Solcon RVS-AX0 User manual

Instruction Manual

Ver. 0519

Digital Soft Starter with internal ByPass

3.5-75A, 220 / 400 / 500V

2

RVS-AXO Instruction Manual

TABLE OF CONTENT

2.

Safety & Warning.......................................................................................3

2.1. Safety ............................................................................................3

2.2. Warnings ....................................................................................... 3

3.

Technical Data........................................................................................... 4

3.1

Introduction..................................................................................... 4

3.2

Rating and Frame Sizes..................................................................4

3.3

Ordering Information.......................................................................5

4.

RVS-AXO selection ...................................................................................6

5.

Recommended wiring schemes...............................................................6

5.1. Typical Wiring Diagram..................................................................6

5.2. Control supply (Terminals 1, 2)......................................................7

5.3. Start/Stop Input (Terminal 3)..........................................................7

5.4. Run contact (Terminals 4, 5) ......................................................... 7

5.5. Fault Contact (Terminals 6, 7)....................................................... 8

6.

Dimensions................................................................................................ 8

7.

Installation.................................................................................................9

7.1…………………………………………………………………..…….......9

7.2…………………………………………………………………….……….9

7.3………………………………………………………………..……………9

8.

Operation Interface ..............................................................10

8.1. Control........................................................................................... 10

8.2. Control Terminals..........................................................................10

8.3. User Interface.................................................................................11

9.

Protections ................................................................................................ 12

9.1. Protection List.................................................................................12

9.2. Faults Display.................................................................................13

9.3. Overload Trip Time.........................................................................13

10.

Setting parameters...................................................................................14

11.

Communication Manual........................................................................... 15

3

2. SAFETY & WARNINGS

2.1

Safety

1

Read this manual carefully before operating the equipment and follow its

instructions.

2

Installation, operation and maintenance should be in strict accordance

with this manual, national codes and good practice.

3

Installation or operation not performed in strict accordance with these

instructions will void manufacturer’s warranty.

4

Disconnect all power inputs before servicing the soft-starter and/or the

motor.

5

After installation, check and verify that no parts (bolts, washers, etc.)

have fallen into the starter.

6

During shipping, the soft-starter might have been roughly handled,

therefore, it is recommended to initialize the soft-starter by connecting

supply voltage prior to operating the soft-starter with a motor

2.2

Warnings

1

Internal components and P.C.Bs are at mains potential when the

RVS-AXO is connected to mains. This voltage is extremely dangerous

and will cause death or severe injury if contacted.

2

When RVS-AXO is connected to mains, even if start command has not

been issued and motor is stopped, full voltage may appear on starter’s

output and motor’s terminals.

Therefore, for isolation purposes it is required to connect an isolation

device upstream to the RVS-AXO.

3

The starter must be properly grounded to ensure correct operation, safety

and to prevent damage.

4

Check that Power Factor capacitors are not connected to the output side of the

soft starter.

5

Do not interchange line and load connections

4

T1

3. Technical data

3.1. Introduction

The RVS-AXO is a starter designed for use with standard three-phase, three-wire, squirrel

cage, induction motors.

It provides the best method of reducing current during motor starting.

The RVS-AXO starts the motor by supplying a slowly increasing voltage, providing soft start

and smooth acceleration, while drawing the minimum current necessary to start the motor.

U

Um Um –mains voltage

U0 –initial voltage

U0 T1 –voltage rise time

t

The RVS-AXO is equipped with internal by-pass controlled by its micro-controller. The by-pass

closes after the end of the starting process, thus reducing heating and saving power.

3.2 Rating and frames sizes

Frame

Starter

type

Starter

FLC

[A]

Dimensions

WxHxD

[mm]

Weight

[Kg]

A

RVS-AXO 3

3

175*92*95

0.8

RVS-AXO 4.5

4.5

175*92*95

0.8

RVS-AXO 7.5

7.5

175*92*95

0.8

RVS-AXO 11

11

175*92*95

0.8

B

RVS-AXO 15

15

200*108*105

1

RVS-AXO 22

22

200*108*105

1

C

RVS-AXO 30

30

222*125*132

2

RVS-AXO 37

37

222*125*132

2

RVS-AXO 45

45

222*125*132

2

RVS-AXO 60

60

222*125*132

2

RVS-AXO 75

75

222*125*132

2

5

3.3 Ordering Information

RVS-

AXO

3-

400-

230-

3M-

S

Full

load

Current

Mains

Voltage

Control

Voltage

Options

Front

Panel

Full load Current

Specify

Description

Starter’s

FLC [A]

3, 4.5, 7.5, 11, 15, 22, 30, 37, 45, 60, 75

Mains Voltage

Specify

Description

220

220 VAC, 50/60Hz , +10% -15%

400

400 VAC, 50/60Hz , +10% -15%

500

500 VAC, 50/60Hz , +10% -15%

Control Voltage

Specify

Description

230

100-240VAC, 50/60Hz , +10% -15%

Options

Specify

Description

0

No options

3M

Communication RS-485 Board (MODBUS)

Front Panel

Specify

Description

S

Standard lexan

Example:

RVS-AXO rated 22A, mains voltage 400V:

RVS-AXO 22- 400 –230 –3M-S

6

4. RVS-AXO selection.

Select RVS-AXO according to motor’s Full Load Ampere (FLA) - as indicated on its

nameplate (even if the motor will not be fully loaded).

RVS-AXO is designed to operate under the following maximum conditions:

Ambient

temperature ⁰C

Starting current

(A)

Acceleration

time(Sec)

Starts per hour

40

3 * In

7

6

When operating under ambient temperature higher than 40 ⁰C, RVS-AXO nominal current

decreases 0.8% / 1⁰C.

When operating at altitude above 1000m, RVS-AXO nominal current decreases 1% / 150m.

5. Recommended wiring schemes

5.1.

Typical wiring diagram

7

Notes:

(1) –Circuit breaker provides IEC type 1 coordination. Use fuses for IEC type 2

coordination. Refer to table below.

Model

SCR 𝒊𝟐∗ 𝒕(A^2 * sec)

Fuse value

RVS-AXO 3

270

10A

RVS-AXO 4.5

610

16A

RVS-AXO 7.5

1700

25A

RVS-AXO 11

3630

32A

RVS-AXO 15

6750

32A

RVS-AXO 22

14250

50A

RVS-AXO 30

27000

63A

RVS-AXO 37

41070

100A

RVS-AXO 45

60750

125A

RVS-AXO 60

108000

125A

RVS-AXO 75

168750

200A

5.2.

Control supply (Terminals 1, 2)

100-240VAC, 50/60Hz is required to power the electronic circuitry and the bypass.

5.3.

Start / Stop input (Terminal 3)

Close contact between 1 and 3 to soft start the motor.

To stop the motor open the contact. If deceleration time is set to 0 Sec, then the engine stops

in a minimum time, depending on own losses.

Commands to start / stop cam be send via Modbus communication channel as well.

5.4.

Run contact (Terminals 4, 5)

It is voltage free, N.O. 5A, 250Vac contact.

Via AXO Modbus communication channel we can select from two possibilities.

a.

Contact is closed immediately on getting Start command and stays closed until Stop

command. This is a factory setting.

b.

Contact is closed / opened synchronously with bypass.

8

5.5.

Fault contact (Terminals 6, 7)

It is voltage free, N.O. 5A, 250Vac contact.

Contact is closed when soft starter is in Trip state. To reset this state control voltage has to be

disconnected and then reconnected.

Trip reset can be done via Modbus communication channel as well.

6. Dimensions

9

7. Installation

7.1

Prior to Installation

Check that Motor’s Full Load Ampere (FLA) is lower than, or equal, to the starter’s Full Load

Current (FLC) and that Mains and Control voltages are as indicated on the starter’s side label.

7.2

Mounting

The starter must be mounted vertically. Allow sufficient space (at least 100mm) above and

below the starter for suitable airflow.

Do not mount the starter near heat sources.

Surrounding air temperature in the cabinet should not exceed 40ºC

Protect the starter from dust and corrosive atmospheres.

7.3

Power wiring instructions

Input power and output motor field wiring shall be copper conductors, rated 75ºC.

Minimal wire size, terminal screw and torque ratings for attachment to power inputs of RVS-

AXO are presented below.

RVS-AXO

Terminals Screw

Minimal wire size

(mm^2)

Mechanical Torque

(N*m)

RVS-AXO 3

M5

2.5

3

RVS-AXO 4.5

M5

2.5

3

RVS-AXO 7.5

M5

2.5

3

RVS-AXO 11

M5

2.5

3

RVS-AXO 15

M5

2.5

3

RVS-AXO 22

M5

4

5

RVS-AXO 30

M5

4

5

RVS-AXO 37

M5

6

5

RVS-AXO 45

M6

10

5

RVS-AXO 60

M6

16

5

RVS-AXO 75

M6

16

5

10

8. Operation Interface.

8.1. Control

- Initial voltage at Start and voltage rise (Start) / reduction time (Stop) set by 3 built-in

potentiometers or via Modbus communication channel.

-

Start / Stop command supplied by external voltage free contact or via

Modbus communication channel.

-

Fault reset can be done by switching control voltage OFF / ON or via

Modbus communication channel.

8.2. Control terminals

#

Name

Duty

1

L

Control voltage (100-240Vac) phase input

2

N

Control voltage neutral input

3

Start / Stop

Connect 100-240Vac related to N to start the motor.

Disconnect –to stop the motor.

4

Run relay NO

Closed in Start and Run or only Run state of the starter.

5

Run relay common

6

Fault relay NO

Closed in Fault state of the starter.

7

Fault relay common

8

RS485 A-Line (+)

RS485, Modbus communication port.

9

RS485 B-Line (-)

10

Ground

11

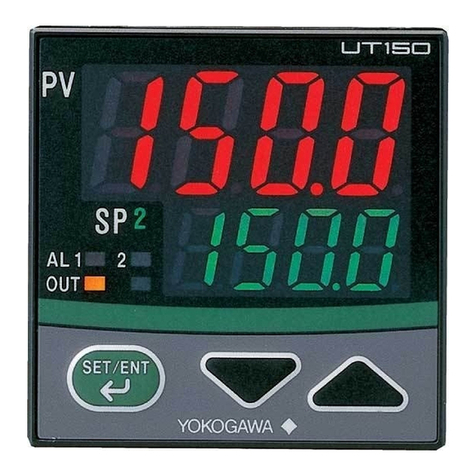

8.3. User interface

Potentiometers description:

Potentiometer

Duty

Set initial voltage to 30-70%.

Set voltage rise time to 1-30Sec.

Set voltage reduction time to 0-30Sec.

12

LEDs description:

LED

duty

Power

Lights when RVS-AXO energized

Run

Blinks at start / soft stop. Lights when

bypass is closed.

Fault 1

Blinks or lights when RVS-AXO is in fault

state.

Fault 2

9. Protections

9.1

Protections list:

Fault

Active at

Setting range

Factory set

Stop

Start

Soft

Stop

Bypass

Wrong phase

sequence

x

v

v

v

Enabled /

Disabled

Enabled

Phase loss / No

voltage

x

v

v

v

Max Start Time

x

v

x

x

0 –35Sec.

30Sec

Over current

instantaneous

v

v

v

v

850% FLA

850% FLA

Over current

delayed

v

v

v

v

200-600% FLA

with delay 0.1-

1Sec.

450%, 1Sec

Overload

x

x

x

v

Pickup 100-

200% FLA,

Grade 10A, 10,

20, 30

115%, 10A

Unbalance

X

X

X

v

10-50% of FLA,

0 –25Sec delay

30%, 10Sec

Over

Temperature

v

v

v

v

80⁰C (heat sink

temperature)

80⁰C

Note:

Factory settings can be changed via Modbus communication channel.

13

9.2

Faults display:

Fault

LED Fault 1

LED Fault 2

Wrong phase sequence

Blinks

Phase loss / No voltage

Blinks

Max Start Time

Blinks

Blinks

Over current

Lights

Overload

Lights

Blinks

Current unbalance

Lights

Over Temperature

Blinks

Lights

9.3

Overload trip time

Overload trip delay depends on motor initial state (cold / hot), motor current, selected overload

protection grade and selected overload protection pickup.

Delays for hot motor and selected pickup = 115% FLA are presented below:

Overload

grade

Motor current %FLA

800

700

600

500

400

300

200

10A

1.6Sec

2Sec

3Sec

4Sec

6Sec

12Sec

26Sec

10

3

4

6

8

13

23

52

20

5

6

9

12

19

35

78

30

7

9

13

19

29

52

112

14

10. Setting parameters.

Those parameters can be changed via Modbus communication channel.

Parameter

Setting range

Factory setting

Motor FLA

1-100A

According to RVS-AO model

Start parameters

setting

0 –by potentiometers

1 –by Modbus channel

0

Initial Voltage

at Start

1 –15 (1 ->30%, 15 ->70%)

Applicable when [Start parameters

setting] set to Modbus channel

Voltage rise time at

Start

1 –15 (1 ->1Sec, 15 ->

30Sec)

Voltage reduction

time at stop

1 –15 (1 ->0Sec, 15 ->

30Sec)

Current Limit

300- 500 %FLA

340%

Max Start Time

0-35 Sec.

30 Sec.

Over current trip

level

200-600%FLA

450%

Over current trip

delay

0 –2Sec

1 Sec

Overload protection

pickup

100 –200%FLA

115%

Overload protection

grade

0 –10A

1 –10

2 –20

3 - 30

10A

Phase sequence

protection

0 –OFF

1 - ON

ON

Modbus Address

1 - 127

1

Baud Rate

0 - 1200

1 –2400

2 –4800

3 –9600

4 - 19200

9600

Parity check

0 –Even

1 –Odd

2 - None

Even

15

11. RVS-AXO Instruction Manual

TABLE OF CONTENT

1. INTRODUCTION…......................................................................16

2. BASIC STRUCTURE OF THE SERIAL LINK FRAME ....................... 17

3. LIST OF FUNCTIONS SUPPORTED BY THE RVS-AXO ...................18

4. ACTUAL DATA (Input registers) ................................................. 19

5. SETTING PARAMETERS (Holding Registers) ................................21

6. DISCRETE COMMANDS .............................................................. 25

7. DIAGNOSTICS .............................................................................27

16

1. INTRODUCTION

This document summarizes the serial link protocol to / from the DIGITAL SOFT STARTER (RVS-AXO).

Features:

* RS485 Hardware.

* Asynchronous serial link.

* Half duplex.

* Format: Modbus RTU Mode (Remote Terminal Unit Mode).

- Binary,

- Each character includes 11 bits:

- 1 start bit

- 8 data bits, least significant bit sent first.

- 1 Parity bit. Even / Odd / No can be selected..

- 1 Stop bit if Parity is used, 2 stop bits if Parity is not used.

- Cyclical Redundancy Check (CRC), 16 bits.

* Baud Rates: 1200/2400/4800 / 9600/19200 bits per second..

* Response time of the RVS-AXO:

- Normally, 4ms <= time response <= 40mS.

- For a long response, time response <= 200mS.

* It is not recommended to transmit to theRVS-AXOtoo often, at afaster rate than once per second,

as it can slow down RVS-AXO time delays.

* After storing setting parameters, it is forbidden to transmit again to the same RVS-AXO in less

than 1 Sec.

* Broadcast commands: not supported.

Notes:

* It is recommended to connect 120 OHM resistors on both ends of the serial link.

* Turn off (and on again) control power after changing Baud Rate, Parity Check orSerial Link No (Slave

Address).

* It is a must to connect earth to the RVS-AXO earth terminal before connecting serial link wires.

Ignoring this instruction may result in permanent damage to the Serial Link Hardware.

* Being in Start / Soft Stop state RVS-AXO is busy controlling its SCRs and will not respond to

requests.

17

2. BASIC STRUCTURE OF THE SERIAL LINK FRAME

Modbus RTU frame have the same principal structure for both the "Query" transmission from the Master

to the Slave (RVS-AXO) and the Response transmission from the Slave to the Master.

"Sync":

Silent time of at least 3.5 character (3.5 *

11 bit times).

Byte 1:

Serial Link No. (= Slave Address)

(1...247)

Byte 2:

Function

(1, 2, 3,4,5,6,8,15 &16 are supported)

Byte 3:

Data Bytes

($XX)

.

.

($XX)

.

.

($XX)

Byte n-1: CRC_Low ($XX)

Byte n: CRC_High ($XX)

"Sync": Silent time of at least 3.5 character (3.5 * 11 bit times).

SYNC (Silent Interval)

In RTU mode messages “synchronize" by a "Silent Interval" of more than 3.5 character times. This silent

interval separates between transmission frames.

The entire frame must be transmitted as a continuous stream. A silent time of more than 3.5 character

times during frame transmission will cause the receiving device to ignore the incomplete frame. Next byte

will be assumed as the Serial Link No. of the next frame.

Same result of ignoring the frame can occur if a second message is transmitted before 3.5 character

times from the end of the previousone. This willcause the receiving device to consider it as acontinuation

of the first frame, resulting with CRC error.

SERIAL LINK NO. (SLAVE ADDRESS)

Contains RVS-AXO Slave Number (1-127) on theserial link. The RVS-AXO default value is 1. Serial Link

No. is used as the first byte in both the "Query" transmission from Master to Slave and in Response

transmission from Slave to Master.

FUNCTION

The Function code informs the RVS-AXO what is the requested action to take. In normal cases, Function

is used as the second byte in both the "Query" transmission from Master to Slave and in Response

transmission from Slave to Master.

18

3.LIST OF FUNCTIONS SUPPORTED BY THE RVS-AXO

Function Modbus Name Use in RVS-AXO

01

Read Coil Status

Read Discrete Commands status.

02

Read Input Status

Read Discrete Inputs status.

03

Read Holding Registers.

Read Setting Parameters.

04

Read Input Registers.

Read actual data.

05

Force Single Coil.

Force one discrete command.

06

Preset Single Register.

Write one setting parameter.

08

Diagnostics.

Loopback Diagnostics.

15

Force Multiple Coils.

Force Discrete Commands.

16

DATA

Force Multiple Registers

Write Setting Parameters

Control Commands

Data field includes information transferred to and from the RVS-AXO. The specific dataformat is changed

with Function. When Word data parameters are transmitted, High Byte is transmitted first, followed by

the Low Byte.

CRC

The CRC (Cyclic Redundancy Check) two bytes (16 bit) are used to check the entire frame bytes.

It is generated in the master device and transmitted as the last two bytes of the frame (Low byte is

appended first followed by the High byte). The slave device generates the CRC bytes again and

compares it to the received CRC bytes. If the CRC bytes are not identical, the frame is flushed and no

response is transmitted to the master.

19

4. ACTUAL DATA (Input registers)

Actual data includes measured values such as currents and mains frequency. It includes also logic

information aswell as statistic information. All parameters are word (two bytes) parameters. The protocol

supports only Reading of these parameters.

Address

Register

Range / Unit

Note

0

Phase L1 current

%FLA

1

Phase L2 current

%FLA

2

Phase L3 current

%FLA

3

Initial Voltage

0...512 (0~70%, 512~30%)

Represent

potentiometers state.

4

Voltage rise time at start

0..512 (0~30, 512~1 Sec)

5

Voltage reduction time

0…512(0~30,512~0 Sec)

6

Average current

%FLA

7

Mains Frequency

Hz

8

RVX-AXO status

1~Stop, 129~Fault,

9

Hardwire inputs

0~ Start / Stop open, 1~

Start / Stop closed

10

Fault status

Code-2 of active fault. See

faults list below.

11

Accumulated running

time

Hours

12

Accumulated running

time

Tenth of a second.

13

Number of starts

14

Number of faults

15

Reserved

16

Code-1 of 10 last faults.

20

Faults list:

Fault

Code-1

Code-2

Over temperature

1

1

Phase loss/ no voltage

2

2

Over current

3

4

Over load

4

8

Current unbalance

5

16

Negative phase sequence

6

32

Example 1:

Toreadinputregistersataddresses0…2 (Phasecurrents I1, I2, I3) of RVS-AXO#18thehost computer

should send following frame:

Byte 1:

Serial Link No.

($12)

Byte 2:

Function

($04)

Byte 3:

Starting Address High

($00)

Byte 4:

Starting Address Low

($00)

Byte 5:

No. of Points High

($00)

Byte 6:

No. of Points Low

($03)

Byte 7:

CRC_Low

($XX)

Byte 8:

CRC_High

($XX)

The RVS-AXO response, when Current = 80, 81, 82 % FLA, is:

Byte 1:

Serial Link No.

($12)

Byte 2:

Function

($04)

Byte 3:

Byte Count

($06)

Byte 4:

Data High, I1

($00)

Byte 5:

Data Low, I1

($50)

Byte 4:

Data High, I2

($00)

Byte 5:

Data Low, I2

($51)

Byte 6:

Data High, I3

($00)

Byte 7:

Data Low, I3

($52)

Byte 8:

CRC_Low

($XX)

Byte 9:

CRC_High

($XX)

Note: $XX indicates Hexadecimal byte.

This manual suits for next models

9

Table of contents

Other Solcon Controllers manuals

Popular Controllers manuals by other brands

THOMSON

THOMSON WhisperTrak installation manual

Siemens

Siemens Synco700 RMK770 Documentation handbook

Profire Energy

Profire Energy PF3100 Series Software setup guide

Tunze

Tunze 7074/2 Instructions for use

Rain Bird

Rain Bird ESP-TM Series Installation, Programming, & Operation

RNA

RNA ESK 2001 operating instructions