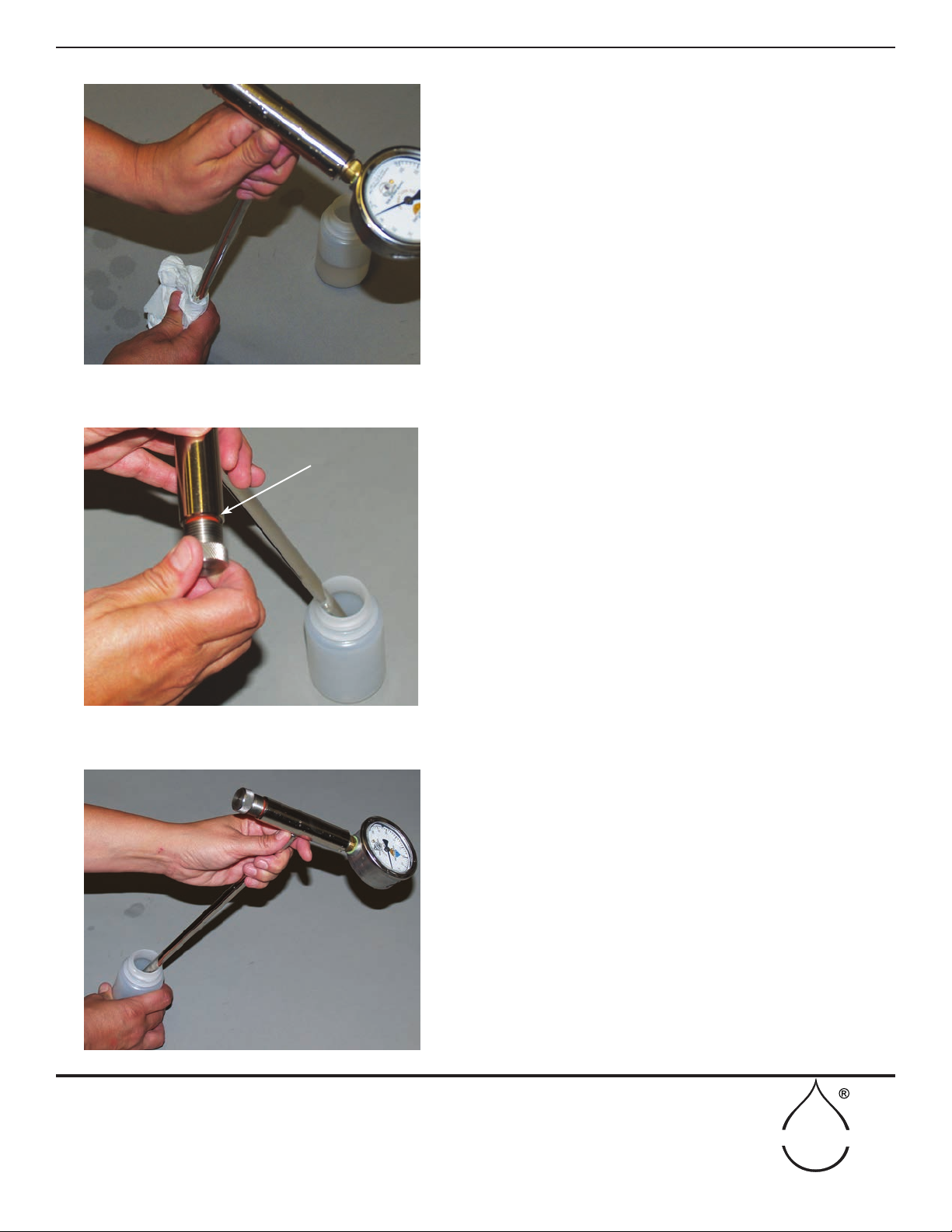

STEP 7

Remove the tip from the water and dry it with an absorbent

tissue. The dial pointer will rise to a reading of 20 or 30 as

moisture is pulled into the dry tissue.

STEP 8

Turn the Null Knob counterclockwise until you just see the

red ring. The pointer will normally rise to a reading of 80

or 90 centibars if you live at an elevation between sea level

and about 2000 ft. If you live at higher elevations, the maxi-

mum reading will be somewhat lower. See page 14, which

describes the effect of altitude on the operation of the Probe.

If the pointer does not rise it can mean that rough handling

has cracked the porous ceramic sensing tip. See section on

“Care and Maintenance” for corrective action.

STEP 9

Immerse the porous sensing tip again in water and wait until

the pointer drops to zero.

REQUIREMENTS PRIOR TO USE / INITIAL FILLING (cont.)

RED RING

Figure 13

Figure 12

Figure 14

10

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

STEP 10

Repeat Step 3, removing the Null Knob again while the sensing tip is in the

water. Repeat Steps 4, 5, and 6, again relling the handle with water. Insert

the Null Knob and turn it clockwise as far as it will go.

STEP 11

Check Response Time. To do this, wipe the Probe and porous ceramic tip

with absorbent tissue to remove all excess water. Turn the Null Knob until

the pointer reaches a reading of 50 on the dial. Now when you dip the sensing

tip in the water, the pointer will normally drop from a reading of 50 to 10 in

approximately one second - the time that it takes to say “one, one thousand”.

The Probe is ready for use if the response time is approximately one second.

STEP 12

Fill the Carrying Case tube, which is labeled “PROBE” with water and allow

it to stand for a minute or two (Fig.15). This will ll the sponge cartridge with

water. Empty out excess water and insert the Probe. The sponge cartridge in

the Carrying Case will now keep the porous ceramic sensing tip wet so it is

ready to use at any time in the eld. In the future, always keep the Probe in

the Carrying Case when not in use.

REQUIREMENTS PRIOR TO USE / INITIAL FILLING (cont.)

After initial lling, if the response time is considerably more than one second, it usu-

ally indicates that an air bubble has been trapped in the handle. To correct this, simply

repeat Steps 8 and 9, then Steps 3, 4, 5, and 6. Again look into the handle cavity after

lling to see if there are any bubbles clinging to the internal wall. In the event there

are bubbles, simply nudge them loose with the sharp end of a pencil. Fill the cavity in

the handle to the top, replace the Null Knob, wipe it dry, and again check the response

time.

NOTE: The pointer may have to be adjusted after the lling operation.

When the Probe is in the Carrying Case and is held vertically, the pointer on the dial

gauge should read zero. You will note, however, that if the Carrying Case is tipped

horizontally, the pointer on the dial gauge will read below zero. This is caused by the

shift in weight of the water column within the Probe. For normal use, the dial pointer

is set at zero when the Probe is held vertically and only when the ceramic sensing tip

is immersed in water. For pointer setting instructions, refer to page 6, "Venting and

Adjusting the Dial Gauge".

Response time is too

long

About the Dial Gauge

and Carrying Case

Figure 15 - Filling the probe with water

11

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

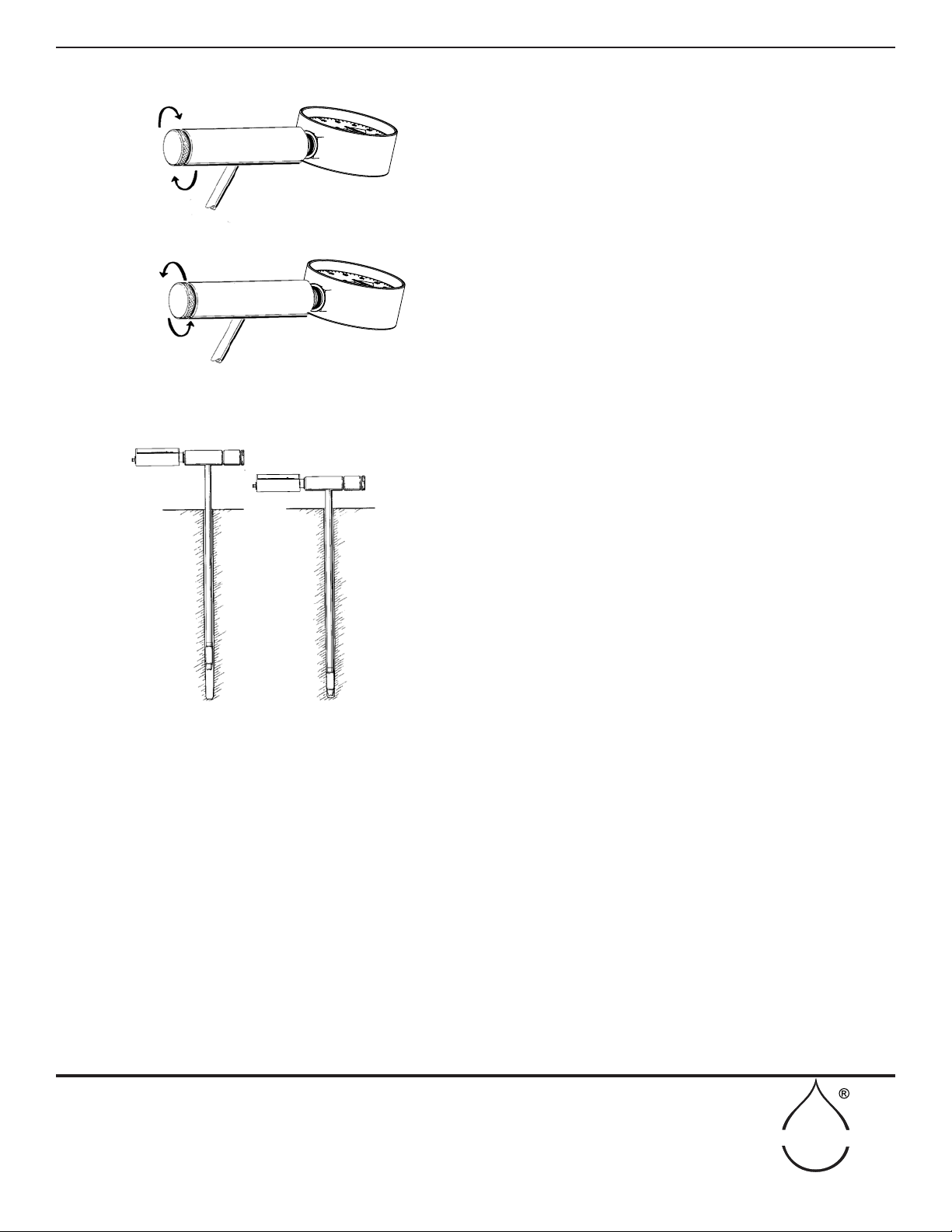

CORING A HOLE

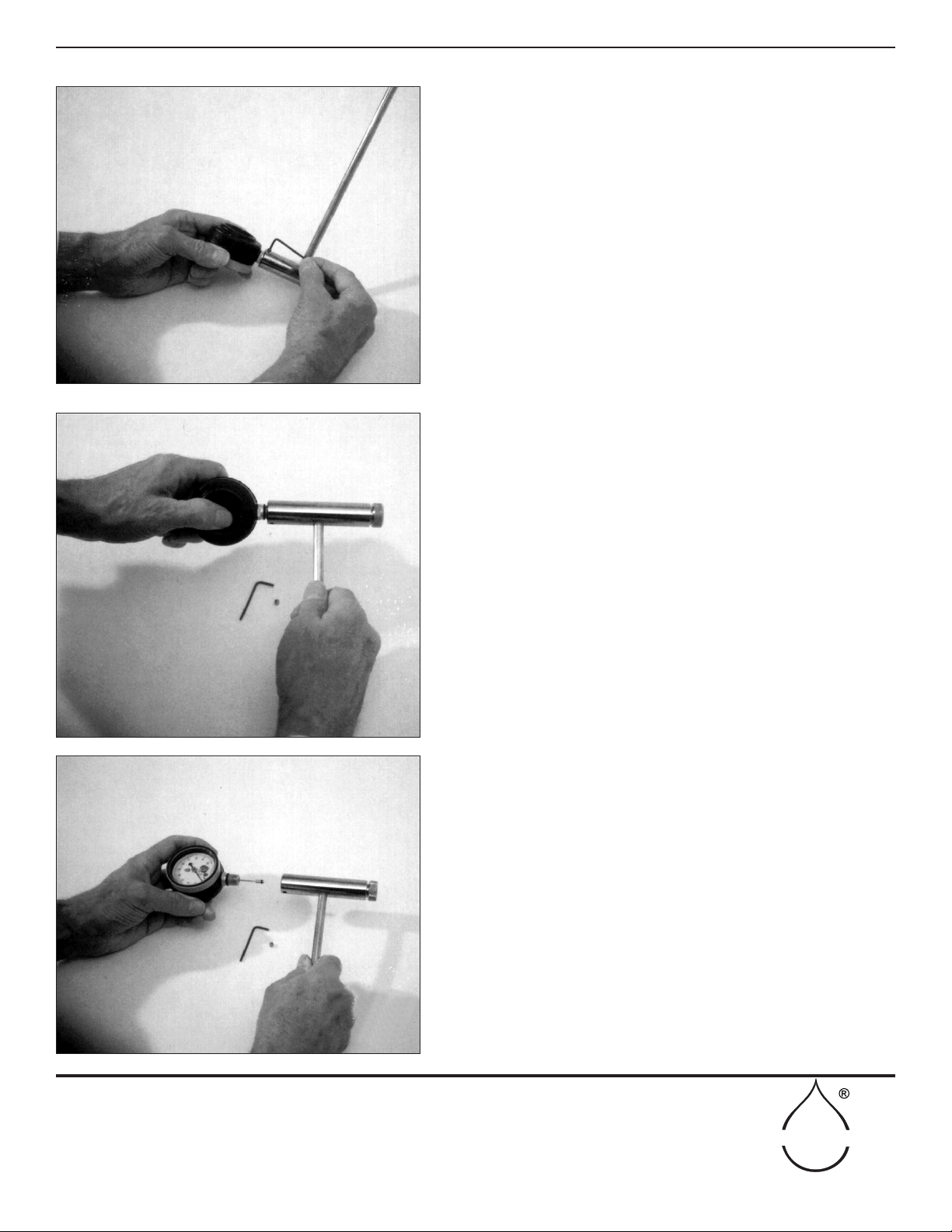

The rst operation in taking a reading is to core a hole to accept the Probe using the Coring Tool. The Coring Tool

is pushed vertically into the soil (Fig. 16). After reaching the depth desired, the Coring Tool is removed. This opera-

tion will pull out the soil core and provide a proper sized hole for insertion of the Probe.

The soil should be cleaned from the coring tool after each coring operation to make sure that the succeeding core

will be properly cut. Remove the core by inverting the coring tool so the core can slip out of the handle end. The

core itself gives a good prole of the soil below the surface. The Cleaning Rod can be used to remove any remaining

soil from the cutting tip (Fig. 17). In the event the soil becomes lodged inside the Coring Tool, strike the side of the

steel Coring Tool with the side of the Cleaning Rod to jar the soil inside loose.

If an impediment is encountered, such as a rock or hard root, when coring the hole simply move to an adjacent loca-

tion and core another hole. After the reading has been made, no attempt should be made to plug the hole, since the

small hole is not detrimental and will provide desirable aeration.

The Coring Tool makes a hole in the soil, which is tapered at the bottom. The larger portion of the hole provides

clearance for the Probe when it is inserted into the hole until it reaches the proper depth for measurement. When

the sensing tip of the Probe reaches the bottom of the hole, push it rmly into the tapered portion of the hole so a

tight contact is made between the sensing tip and the soil. This tight contact is essential to make a good, soil suction

measurement.

The Coring Tool is made from strong, chromemoly steel, and will withstand considerable punishment. If the soil

surface is too hard or dry for the Coring Tool to penetrate, the surface soil can be broken with a larger soil sampling

tool or shovel. The Coring Tool can then be pushed into the hole created to provide a properly sized hole to accept

the Probe.

In loose, cultivated soils and planting mixes, the Probe can frequently be pushed directly into the soil without coring

a hole. When taking measurements in these loose soils make sure the porous ceramic sensing tip is in good contact

with the soil and the Probe is inserted without using undue force.

MAKING A SOIL MOISTURE MEASUREMENT

Figure 17 - Using the Cleaning Rod to remove excess soilFigure 16 - Coring a hole using the Coring Tool

12

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

FIRST: TURN CLOCKWISE ALL THE WAY

SECOND: TURN COUNTER-CLOCKWISE

ONE HALF TURN

CORING TOOL

PUSHED INTO SOIL

“TAPERED” HOLE

MADE IN SOIL

LARGE PORTION

OF HOLE PROVIDES

CLEARANCE FOR PROBE

“TAPERED” PORTION OF

HOLE ASSURES TIGHT

FIT BETWEEN SENSING

TIP AND SOIL

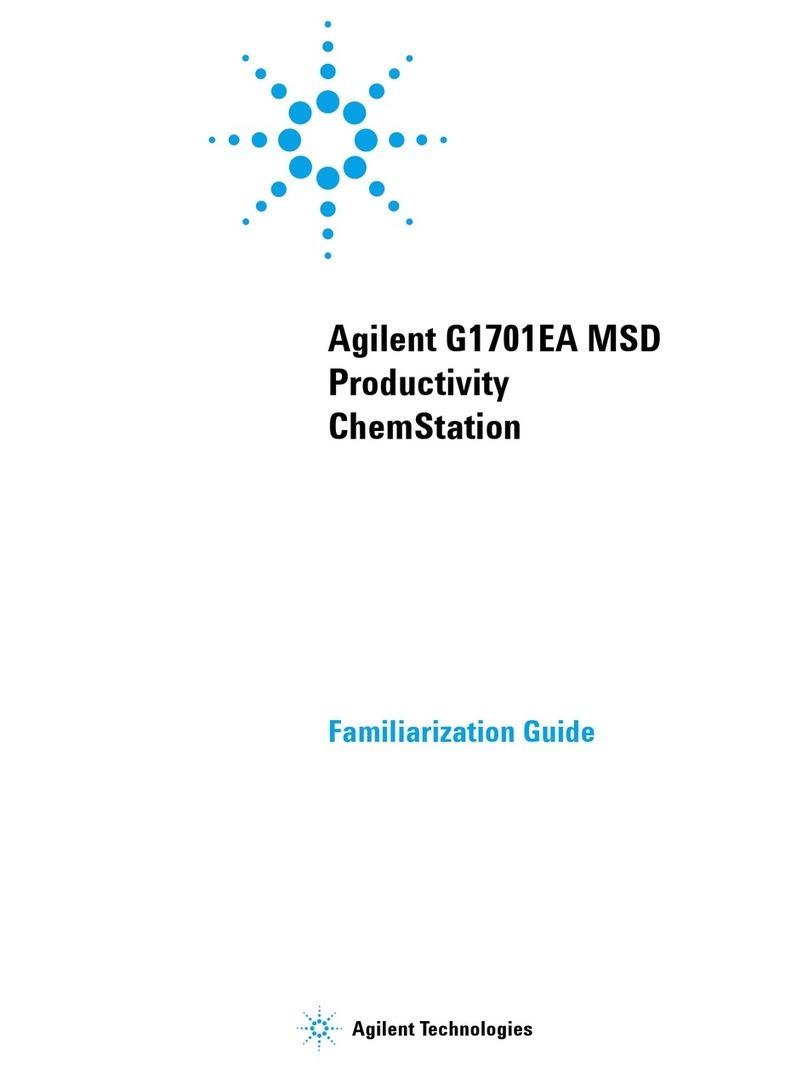

INSERTING THE PROBE

Prior to removing the Probe from the Carrying Case,

turn the Null Knob clockwise as far as it will go and

then undo the knob (counterclockwise) approximately

1/2 turn. This operation will provide the proper range

for the Null Knob when taking a reading (Fig. 18).

Next, remove the Probe from the Carrying Case and in-

sert it into the hole made by the Coring Tool. Push the

Probe into the cored hole so the sensing tip is in rm

contact with the soil (Fig. 19).

NOTE: If the Probe has been stored in a very hot envi-

ronment, such as the back of a truck, you should leave

the Probe in the initially cored hole for two to three

minutes to bring the Probe to approximate temperature

equilibrium with the soil. The Model 2900F Probe has

been designed to have very minimum temperature ef-

fects. However, it is desirable to eliminate extreme tem-

perature variations be-tween the soil and the Probe in

order to obtain the fastest response and ease of use. Af-

ter the initial temperature adjustment, when necessary

return the Probe to the Carrying Case to drop the pointer

reading to zero. Then core an adjacent hole and re-insert

the Probe.

If the soil is saturated with water, the pointer of the dial

gauge will remain at zero. Otherwise, the pointer will

immediately start to rise when the Probe is inserted into

the hole. After insertion, allow the Probe to remain un-

disturbed for approximately one minute. At the end of

one minute, observe the pointer reading.

MAKING A SOIL MOISTURE MEASUREMENT (cont.)

Figure 18

Figure 19

13

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

MAKING A SOIL MOISTURE MEASUREMENT (cont.)

(Figure 20)

MAKING A SOILMOISTURE READING – METHOD

ONE- with an example.

1.) Insert the probe in the ground and wait one minute then

note the reading – tap on the gauge occasionally.

Say our example yields 20 centibars.

2.) Take the reading and multiply it by 1.5

20 x 1.5 = 30.

3.) Use the null knob to dial in this new reading by turning

counter-clockwise.

Make it read 30 centibars.

4.) Wait another 15-30 second for wet soil (like 30) and

maybe 2 to 5 minutes in very dry (like 50) or clay soils.

Yawn.

5.) Observe if the needle moves to a higher or lower num-

ber – remember to tap on the gauge occasionally.

Say our needle drops to 28 centibars

6.) We are now bracketing in an know that the actual value

is in-between 28 and 20 so we pick the midpoint of 24 and

wait another 15-30 seconds also remembering to tap the

gauge a few times..

Use the null knob clockwise to go from 28 to 24 – tap on the gauge a couple of times.

7.) Say our needle climbs to 25. We know the real value is now between 25 and 28. One more dial should do it

and 26 is the dialing number. Wait and tap…………………….

Counter clockwise rotation increases from 25 to 26. The suspension is killing me!

8.) Say our needle moves up from 26-27 in 30 seconds while tapping the gauge.

Bingo – the answer is 27 cb for that location and depth.

ANOTHER EXAMPLE – METHOD TWO with an example

1.) Insert the probe in the ground and immediately dial 40 cb by rotating the null knob counter clockwise. Then

wait one minute tapping the gauge. As soon as we see the needle move in either direction we will make our next

move.

Say the needle move up from 40 cb to 40.5 cb.

2.) Immediately move our needle from 40 cb to 50 cb by rotating the null knob counter clockwise and wait 1-5

minutes to see if the gauge moves in either direction tapping on the gauge occasionally.

Say our needle moves from 50 cb to 50.5 cb.

3.) Immediately move our needle from 50 cb to 60 cb by rotating the null knob counter clockwise and wait 1-5

minutes to see if the gauge moves in either direction tapping on the gauge occasionally.

Say our needle moves down from 60 to 59.5

4.) We can now start the bracketing procedure in-between 50.5 cb and59.5 cb 55 cb being the best candidate rotat-

ing the null knob clockwise with waiting and tapping the gauge.

Say our needle goes up from 55 to 55.5.

5.) One more bracket point and one more wait should do it we pick 57.5 cb we rotate the null knob counter clock-

wise from 55.5 cb to 57.5 cb.

Drum roll while we wait …………………… the needle goes to 58 cb.

6.) 58 cb is declared our reading for that location and depth.

If, after the rst adjustment, the pointer continues to move up to a higher rather than a lower reading, you should

immediately move the pointer approximately 10 centibars higher and observe the pointer movement. If it contin-

ues to move up to a higher value, advance the pointer an additional 10 centibars. Once you reach a level where the

14

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

It has been our experience that accurate, reliable moisture readings can be made within

a few minutes at any one given location. In general, the readings can be made more

quickly when soil suction levels are in the low range than when they are in the high

range.

No problems in measurement will be encountered in sandy or sandy-loam soils. In the

event you are making measurements in extremely heavy clay soils, more time than

normal will be required to reach equilibrium because of the extremely slow movement

of water through this type of soil.

CAUTION!

In wet clay soils, the plastic soil itself can make an airtight closure around the sensing

tip as the Probe is being pushed into the soil. If this happens, pressure can be built up

in the Probe by the air trapped in front of the Probe. Since this air is sealed by the wet

clay soil, a high air pressure can develop as the Probe is pushed further and further into

the soil.

To detect such a condition, observe the dial pointer when pushing the Probe down

into the soil. If the pointer moves below the zero mark and touches the pin, pressure is

DIAL GAUGE

PRESSURE BUILD-UP

CAUTION!

MAKING A SOIL MOISTURE MEASUREMENT (cont.)

Figure 21 - Reading of pressure build up

CENTIBARS OF SOIL

SUCTION

www.soilmoisture.com

90

80

70 60 50 40

30

20

10

0

DRY

WET

100

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

PIN

DIAL GAUGE

PRESSURE

BUILD UP

pointer starts to move back down, you have “bracketed” the reading, and adjustments

can be made, as described above, to arrive at the correct value.

In many moist soils, the Probe will come to equilibrium very quickly without any ap-

preciable adjustment of the Null Knob.

Through experience in using the Probe in your soils, you will soon be able to esti-

mate the nal dial gauge reading by the speed the pointer moves after insertion of

the Probe. It is best to minimize the use of the Null Knob to limit disturbing the soil

moisture conditions being measured.

After making a reading, the Soilmoisture Probe should be wiped free of surplus cling-

ing soil and immediately returned to the Carrying Case so the sensing tip remains

moist by being in contact with the water storage sponge, with the dial gauge reading

zero. When making eld measurements, if the soil suction value exceeds the highest

operating value corresponding to your elevation, the Probe should not be left in the

soil for extended periods.

Soil moisture values can vary considerably within a given area because of differences

in root action, drainage and exposure. For this reason, it is desirable to make several

readings in a given area in order to fully evaluate the soil moisture conditions.

15

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

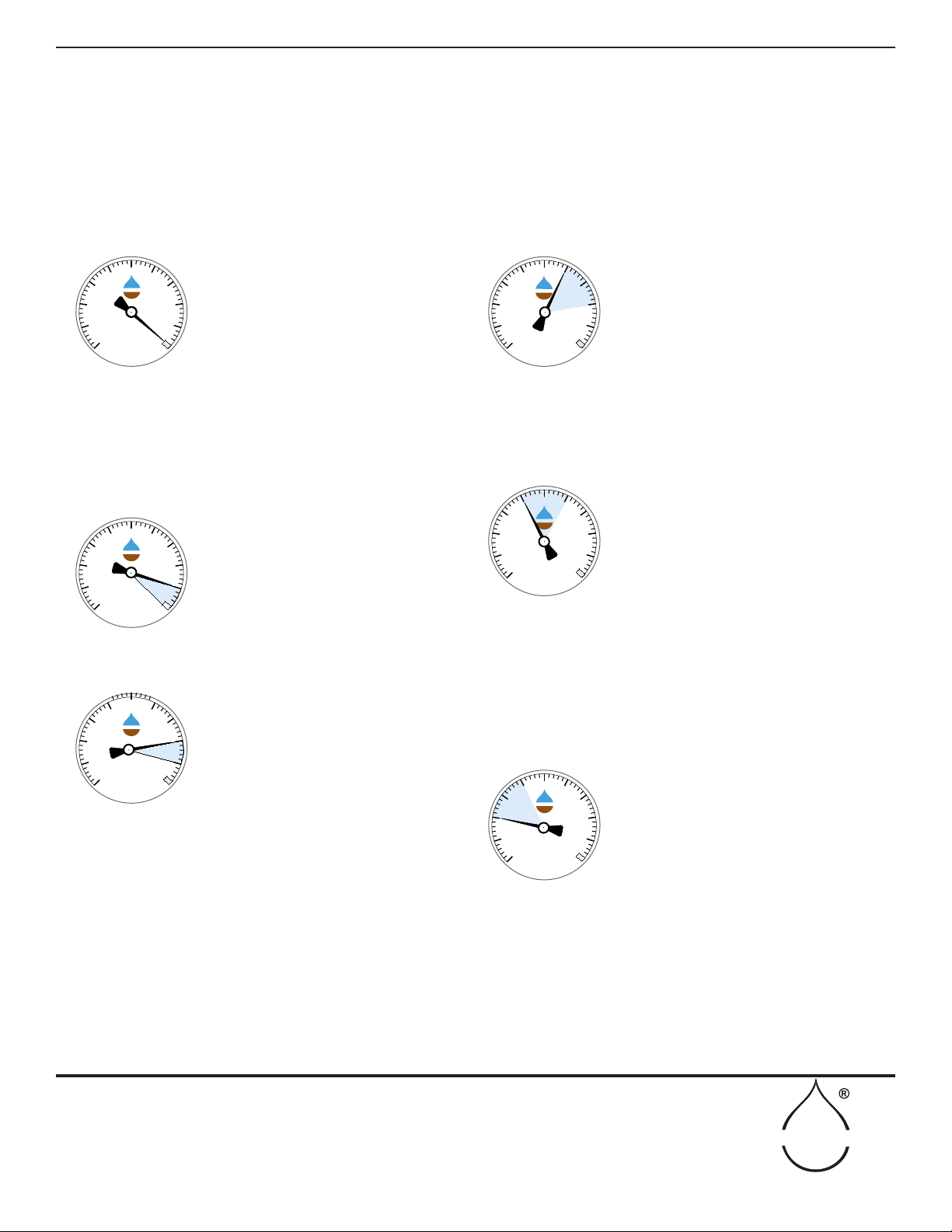

ZERO:

0-10 CENTIBARS:

10-20 CENTIBARS:

20-40 CENTIBARS:

40-60 CENTIBARS:

60-80 CENTIBARS:

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

10

0

DRY

WET

100

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

DRY

WET

100

10

0

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

DRY

WET

100

10

0

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

DRY

WET

100

10

0

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

DRY

WET

100

10

0

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

CENTIBARS OF SOIL

SUCTION

SOILMOISTURE EQUIPMENT CORP

Santa Barbara, CA USA

90

80

70 60 50 40

30

20

DRY

WET

100

10

0

D

O

N

O

T

F

R

E

E

Z

E

SOILMOISTURE

A gauge reading of zero means the

surrounding soil is completely saturated

with water, regardless of the type of soil.

Zero readings can be expected after a

heavy rain or deep irrigation. If the zero

reading persists after a long period of

time, there will be oxygen starvation to

plant roots and development of diseases.

A persistent zero reading after irrigation

indicates poor drainage conditions which

should be investigated and corrected.

Gauge readings in the range of 0-10 cb

indicated a surplus of water for plant

growth. Water held by the soil in this

range drains off within a few days. Persis-

tent readings in this range indicate poor

drainage conditions which should be

corrected to obtain healthy plant growth.

Gauge readings in the range of 10-20cb

indicate that there is ample moisture and

also air in the soil for healthy plant growth

in all types of soils. This range is often

referred to as the “field capacity” range

for soils, which means that the soil has

reached its “capacity” and cannot hold

anymore water for future plant growth.

When soils are at “field capacity”, any

additional water that is added drains out

of the root zone within a day or two before

it can be used by the growing plant. If

irrigation has been in process, it should

be stopped when gauge drops to this

level, since any further additional water

will be quickly drained from the root zone

and wasted, carrying with it valuable

fertilizer.

Available moisture and aeration good

for plant growth.

HEAVY CLAY SOILS: No irrigation

required.

MEDIUM TEXTURED SOILS: No

irrigation required.

SANDY SOILS: Irrigation started for

coarser sandy soils in the 20-30 cb

range. For finer sandy soils in the

30-40 cb range.

Available moisture and aeration are

good for plant growth in finer textured

soils.

HEAVY CLAY SOILS: No irrigation

required.

MEDIUM TEXTURED SOILS: Irriga-

tion started in this range. The finer the

texture the higher the reading before

start of irrigation.

SANDY SOILS: Too dry. Hot windy

conditions can force soil suction to

high reading quickly and damage

plants.

Readily available moisture scarce,

except in heavy clay soils.

HEAVY CLAY SOILS: Start of irriga-

tion desirable as soil suction values

reach 70-80 cb.

MEDIUM TEXTURED SOILS:Too dry.

Hot, windy conditions can force soil

suction to high reading quickly and

damage plants.

SANDY SOILS: Too dry. Damage to

plants will occur before irrigation can

be applied.

GAUGE READINGS (cont.)

building up (Fig. 21). Stop pushing and pull the Probe up to relieve the pressure. Then push the Probe down and pull

up again in short strokes to enlarge the hole in the sensing tip area, which will prevent the entrapment of air. Then

push the Probe to full depth and make a reading.

IRRIGATION SCHEDULING

16

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

The QuickDraw can be used for different types of measurements; for spot checks and measures from a permanent

location:

a) Use for spot checks to determine the wetting area from drippers or to determine if there is enough moisture for

germination in the seed-bed. Simply use the coring tool to shape the hole at the depth of measurement. Insert the

QuickDraw and wait for the reading to become steady.

b) One can make routine measurements at a given depth in the same hole each time measurements are necessary.

Use ½˝ PVC as a riser from the depth to measure to the soil surface. Place the pipe at the depth of measurement,

minus an inch or so. Use an end cap or aluminum foil to prevent irrigation from a sprinkler from entering the pipe

and wetting the soil at depth instead of from surface inltration. Remove the cap and insert the QuickDraw and

force the ceramic tip into the soil at the depth of measurement. Make your measurement as normal. Re-cap the riser

pipe when nished.

Use the null knob to adjust the vacuum in the tensiometer to your set point for irrigation particular to

the soil and crop being monitoring. The advantage of adjusting the null knob is to quickly determine if the set point

has been reached or not and the question "is it time to irrigate?" can be easily determined.

If the vacuum dial gauge exceeds the set point, then it is denitely time to schedule the irrigation. If the vacuum

dial gauge decreases in vacuum, then the soil is more moist than your set point for irrigation and your decision is

to not irrigate.

Using this approach, allows the user to rapidly make management decisions. Absolute, at equilibrium, measure-

ments are not required using this approach.

ROUTINE MEASUREMENTS

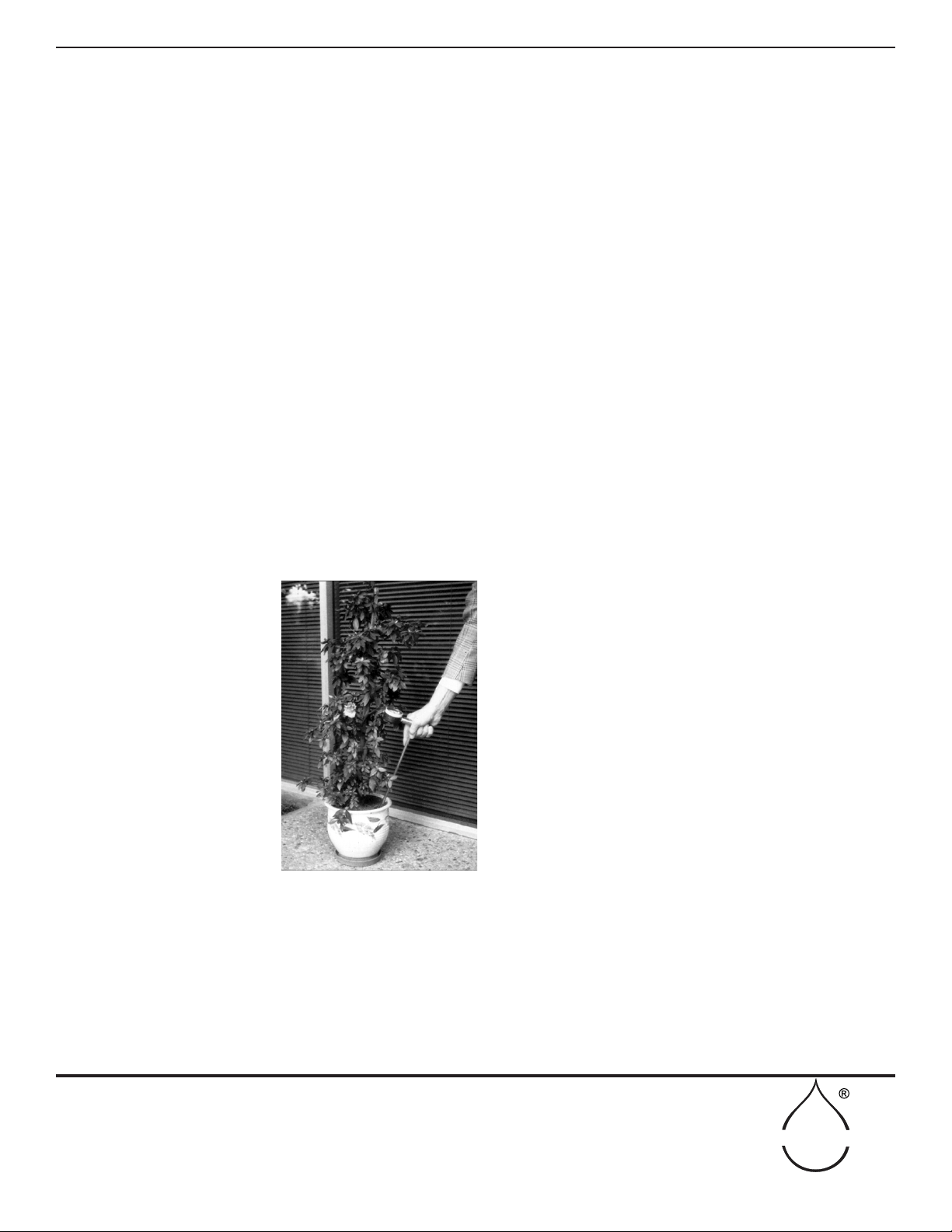

The Model 2900F Soilmoisture Probe is particularly

valuable in determining moisture conditions in potted

plants such as those in commercial buildings or nurs-

eries. The Probe responds quickly in planting mixes

used in potted plants and usually can be pushed direct-

ly down into the root zone without coring a hole. Its

portability eliminates vandalism, which is not true of

xed moisture measuring instruments. With the Mod-

el 2900F, a thoughtful plan can be developed to keep

maintenance and water costs to a minimum.

For frequent evaluation of moisture conditions in large irrigated elds, the use of sev-

eral Probes can speed up the work. As an example, an agricultural consultant who

programs irrigation for his client can insert a number of Probes in a eld without tak-

ing immediate readings. When the crop is high, the Probes would be agged with a

red cloth on a wire stake so they can be easily found. The consultant can then make

his other crop observations. After completing his other work, he would return to pick

up the Soilmoisture Probes. By this time, the Probes would have reached equilibrium,

and the readings would be quickly noted.

Using a number of

Probes at the same

time

Potted Plants

(Figure 37)

17

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

The successful operation of the Model 2900F Soilmoisture Probe is due to its structural

rigidity and the fact that the air has been almost completely removed from the water

and the internal structure of the Probe. For these reasons, any small amount of move-

ment of water through the porous ceramic sensing tip will result in a substantial change

of the vacuum level within the Probe. This very responsive action coupled with the use

of the Null Knob, results in only a small disturbance to the water lms in the surround-

ing soil, which are being measured. Hence, accurate measurements of soil suction can

be made quickly.

If air is present in the unit, then a substantial amount of water must ow through the

wall of the porous ceramic sensing tip to change the vacuum level within the Probe. The

air within the Probe expands as the pressure is reduced (centibar reading in-creased),

which causes a larger amount of water to move in and out of the surrounding soil. The

result is a less responsive movement of the pointer on the dial gauge, a “spongy” ac-

tion of the Null Knob, and a longer time to obtain an accurate soil moisture measure-

ment. The response time is dened as the time required for the dial pointer to drop

from 50 centibars to 10 centibars when the porous ceramic sensing tip is plunged into

a container of water.

Over a period of many months or years, the pores in the ceramic sensing tip have a

tendency to become clogged with deposits, which decreases the permeability of the

ceramic. Such clogging will, of course, slow down the response time of the Probe. If

the Probe has been carefully lled with water to remove all accumulated air, and the re-

sponse time is still in excess of 2 seconds, it is advisable to replace the porous ceramic

sensing tip with a new one (see page 17).

Substantial change in

the vacuum level

Lack of reponse from

gauge

TROUBLESHOOTING

50 centibars can not be

reached

If, at any time, the operation of the Probe appears to be “spongy” and excessive time

is required to make a soil suction reading, simply remove the Probe from the Carrying

Case. Wipe the porous sensing tip with an absorbent tissue and turn the Null Knob so

the pointer on the dial gauge registers 50 centibars. Then plunge the sensing tip of the

Probe into a container of water and note the time required for the pointer to drop from

50 centibars to 10 centibars. If it is appreciably more than one second, it indicates that

there is air accumulated within the Probe. To remove the air from the Probe and restore

the fast response time, rell the Probe with water as described under “Initial Filling”,

page 2.

If the porous ceramic sensing tip as been cracked during use, it will permit air to enter

the system. A very ne crack not be readily observed. Usually under these circum-

stances, it is not possible to obtain a reading of 50 centibars to conduct the response

time test. If a dial reading of 50 centibars cannot be reached by drying the sensing tip

and turning the Null Knob, there is too much air in the system, and there may also be

a crack in the sensing tip. To replace the porous ceramic sensing tip, see the section on

this.

18

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

If the porous ceramic sensing tip has been broken or cracked during use or if the pores of the ceramic have become

clogged resulting in too long Probe response time, it can be readily replaced with a new one. The O-ring seals must

also be replaced when you replace the ceramic sensing tip.

To replace the sensing tip, rst remove the slotted cap nut at the end of the Probe. Use a large screwdriver that ts

the slot in the cap nut, or the small pointer-adjusting screwdriver can be used, by inserting the side of the screw-

driver in the slot in the nut (Fig. 22).

When facing the end of the Probe, turn the cap nut COUNTERCLOCKWISE to loosen it. Completely remove the

cap nut, the porous ceramic sensing tip, and the two O-ring seals at either end of the sensing tip. When you remove

the parts, be sure that the smooth surfaces on the cap nut and on the stem of the Probe, where the O-rings seat, are

not scratched or marred. It is essential that these surfaces are kept smooth to assure a complete vacuum seal when

the new sensing tip is installed. Clean off any accumulated corrosion from the stem of the Probe.

The O-ring seals, porous ceramic sensing tip and slotted cap nut are arranged (see Fig. 23) in the same manner as

they t on to the stem of the Probe. (Continued on next page)

Figure 22 - Removing the slotted cap nut Figure 23

REPLACING THE POROUS CERAMIC SENSING TIP

19

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

Figures 24 through 28 show the successive operations in

mounting the parts on the stem of the Probe.

In the nal assembly operation, screw on the slotted cap nut

and tighten it securely with a screwdriver. The slotted cap

screw should be tightened as far as it will go. Parts have been

carefully machined so the O-ring seals are properly squeezed

when the slotted cap nut is screwed completely on until it

seats on the end of the Probe stem. The O-rings make a vac-

uum-tight seal between the brass surfaces of the Probe stem

parts and the ends of the porous ceramic sensing tip.

The ends of the porous ceramic sensing tip have been ma-

chined smooth to assure a vacuum-tight seal. When you

mount the porous ceramic sensing

tip on the Probe, make sure that the sensing tip is not scratched

or chipped.

The Porous Ceramic Sensing Tip is supplied with a tapered

conguration. The taper matches the taper of the Coring Tool.

The taper assures better contact with the soil, which increases

sensitivity and speed of response.

When you replace the tip, special care must be taken to see

that the “top” arrow marked on the tip points in the direction

as shown in Fig. 29.

After replacing the tip, ll the Probe as described in “Initial

Filling” (see page 7).

Replacing the Porous Ceramic Sensing Tip (cont.)

Figure 24

Figure 25

Figure 26

Figure 27

Figure 28 Figure 29

20

SOILMOISTURE EQUIPMENT CORP.

P.O. Box 30025, Santa Barbara, CA 93105 U.S.A.

Telephone 805-964-3525 - Fax No. 805-683-2189

www.soilmoisture.com - sales@soilmoisture.com

SOILMOISTURE

Replacing The Dial Gauge

If the dial gauge has been mechanically damaged making it

inoperative, it may be replaced in the eld.

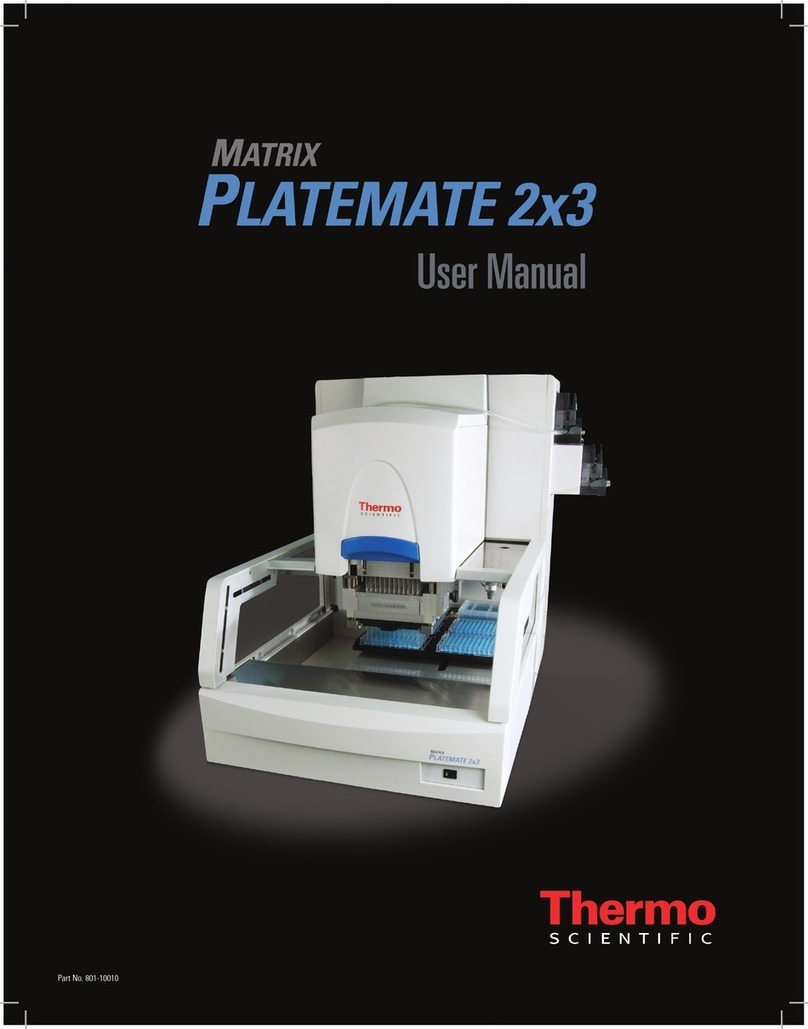

First remove the socket head set screw from the handle,

as shown in Fig. 30. This is an “Allen” head set screw that

accepts a 3/32” size Allen wrench, which is supplied in the

Accessory Kit.

Then grasp the dial gauge rmly, as shown in Fig. 31, and turn it

counterclockwise until it is free from the handle.

Fig. 32 shows the dial gauge removed from the handle.

The internal connecting tube usually remains in the dial

gauge. Carefully pull out the internal connecting tube from the

dial gauge.

Figure 30

Figure 31

Figure 32

Table of contents

Other Soilmoisture Equipment Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Ametek

Ametek VersaSTAT MC Hardware manual

Agilent Technologies

Agilent Technologies G1701EA Familiarization guide

Thermo Scientific

Thermo Scientific MATRIX PLATEMATE 2x3 user manual

Buchi

Buchi Rotavapor R-220 Operation manual

Thermo Scientific

Thermo Scientific VARIOMAG MINI 07 operating manual

Nippon Genetics

Nippon Genetics FASTGENE ELECTRONIC PIPETTE-200 manual

PASCO

PASCO EM-6720 instruction sheet

Buchi

Buchi HydrolEx H-506 Operation manual

Lumascape

Lumascape PowerSync PS installation instructions

Agilent Technologies

Agilent Technologies 11970 Series user guide

Micromeritics

Micromeritics Mercury QuikVac 090 Operator's manual

WPI

WPI NANOLITER2020 instruction manual