SolaX Power G2 User manual

品名

材料

料号

单位 页次

设计

审核

核准

320101064101 浙江艾罗网络能源技术股份有限公司

NA

REV. REV.

Description Description

0.0

品名

料号

单位

320101064101

页次

浙江艾罗网络能源技术股份有限公司

SolaX Power Network Technology (Zhejiang) Co., Ltd.

技术要求:

1.封面封底157g铜版纸覆哑膜彩打,内部纸80g双胶纸黑白印刷,正反打印

2.装订方式:页码大于60需用胶装

3.未注尺寸公差按 +- 1.5mm

4.图面、字体印刷清晰、无毛边、不起边、油墨不脱落

5.字体颜色为PANTONE Black C,无边框,底色为白色

6.符合RoHS要求

赵焱

施鑫淼

郑安琪 2023/10/26

210 mm

143mm

User Manual

说明书 BMS Parallel Box-Ⅱ G2 英文版 SolaX 01版

2023/10/26

2023/10/26

说明书 BMS Parallel Box-Ⅱ G2 英文版 SolaX 01版

Triple Power BMS Parallel Box- G2

EN

Ⅱ

修改所有涉及并联盒外观及端口细节的示意

图,连接T30&T58及逆变器的接线示意图。

修改丝印CAN为M-CAN/S-CAN。

0.1

郑安琪 2023/10/26

郑安琪 2023/09/20

首次发布

Triple Power BMS Parallel Box- G2

User Manual

Copyright © SolaX Power Technology (Zhejiang) Co., Ltd. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any

means without prior written consent of SolaX Power Technology (Zhejiang) Co., Ltd.

(hereinafter referred to as SolaX). SolaX reserves the right of final interpretation.

320101064101

SolaX Power Network Technology (Zhejiang) Co., Ltd.

Add.: No. 288, Shizhu Road, Tonglu Economic Development Zone, Tonglu City,

Zhejiang Province, 310000 P.R. CHINA

Tel.: +86 (0) 571-5626 0011

E-mail: info@solaxpower.com

EN

Ⅱ

CHANGE HISTORY

Changes between document versions are cumulative. The latest version

contains all updates made in previous versions.

Version 01 (Oct. 26, 2023)

Version 00 (Sept. 21, 2023)

Initial release

Updated all pictures that include the appearance and port details of

the parallel box.

Contents

1 NOTE ON THIS MANUAL

1.1 SCOPE OF VALIDITY..........................................................................................

1.2 TARGET GROUP...................................................................................................

1.3 SYMBOLS USED..................................................................................................

2 SAFETY................................................................................................................................

2.1 APPROPRIATE USAGE.......................................................................................

2.2 IMPORTANT SAFETY INSTRUCTIONS.........................................................

2.3 QUALIFIED INSTALLER......................................................................................

3 PRODUCT INTRODUCTION.......................................................................................

3.1 PRODUCT OVERVIEW......................................................................................

3.1.1 DIMENSIONS .........................................................................................................

3.1.2 APPEARANCE.......................................................................................................

3.2 BASIC FEATURES................................................................................................

3.2.1 FEATURES...............................................................................................................

3.2.2 CERTIFICATIONS.................................................................................................

3.3 TECHNICAL DATA...............................................................................................

4 INSTALLATION.................................................................................................................

4.1 INSTALLATION PREREQUISITES...................................................................

4.2 SAFETY GEAR......................................................................................................

4.3 TOOLS....................................................................................................................

4.4 INSTALLATION.....................................................................................................

4.4.1 CHECK FOR TRANSPORT DAMAGE...........................................................

4.4.2 UNPACKING...........................................................................................................

4.4.3 ACCESSORIES.....................................................................................................

4.4.4 MOUNTING STEPS.............................................................................................

.............................................................................................

OVERALL INSTALLATION................................................................................

14

4.5

1

1

1

1

2

2

3

11

11

11

12

12

4

6

6

6

7

8

8

9

10

10

10

11

8

1 NOTE ON THIS MANUAL..............................................................................1

1.1 SCOPE OF VALIDITY...............................................................................1

1.2 TARGET GROUP......................................................................................1

1.3 SYMBOLS USED.......................................................................................1

2 SAFETY .....................................................................................................2

2.1 APPROPRIATE USAGE ...........................................................................2

2.2 IMPORTANT SAFETY INSTRUCTIONS................................................3

2.3 QUALIFIED INSTALLER ..........................................................................4

3 PRODUCTION INTRODUCTION ................................................................6

3.1 PRODUCTION OVERVIEW ...................................................................6

3.1.1 DIMENSIONS............................................................................6

3.1.2 APPEARANCE ...........................................................................7

3.2 BASIC FEATURES ....................................................................................8

3.2.1 FEATURES .................................................................................8

3.2.2 CERTIFICATIONS.....................................................................8

3.3 TECHNICAL DATA ..................................................................................8

4 INSTALLATION..............................................................................................10

4.1 INSTALLATION PREREQUISITES........................................................10

4.2 SAFETY GEAR ........................................................................................10

4.3 TOOLS ...................................................................................................11

4.4 INSTALLATION.......................................................................................11

4.4.1 CHECK FOR TRANSPORT DAMAGE..................................11

4.4.2 UNPACKING............................................................................11

4.4.3 ACCESSORIES ........................................................................12

4.4.4 MOUNTING STEPS................................................................12

4.5 OVERALL INSTALLATION ....................................................................14

4.6 CABLE CONNECTION.........................................................................16

4.6.1 CONNECTING CABLES TO INVERTER .............................16

4.6.2 CONNECTING BATTERY MODULES.................................18

4.6.3 CONNECTING COMMUNICATION CABLES...................20

5 COMMISSIONING ........................................................................................21

5.1 CONFIGURING BATTERY SYSTEM....................................................21

5.2 COMMISSIONING ................................................................................22

5.3 STATUS INDICATORS ..........................................................................23

6 TROUBLESHOOTING..................................................................................24

7 DECOMMISSIONING ..................................................................................26

7.1 DISMANTLING THE BOX ....................................................................26

7.2 PACKAGING ..........................................................................................26

8 MAINTENANCE.............................................................................................27

9 WARRANTY ..................................................................................................28

* WARRANTY REGISTRATION FORM

1 Note on this Manual

1.1 Scope of Validity

This manual is an integral part of the Parallel Box Series.

It describes the assembly, installation, commissioning, maintenance and

failure of the product. Please read carefully prior to operation.

Model:

1.2 Target Group

This manual is for qualified electricians. The tasks described in this manual

should only be performed by qualified electricians.

1.3 Symbols Used

The following types of safety instructions appear in this document are descri-

-bed below:

NOTE!

“NOTE” provides tips that are valuable for the optimal operation

of your product.

BMS Parallel Box- G2

The BMS Parallel Box- G2 can be used with T-BAT-SYS-HV-5.8 or T-BAT-SYS-

CAUTION!

“CAUTION” indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

WARNING!

“WARNING” indicates a hazardous situation which, if not avoided,

could result in serious injury or death.

DANGER!

“DANGER” indicates a hazardous situation which, if not avoided,

will result in serious injury or death.

Notes on this Manual

HV-3.0. Please refer to section 4 “Installation ”from page 10 to page 20 for

NOTE!

details.

Ⅱ

Ⅱ

23

2 Safety

2.1 Appropriate Usage

For safety reasons, installers are responsible for familiarizing themselves with the

contents of this manual and all warnings before performing installation.

Safety Safety

2.2 Important Safety Instructions

CAUTION!

Danger of burn injuries due to hot enclosure parts!

During operation, the upper lid of the enclosure and the

enclosure body may become hot.

Only touch the lower enclosure lid during operation.

CAUTION!

Possible damage to health as a result of the effects of

WARNING!

Authorized service personnel must disconnect the cables

before attempting any maintenance or cleaning or work-

-ing on any circuits connected to the box.

Do not operate the parallel box when the device is

WARNING !

Risk of electric shock!

WARNING !

DANGER!

Danger to life due to high voltages in the parallel box!

All work must be carried out by qualified electrician.

The appliance is not to be used by children or persons

with reduced physical sensory or mental capabilities, or

lack of experience and knowledge, unless they have been

given supervision or instruction.

Children should be supervised to ensure that they do not

play with the appliance.

Do not stay closer than 0.66 ft/20 cm to the parallel box

radiation!

for any length of time.

running.

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

Ÿ

① Connect with T-BAT-SYS-HV-5.8

② Connect with T-BAT-SYS-HV-3.0

45

Prior to the application, please read this section carefully to ensure correct and

safe application.

Use only attachments recommended or sold by our company. Otherwise, it may

result in a risk of fire, electric shock, or injury to person.

Make sure that the existing wiring is in good condition and that the wire is not

Do not disassemble any parts of the box which are not mentioned in the user

manual. The parallel contains no user-serviceable parts.

yourself may result in a risk of electric shock or fire and will void your warranty.

Keep the parallel box away from flammable, explosive materials to avoid fire

The installation place should be away from humid or corrosive substance.

Authorized service personnel must use insulated tools when installing or working

with this equipment.

Explanation of Symbols

This section gives an explanation of all the symbols shown on the warning label.

Wear protective glasses.

Observe enclosed documentation.

Keep the battery system away from open flames or ignition

sources.

Symbol Explanation

The system must be disposed of at a proper facility for

environmentally-safe recycling.

The system should not be disposed of together with

household waste. Disposal information can be found in the

enclosed documentation.

Danger of high voltages.

Keep the battery system away from children.

Danger. Risk of electric shock.

2.3 Qualified Installer

A skilled worker is defined as a trained and qualified electrician or installer who

has all of the following skills and experience:

Knowledge of the functional principles and operation of grid-tied systems

Knowledge of the dangers and risks associated with installing and using

electrical devices and acceptable mitigation methods

Knowledge of the installation of electrical devices

Knowledge of and adherence to this manual and all safety precautions and

best practices

WARNING!

All operations of box relating to electrical connection and installation

must be carried out by qualified personnel.

TUV certification

Please keep the user manual properly.

Symbol Explanation

Keep the battery system away from open flames or ignition

sources.

Keep the battery system away from children.

Caution, risk of electric shock

Caution, risk of danger

Read the enclosed documentation.

TUV certification

undersized.

disaster.

2.4

See Warranty for instructions on obtaining service. Attempting to service the box

CE mark of conformity

UKCA mark of conformity

•

•

•

•

•

•

•

•

•

•

•

•

•

Safety

Safety

67

3 Product Introduction

3.1 Product Overview

For safety reasons, installers are responsible for familiarizing themselves with the

contents of this manual and all warnings before performing installation.

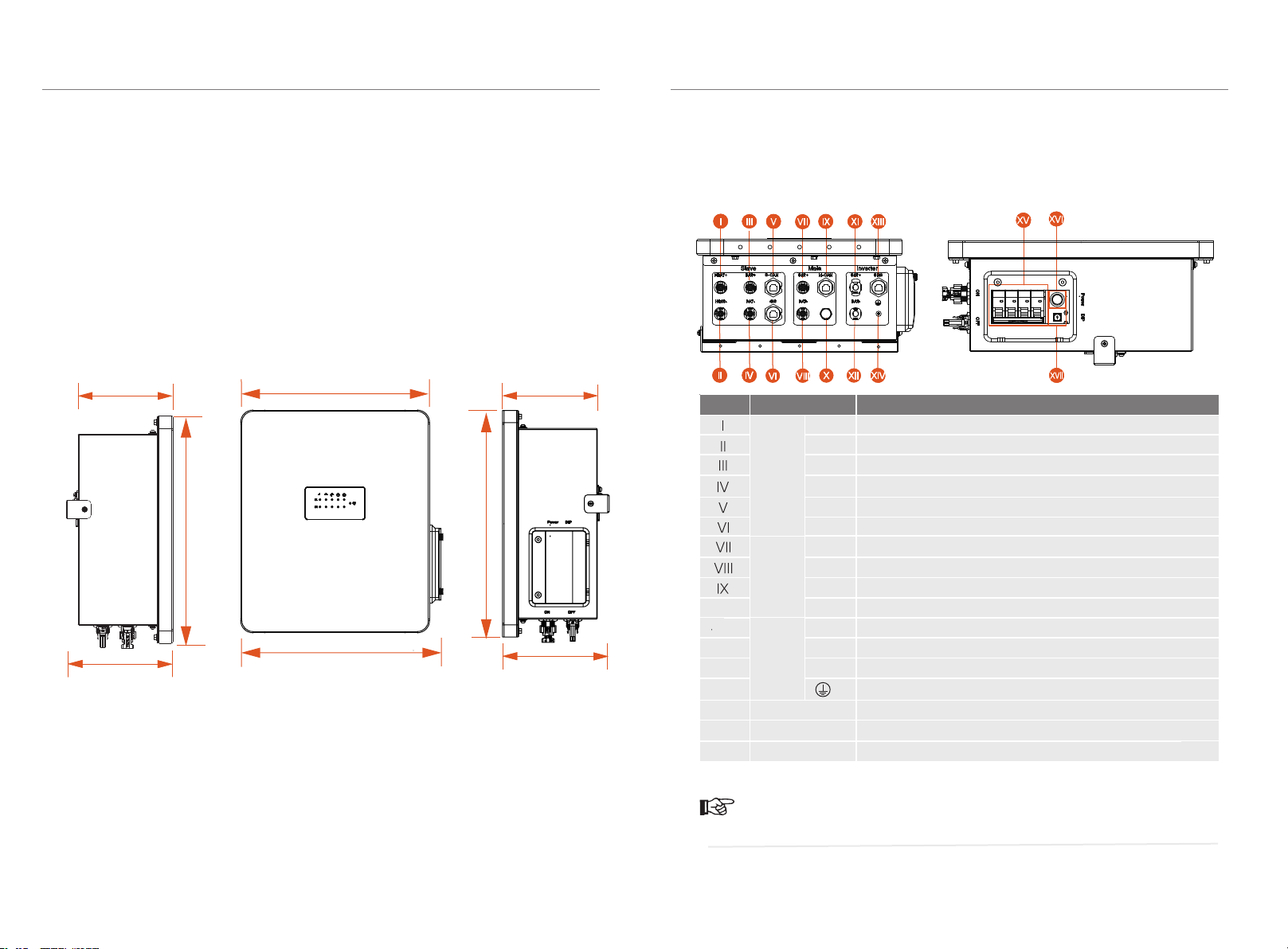

3.1.1 Dimension

Product Introduction

3.1.2 Appearance

ŸTerminals of the BMS Parallel Box-Ⅱ G2

13.15 in./334.00 mm

14.48 in./368.00 mm

12.28 in./312.00 mm

6.04 in.

153.50 mm

Object Mark Description

HEAT-

BAT-

CAN

BAT-

CAN

HEAT+

XI

X

XII

XIII

XIV

BAT+

485

BAT+

BAT+

BAT-

BMS

ON/OFF

POWER

Circuit Breaker

Power Button

DIP DIP Switch

XV

XVI

XVII

Bottom view: Right side view:

The cable connection between the BMS Parallel Box-Ⅱ G2 and T-BAT-SYS-HV-5.8

is different from that between the BMS Parallel Box-Ⅱ G2 and T-BAT-SYS-HV-3.0.

/

Connector "Heat+" of the parallel box to "Heat+" of Slave

Connector "Heat-" of the parallel box to "Heat-" of Slave

Connector "BAT+" of the parallel box to "B+"/"+" of Slave

Battery module communication of Slave

Battery module communication of Slave

Connector "BAT+" of the parallel box to "BAT+" of Main

Connector "BAT-" of the parallel box to "BAT+" of Main

Connector "BAT-" of the parallel box to "BAT+" of Main

Air Venue

Connector "BAT+" of the parallel Box to "BAT+" of inverter

Connector "BAT-" of the parallel Box to "BAT-" of inverter

Connector "BMS" of the parallel Box to "BMS" of inverter

NOTE!

6.04 in.

153.50 mm

14.48 in./368.00 mm

GND

Slave

Main

Inverter

6.79 in.

172.50 mm

6.79 in.

172.50 mm

Connector "BAT-" of the parallel box to "B-"/"XPLUG" of Slave

Please refer to Section 4. Installation starting from page 10 for detailed information.

Product Introduction

I III V VII IX XI

XIII

S-

Product Introduction

9

Product Introduction

3.2 Basic Features

3.2.1 Features

The box has advanced technology, high reliability and convenient control functions,

Secondary protection by hardware

IP65 protection level

Safe and reliable

Small occupied area

Wall mounting

3.2.2 Certifications

Safety IEC 62477-1, IEC 61439-1, IEC 61439-2

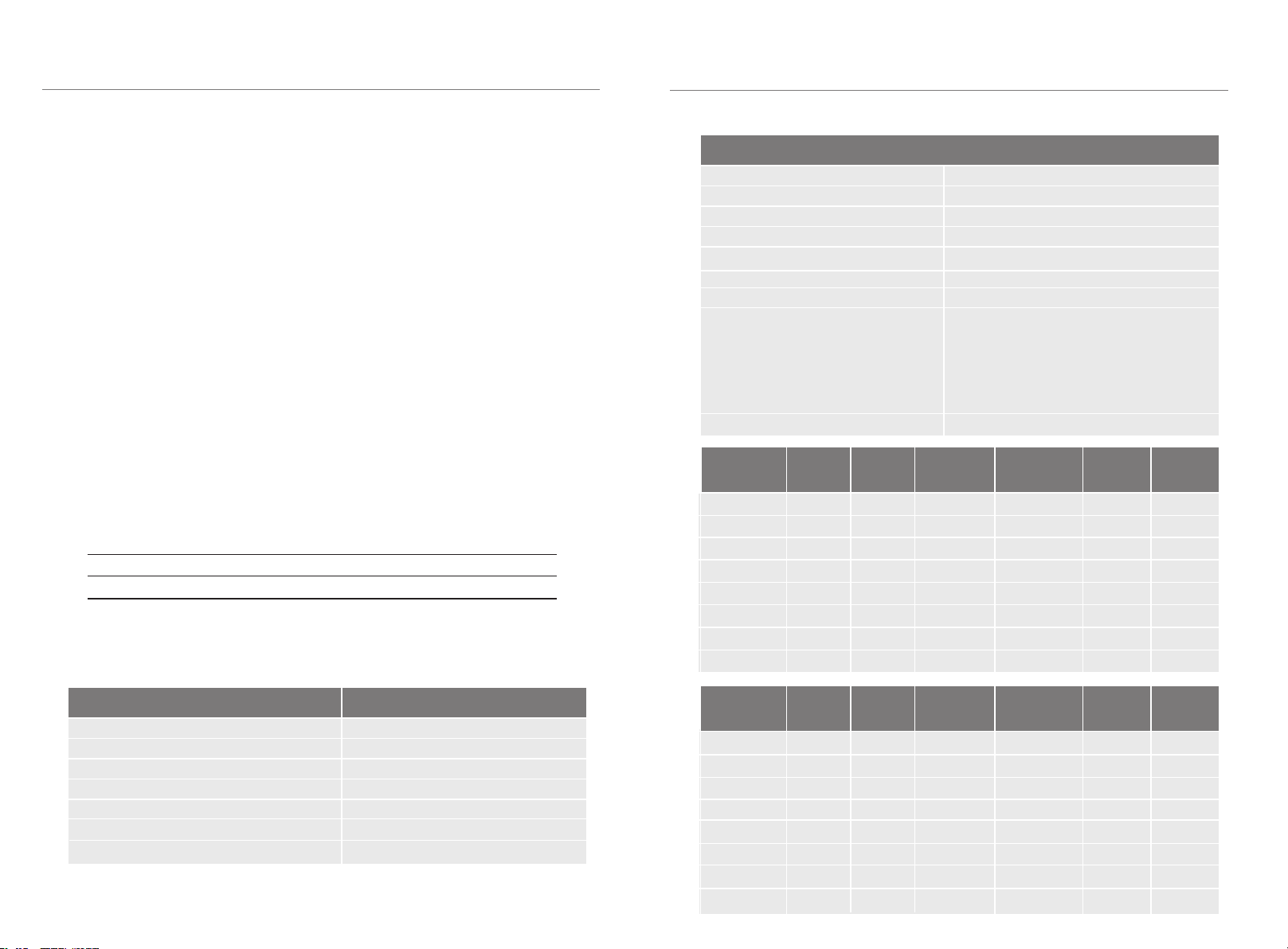

3.3 Technical Data

Interact with inverter

According to the interactive information, judge and control the

running state of the battery system

BMS related control processing

Realize the corresponding fault identification and processing

Ensure the safe operation of the battery system.

Maximum Charge/Discharge Current (A)

35

Model

BMS Parallel Box-II G2

Dimension (W/H/D)(in/mm)

Dimension of Packing (W/H/D)(in/mm)

Net Weight (lbs/kg)

14.48*13.15*6.04/368*334*153.5

17.32*15.63*10.12/440*397*257

19.12/8.7

Overvoltage Category (OVC)

II

I

Protective Class

EMC IEC 61000-6-1/2/3/4

as shown below:

System one Nominal

voltage [V]

Operating

voltage [V]

Total capacity

[kWh]

Usable capacity

[kWh]

Nominal

power [kW]

Max power

[kW]

T-BAT S 5.8 G2

T-BAT S 11.5 G2

T-BAT S 17.3 G2

T-BAT S 23.0 G2

T-BAT P 5.8 G2

T-BAT P 11.5 G2

T-BAT P 17.3 G2

T-BAT P 23.0 G2

115.2

230.4

345.6

460.8

115.2

230.4

345.6

460.8

110-131

200-262

300-393

400-524

100-131

200-262

300-393

400-524

5.8

11.5

17.3

23.0

11.5

23.0

34.6

46.1

5.1

10.3

15.5

20.7

10.3

20.7

31.1

41.4

2.8

5.7

8.6

11.5

2.8

5.7

8.6

11.5

4.0

8.0

12.0

16.1

4.0

8.0

12.0

16.1

System two Nominal

voltage [V]

Operating

voltage [V]

Total capacity

[kWh]

Usable capacity

[kWh]

Nominal

power [kW]

Max power

[kW]

T-BAT S 3.0 G2

T-BAT S 6.0 G2

T-BAT S 9.0 G2

T-BAT S 12.0 G2

T-BAT P 3.0 G2

T-BAT P 6.0 G2

T-BAT P 9.0 G2

T-BAT P 12.0 G2

102.4

204.8

307.2

409.6

102.4

204.8

307.2

409.6

90-116

180-232

270-348

360-464

90-116

180-232

270-348

360-464

3.1

6.1

9.2

12.3

6.1

12.3

18.4

24.6

2.7

5.5

8.2

11.0

5.5

11.0

16.5

22.1

2.5

5.1

7.6

10.2

2.5

5.1

7.6

10.2

3.0

6.1

9.2

12.2

3.0

6.1

9.2

12.2

Input/Output voltage Range (V)

Standard Power (kW)

Maximum Power (kW)

70-550

11.5

16.1

Pollution Degree

Operating Temperature

Ingress Protection

PD 3

II

Environment Requirement

Outdoor

Altitude (ft/m)

≤ 6561.68/2000

Noise Level

<30dB

Environment

T-BAT-SYS-HV-3.0:

-30°C~55°C (with heating function)

-10°C~55°C (no heating function)

T-BAT-SYS-HV-5.8:

0°C ~ 55°C (no heating function)

P65

Recommend charge/discharge current [A]

25

8

(T-BAT-SYS-HV-3.0)

(T-BAT-SYS-HV-5.8)

•

•

•

•

•

•

•

•

•

•

10 11

4 Installation

4.1 Installation Prerequisites

When assembling the system, avoid touching the terminal with any metal objects

or bare hands. The box provides a safe source of electrical energy when operated

as designed.

The previous safety precautions and the warning messages described in this

section must be observed. If any of the previous precautions are not fully

understood, or if you have any questions, contact customer service for guidance.

The Safety Section may not include all regulations for your region.

Ensure that the installation location meets the following conditions:

The building is designed to withstand earthquakes

The floor is flat and level

No inflammable or explosive materials within a range of at least 3 ft/0.91 m.

The ambiance is shady and cool, away from heat and direct sunlight

The temperature and humidity remain at a constant level

There is minimal dust and dirt in the area

There are no corrosive gases present, including ammonia and acid vapor

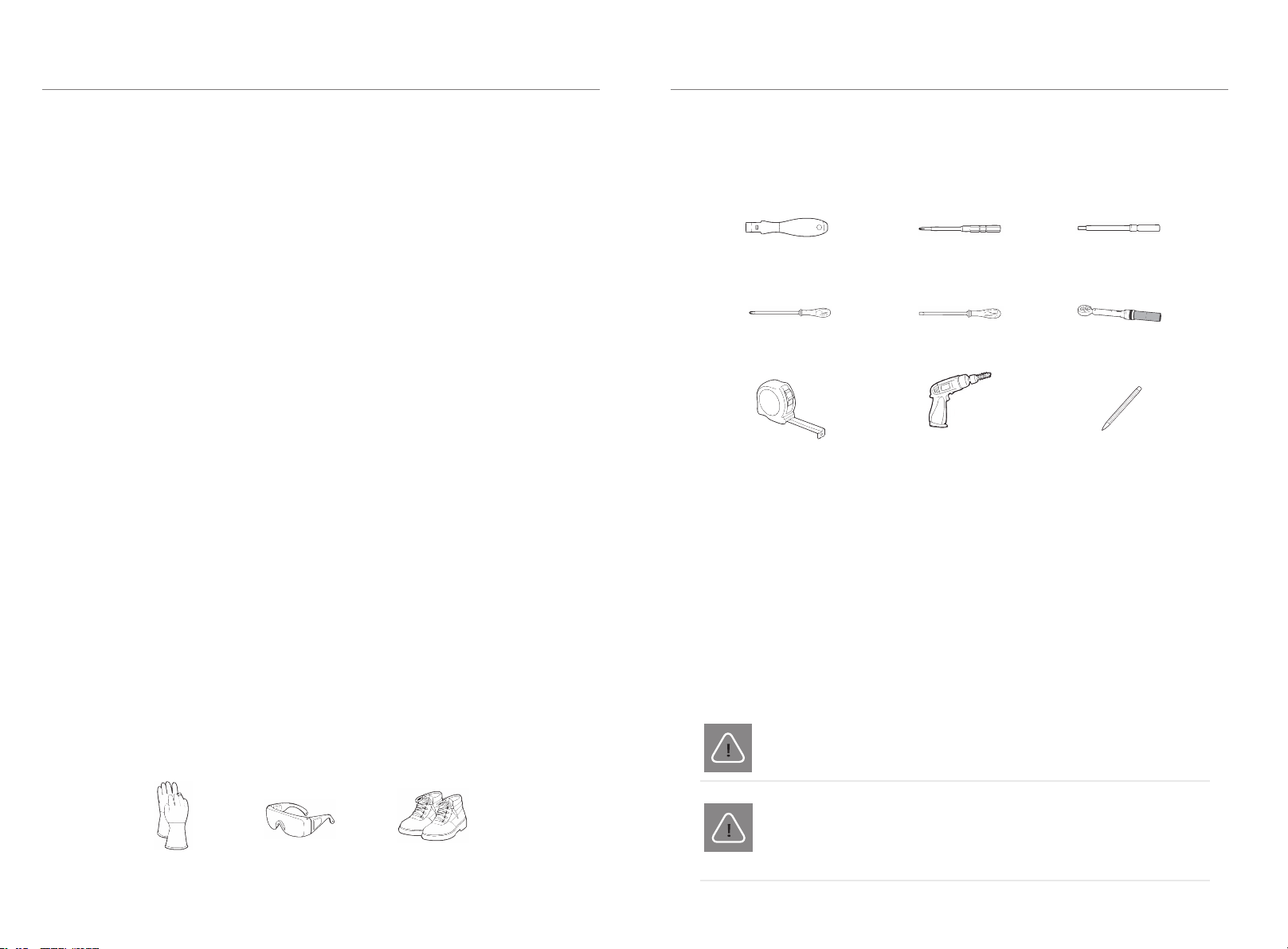

4.2 Safety Gear

Insulated Gloves Safety Goggles Safety Shoes

Installation and maintenance personnel must operate according to applicable

federal, state, and local regulations as well as industry standards regarding product

installation. Personnel must wear safety gear as indicated below in order to avoid

short circuit and personal injury.

4.3 Tools

The following tools are required to install the box.

Torque Screw Driver Phillips-Screw Driver Hexagon Wrench

Phillips-Head Screw Driver Flat-Head Screw Driver Torque Wrench

Tape Measure Drill Pencil or Marker

4.4 Installation

4.4.1 Check for Transport Damage

Ensure the box is intact during and after transportation. If there are visible

damages such as cracks, contact your supplier immediately.

4.4.2 Unpacking

CAUTION!

According to regional regulations, it may require several people to

move the equipment.

WARNING!

Unpack the box package by removing the packing tape. Ensure the box

modules and relevant items are complete. See the package items on section

4.4.3 and check the packing list carefully. If there is any items missing, please

contact our company or your distributor directly.

Please follow the installation steps strictly. Our company will not be

responsible for any injuries or loss incurred by incorrect assembly

and operation.

In practice, the requirements of the parallel box installation may be different due to

enviroment and locations. In that case, please follow up the exact requirements of

the local laws and standards.

The location is far from the sea to avoid salt water and humidity, over 0.62

miles/997.79 meters

Installation

•

•

•

•

•

•

•

•

Installation

12 13

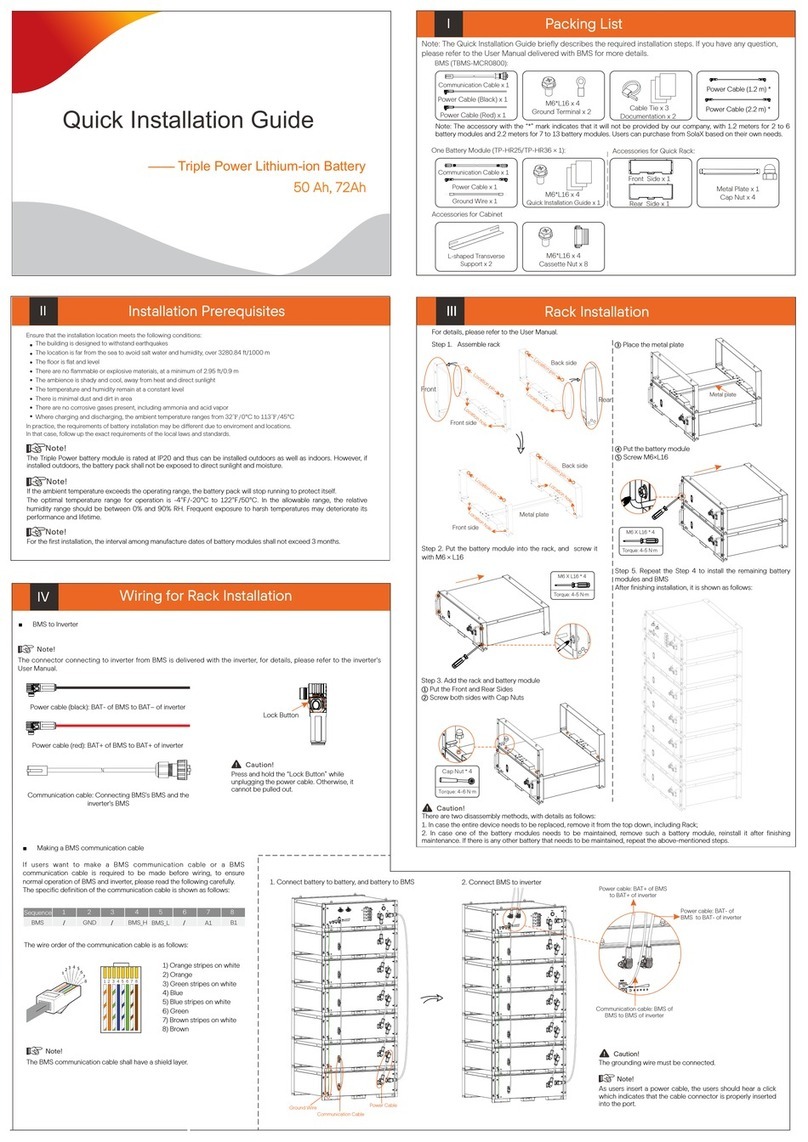

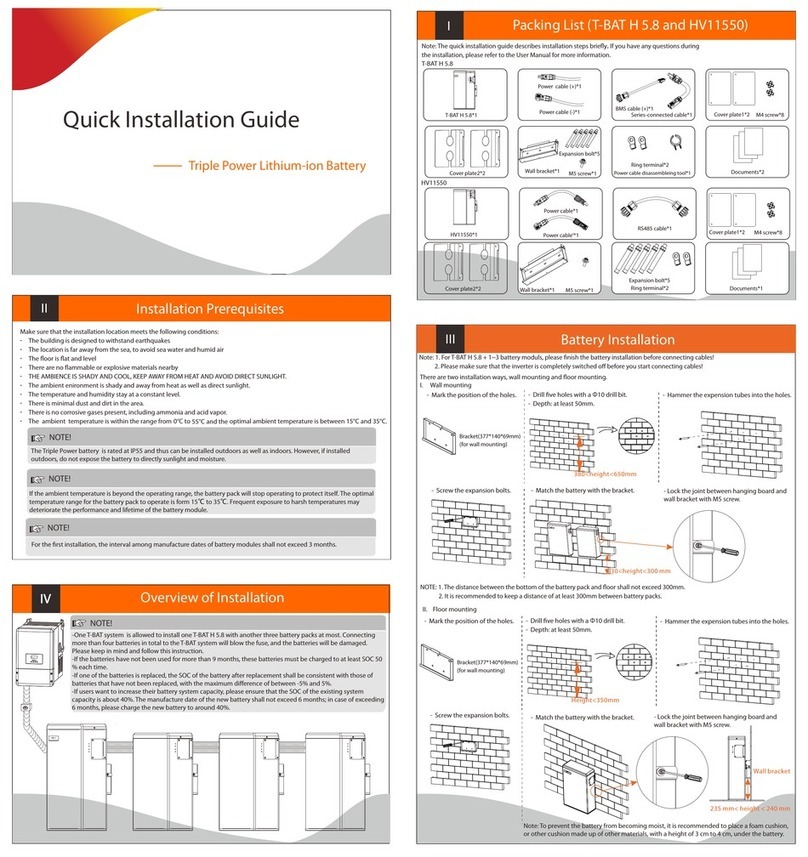

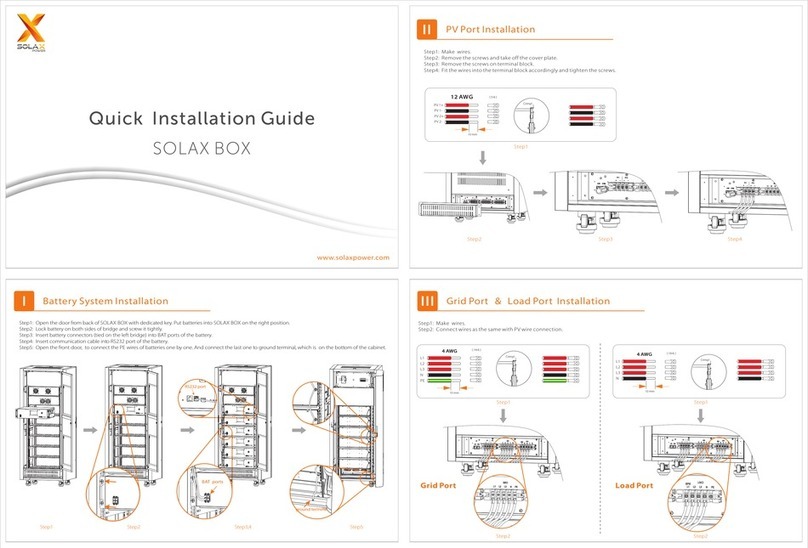

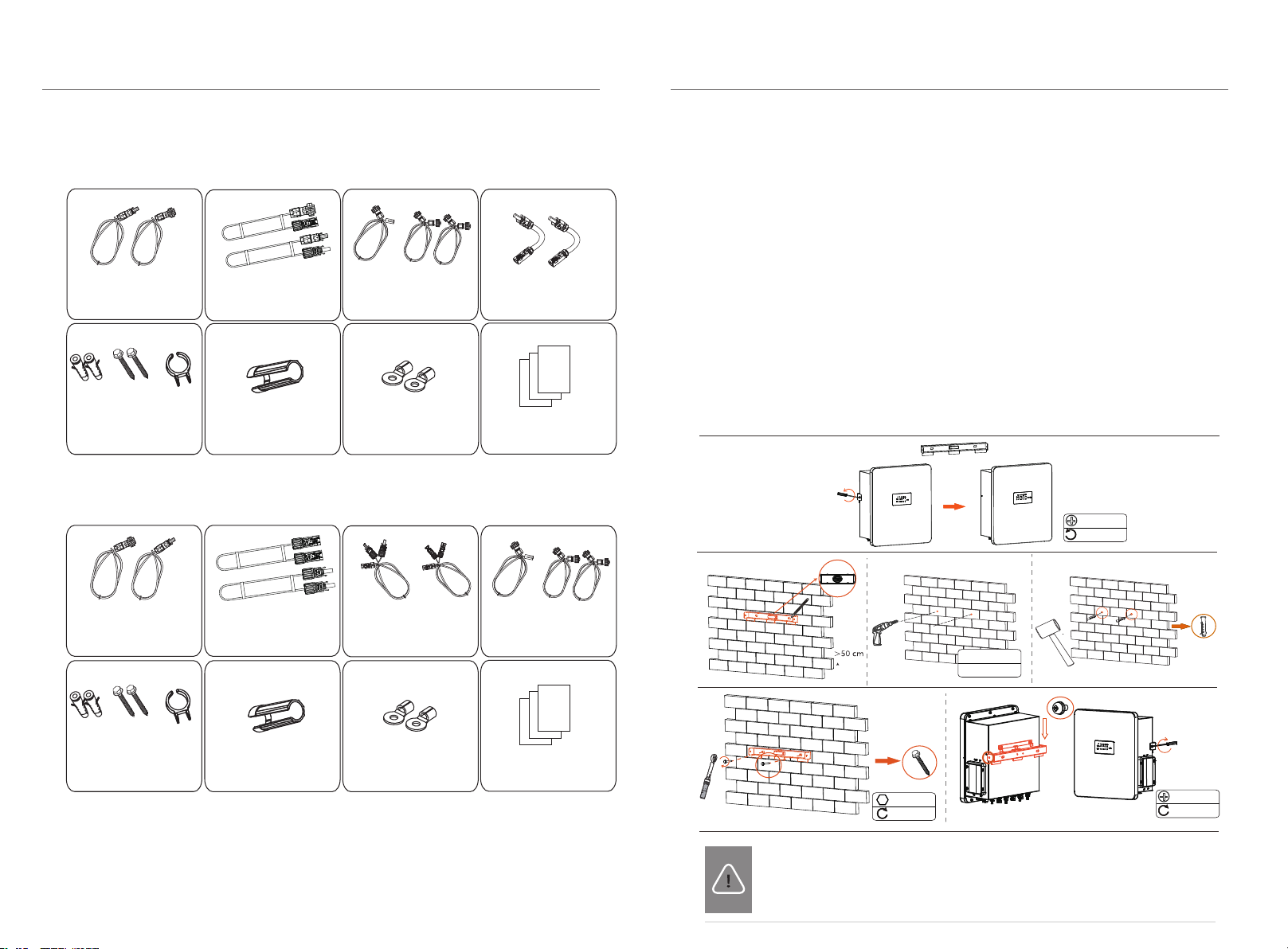

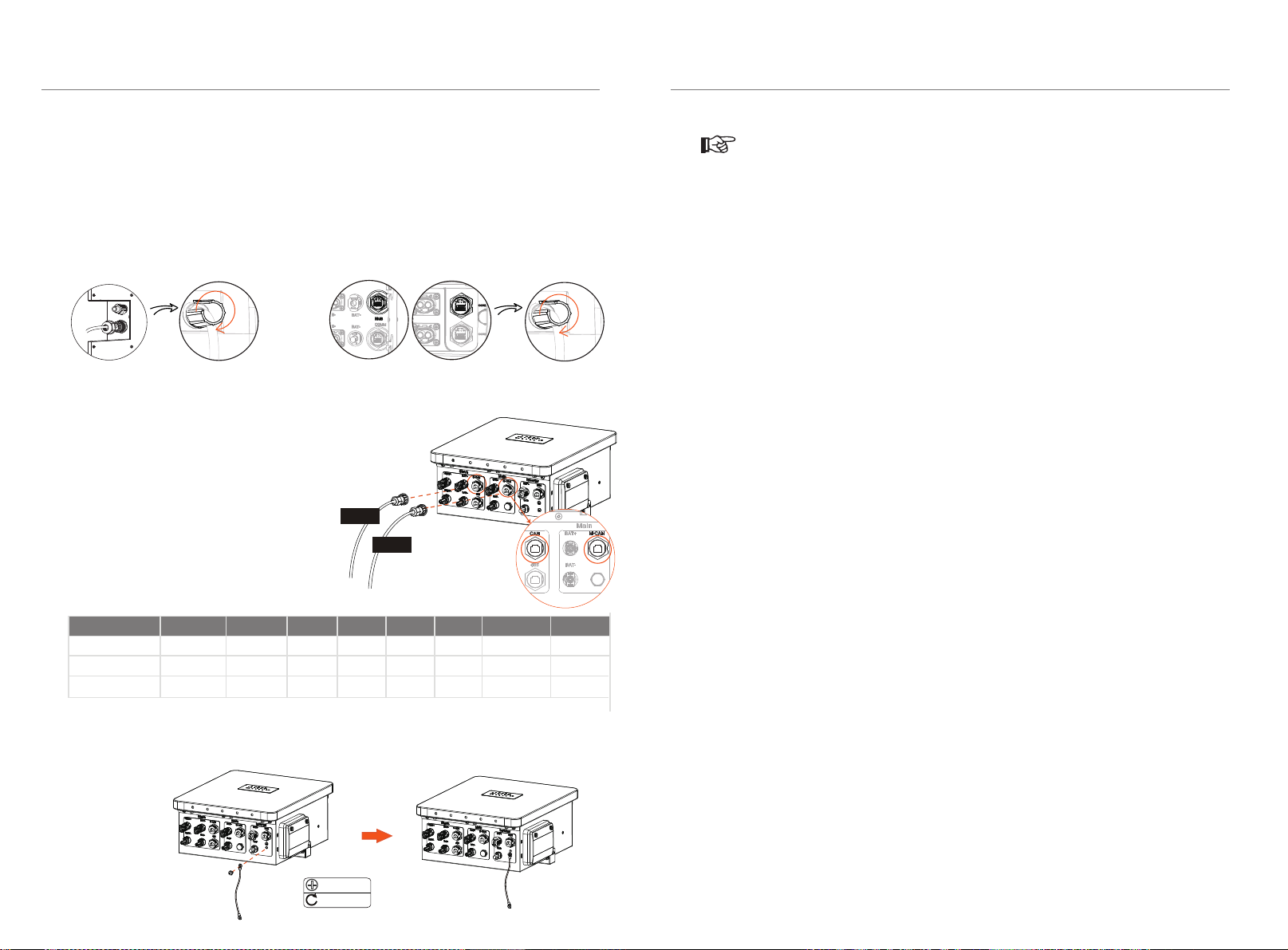

4.4.3 Accessories 4.4.4 Mounting Steps

Wall Mounting:

Step 1: Fix the wall bracket on the wall

The bracket needs to be removed from the box. Measure it and mark the

Install the expansion screw tubes on the wall, and screw the wall bracket by

a torque wrench.

Step 2: Match the box with the wall bracket

Hang the box over the wall bracket, move the box close to it and match it

on the wall bracket. Clip the buckle on the back of the box into the three

CAUTION!

Ensure that the system is always exposed to ambient air. The system

is cooled by natural convection. If the system is entirely or partially

covered or shielded, it may cause the system to stop operating.

position of the two holes. The bubble of the spirit level should be centered.

The height difference from battery modules to here should be >50cm.

Drill holes at the depth of at least 2.36 inches/60 mm by a drill.

①For use with T-BAT-SYS-HV-5.8

②For usewith T-BAT-SYS-HV-3.0

Expansion tube x2

Power Cable Disassembling

Tool x1

Power cable (+) x1

Power cable (-) x1

(6.56ft/200cm)

BMS Communication Cable

(6.56ft/200cm) x1

CAN/485 Communication Cable

(7.22ft/220cm) x2

Series-connected

plug x2

Documents

Power Cable (Heat+) x1

Power Cable (Heat-) x1

(6.56ft/200cm)

slots of the back plate accurately. (Torque: 1.0-1.2 N·m)

Expansion Screw x2

\c1382435;320204091001

Expansion tube x2

Power Cable Disassembling

Tool x1

Documents

Expansion Screw x2 Rotation Wrench x1

Power cable (+) x1

Power cable (-) x1

(6.56ft/200cm)

Power cable (+) x1

Power cable (-) x1

RS485 Communication Cable

(7.22ft/220cm) x2

BMS Communication Cable

(6.56ft/200cm) x1

M4*10

1.0-1.2 N·m

M4*10

1.0-1.2 N·m

M6*L55

5 N·m

Ø 10 drill

Depth:>60 mm

•

•

•

•

Installation

Installation

Power Connecter (+) x1

Power Connecter (-) x1

Grounding Terminal x2

Rotation Wrench x1 Grounding Terminal x2

Power cable (+) x2

Power cable (-) x2

(7.22ft/220cm)

(7.22ft/220cm)

15

14

Warning!

11.81-23.62 inches

300-600 mm

Overall Installation

CAUTION!

It is supported to only connect the slave battery modules.

It is not supported to only connect the master battery modules.

The number of modules connected at the master side and the slave side should

be consistent. At most four modules can be connected at one side.

Depending on the connection with different battery systems, there are two parallel

options, with details as follows:

① Connect with T-BAT-SYS-HV-5.8

Connect with a T-BAT H 5.8 (BMS)

and a HV11550 battery module:

Connect with a T-BAT H 5.8 (BMS)

and 3 HV11550 battery modules:

Connect with a T-BAT H 5.8 (BMS)

and 5 HV11550 battery modules:

Connect with a T-BAT H 5.8 (BMS)

4.5

and 7 HV11550 battery modules:

② Connect with T-BAT-SYS-HV-3.0

Installation

Installation

Connect with a MC0600 (BMS)

Connect with a MC0600 (BMS)

and 4 HV10230 battery modules:

Connect with a MC0600 (BMS) and 6 HV10230 battery modules:

Connect with a MC0600 (BMS) and 8 HV10230 battery modules:

Inverter

BMS+Battery

module 1

Battery

module 1

Inverter

Inverter Inverter

BMS+Battery

module 1

BMS+Battery

module 1

BMS+Battery

module 1

Battery

module 1

Battery

module 2 Battery

module 2

Battery

module 1

Battery

module 2

Battery

module 3

Battery

module 2

Battery

module 3

Battery

module 1

Battery

module 2

Battery

module 3

Battery

module 4

Battery

module 2

Battery

module 3

Battery

module 4

Battery

module

2-1

Battery

module

2-2

Battery

module

2-3

*Wiring at the back

inverter

inverter

BMS BMS

BMS

Battery

module

1-1

Battery

module

2-1

Battery

module

1-1

Battery

module

1-2

Battery

module

1-3

Battery

module

2-1

Battery

module

2-2

Battery

module

1-1

Battery

module

1-2

inverter

BMS

Battery

module

2-1

Battery

module

2-2

Battery

module

2-4

Battery

module

2-3

Battery

module

1-1

Battery

module

1-2

Battery

module

1-4

Battery

module

*Wiring at the back

1-3

*Wiring at the back *Wiring at the back

16 17

Step1.

The wire order of the communication cable is as follows:

1 2 3456 7 8

Sequence 123 4 5 6 7 8

BMS /GND /BMS_H BMS_L /A1 B1

1) Orange stripes on white

2) Orange

3) Green stripes on white

4) Blue

5) Blue stripes on white

6) Green

7) Brown stripes on white

8) Brown

It is required for the BMS to communicate with the inverter for proper operation.

The BMS communication cable is shielded by aluminum foil.

• Connecting the BMS Communication Cable

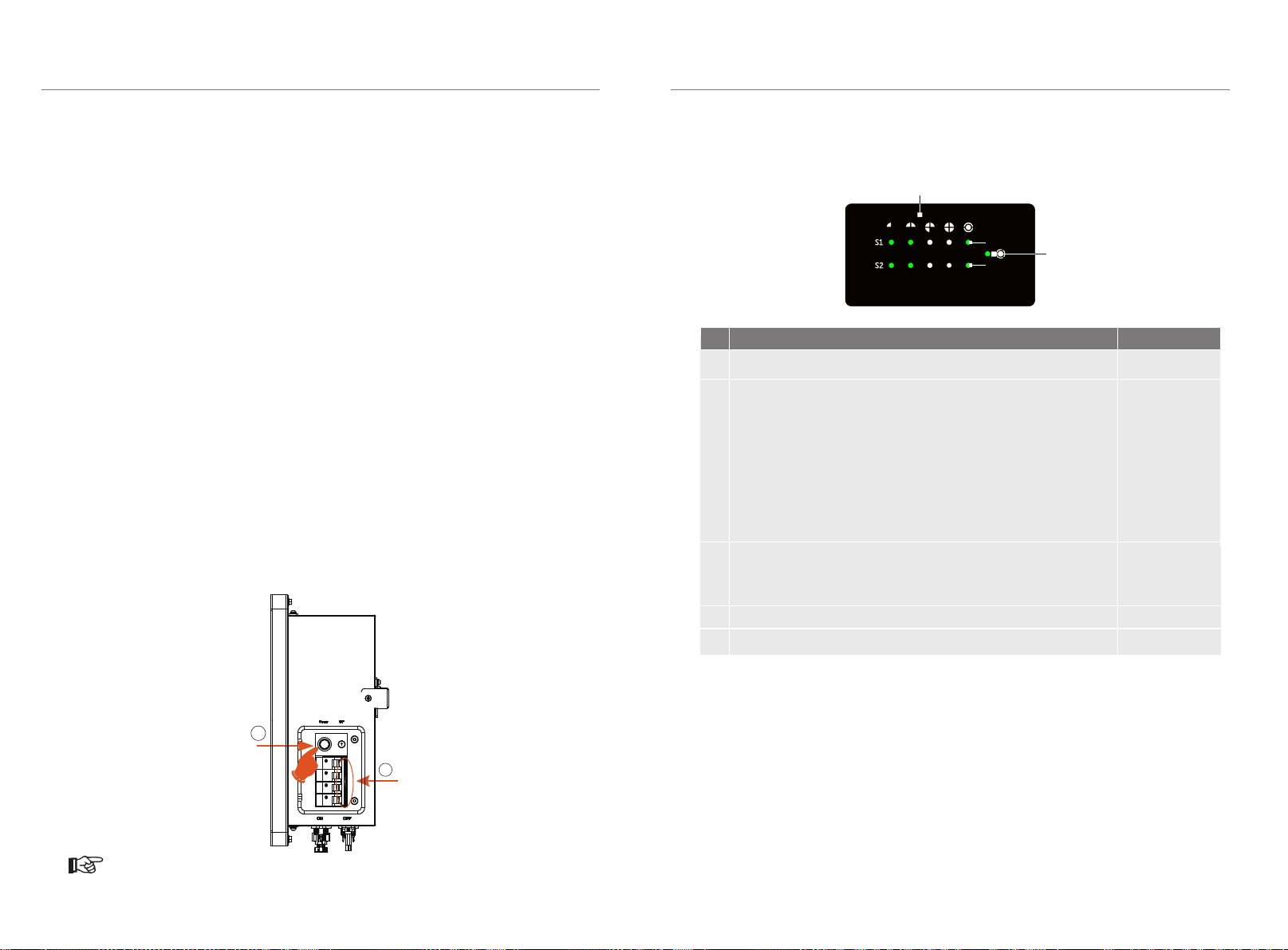

4.6 Cable Connection

Cable connection from the parallel box to the inverter:

"BAT+" to "BAT+";

"BAT-" to "BAT-";

"BMS" to "BMS".

*It is recommended to protect the cables by using corrugated pipe.

*If you plug the cable into the wrong port, you can insert the power cable disas-

-semblingtool into the gap on the side of the joint to unplug the cable easily.

* Please refer to "battery connection" section of the inverter's user manual/quick

installation guide for details about inverter connection.

Remember to always keep the unused port plugged.

NOTE!

NOTE!

Step 1. Prepare a 6 mm² BAT cable. Use a wire stripper to strip the 7mm insulation

layer of the wire end.

Step 2. Tighten the cable with the insulation layer stripped and insert it into the

battery pin contacts, make sure all wires are well connected.

Step 3.Tighten the BAT pin needle and the wiring harness to make the connection

tight without looseness.

Step 4.The battery connectors are divided into 2 parts - the plug and the fastening

head. Insert the cable through the fastening head and the opposite plug.Note that

the red and black lines correspond to different of plugs.

Step 5. Force the cable pair into the plug, will a "click" sound ,which indicates that

the connection is complete.

Step2.Step3.

Step4.Step5.Step6.

7mm

6 mm²

Wire stripper

+

-

+

-

+

+

+

-

-

-

Click!

Click!

Step7.

Step 6. Tighten the fastening head and into insert the corresponding positive

and negative (BAT-/BAT+) ports of the inverter.

Step 7: Insert the cable into the corresponding BAT port (+), (-) of the inverter.

4.6.1 Connecting Cables to Inverter

NOTE!

Installation Installation

* If the connector of the T-BAT-SYS-HV-3.0 controller does not match the

connector provided with the accessory cable, you can trim the blue connector

and replace it with a black connector. The replacement should follow the rule

of male-to-male and female-to-female connections. The Installation mode of

black connector is as follows:

DC socket housing(+)

screw connection

DC plug housing(-)

screw connection

spring

chamber

wire strands

②① ②

④

③

BMS

BAT- BAT+

To Inverter BMS

BAT- BAT+

The recommended installation distance between the box and the battery group

(including slave group and master group) is 11.81-23.62 inches /300-600 mm,

and the distance between the modules is 9.84 inches/250.00 mm.

NOTE!

Before installation, please make sure that the wall can bear the weight of the

batteries installed. If not, please take the mode of floor installation.

slave

inverter

main

Installation

18 19

4.6.2 Connecting Battery Modules

①For BMS Parallel box-Ⅱ G2 + T-BAT H 5.8 + 1/3/5/7 HV11550 battery pack(s)

From BMS Parallel box-Ⅱ G2 to T-BAT-SYS-HV-5.8:

Main "BAT+" to T-BAT H 5.8 "BAT+";

Main "BAT-" to T-BAT H 5.8 "BAT-".

If there is(are) a port(s) that is(are) not wired after wiring is completed, please

don't forget to put the waterproof cap(s) on the port(s).

To form a complete circuit, connect "-" and "YPLUG" with series-connected

cable on the right side of the last battery module. Please check

T-BAT-SYS-HV-5.8 User Manual/Quick installation guide for detailed tutorial

on cable-connecting between T-BAT H 5.8 and HV10230 battery modules.

NOTE!

②For BMS Parallel box-Ⅱ G2 + MC0600 + 2/4/6/8 HV10230 battery modules

From BMS Parallel box-Ⅱ G2 to T-BAT-SYS-HV-3.0:

Main "BAT+" to MC0600 "BAT+";

Main "BAT-" to MC0600 "BAT-".

Regardless of how many battery modules installed, please put a waterproof cap

on the communication port of the unconnected port of battery module.

Slave "BAT+", Slave "Heat+" to HV10230 "B+";

Slave "BAT-", Slave "Heat-" to HV10230 "B-".

Please check T-BAT-SYS-HV-3.0 User Manual/Quick installation guide for detailed

tutorial on cable-connecting between MC0600 and HV10230 battery modules.

NOTE!

Slave "BAT+" to HV11550 "+";

Slave "BAT-" to HV11550 "XPLUG".

Installation

Ⅱ

B

+

B

-

20 21

Commissioning

4.6.3 Connecting Communication Cables

Sequence 1 2 3 4 5 67 8

SLAVE RS485 I

VCC_485

GND_485

B2 N- P+ A2

VCC_485_2

GND_485

The wire order of the communication cable is as follows:

1) There is a protection cover for the RS485 connector. Unscrew the cover and plug

one end of the RS485 I communication cable to the RS485 I connector. Tighten the

plastic screw nut which is set on the cable with a rotation wrench. The operation is

the same as above if connecting to the COM1/BMS connecter.

4.6.4 Connecting the Ground Wire

Remove the M5*10 screw from the bottom of the BMS Parallel box-Ⅱ G2 with a

screwdriver, and then screw the groung wire(10 AWG/6 mm) to the corresponding

grounding port.

5 Commissioning

5.1 Configuring the Box

2) Connect the communication cable from the parallel box to the COMM/BMS/RS485 I

communication port that is on the left side of the battery module.

For T-BAT-SYS-HV-5.8 (RS485 I, BMS): For T-BAT-SYS-HV-3.0 (COM1, BMS):

HV11550 to Parallel box SLAVE "RS485 I";

HV10230 to Parallel box SLAVE "S-CAN";

T-BAT H 5.8 or MC0600 to Parallel box MAIN "M-CAN".

MAIN CAN

SLAVE CAN VCC_1 GND VCC_2 CANH CANL GND N- P+

///A1 B1

GND BMS_H BMS_L

• The DIP switch is used to configure the communication between battery

module(s) and the device. By default, only two groups of batteries can be

matched for use.

• The black-start function is only used in an off-grid application and when

there is no other power supply. To Black-start, hold down the button for 20

seconds until the soc light starts flashing blue to indicate successful black-start.

If the box is started in the black-start mode, remind that even when there is no

BMS communication, the port still contains high voltage with risk of electric

shock.

If the BMS communication has still not been established within 3 minutes after

starting the black-start mode, it indicates that the black start fails to start.

• After the BMS Parallel box- G2 is powered on, if the indicator lights Ⅱ

alternate flashing red and green for more than two minutes, and then change

to green flashing with the inverter reporting “Batt_ClusterCommuCountMis-

-Match", please check the communication connection of the second group of

BMS Parallel box- G2, as well as the power-on status of T-BAT H 5.8 or Ⅱ

MC0600 connected to the second group.

• After the BMS Parallel box- G2 is powered on, if the indicator lights Ⅱ

alternate flashing red and green for more than three minutes, and then change

to flashing red for one second and off for three seconds, with the inverter

reporting "BMS_Internal_Err 1", it indicates that the corresponding slave at

position 1 failed to connect to the communication successfully. According to

the error number, please check if the communication line of the slave at the

corresponding position is properly connected.

M5*10

2.5-3 N·m

B

+

B

-

Installation

When BMS Parallel box-Ⅱ G2 is connected to T-BAT-SYS-HV-5.8 battery

modules, if master group's CAN is connected to slave group's CAN port, it can

operate and function normally. However, the master group cannot be

upgraded properly in this configuration.

NOTE!

Slave

Main

2223

Commissioning

5.2 Commissioning

Verify the model number of each battery module to ensure that they are all the

same model.

Frequently pressing the POWER button may cause a system error. Allow at least 10

seconds after pressing the POWER button prior to making another attempt.

5.3 Status Indicators

The LED indicators on the front panel of the BMS and the battery modules indicate

the operating status.

The capacity indicators show the state of charge (SOC):

When the battery module is neither charging nor discharging, the indicator

lights are off.

When the battery module is charging, a part of the blue LED flashes once

every 5 seconds, and a part of the blue LED is on. Take SOC 60% for instance,

when in charging state:

1) The last two blue LED indicators are on

2) The third blue LED indicators flash once evey 5 seconds

When the battery module is discharging, the blue LED indicators flash once

every 5 seconds. Take SOC 60% for instance, when in discharging state:

1) The last three blue LED indicators flash once every 5 seconds

Description of the status indicators of BMS is shown as follows:

4

5

Protection

Normal

Upgrade for BMS

Power off

No.

1

2

Mode

Inverter sends

Status of BMS

Green LED flashes on 1 sec and off for 4 sec

3

After all battery modules are installed, please follow the following steps to

start the box:

1) Open the waterproof cover board of the box;

2) Move the circuit breaker switch to “ON”;

3) Press the POWER button to start the box;

4) Reinstall the cover board to the box;

5) Turn on the inverter DC switch;

6) After starting the box, please confirm that the waterproof cover board is

closed again.

Status Light

Capacity

25% 50% 75% 100%

SOC

Status Light 2

Status Light 1

NOTE!

Idle command

The status light of one of the two groups is off if it works normally.

The general status light will flash green (light for 1 second and off

for 4 seconds) will stay on green light if an inverter is connected.

Green LED flashes once every 0.5 sec

Light off

(1) When both groups have faults, the status lights of the two

groups will flash red at intervals of 0.5 seconds. The general

status light will keep the red light on.

(2)When one of the two groups has a fault, and the status light

of one group flashes red (light for 1 second and off for 4

seconds), while the other group keeps the green light on.

* When the fault is reported, the fault light of the

corresponding branch will stay red.

•

•

•

Commissioning

• The BMS Parallel box-II G2 must be connected to two groups of batteries

simultaneously in order to function properly, and the number of slaves in both

groups must be the same. The second group of BMS Parallel box-II G2 must

contains a T-BAT H 5.8 or Mc0600. And the two battery circuits connected to the

BMS Parallel box- G2 must be all HV11550 or all HV10230, and it is not allowed to Ⅱ

connect one group with HV11550 batteries and the other group with HV10230

batteries.

• It is prohibited to plug or unplug the power line during the operation of the BMS

Parallel box- G2. Ⅱ

3

2

2425

6 Troubleshooting

Check the indicators on the front to determine the state of the box.

A warning state is triggered when a condition, such as voltage ortemperature, is

beyond design limitations. Boxperiodically reports its operating state to the inverter.

When the box falls outside the prescribed limits, it entersinto a warning state.

Use the monitoring software on the inverter to identify what caused the warning.

The possible warning messages are as follows:

Troubleshooting

When a warning is reported, the inverter immediately stops its operation.

1) Ensure the power cable is

correctly and properly connected

to the power connector (XPLUG)

of the BMS

2) If the first step still does not

work, contact your distributor or

our company directly.

Troubleshooting

BMS_TemHigh Battery over

temperature

BMS_TemLow Battery under

temperature

BMS_CellImblance The capacities of

cells are different

BMS_Hardware_Protect Battery hardware

under protection

BMS_Insulation_Fault Battery insulation

fault

BMS_VoltSensor_Fault Battery voltage

sensor fault

BMS_TempSensor_Fault

Battery

temperature

sensor fault

BMS_CurrSensor_Fault Battery current

sensor fault

BMS_Relay_Fault Battery relay fault

BMS_Type_Unmatch The type of BMS

isunmatched

BMS_Ver_Unmatch The version of

BMS isunmatched

Warning Messages Description Troubleshooting

Wait until the temperature of the

cells returns to the normal state.

Wait until the temperature of the

cells returns to the normal state.

Warning Messages Description Troubleshooting

1. Move the DIP switch to the

correct position;

2. Check if the communication

cable between battery

modules is correctly and well

connected.

BMS_Internal_Err

1) DIP switch on the

wrong position

2) The communication

between battery

modules is interrupted.

1) Move the DIP switch to the

correct position

2) Check if the communication

cable between thebattery

modules is correctly and

properly connected.

BMS_OverVoltage Battery over voltage

BMS_LowerVoltage Battery under voltage

BMS_ChargeOCP Battery charge over

current protection

BMS_DishargeOCP Battery discharge over

current protection

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

Contact your distributor or our

company directly for servicing.

2627

7 Decommissioning

7.1 Dismantling the Box

Disconnect the cables between the box and inverter.

Disconnect the series wiring terminal on the box.

Disconnect the rest of cables.

7.2 Packing

Pack the box in the original packaging.

If the original packaging is no longer available, use an equivalent carton or box that

meets the following requirements:

Suitable for loads over 154.32 lbs/69.94 kg

Properly closed and sealed

Decommissioning Maintenance

8 Maintenance

If the ambient temperature for storage is 86°F~122°F/30℃~50℃, recharge

the batteries at least one time every 6 months.

If the ambient temperature for storage is -4°F~-86°F /-20℃~30℃, recharge

the batteries at least one time every 12 months.

Maintain periodically

Only qualified person may perform the following works.

During the process of using the box,the manage person shall examine and

maintain the machine regularly.The concrete operations are as follows.

1) Check that if the cooling fans on the rear of house are covered by dirts,

and the machine should be cleaned and absorbed dust when necessary.

This work shall be check time to time.

2) Check that if the indicators of the box are in normal state,check if the keys

of the box are in normal state,check if the display of the system is normal.

This check should be performed at least every 6 months.

3) Check that if the input and output wires are damaged or aged. This check

should be performed at least every 6 months.

4) Check whether the ground terminal and ground cable are securely con-

-nected and all terminals and ports are properly sealed every 12 months.

5) You should get the box panels cleaned and their security checked at least

every 6 months.

To shut down the system and dismantling the box, please follow the steps below:

According to the actual situation, please turn off the breaker located between

the inverter and the parallel box.

Press the POWER button to shut down the box.

Move the circuit breaker switch to the OFF position.

Ensure that every indicator on the box is off.

If the batteries have not been used for more than 9 months, these batteries

must be charged to at least SOC 50 % each time.

For the first installation, the interval among manufacture dates of battery

modules shall not exceed 3 months.

If a battery is replaced or added for capacity expansion, each battery's SOC

should be consistent. The max. SOC difference should be between ±5%.

If users want to increase their battery system capacity, please ensure that

the SOC of the existing system capacity is about 40%. The manufacture

date of the new battery shall not exceed 6 months; in case of exceeding 6

months, please charge the new battery to around 40%.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

If needed, unmount the box from the wall bracket to remove it from the wall.

9 Warranty

Triple Power protects this product under warranty when it is installed and used as

listed in this manual.

in this manual will immediately void all warranties on the product.

Triple Power does not provide warranty coverage or assume any liability for direct

or indirect damages or defects that result from the following causes:

Force majeure (flooding, lightning strike, overvoltage, fire, thunderstorm, etc.)

Improper or noncompliant use

Improper installation, commissioning, start up or operation (contrary to the

guidance detailed in the installation manual supplied with each product)

Inadequate ventilation and circulation resulting in minimized cooling and

natural air flow

Installation in a corrosive environment

Damage during transportation

Unauthorized repair attempts

Failure to adequately maintain the equipment. An on-site inspection by a

qualified technician is possible following 120 months of continuous use.

Warranty claims made beyond 120 months from date of commissioning may

be declined if it cannot be demonstrated that the equipment has been

adequately maintained.

External influence including unusual physical or electrical stress (power failure

surges, inrush current, etc.)

Use of an incompatible inverter or devices

28

Warranty Warranty

Registration

Form

For Customer (Compulsory)

For Installer

Name

Product Serial Number

Date of Commissioning

Installation Company Name

Installer Name Electrician License No.

Phone Number

Address

State

Country

Zip Code

Email

Module Brand

Module Size(W)

Number of String Number of Panel Per String

Battery Type

Brand

Number of Battery Attached

Battery ( If Any )

Module ( If Any )

Date of Delivery Signature

Please visit our warranty website: https://www.solaxcloud.com/#/warranty

to complete the online warranty registration or use your mobile phone to

scan the QR code to register.

For more detailed warranty terms, please visit SolaX official website: www.solaxpower.com

to check it.

Violation of the installation procedure or use of the product in any way not described

Connect to other brands of inverter without authority from our company.

•

•

•

•

•

•

•

•

•

•

•

•

PLEASE REGISTER THE WARRANTY

IMMEDIATELY AFTER INSTALLATION!

GET YOUR WARRANTY CERTIFICATE

FROM SOLAX!

KEEP YOUR INVERTER ONLINE & WIN

SOLAX POINTS!

Open your

camera app

and point

your device

at the QR

code

Wait for the

camera to

recognize

the QR code

Click banner

or notification

when it appears

on the screen

Warranty

registration

page will be

loaded

automatically

1

2

3 4

Not ificat ion

Cli ck the no tifica tion ba nner

OK

Table of contents

Other SolaX Power Batteries Pack manuals