Solartron Metrology Ametek OD2 Manual

OD2 USER LEAFLET

2Part No. 501107 Issue 13

SAFETY SUMMARY

S1. Safety Characteristics

This apparatus has been tested and supplied in a safe condition. This manual contains some

information and warnings which must be followed by the user to ensure safe operation and to

retain the apparatus in a safe condition.

S1.1 Terms in This Manual

CAUTION statements identify conditions or practices that could result in damage to the equipment

or other property.

S1.2 Symbols in This Manual

This symbol indicates where applicable cautionary or other information is to be found.

S2. Safety Instructions

Upon delivery from the factory the instrument complies with the required safety regulations, see

para. S1. To maintain this condition and to ensure safe operation, the instructions below must be

carefully followed.

S2.1 Power Source

This product is intended to operate from a power source that will not apply more than 48 volts DC

between the supply conductors.

S2.2 Do Not Operate in Explosive Atmospheres

To avoid explosion, do not operate this product in an explosive atmosphere unless it has been

specically certied for such operation.

S2.3 Grounding the Product

This product is grounded through the grounding conductor of the power supply.

S2.4 Do Not Remove Covers or Panels

To avoid personal injury, do not remove the lid. Do not operate the product without the lid properly

tted.

CAUTION: Electrical Safety

Under normal circumstances, you are unlikely to suffer any real harm from the low voltages and

currents used in the OD2 Transmitter. However, the electrical connections should be made with

the power off.

SERVICE SAFETY SUMMARY

FOR QUALIFIED SERVICE PERSONNEL ONLY

Refer also to the preceding Operators’ Safety Summary

This product contains no user serviceable parts

Adjustments may be made to the internal gain settings by qualied personnel, Chapter 5 refers.

3

Part No. 501107 Issue 13

Section Title Page

Safety Summary .................................................................................... 2

Service Safety Summary ....................................................................... 2

List of Contents ...................................................................................... 3

List of Drawings ..................................................................................... 4

List of Tables .......................................................................................... 4

1. GENERAL

1.1 Introduction ..................................................................................... 5

1.2 Specification.................................................................................... 5

1.3 Safety Considerations..................................................................... 5

1.4 Instruments Covered by Manual ..................................................... 5

1.5 Maintenance and Repair ................................................................ 5

1.6 Dismantling the Instrument ............................................................ 5

2. INSTALLATION

2.1 Introduction .................................................................................... 6

2.2 Initial Inspection ............................................................................. 6

2.3 Preparation for Use ........................................................................ 6

2.4 Power Requirements ..................................................................... 6

2.5 Working Environment ..................................................................... 6

2.6 Physical Description ....................................................................... 6

2.7 Mounting ........................................................................................ 7

3. OPTIONS

3.1 Introduction .................................................................................... 8

3.2 4-20mA or 0-20mA Operation ........................................................ 8

3.3 4-20mA Operation .......................................................................... 8

3.4 0-20mA Operation .......................................................................... 8

3.5 Frequency Selection ...................................................................... 9

3.6 Tuning Capacitor Selection ............................................................ 9

3.7 Gain Selection ................................................................................ 10

4. ELECTRICAL CONNECTIONS

4.1 Terminal Designation ..................................................................... 11

4.2 Transducer Connections ................................................................ 11

4.3 Non-Standard Connections ............................................................ 12

4.4 Connecting Instrumentation ........................................................... 12

5. SETTING UP

5.1 Gain Selection ................................................................................ 14

5.2 Zero Adjustment ............................................................................. 14

5.3 Other Switch Settings .................................................................... 14

4Part No. 501107 Issue 13

Section Title Page

6. CALIBRATION

6.1 Calibration with Standard Solartron Transducers ........................... 15

6.1.1 As 4-20mA Transmitter ................................................................ 15

6.1.2 As 0-20mA Transmitter ................................................................ 15

APPENDIX A - Generation Transducer Connections (LVDT) ..................... 16

APPENDIX B - Specification ...................................................................... 17

LIST OF DRAWINGS

1.1 Instrument Identification................................................................ 5

2.1 Mounting Holes ............................................................................ 7

3.1 4-20mA Option ............................................................................. 8

3.2 0-20mA Option ............................................................................. 8

3.3 Gain Selection Switch .................................................................. 10

4.1 Connector 1 ................................................................................. 11

4.2 Connection 2 ................................................................................ 12

4.3 4-20mA Transmitter Connections ................................................. 13

4.4 0-20mA Transmitter Connections ................................................. 13

LIST OF TABLES

3.1 Frequency Selection .................................................................... 9

3.2 Switch Settings ............................................................................ 9

3.3 Gain Selection Switch 8 ................................................................ 10

4.1 Connector 1 ................................................................................. 11

4.2 LVDT Connections ....................................................................... 11

5.1 Gain Selection............................................................................... 14

B1.1 Common Specifications ............................................................... 17

B1.2 Instruments Referred to by this Manual ....................................... 17

Return Of Goods

Solartron Sales Ofces

5

Part No. 501107 Issue 13

1. GENERAL

1.1 INTRODUCTION

The Model OD2 Transmitter is designed for use with ac inductive type LVDT displacement trans-

ducers. It has a dual function: (1) its onboard oscillator derives power from the supply and pro-

duces a sine wave carrier to drive the transducer primary winding; (2) its amplier, demodulator

and lter circuit conditions the transducer output and a voltage-to-current converter produces

this as a dc milliamp drive. The transmitter is especially suitable where a readout is required at a

substantial distance from the transducer and for interfacing with a controller, or computer in auto-

mated manufacturing processes.

1.2 SPECIFICATIONS

Instrument specications are listed in Table B1.1. These specications are the performance stan-

dards or limits against which the instrument is tested.

1.3 SAFETY CONSIDERATIONS

Before operation, the instrument and manual, including the safety page, should be reviewed for

safety markings and instructions. These must then be followed to ensure safe operation and to

maintain the instrument in a safe condition.

1.4 INSTRUMENTS COVERED BY MANUAL

Attached to the top of this instrument is a name plate (Fig. 1.1 ), this manual only refers to instru-

ments listed in Table B1.2.

1.5 MAINTENANCE AND REPAIR

If the instrument is suspected of being unsafe, take it out of operation permanently. This is the

case when the instrument:

- shows physical damage;

- does not function anymore;

- is stressed beyond the tolerable limits (eg. during storage and transportation).

1.6 DISMANTLING THE INSTRUMENT

Before opening the instrument, disconnect it from all power sources. Refer to the Service Safety

Summary. Calibration, maintenance or repair must be performed only by trained personnel being

aware of the risks.

Fig. 1.1 - Instrument Identication

6Part No. 501107 Issue 13

2. INSTALLATION

2.1 INTRODUCTION

This section provides installation instructions for the instrument. It also includes information about

initial inspection and damage claims, preparation for use and packaging, storage and shipment.

2.2 INITIAL INSPECTION

Inspect the shipping container for damage. If the container or cushioning material is damaged,

it should be kept until the contents of the shipment have been checked for completeness and

the instrument has been checked mechanically and electrically. If the contents are incomplete,

or if there is a mechanical damage or defect, or if the instrument does not pass the operator’s

checks, notify the nearest Solartron Metrology office. Keep the shipping materials for carrier’s

inspection.

2.3 PREPARATION FOR USE

CAUTION:

Do not perform electrical tests when there are signs of shipping damage to any portion of the

outer enclosure.

It is recommended that all installation instructions are read fully prior to installation of the

instrument.

2.4 POWER REQUIREMENTS

A dc power supply of 13V to 48V and up to 30mA is required. Because the transmitter is

frequently installed at a considerable distance from the indicator/control point, there is a

possibility that the supply cable connections will be reversed. The transmitter is protected by an

internal diode against possible damage caused by reversed polarity.

For correct operation 13V must be achieved at the transmitter at 20mA full scale, the total

resistance of the installed indicator and cable must not be too large. As a general guide do not

exceed the value of R calculated using the following formula:

Where Vs = actual power supply voltage

For example, if Vs = 24V, R O 550 ohms.

2.5 WORKING ENVIRONMENT

Model OD2 Transmitters will operate in environmental temperatures from 0 to 60oC (32 to

140oF).

Provided the lid and cable entry seals have been properly applied, the enclosure will withstand

low pressure water hosing to IP65 specification requirements. This version is therefore ideally

suited for installation in dirty or damp industrial environments or in the open where it may be

exposed to rain.

2.6 PHYSICAL DESCRIPTION

The OD2 Transmitter can be supplied enclosed in a grey ABS plastic box measuring 120mm x

80mm x 55mm (4.75in x 3.15in x 2.16in) deep with sealed cover and cable entries, one for the

transducer wire and the other for the supply cable.

Alternatively, it is available simply as a basic printed circuit card measuring 94mm x 72mm (2.7in

x 2.83in) for mounting into the customer’s own enclosure. Cable glands accept wires from 1mm

to 5mm (0.04in to 0.02in) diameter.

Vs

- 13

0.02

ohms

R≤

7

Part No. 501107 Issue 13

2.7 MOUNTING

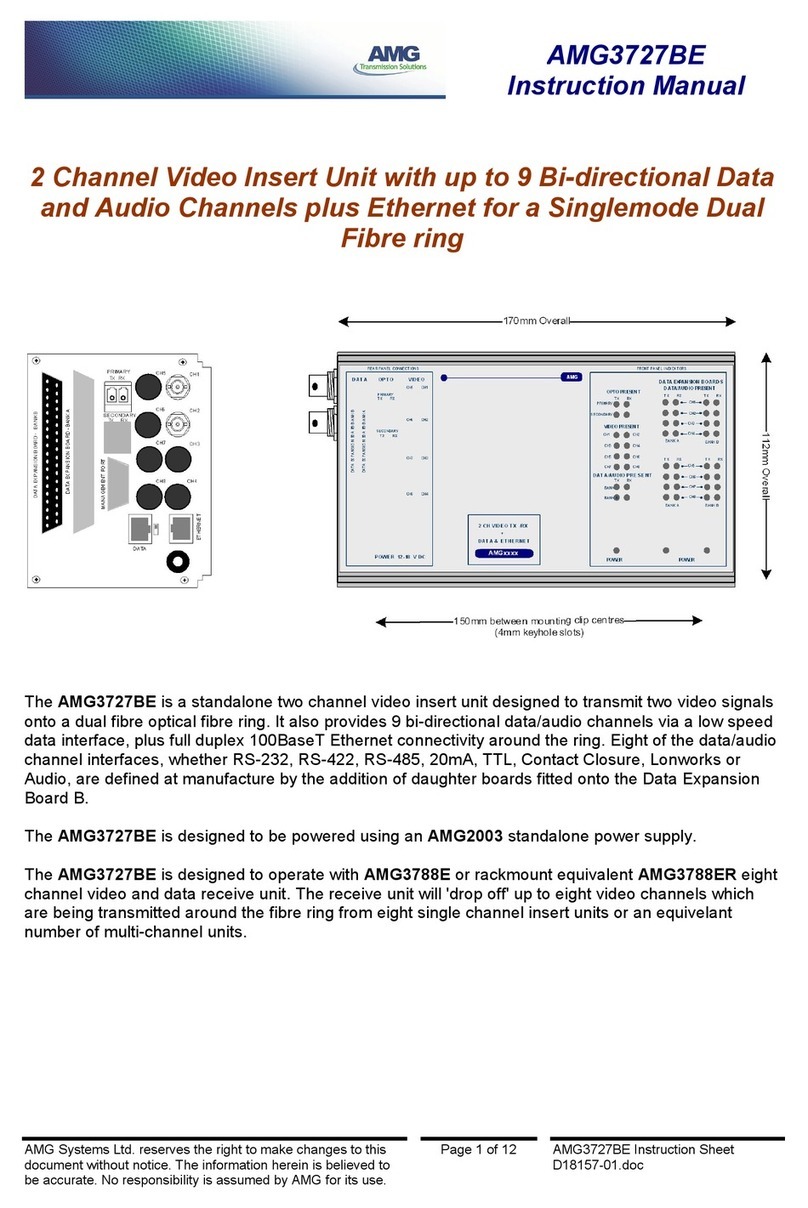

The instrument has four (4) 4.2mm (0.165in) diameter mounting holes on 108mm x 50mm (4.25in

x 1.97in) centres. These mounting holes are segregated from the electronics by partitioning in the

box moulding which may thus be secured to any surface using only two screws without affecting

the sealing.

Fig. 2.1 - Mounting Holes Fig. 2.1 - Mounting Holes

2.8 ELECTRICAL AND EMC CONSIDERATIONS

The OD2 meets the following requirements

Emissions

EN61000-6-3, specically EN 55022 Conducted Emissions Class B and EN55022 Radiated Emis-

sions Class B.

Susceptibility

EN610004-3 Radiated Immunity 1.4GHz to 2.7GHz 3V/m

EN610004-3 Radiated Immunity 80MHz to 1GHz 10V/m

ESD

EN610004-4-: ±4kV contact and ±8kV air

Installation Guidance

The type of cabling used to connect the OD2 depends on the electrical environment. In a clean

environment unscreened twisted pairs provide a low cost suitable connection, in an environment

where electrical noise is higher, such as installation inside a machine or on the factory oor it is

advised to use screened cables.

Do not route power cables close to the OD2 or any interconnecting cables as these may cause a

disturbance in the performance. Avoid as much as possible mounting the OD2 close to any kind of

switch gear or other equipments that can produce high intensity electrical or magnetic elds.

Wherever possible keep cables below 3m in length.

50mm

108mm

Fig. 2.1 Mounting Holes

Note: Two securing screws and two nuts

for alternative xing to a DIN46277-1 rail are

supplied loose with the transmitter.

8Part No. 501107 Issue 13

3. OPTIONS

3.1 INTRODUCTION

OD2 Transmitter will operate with most Solartron transducers having strokes up to E100mm

(E4in), in particular with the SM, AC, AX, AT and some of the MACH 1’s. Switches on the printed

circuit card are used to set up the transmitter for a specific transducer type and onboard Span/

Zero controls are provided for calibration purposes.

3.2 4-20mA OR 0-20mA OPERATION

The OD2 will operate equally well as either a 4-20mA two wire transmitter or a 0-20mA three wire

transmitter.

3.3 4-20mA OPERATION

As a 4-20mA transmitter, only two wires are used to connect to the power supply and indicator:

Fig. 3.1 - 4-20mA Option

The transmitter draws 4mA to operate the electronics and the position of the transducer controls

a 0-16mA current sink wired in parallel. Therefore the position of the transducer is indicated by

the current consumption and a broken cable by zero current. Due to its inherent fault indication,

the need for only two wires and its low susceptibility to electrical noise/cable resistance, it is ideal

for industrial environments.

3.4 0-20mA OPERATION

The 0-20mA transmitter works on the same principle, but has three wires.

Fig. 3.2 - 0-20mA Option

This has the extra complication of the third wire, but a simpler indicator can be used.

Current

Driven

Indicator

Supply

Conditioner

Transducer

Indicator

Supply

Conditioner

Transducer

9

Part No. 501107 Issue 13

3.5 FREQUENCY SELECTION

Switch S1, S2, S3 and S4 select the excitation frequency with reference to Table 3.2. The opti-

mum frequency for the transducer in use should be selected (see Table 3.1).

Table 3.1 - Frequency Selection

3.6 TUNING CAPACITOR SETTING

Switch S5, S6 and S7 introduce tuning capacitors in parallel with the transducer primary coil with

reference to Table 3.3 set S5 to S7 to the optimum capacitance for the transducer in use.

Transducer SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

SM/1 On On Off Off On On Off On

SM/3 On On Off Off Off On Off Off

AC/15 & 100 Off Off On On Off Off On Off

AC/25 & 50 Off Off On On Off On Off Off

AC/250 Off Off On On Off Off On On

AX1 to 5 Off Off On On On On On Off

MACH 1 Series (5kHz)

BS/1.5 & BS/15 Off Off On On On On On Off

BS/2.5 & BS/7.5 Off Off On On On On Off Off

BS/5 & BS/10 Off Off On On Off Off On Off

BS/25 Off Off On On On On On Off

Table 3.2 - Switch Settings

Note: Refer to BS settings for BT transducers

Frequency Selection

Switch 1, 2, 3 and 4

13kHz

5kHz

Off On

S1

S2

S3

S4

S1

S2

S3

S4

S5

Off On

10 Part No. 501107 Issue 13

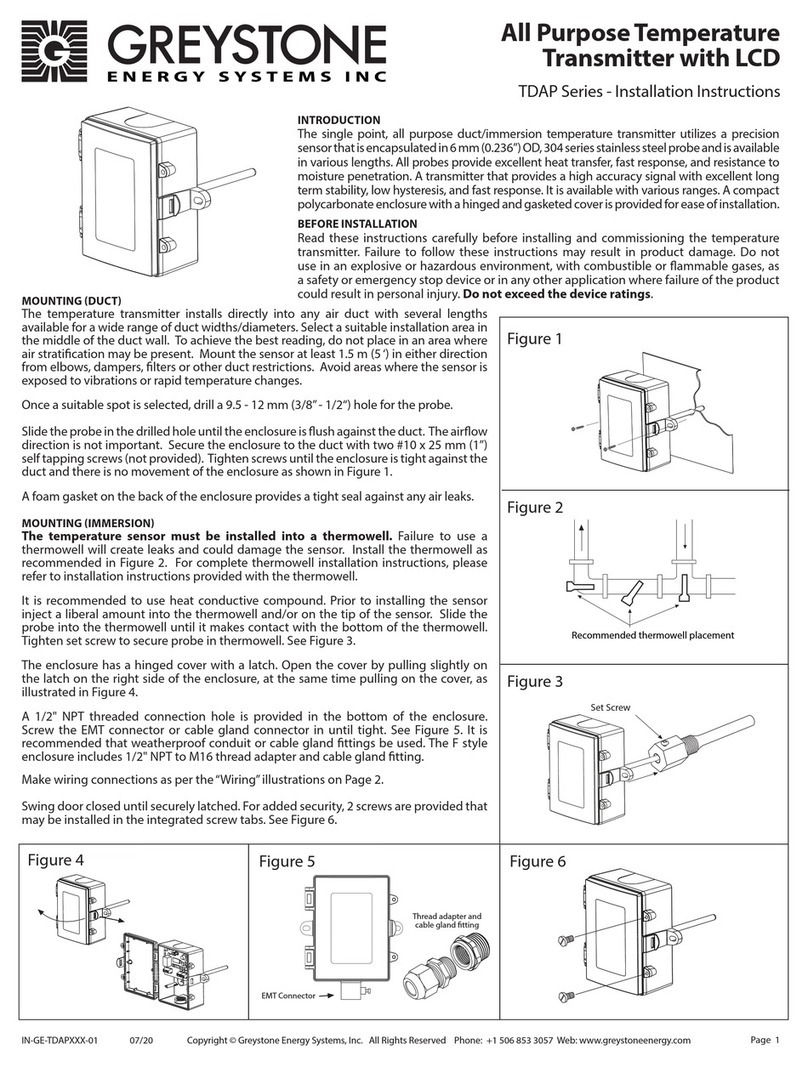

Fig. 3.3 - Gain Selection Switch 8

3.7 GAIN SELECTION

Switch 8 allows selection of Hi and Lo gain. In the Hi position (normal for gauging transducer)

the span pot RV2 will allow a gain adjustment of 5 and has an input range of 0 to 320mV for a

4-20mA output. In the Lo position (normal for displacement transducers) the span pot RV2 will

allow a gain adjustment of 5 and an input range of 0 to 150mV for a 4-20mA output (ref. Table

5.1).

Table 3.3 - Gain Selection Switch 8

5

6

7

4

3

2

1

Span

Zero

Gain Switch

On

RV1

RV2

2

3

4

5

6

7

8

1

Gain Selection

Switch 8

Lo

Hi

7

8

7

8

11

Part No. 501107 Issue 13

4. ELECTRICAL CONNECTIONS

4.1 TERMINAL DESIGNATION

Connections should be made to the appropriate terminals detailed in Table 4.1 and 4.2. Refer to

Section 2 prior to making any connections.

Transducer Connections

Terminal Number Designation

1 Excitation (+)

2 Excitation (-)

3 Input (+)

4 Input (-)

Table 4.1 - Connector 1

Fig. 4.1 - Connector 1

4.2 TRANSDUCER CONNECTIONS

LVDT Connections - The following connections for standard Solartron transducers should be

made:

AX/AC/SM/AE Series

and MACH 1 (5kHz)

Pin Number Function

Red 1 Excitation (+)

Blue 2 Excitation (-)

White 3 Demodulator Input (+)

Green 4 Demodulator Input (-)

Yellow to White or Green via resistor provided

Table 4.2 - LVDT Connections

4

3

2

1

Con 1

12 Part No. 501107 Issue 13

4.3 NON-STANDARD CONNECTIONS

For non-standard transducer connections please contact your nearest Solartron Metrology office.

Note: To reverse the transducer output, ie. change for + for inward movement from null to - for

inwards movement from null, reverse connections for the green and white wires (AX/AC series)

or the black and red wires (MACH 1 series).

4.4 CONNECTING INSTRUMENTATION

Connections should be made with no power applied to the OD2. Once connections have been

made pass the wire through the grommet in the case. If required provide some cable retention to

prevent unwanted disconnection from the terminal block. Do not operate the OD2 unit without the

top cover securely fastened.

Fig. 4.2 - Connector 2

5

6

7

1

8

Con 2

13

Part No. 501107 Issue 13

A 4-20mA Transmitter is suited to current-driven indicators and provides a directly compatible

interface with computerised data acquisition and control systems. The Transmitter (Figure 4.3)

draws 4mA to operate the electronics while the position of the transducer controls a 0-16mA

current sink wired in parallel. Thus, the position of the transducer is indicated by the current con-

sumption and a broken cable is identied by zero current. This inherent ability for fault indication,

together with its low susceptibility to electrical noise and cable resistance, and the need for only

two wires make the 4-20mA Transmitter ideal for use in industrial environments.

Fig. 4.3 - 4-20mA Transmitter Connections

A 0-20mA Transmitter (Figure 4.4) works on the same principle, but without linking the two current

drives. It can therefore be used with a simpler indicator although it needs a third wire.

Fig. 4.4 - 0-20mA Transmitter Connections

Supply

Transducer

Current Driven

Indicator

Vs

Resistance = R

Two Wire Transmitter

OD2 Transmitter

7

6

4

mA

5

0-16

mA

Supply

Transducer

Current Driven

Indicator

Vs

Three Wire Transmitter

OD2 Transmitter

Resistance = R

0-20

mA

7

6

4

mA

5

14 Part No. 501107 Issue 13

5. SETTING UP

5.1 GAIN SELECTION

The coarse gain should be selected using Table 5.1 RV2 (span) may then be used for fine

adjustment.

Transducer

Range Useable (mm)

4-20mA 0-20mA

Low Gain High Gain Low Gain High Gain

SM/1 0.7 to 3.6 0.2 to 1.0 0.9 to 4.5 0.3 to 1.3

SM/3 0.8 to 4.1 0.2 to 1.1 1.0 to 5.1 0.3 to 1.5

AC/15 3.1 to 15.6 0.9 to 4.4 3.9 to 19.5 1.1 to 5.5

AC/25 5.3 to 26.5 1.5 to 7.5 6.7 to 33.2 1.9 to 9.4

AC/50 11.4 to 57.0 3.2 to 16.1 14.3 to 71.3 4.1 to 20.2

AC/100 21.2 to 106.0 6.0 to 30.0 26.6 to 132.6 7.6 to 37.6

AC/250 14.2 to 71.4 50.5 to 252.4 18.0 to 90.0 63.0 to 316.0

AX/1 0.5 to 2.5 0.14 to 0.7 0.6 to 3.2 0.2 to 0.9

AX/1.5 & AX/2.5 0.7 to 3.5 0.2 to 1.0 0.9 to 4.4 0.3 to 1.3

AX/5 1.0 to 5.0 0.3 to 1.4 1.3 to 6.3 0.4 to 1.8

MACH 1 Series

(5kHz only)

BS/1.5 0.4 to 2.0 0.1 to 0.6 0.5 to 2.5 0.1 to 0.7

B S/2.5 0.5 to 2.5 0.1 to 0.7 0.6 to 3.2 0.2 to 0.9

BS/5 1.0 to 5.2 0.3 to 1.5 1.3 to 6.5 0.4 to 1.8

BS/7.5 2.1 to 10.4 0.6 to 2.9 2.6 to 13.0 0.7 to 3.7

BS/10 3.9 to 19.3 1.1 to 5.5 4.8 to 24.1 1.4 to 6.8

BS/15 3.7 to 18.6 1.1 to .3 4.7 to 23.3 1.3 to 6.6

BS/25 6.8 to 34.0 1.9 to 9.6 8.5 to 42.5 2.4 to 12.0

Table 5.1 - Gain Selection

Note: The upper gain limit will be set by the transducer. For example, although the 4-20mA

electronics with low gain will allow an AX transducer to be used over the stroke range E2.5mm

(0.31in), it is only a 1mm (0.24in) transducer, so E1mm (E0.24in) is the practical limit.

5.2 ZERO ADJUSTMENT

The Zero (RV1) control allows the zero voltage output position to be adjusted within the normal

stroke of the transducer. Sufficient zero adjustment is provided so that the minimum stroke range

can be used anywhere within the maximum range. For example, with the SM3 transducer and

the 4-20mA transmitter operating with switch 8 OFF (low gain), the Span range is approximately

for E0.8mm (E0.03in) up to E4.1mm (E0.17in) (E3mm in practice). Adjustment of the Zero

control can place the E0.8mm (E0.03in) anywhere in the length of the transducer from -3.0 to

-1.4mm (-0.12 to -0.057in) and from +1.4 to +3.0mm (+0.057 to +0.12in). Less Zero adjustment

is available with a wider span, but does not apply in this case since it would involve moving

outside the transducer’s range.

5.3 OTHER SWITCH SETTINGS

Referring to Chapter 3, Table 3.2, set the other switch settings S1 to S7 to a suitable position.

15

Part No. 501107 Issue 13

6. CALIBRATION

6.1 CALIBRATION WITH STANDARD SOLARTRON TRANSDUCERS

6.1.1 4-20mA Transmitter

Move the transducer to the 4mA end of its required travel and adjust the Zero control to give 4mA.

If 4mA cannot be obtained, rotate the Span control clockwise until it can.

Move the transducer to the 20mA end of its required travel and adjust the Span control to give

20mA. If the output stays at 4mA or falls, again the transducer white and green connections are

probably reversed. It will prove necessary to adjust the Zero and Span controls more than once to

achieve a satisfactory stroke range.

6.1.2 0-20mA Transmitter

Move the transducer to the 0mA end of its required travel and adjust the Zero control to give 0mA

on an indicator. The control should be set for just 0mA since the current cannot go negative and a

wide range of Zero control may produce 0mA. It may be necessary to slightly adjust the Span con-

trol clockwise, in association with Zero control, in order to achieve 0mA if the transducer is being

operated over a small range at one end of its travel.

Move the transducer to the 20mA end of its required travel and adjust the Span control to give

20mA. If the current stays at 0mA, try reversing the white and green transducer connections. It

may prove necessary to adjust the Zero and Span controls more than once to achieve a satisfac-

tory stroke range.

16 Part No. 501107 Issue 13

APPENDIX A

GENERAL TRANSDUCER CONNECTIONS: AX, AC, MD, SA, SM Series, & MACH 1

Connections to connector 2 should be made as indicated:

Yellow wire on LVDT’s:

a) Normally left unconnected and insulated.

b) On some transducers a resistor must be connected from yellow to green or white as

instructed on transducer calibration sheet.

c) Do not extend beyond standard cable length fitted to transducer.

Where screen is used, connect to case of plug. Ensure that elsewhere the screen is isolated

electrically.

Cable colours are as fitted to Solartron transducers.

Increase of element impedance marked P gives a positive going voltage output.

Note: The black lead should only be connected if the transducer case is to be grounded.

P

LVDT

Blue

Pin

Red

Screen

2 Energising

1 Voltage

White

Green

4

To Conditioner

3

Black

Ground (4)

17

Part No. 501107 Issue 13

APPENDIX B

Common Specications

Power Supply Oscillator/Demodulator

Power Supply 13 - 42V dc Oscillator frequency 5kHz or 13kHz switchable

Oscillator output voltage 0.9V rms

Oscillator max. current 16mA

Loading Up to 30mA Input sensitivity for rated

output

30 to 530mV/V

in 2 coarse gain positions

Supply Protection Protected internally

against reversed

connections

Range of gain control 3.5:1 switched

5:1 adjustable

Output

Mechanical Non-Linearity Better than 0.02%

Output zero Offset Up to 100% on maximum

gain

Case Size 120mm x 80mm x

54.5mm

Output protection Output open/short circuit

protected

Weight 400g Output ripple @ 5kHz 0.1% rms maximum

Mounting Four (4) Fixing Holes Output lter 25Hz cut off, critically

damped

Termination Connector Screw

Terminals

Effect of Supply Change Negligible

Cable Gland Accept wire 1 to 5mm

dia.

Effect of Temperature

Change

Zero 0.01% per oC

typical

0-60oC Span 0.01% per oC

typical

Case Material Light grey ABS plastic Zero 0.02% per year

typical

Span 0.03% per year

typical

Environment Sealed to IP65 Oscillator protection Open and short circuit

protected

Table B1.1

Instruments Referred to by this Manual

Part Number Description

910764 OD2 Displacement Transmitter

Table B1.2

Table of contents

Popular Transmitter manuals by other brands

YOKOGAWA

YOKOGAWA Dpharp vigilantplant EJA210A user manual

Emerson

Emerson Rosemount Oxymitter 4000 instruction manual

IDTOLIGHT

IDTOLIGHT OKLAHOMA installation instructions

Crystal Vision

Crystal Vision Vision FTX-VF user manual

VESALA

VESALA MicroSonde VMS6-33 user manual

GESTRA

GESTRA LRGT 16-2 installation instructions

UniKit

UniKit UX300-FCC user manual

Emerson

Emerson Rosemount 3095FB MultiVariable MODBUS Quick installation guide

Altinex

Altinex Intera Video+Audio to Twisted Pair (UTP) Transmitter... user guide

Questtel

Questtel L-1SDI-FE-HD-TX user manual

SPOTTUNE

SPOTTUNE STREAM user manual

ICS

ICS LH-10 operating instructions