SolaX Power TBMS-MCR0800 User manual

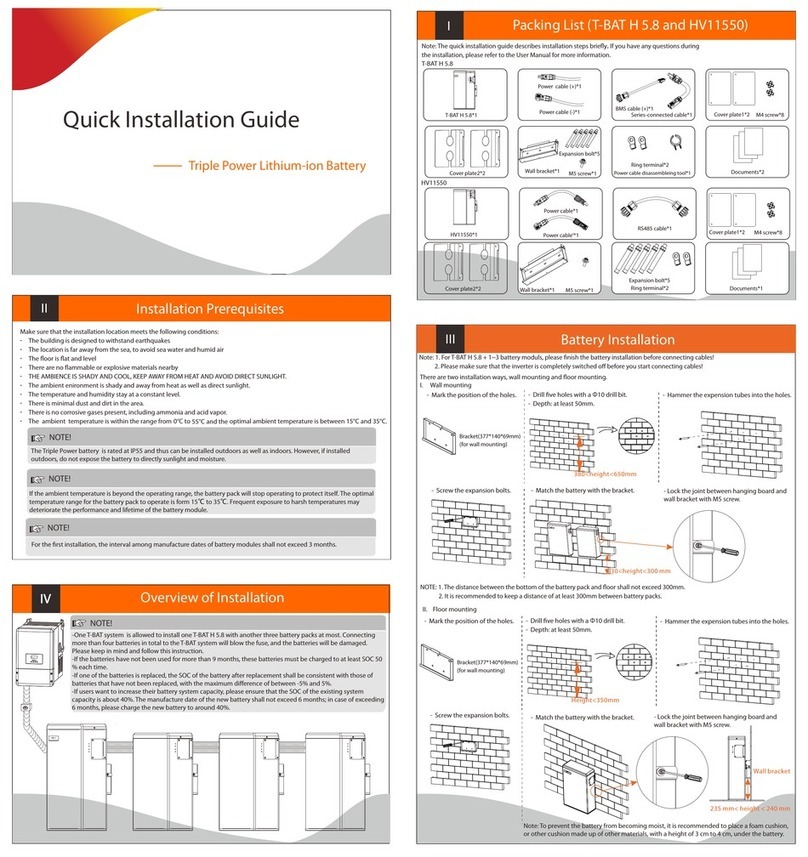

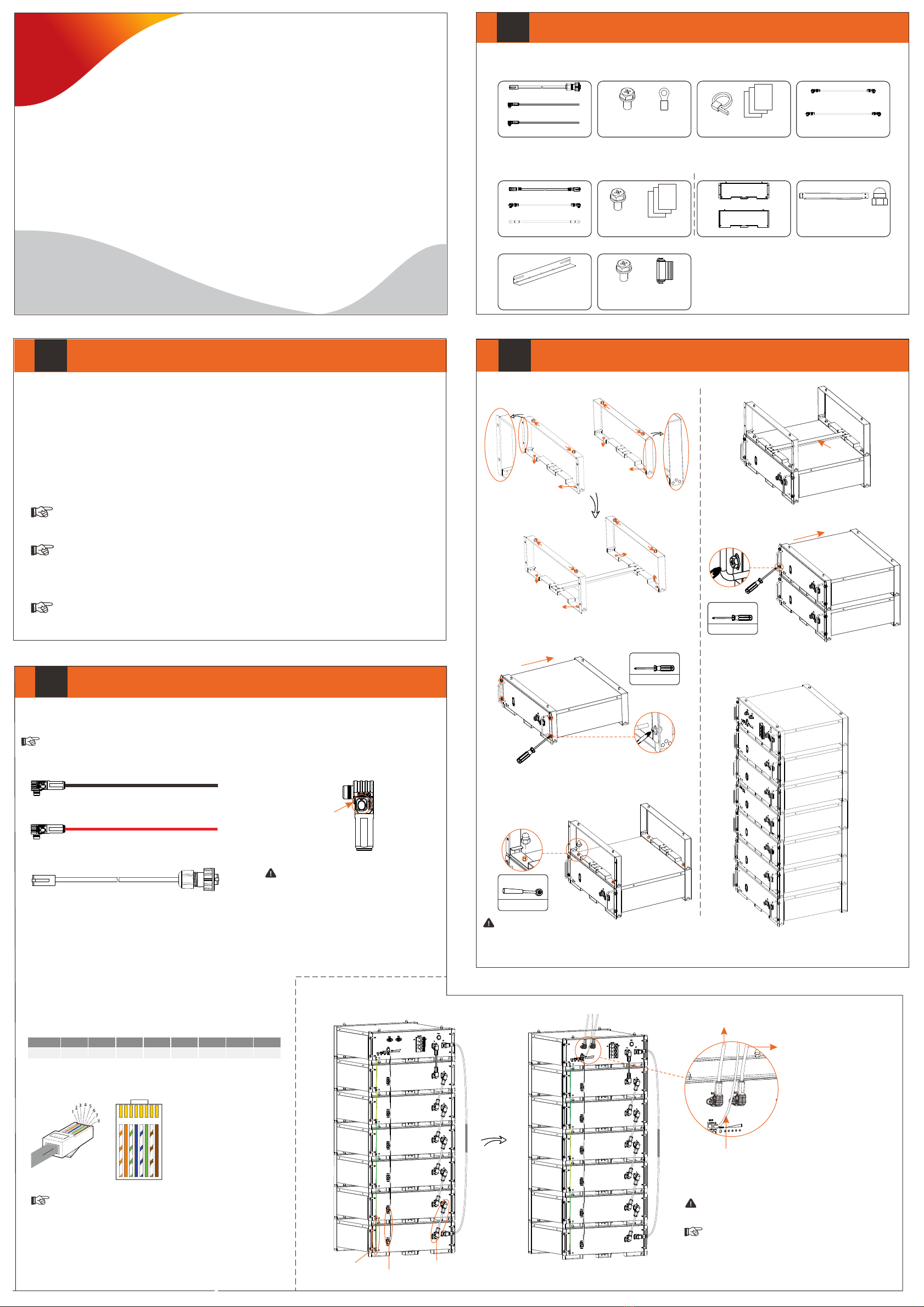

Packing List

I

II Installation Prerequisites III

Wiring for Rack Installation

IV

Ensure that the installation location meets the following conditions:

The building is designed to withstand earthquakes

The location is far the sea to avoid salt water and humidity, over 3280.84 ft/1000 mfrom

The floor is flat and level

There are no flammable or explosive materials, at a minimum of 2.95 ft/0.9 m

The ambience is shady and cool, away from heat and direct sunlight

The temperature and humidity remain at a constant level

There is minimal dust and dirt in area

There are no corrosive gases present, including ammonia and acid vapor

Where charging and discharging, the ambient temperature ranges from 32℉/0°C to 113℉/45°C

ŸŸŸŸŸŸŸŸŸŸ

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

In practice, the requirements of battery installation may be different due to enviroment and locations.

In that case, follow up the exact requirements of the local laws and standards.

BMS (TBMS-MCR0800):

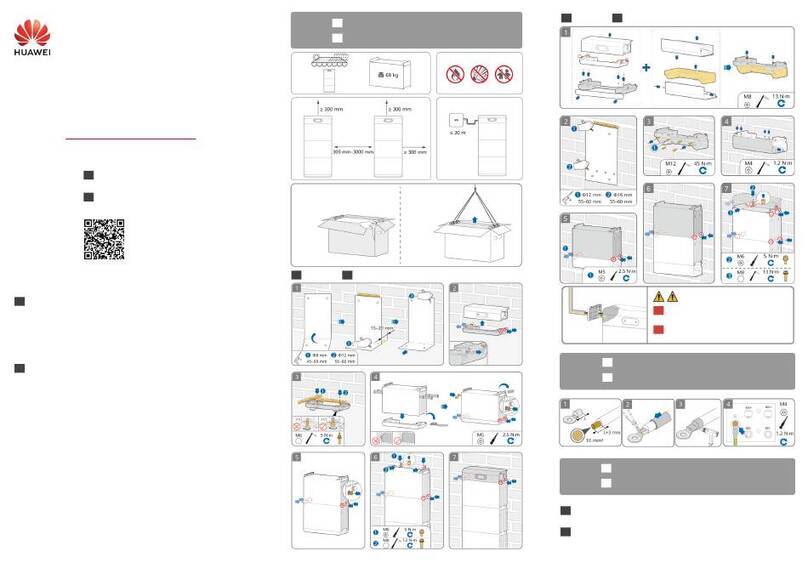

Rack Installation

For details, please refer to the User Manual.

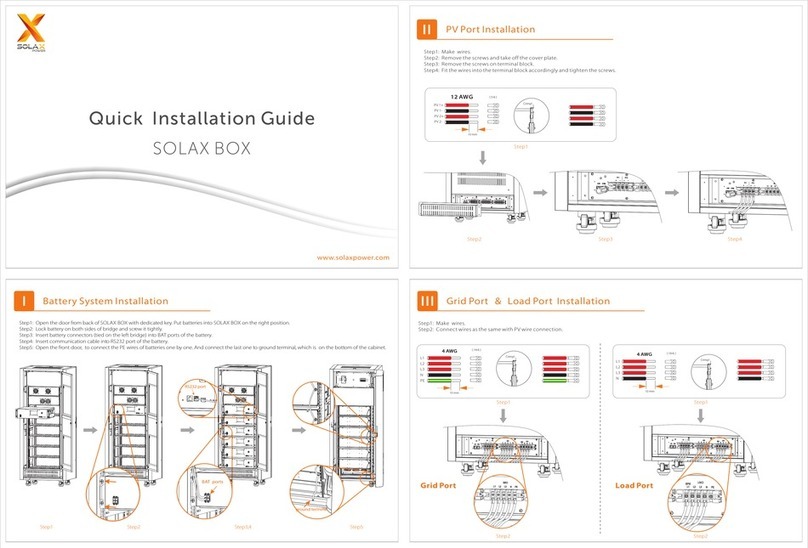

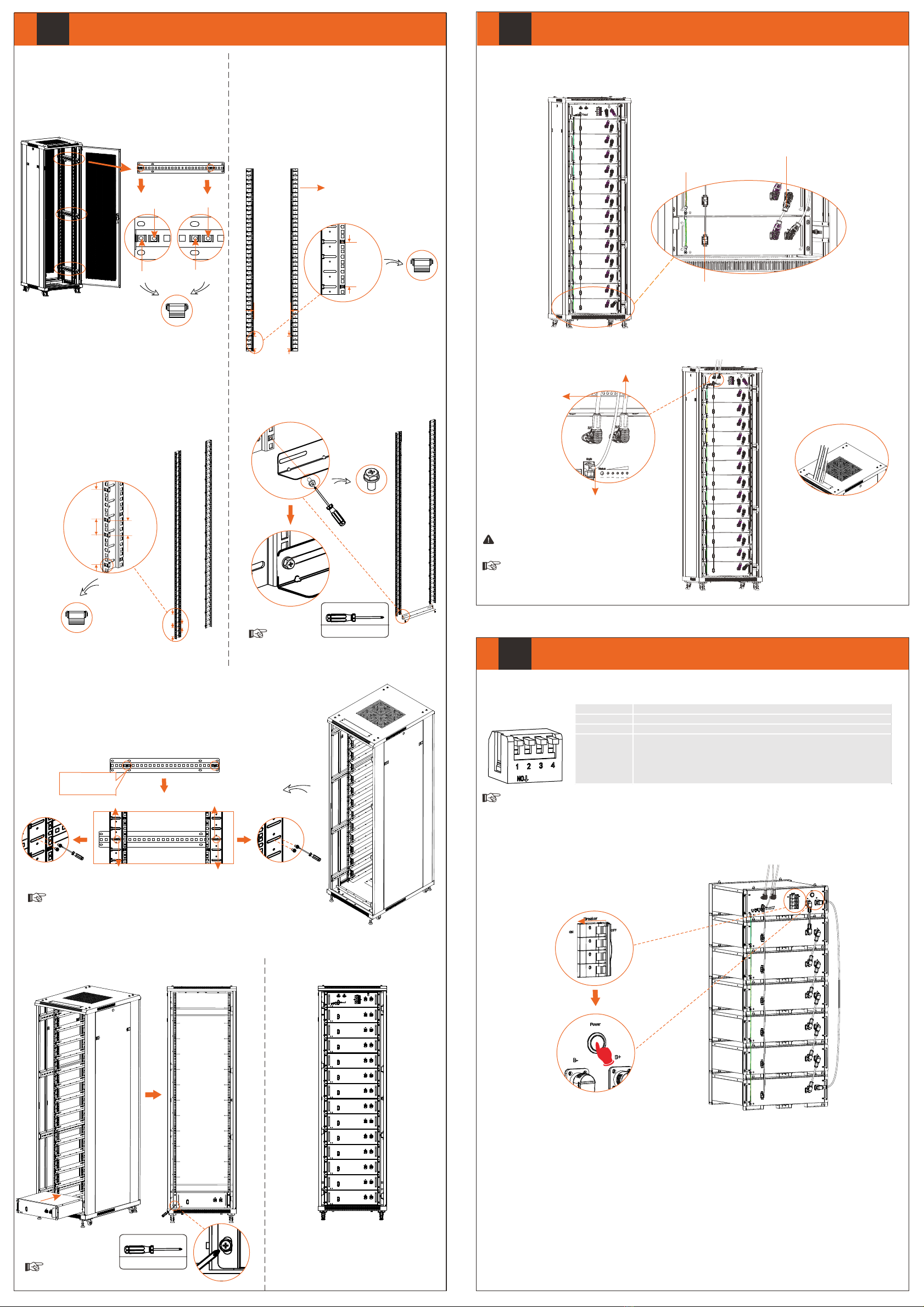

Step 1. Assemble rack

Note: The Quick Installation Guide briefly describes the required installation steps. If you have any question,

please refer to the User Manual delivered with BMS for more details.

Quick Installation Guide

—— Triple Power Lithium-ion Battery

50 Ah, 72Ah

Accessories for Cabinet

L-shaped Transverse

Support x 2

M6*L16 x 4

Cassette Nut x 8

Step 2. Put the battery module into the rack, and screw it

with M6 × L16

M6 X L16 * 4

Torque: 4-5 N·m

Step 3. Add the rack and battery module

① Put the Front and Rear Sides

② Screw both sides with Cap Nuts

③ Place the metal plate

Metal plate

④ Put the battery module

⑤ Screw M6×L16

M6 X L16 * 4

Torque: 4-5 N·m

Step 5. Repeat the Step 4 to install the remaining battery

modules and BMS

After finishing installation, it is shown as follows:

Caution!

There are two disassembly methods, with details as follows:

1. In case the entire device needs to be replaced, remove it from the top down, including Rack;

2. In case one of the battery modules needs to be maintained, remove such a battery module, reinstall it after finishing

maintenance. If there is any other battery that needs to be maintained, repeat the above-mentioned steps.

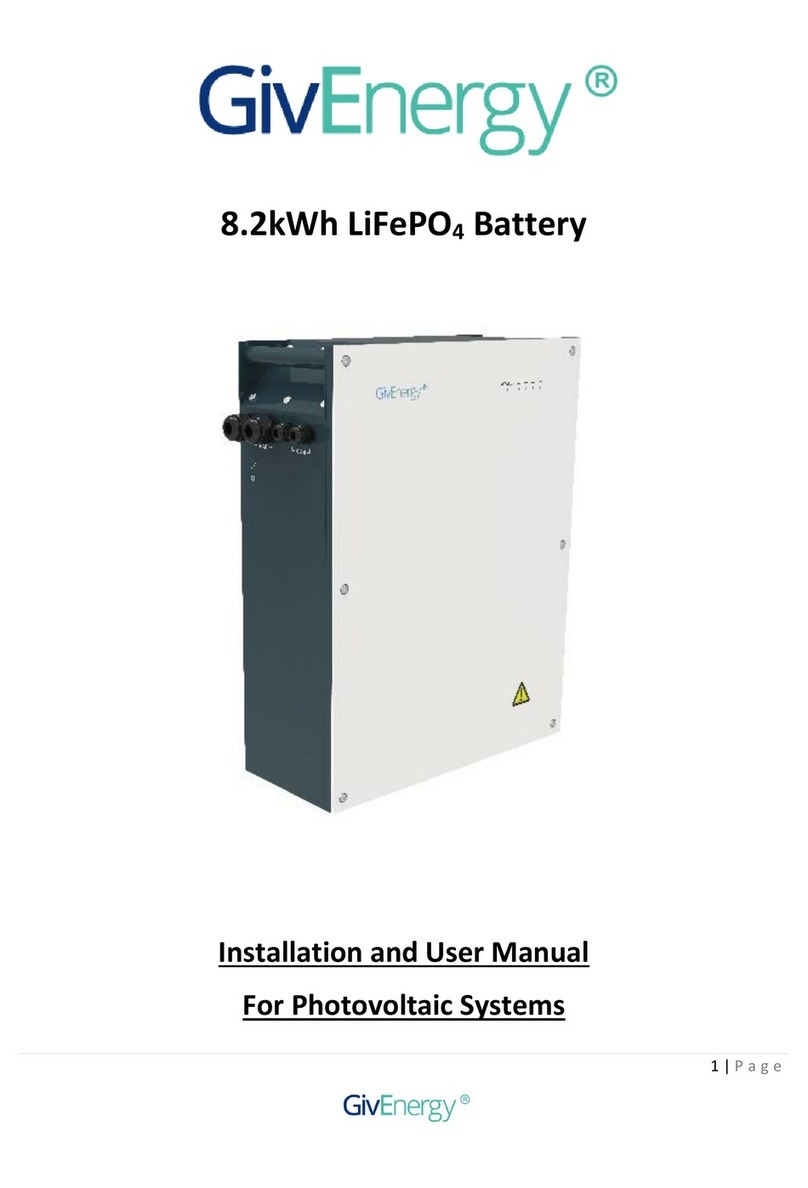

Power Cable

Communication Cable

Ground Wire

1. Connect battery to battery, and battery to BMS

Power cable: BAT+ of BMS

to BAT+ of inverter

Communication cable: BMS of

BMS to BMS of inverter

Power cable: BAT- of

BMS to BAT- of inverter

2. Connect BMS to inverter

■BMS to Inverter

As users insert a power cable, the users should hear a click

which indicates that the cable connector is properly inserted

into the port.

Note!

The Triple Power battery module is rated at IP20 and thus can be installed outdoors as well as indoors. However, if

installed outdoors, the battery pack shall not be exposed to direct sunlight and moisture.

Note!

If the ambient temperature exceeds the operating range, the battery pack will stop running to protect itself.

The optimal temperature range for operation is -4℉/-20°C to 122℉/50°C. In the allowable range, the relative

humidity range should be between 0% and 90% RH. Frequent exposure to harsh temperatures may deteriorate its

performance and lifetime.

Note!

For the first installation, the interval among manufacture dates of battery modules shall not exceed 3 months.

Note!

OneBattery Module (TP-HR25/TP-HR36 × 1): Accessories for Quick Rack:

Front Side x 1

Rear Side x 1

Metal Plate x 1

Cap Nut x 4

Communication Cable x 1

Power Cable x 1

Ground Wire x 1 Quick Installation Guide x 1

M6*L16 x 4

Note: The accessory with the “*” mark indicates that it will not be provided by our company, with 1.2 meters for 2 to 6

battery modules and 2.2 meters for 7 to 13 battery modules. Users can purchase from SolaX based on their own needs.

Note!

Power cable (red): BAT+ of BMS to BAT+ of inverter

Power cable (black): BAT- of BMS to BAT– of inverter

Lock Button

Press and hold the “Lock Button” while

unplugging the power cable. Otherwise, it

cannot be pulled out.

Caution!

Communication cable: Connecting BMS's BMS and the

inverter's BMS

The grounding wire must be connected.

Caution!

Sequence 1 2 3 4 5 6 7 8

BMS //BMS_H BMS_L /A1 B1

GND

■Making a BMS communication cable

If users want to make a BMS communication cable or a BMS

communication cable is required to be made before wiring, to ensure

normal operation of BMS and inverter, please read the following carefully.

The specific definition of the communication cable is shown as follows:

The wire order of the communication cable is as follows:

1 2 3456 7 8

1) Orange stripes on white

2) Orange

3) Green stripes on white

4) Blue

5) Blue stripes on white

6) Green

7) Brown stripes on white

8) Brown

The BMS communication cable shall have a shield layer.

Note!

Communication Cable x 1

Power Cable (Black) x 1

Power Cable (Red) x 1

M6*L16 x 4

Ground Terminal x 2 Cable Tie x 3

Documentation x 2

The connector connecting to inverter from BMS is delivered with the inverter, for details, please refer to the inverter's

User Manual.

Note!

Power Cable (1.2 m) *

Power Cable (2.2 m) *

Front side

Location hole

Location pin

Front

Back side

Location pin

Location hole

Rear

Metal plate

Back side

Front side

Location hole

Location pin

Location pin

Location hole

Torque: 4-6 N·m

Cap Nut * 4

V

VI

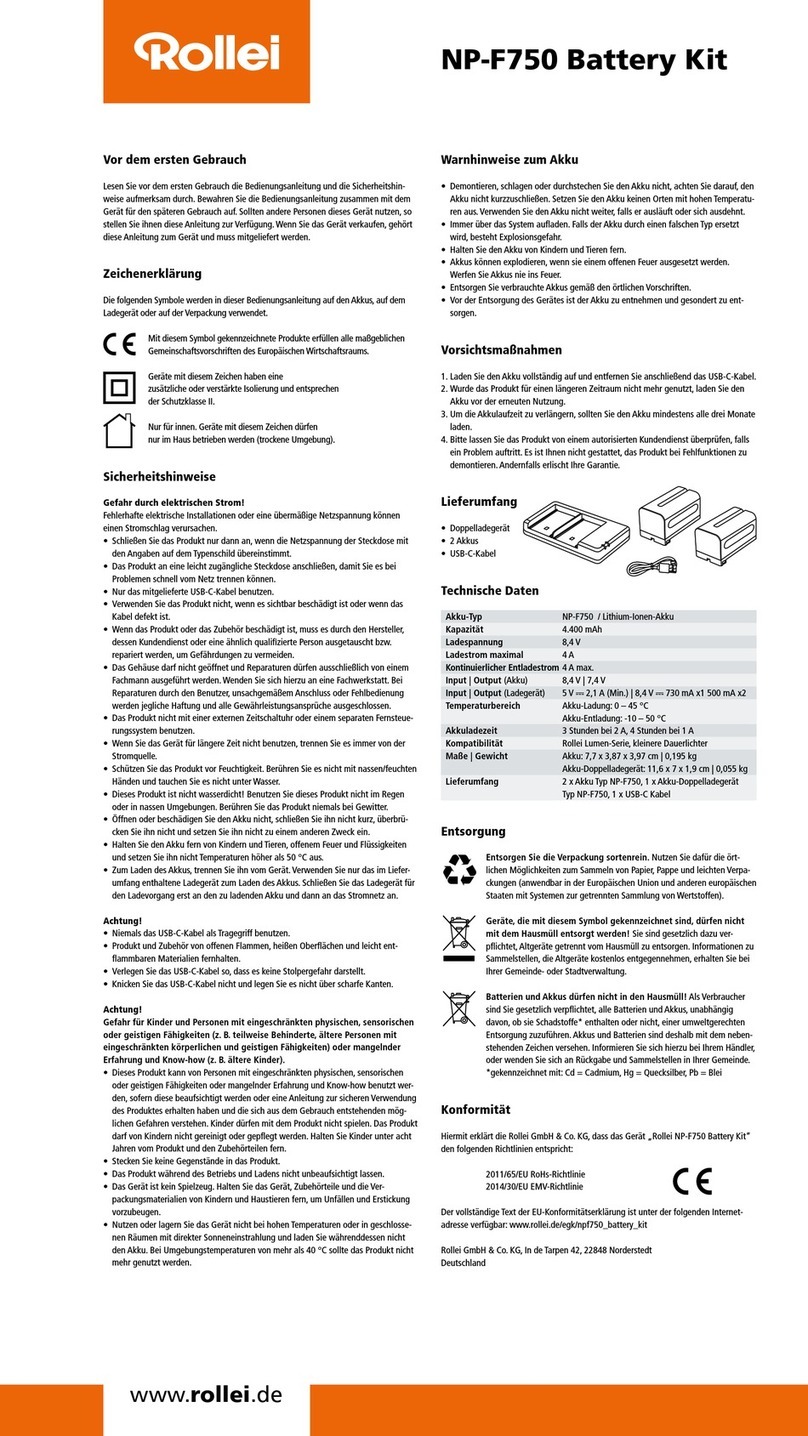

Wiring for Cabinet Installation

VII

Commissioning

Cabinet Installation

As for the installation of outside cabinet, please follow the

guide delivered with the cabinet.

Note: When installing outside cabinet, Cassette Nuts shall

be inserted before installing Fixed Rails, with 4 Cassette

Nuts for one Fixed Rails. There are totaling 3 Fixed Rails.

See figure below.

Step 2. Insert Cassette Nuts into holes on the front

Mounting Rail facing the cabinet door, with totaling 28

Cassette Nuts of one front Mounting Rail.

① Insert the first Cassette Nut;

② Insert the second Cassette Nut 2U from the first;

③ Insert the third Cassette Nut 1U from the second;

④ Then repeat ② and ③.

Step 3. Fix and screw the L-shaped Transverse Support on

the Mounting Rails with Cross External Hexagon Screw

(M6*L16 X 4) (Torque: 4-5 N·m). Make sure the two

Mounting Rails on one side are at the same level.

Step 5. Place battery modules into the cabinet, and screw them

(Torque: 4-6 N·m)

Step 6. Repeat the Step 5 until BMS has been

put into the cabinet.

Regarding installing PV terminal to the power cables and making a BMS communication cable, please refer to “IV Wiring

for Rack Installation”.

1. Connect battery to battery, and battery to BMS

Power Cable

Communication Cable

Ground Wire

2. Connect BMS to inverter

320102038401

M6 X L16 * 2

Torque: 4-5 N·m

The two location holes on the L-shaped Transverse

Support are long, please attach the screws at the end of

holes near mounting rail.

Note!

Step 4. After all L-shaped Transverse Support are secured,

(1) Attach the assembled Mounting Rails into the cabinet, making sure all four Mounting

Rails are at the same level.

(2) Fix the assembled Mounting Rails on Fix Rail by using 4 screws (delivered with the

cabinet), and insert 2 screws into the 4th and 5th location holes near the front side, and

2 screws into the 1st and 2nd holes near rear side.

• Please prevail in kind.

• Cassette Nuts shall be inserted before installing the assembled

Mounting Rails, with 4 screws for one Fixed Rails.

• Ensure that heavy duty castors are tight and firm.

Note!

• DIP Switch

The DIP switch is equipped on BMS.

Black Start: In case of pressing and hold the POWER button for less than 20 sec, the status light will flash green light for 1 sec

and then turn off for 4 sec, with a period of 5 sec. After pressing and holding the POWER button for 20 sec, the status light will

come on solid green light, and the SOC power indicators will flash as follows: 1) the 3rd indicator (from left to right) flashes

yellow light, and the remaining indicators are off; 2) the 2nd and 4th indicators flash yellow light, and the remaining indicators

are off; 3) the 1st and 5th indicators flash yellow light, and the remaining indicators are off; 4) all the power indicators are off.

The whole process will last for 0.4 sec.

But, we do not recommend to use the Black Start as it may cause communication port to be charged, resulting in an electric

shock.

Before commissioning, please check to ensure that, the installed battery modules are the same model battery module, and all

the ground wires, power cables and communication cables are connected.

Power ON

After finishing wiring,

1. Turn the Breaker on;

2. Press the POWER buttom for 5 sec, to start system.

■If the batteries have not been used for more than 9 months, these batteries must be charged to at least SOC 50 % each

time.

■For the first installation, the interval among manufacture dates of battery modules shall not exceed 3 months.

■If a battery is replaced or added for capacity expansion, each battery's SOC should be consistent. The max. SOC

difference should be between ±5%.

■If users want to increase their battery system capacity, please ensure that the SOC of the existing system capacity is

about 40%. The manufacture date of the new battery shall not exceed 6 months; in case of exceeding 6 months, please

charge the new battery to around 40%.

The DIP switch 4 is pressed at the factory settings.

To adjust the DIP switch, a small flat-head screwdriver shall be prepared by users themselves.

Note!

Communication cable: BMS of BMS to BMS of inverter

(Note: The Link port on the BMS is for parallel

connection only. DO NOT use for any other purposes.)

Power cable:

BAT+ of BMS to

BAT+ of inverter

Power cable: BAT- of BMS

to BAT- of inverter

As users insert a power cable, the users should

hear a click which indicates that the cable

connector is properly inserted into the port.

Note!

The grounding wire must be connected.

Caution!

After completing wiring, these cable

shall be through the threading hole

on the caber plank.

Front

Rear

Cables

As for the installation of inside cabinet, please follow the

steps as below.

There are two alternative sizes (22U and 42U) of cabinets

available for users. The following steps take 42U (1U = 4.445

cm) with 13 battery modules as an example.

Step 1. Insert Cassette Nuts into the holes on the Mounting

Rails (*4) every 3U (1U = 4.445 cm), with totaling 14

Cassette Nuts of one Mounting Rail. The distance between

two Mounting Rails on one side shall be at about 12.99

inches/330 mm.

Front sideRear side

Second

First

Fourth

Fifth

M6 X L16 * 4

Torque: 4-6 N·m

Please prevail in kind.

Note!

Side View of Cabinet

The four Mounting Rails are in

the Package C of NCB Network

Cabinet.

(Cassette Nuts *14) x

( Mounting Rail * 4)

Front Rear

12.99 inches

330 mm

3U

3U

3U

First Cassette Nut

Second Cassette Nut

Third Cassette Nut

Forth Cassette Nut

2U

1U

2U

Front

Rear

(Cassette Nuts *28) x

( Mounting Rail (front) *2)

2U

1U

2U

Front

Rear

Adjust

Refer to the

step above

Front side Rear side

Fourth

Fifth First

Second

Front side Rear side

DIP switch 1 A reserved function

DIP switch 2 A reserved function

DIP switch 3 A reserved function

DIP switch 4

Terminal resistance

Note: 1. The DIP switch 4 shall be flipped down (open the circuit) when

connecting BMS to inverter; 2. In case of parallel connection, only shall the

DIP switch 4 on the last BMS be flipped down (open the circuit), and the DIP

switch 4 on the rest of BMS shall be flipped up (close the circuit).

This manual suits for next models

2

Other SolaX Power Batteries Pack manuals

Popular Batteries Pack manuals by other brands

Clas Ohlson

Clas Ohlson PW-290A quick start guide

SUEX

SUEX 71212 USER INSTRUCTION MANUAL AND WARNINGS

GivEnergy

GivEnergy Giv-Bat8.2 Installation and user manual

Rollei

Rollei NP-F750 manual

Harris Battery

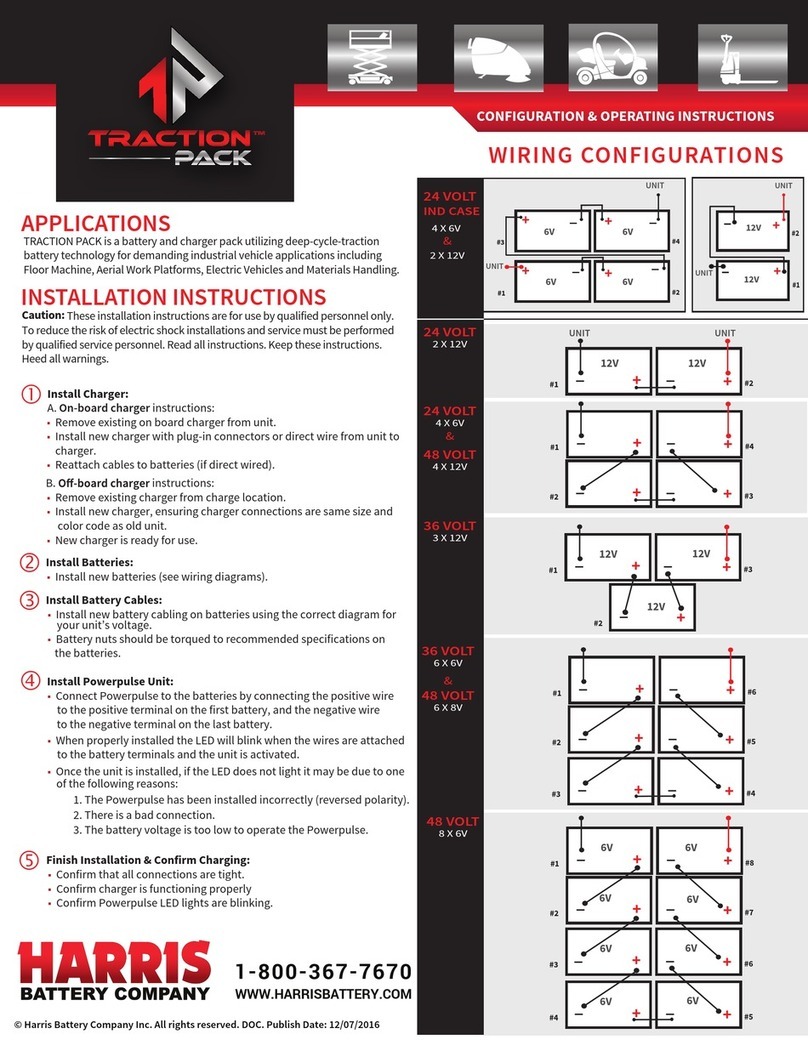

Harris Battery TRACTION PACK Configuration and Operating Instructions

Panasonic

Panasonic CF-VZSU29U operating instructions