CONTROLS, INCORPORATED

C O N T R O L S Y S T E M S & S O L U T I O N S

- 1 -

1) Introduction

1.1 The C3M-100-AS is a sealed microprocessor-based engine control system for industrial engines. It is based

on the Controls, Inc. iMech series controller platform with a Freescale 8 bit processor.

1.2 The product is packaged into a water tight, polycarbonate enclosure for maximum durability. The controller

is plug & play with a sealed bulkhead engine connector incorporated into the case.

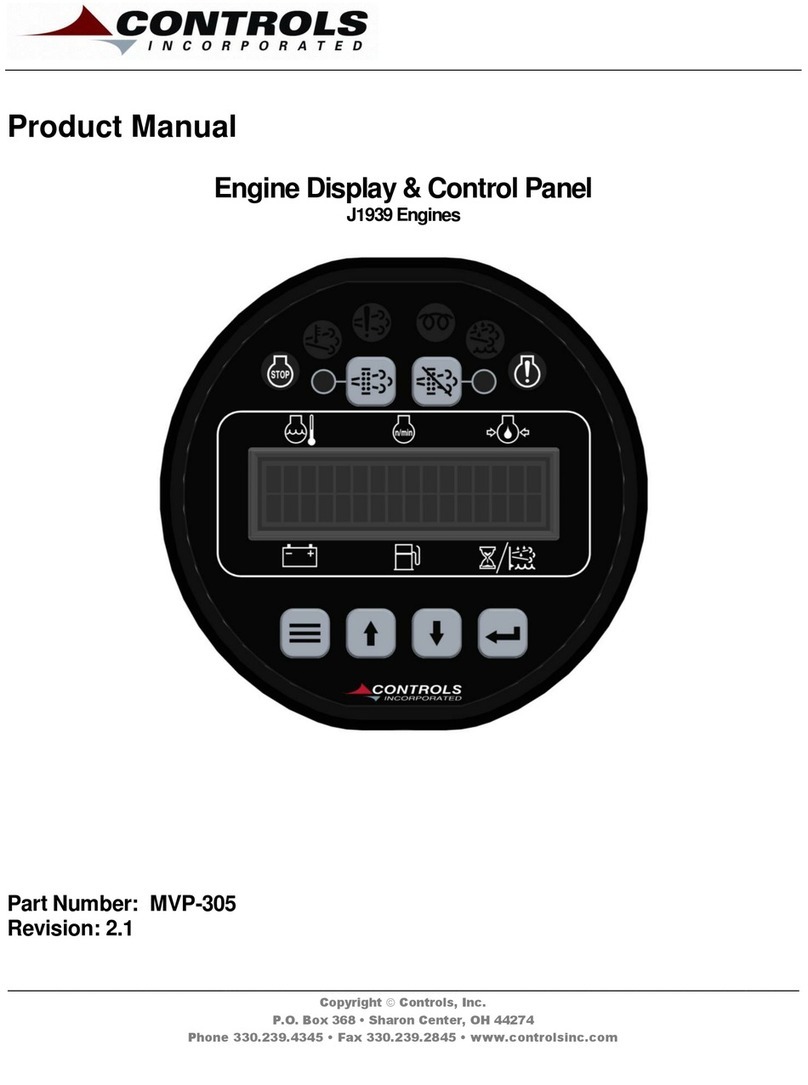

1.3 The digital display is 1”H x 4”W with two rows of 16 characters. Character height is approximately ½”. The

display has automatic temperature compensation for optimal viewing across the entire operating

temperature range of –20C to +70C. Backlight intensityis also adjustable. An extreme temperature option

is available, which extends the operating temp to –45C to +85C and the storage temp to –55C to +95C.

1.4 The unit monitors all critical engine functions and has full time display of Oil Pressure, Engine Temperature,

Engine Speed, Battery Voltage, Fuel Level and Engine Hours.

1.5 Analog Input is available for fuel level monitoring or can be used as a digital switch input. OEM

Programming is available for other parameter monitoring.

1.6 Digital Flex Input is available for Auto Start.

1.7 The controller with corresponding amber or red LED illuminations above the digital displaymonitors engine

safetyalarms. Text messages are displayed automatically.

iMech™ C3M-100-AS